Your Ultimate Guide to Sourcing Spongebob Backpack

Guide to Spongebob Backpack

- Introduction: Navigating the Global Market for spongebob backpack

- Understanding spongebob backpack Types and Variations

- Key Industrial Applications of spongebob backpack

- Strategic Material Selection Guide for spongebob backpack

- In-depth Look: Manufacturing Processes and Quality Assurance for spongebob backpack

- Comprehensive Cost and Pricing Analysis for spongebob backpack Sourcing

- Spotlight on Potential spongebob backpack Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for spongebob backpack

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the spongebob backpack Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of spongebob backpack

- Strategic Sourcing Conclusion and Outlook for spongebob backpack

Introduction: Navigating the Global Market for spongebob backpack

Navigating the vibrant world of SpongeBob backpacks offers unique opportunities for international B2B buyers looking to tap into a beloved brand that resonates with diverse consumer demographics. This product not only stands out in terms of design but also serves as a versatile accessory for various markets, including education, travel, and leisure. As a result, SpongeBob backpacks have become critical for retailers aiming to attract young audiences and parents alike.

This guide provides a comprehensive overview of the SpongeBob backpack market, including an exploration of types and styles available, the materials used for durability and aesthetics, and the manufacturing and quality control processes that ensure product reliability. Additionally, it highlights how to source reliable suppliers and navigate the cost structures involved in procurement.

By addressing common questions and offering actionable insights, this guide empowers B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including markets like Colombia and Australia—to make informed sourcing decisions. Whether you are a retailer looking to expand your product line or a distributor aiming to enhance your portfolio, the knowledge contained herein will equip you with the tools necessary to optimize your purchasing strategies and enhance your competitive advantage in the global market.

Understanding spongebob backpack Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Spongebob Backpack | Iconic character design, spacious compartments | Retailers, educational institutions | Pros: High brand recognition; Cons: Limited functionality beyond aesthetics. |

| Spongebob Rolling Backpack | Wheels and retractable handle, ergonomic design | Schools, travel retailers | Pros: Easy to transport; Cons: More expensive due to added features. |

| Spongebob Mini Backpack | Compact size, adjustable straps | Fashion retailers, children’s boutiques | Pros: Trendy and lightweight; Cons: Limited storage capacity. |

| Spongebob Backpack with Lunchbox | Integrated lunch compartment, vibrant colors | Schools, daycare centers | Pros: Convenient for students; Cons: May lack durability for heavy use. |

| Spongebob Eco-Friendly Backpack | Made from sustainable materials, unique designs | Eco-conscious brands, promotional giveaways | Pros: Appeals to environmentally aware consumers; Cons: Higher production costs. |

Classic Spongebob Backpack

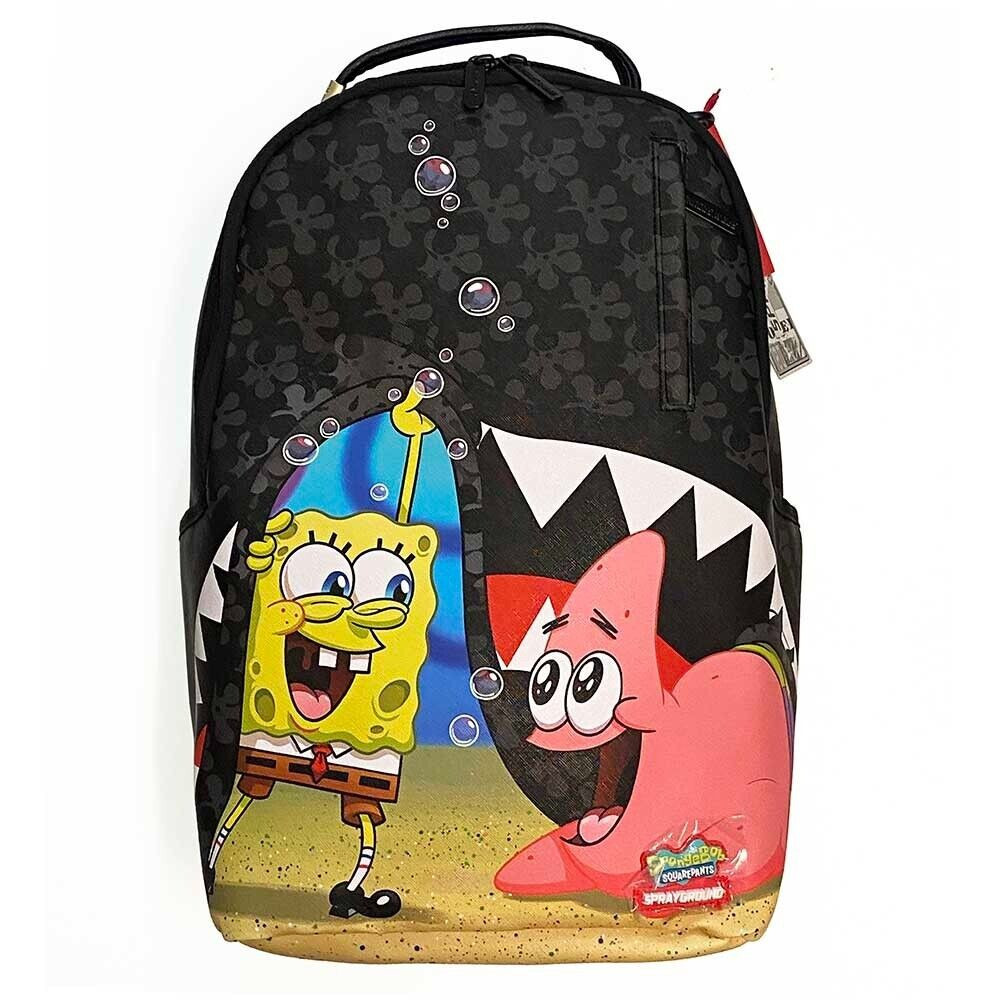

The classic Spongebob backpack features the beloved character prominently, making it a favorite among children and collectors alike. With spacious compartments, this backpack is ideal for school supplies and personal items. B2B buyers should consider the appeal of brand recognition when sourcing these backpacks, as they can drive sales in retail environments. However, the focus on aesthetics may limit their functionality compared to more specialized backpacks.

Spongebob Rolling Backpack

Designed for ease of transport, the Spongebob rolling backpack comes equipped with wheels and a retractable handle. This ergonomic design is particularly suited for students who carry heavy loads, making it popular among schools and travel retailers. Buyers should evaluate the durability of the wheels and handle, as these components are crucial for long-term use. While they offer convenience, the added features can lead to higher pricing.

Spongebob Mini Backpack

The Spongebob mini backpack caters to a trendy market, appealing to young consumers who prefer a compact and stylish option. Its adjustable straps make it versatile for various age groups, while its lightweight design ensures comfort. B2B applications include fashion retailers and children’s boutiques looking to attract younger demographics. However, potential buyers should be aware of the limited storage capacity, which may not suit all needs.

Spongebob Backpack with Lunchbox

This innovative backpack features an integrated lunch compartment, providing added convenience for students. Its vibrant colors and fun design make it appealing to children, making it a suitable choice for schools and daycare centers. When sourcing, B2B buyers should consider the quality of the lunch compartment and overall durability, especially for everyday use. However, the focus on multifunctionality may compromise durability under heavy loads.

Spongebob Eco-Friendly Backpack

As sustainability becomes increasingly important, the Spongebob eco-friendly backpack stands out due to its use of sustainable materials. This product appeals to environmentally conscious brands and consumers, making it a great choice for promotional giveaways. Buyers should assess the sourcing and production processes to ensure they align with eco-friendly values. While production costs may be higher, the growing demand for sustainable products can justify this investment.

Related Video: Large Language Models (LLMs) – Everything You NEED To Know

Key Industrial Applications of spongebob backpack

| Industry/Sector | Specific Application of spongebob backpack | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Education | Promotional items for schools and educational events | Enhances school spirit and brand loyalty | Customization options, durability, and safety standards |

| Retail | Merchandise for children’s stores | Attracts young consumers and boosts sales | Pricing strategies, seasonal trends, and inventory management |

| Events & Promotions | Giveaways at children-focused events | Increases brand visibility and engagement | Production timelines, branding options, and logistics |

| Entertainment | Merchandise for theme parks and entertainment venues | Drives customer experience and brand engagement | Licensing agreements, quality assurance, and supply chain reliability |

| Corporate Gifts | Employee gifts for companies with family-oriented cultures | Enhances employee satisfaction and company culture | Customization options, material quality, and cost efficiency |

Education

In the education sector, Spongebob backpacks can serve as effective promotional items for schools and educational events. They not only foster school spirit but also create a sense of community among students. For international buyers, particularly those in Africa and South America, sourcing durable and safe backpacks that can withstand daily use is critical. Customization options, such as school logos and colors, further enhance their appeal and relevance to the target demographic.

Retail

Children’s retail stores can leverage Spongebob backpacks as a key merchandise item. These backpacks attract young consumers and encourage impulse purchases, thereby boosting sales. For B2B buyers in Europe and the Middle East, understanding seasonal trends and pricing strategies is essential for maximizing profit margins. Ensuring that the backpacks are appealing, functional, and aligned with current trends will help retailers maintain a competitive edge in the market.

Events & Promotions

Spongebob backpacks are ideal for giveaways at children-focused events, such as fairs, festivals, and birthday parties. They serve as excellent promotional items that increase brand visibility and customer engagement. For international buyers, particularly in South America and Africa, considerations around production timelines and logistics are crucial to ensure timely delivery for events. Additionally, branding options should be carefully evaluated to align with the event’s theme and target audience.

Entertainment

In the entertainment industry, particularly within theme parks and venues, Spongebob backpacks can enhance customer experiences by serving as branded merchandise. They not only act as functional items for visitors but also as memorabilia that enhances brand engagement. Buyers from Europe and the Middle East should focus on securing licensing agreements and ensuring quality assurance in production. Reliable supply chains are essential to meet consumer demand during peak seasons.

Corporate Gifts

Spongebob backpacks can be utilized as corporate gifts in companies that emphasize family-oriented cultures. They enhance employee satisfaction and contribute positively to company culture by providing fun, practical items for employees’ children. For B2B buyers, especially in Africa and Europe, the focus should be on material quality and customization options to reflect the company’s branding. Cost efficiency is also a key consideration to ensure that the gifts align with budget constraints while still offering value.

Related Video: LABORATORY APPARATUS AND THEIR USES

Strategic Material Selection Guide for spongebob backpack

When selecting materials for a Spongebob-themed backpack, it is crucial to consider not only aesthetic appeal but also the performance characteristics that will meet the demands of various international markets. Below, we analyze four common materials used in the production of backpacks, focusing on their properties, advantages, disadvantages, and specific considerations for B2B buyers from regions such as Africa, South America, the Middle East, and Europe.

1. Polyester

Key Properties:

Polyester is known for its excellent strength-to-weight ratio, resistance to stretching and shrinking, and quick-drying capabilities. It is also resistant to mildew, making it suitable for various environments.

Pros & Cons:

Polyester is durable and cost-effective, making it a popular choice for mass production. However, it may not be as breathable as other materials, which could affect comfort during prolonged use. Manufacturing complexity is relatively low, allowing for efficient production processes.

Impact on Application:

Polyester can withstand a range of temperatures and is compatible with various dyes, enabling vibrant prints, including Spongebob designs.

Considerations for International Buyers:

Buyers should ensure compliance with international textile standards (e.g., ASTM D5034 for breaking strength) and consider the environmental impact of polyester production, especially in regions with strict sustainability regulations.

2. Nylon

Key Properties:

Nylon is renowned for its high tensile strength, abrasion resistance, and elasticity. It performs well in a variety of temperatures and is resistant to mildew and rot.

Pros & Cons:

While nylon is highly durable and can withstand heavy use, it tends to be more expensive than polyester. The manufacturing process can be more complex due to its properties, which may increase production costs.

Impact on Application:

Nylon backpacks can be designed to be lightweight yet robust, making them suitable for both everyday use and outdoor activities. The material’s ability to hold vibrant colors enhances the appeal of Spongebob-themed designs.

Considerations for International Buyers:

International buyers should verify that nylon products meet relevant safety and environmental standards, such as REACH in Europe, which regulates chemical substances.

3. Canvas

Key Properties:

Canvas is a heavy-duty fabric typically made from cotton or a cotton-polyester blend. It is known for its durability and ability to withstand wear and tear.

Pros & Cons:

Canvas is highly durable and can be treated for water resistance, making it suitable for various applications. However, it is heavier than synthetic materials, which may affect comfort and usability. The cost of canvas can vary depending on the blend and treatment processes.

Impact on Application:

Canvas is ideal for creating a rustic or vintage look, appealing to consumers who appreciate a classic aesthetic. It is also suitable for screen printing, allowing for detailed Spongebob graphics.

Considerations for International Buyers:

Buyers should consider the sourcing of cotton and ensure compliance with ethical standards, particularly in regions where sustainable practices are prioritized.

4. Eco-Friendly Fabrics (Recycled PET)

Key Properties:

Eco-friendly fabrics, such as those made from recycled PET (rPET), are gaining popularity due to their sustainability. They maintain properties similar to virgin polyester, including durability and moisture resistance.

Pros & Cons:

These materials appeal to environmentally conscious consumers and brands, enhancing corporate social responsibility. However, the production cost can be higher, which may affect retail pricing.

Impact on Application:

Eco-friendly fabrics can be used to create fashionable and functional backpacks that resonate with a growing demographic focused on sustainability, making them a strong candidate for Spongebob-themed products.

Considerations for International Buyers:

Buyers should ensure that eco-friendly materials meet local and international sustainability certifications, which can vary by region, impacting marketability.

Summary Table

| Material | Typical Use Case for spongebob backpack | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | General use, school, casual wear | Cost-effective, durable | Less breathable than other materials | Low |

| Nylon | Outdoor, heavy-duty backpacks | High durability, abrasion resistance | More expensive, complex manufacturing | Medium |

| Canvas | Vintage style, casual use | Highly durable, classic aesthetic | Heavier, may affect comfort | Medium |

| Eco-Friendly Fabrics | Sustainable, eco-conscious markets | Appeals to eco-conscious consumers | Higher production costs | High |

This strategic material selection guide is designed to assist international B2B buyers in making informed decisions when sourcing Spongebob backpacks, ensuring that they meet both consumer demands and regulatory requirements in their respective markets.

In-depth Look: Manufacturing Processes and Quality Assurance for spongebob backpack

The manufacturing process of a Spongebob backpack involves several key stages, each critical to ensuring the final product meets quality and safety standards. For B2B buyers, understanding these processes can enhance sourcing decisions, ensuring that products align with brand expectations and consumer needs.

Manufacturing Processes

1. Material Preparation

The first step in manufacturing a Spongebob backpack is material preparation. This involves sourcing high-quality fabrics, such as polyester or nylon, which are durable and lightweight. Additionally, materials may include waterproof coatings and eco-friendly options to appeal to a wider consumer base. Suppliers often conduct quality checks on raw materials to ensure they meet required specifications.

- Key Techniques:

- Material Sourcing: Engaging with reliable suppliers who provide certified materials.

- Fabric Testing: Conducting tests for tensile strength, colorfastness, and water resistance before production.

2. Forming

Once materials are prepared, they undergo forming processes. This typically includes cutting the fabric into specific shapes and sizes according to design specifications. Advanced techniques like laser cutting may be employed to enhance precision, especially for intricate designs featuring Spongebob characters.

- Key Techniques:

- Pattern Making: Using CAD (Computer-Aided Design) software to create accurate patterns.

- Cutting Methods: Implementing automated cutting machines for efficiency and accuracy.

3. Assembly

The assembly stage involves stitching the cut pieces together. This is where the backpack begins to take its final shape. Multiple sewing techniques are employed, including double stitching for durability, especially in areas that experience stress, such as straps and zippers.

Illustrative Image (Source: Google Search)

- Key Techniques:

- Sewing: Using industrial sewing machines that can handle various fabric thicknesses.

- Reinforcement: Adding extra layers of fabric or stitching in high-stress areas to prevent wear and tear.

4. Finishing

The final stage of manufacturing is finishing, where the backpack is inspected, and any additional features are added, such as zippers, pockets, and branding elements. This stage may also include applying protective coatings or treatments to enhance durability and aesthetics.

- Key Techniques:

- Quality Inspection: Conducting thorough inspections to ensure all components function correctly.

- Branding: Affixing labels or patches that feature Spongebob, ensuring compliance with licensing agreements.

Quality Assurance

Quality assurance is critical in ensuring that the Spongebob backpacks meet international standards and satisfy customer expectations. B2B buyers should be familiar with relevant standards and the QC processes employed by manufacturers.

International Standards

The most relevant international quality standard for manufacturers is ISO 9001, which focuses on quality management systems. Compliance with this standard indicates that the manufacturer has established processes for consistent product quality. Additionally, certifications such as CE (Conformité Européenne) for safety and API (American Petroleum Institute) for materials used in specific applications may also be relevant, depending on the market.

QC Checkpoints

Quality Control (QC) involves several critical checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspecting raw materials upon receipt to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing checks during production to identify defects early.

- Final Quality Control (FQC): Comprehensive inspection of finished products before packaging and shipment.

Common Testing Methods

Various testing methods are employed to ensure the backpacks meet safety and durability standards:

- Physical Testing: Assessing stitching strength, zipper functionality, and overall durability through stress tests.

- Chemical Testing: Ensuring that materials are free from harmful substances, which is especially important for products targeting children.

Verifying Supplier Quality Control

B2B buyers must take proactive steps to verify the quality control processes of their suppliers. Here are some actionable strategies:

- Audits: Conducting regular audits of suppliers to review their manufacturing processes, quality assurance practices, and compliance with international standards.

- Quality Reports: Requesting detailed quality reports that outline inspection results, testing methodologies, and any corrective actions taken.

- Third-Party Inspections: Engaging third-party inspection services to conduct unbiased evaluations of the manufacturing process and final products before shipment.

QC and Certification Nuances for International Buyers

When sourcing from manufacturers in different regions, it’s essential to understand the nuances of quality control and certifications:

- Cultural Differences: Different regions may have varying standards for quality and safety. B2B buyers should familiarize themselves with local regulations and expectations.

- Documentation: Ensure that all necessary documentation, including compliance certificates and quality test reports, is provided and verified.

- Supply Chain Transparency: Building relationships with suppliers who offer transparency in their operations can facilitate better communication regarding quality issues and compliance.

By understanding the manufacturing processes and quality assurance measures involved in producing Spongebob backpacks, international B2B buyers can make informed decisions that enhance their product offerings and brand reputation. This knowledge not only aids in selecting reliable suppliers but also helps in ensuring that the end products meet the desired quality standards, ultimately leading to increased customer satisfaction.

Related Video: How a Backpack is Made : Every Step on the Production Line

Comprehensive Cost and Pricing Analysis for spongebob backpack Sourcing

When sourcing Spongebob backpacks, international B2B buyers must carefully navigate the cost structure and pricing dynamics. Understanding the various cost components and price influencers can significantly enhance sourcing decisions and profitability.

Cost Components

-

Materials: The choice of materials directly impacts the cost of Spongebob backpacks. Common materials include polyester, nylon, and eco-friendly options. High-quality fabrics will increase costs but can also enhance durability and appeal.

-

Labor: Labor costs vary significantly by region. Countries with lower labor costs may offer more competitive pricing; however, it’s essential to consider the trade-off with quality. Skilled labor can lead to better craftsmanship, which is crucial for branded products.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses associated with production. Overhead can fluctuate based on the supplier’s location and operational efficiency.

-

Tooling: Custom tooling for Spongebob designs, such as unique stitching or logos, incurs additional costs. The complexity of the design influences the tooling cost, so simpler designs may be more cost-effective.

-

Quality Control (QC): Implementing rigorous QC processes ensures the final product meets quality standards. While this may add to upfront costs, it can reduce returns and increase customer satisfaction.

-

Logistics: Shipping and handling costs vary based on the shipping method, distance, and volume. Buyers should account for both domestic and international logistics, including customs duties and taxes.

-

Margin: Suppliers typically add a profit margin to cover their costs and earn a profit. Understanding the typical margins in your target market can help buyers negotiate better pricing.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Ordering larger quantities often results in lower per-unit costs. Buyers should assess their sales projections to determine optimal order sizes.

-

Specifications/Customization: Custom designs or features (e.g., additional compartments, unique prints) can increase costs. Buyers should balance the desire for customization with budget constraints.

-

Materials: The selection of high-performance or sustainable materials can elevate costs but may justify a higher retail price due to consumer demand for quality.

-

Quality/Certifications: Products that meet specific quality standards or certifications (e.g., safety standards for children’s products) may command higher prices but can enhance marketability.

-

Supplier Factors: The reliability and reputation of suppliers can influence pricing. Established suppliers may charge more for their expertise, while newer suppliers might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is crucial for managing logistics costs. Terms like FOB (Free On Board) or CIF (Cost Insurance and Freight) affect the total landed cost of the product.

Buyer Tips

-

Negotiation: Engage suppliers in negotiations to discuss pricing based on volume and long-term partnerships. Building a good relationship can lead to better terms.

-

Cost-Efficiency: Analyze the Total Cost of Ownership (TCO), which includes initial costs and ongoing expenses like shipping, warehousing, and potential returns. This holistic view helps in making informed purchasing decisions.

-

Pricing Nuances: Be aware that prices may vary significantly across regions due to local economic conditions, tariffs, and shipping costs. Buyers from Africa, South America, the Middle East, and Europe should conduct thorough market research.

Disclaimer

Prices for Spongebob backpacks are indicative and can vary based on the factors mentioned above. It is advisable for buyers to conduct their own market analysis and supplier assessments to obtain accurate pricing tailored to their specific needs.

Spotlight on Potential spongebob backpack Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘spongebob backpack’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for spongebob backpack

Key Technical Properties of Spongebob Backpacks

When sourcing Spongebob backpacks, several technical properties are critical for ensuring product quality and meeting market demands. Understanding these properties allows B2B buyers to make informed decisions that align with their business needs.

-

Material Grade

The material grade refers to the type of fabric used in the backpack’s construction, commonly including polyester, nylon, or canvas. Each material has distinct characteristics in terms of durability, weight, and water resistance. For instance, high-denier nylon is known for its strength and lightweight properties, making it ideal for children’s backpacks that endure daily wear and tear. -

Zipper Quality

The quality of zippers is crucial for the functionality and longevity of the backpack. Heavy-duty zippers, often made from YKK or similar brands, offer enhanced durability and smooth operation. This is particularly important for backpacks aimed at children, where ease of use and reliability are paramount. B2B buyers should prioritize suppliers who use high-quality zippers to minimize returns and enhance customer satisfaction. -

Tensile Strength

Tensile strength measures the backpack’s ability to withstand pulling forces without breaking. This property is essential for ensuring that the backpack can carry heavy items without compromising its integrity. Buyers should look for materials with a tensile strength rating that meets or exceeds industry standards, ensuring the product can handle the rigors of everyday use.

-

Water Resistance

Water resistance is a key feature for backpacks, especially for outdoor use or in regions with unpredictable weather. This property is often achieved through special coatings or treatments on the fabric. For B2B buyers, offering water-resistant Spongebob backpacks can significantly enhance their appeal, particularly among parents looking for reliable products for their children. -

Weight Capacity

Each backpack has a specified weight capacity that indicates how much load it can safely carry. This specification is crucial for ensuring that the backpack can accommodate school supplies, sports gear, or other items without risk of damage. Buyers should verify weight capacity ratings to align with their target market’s needs.

Common Trade Terminology

Familiarity with industry jargon is vital for effective communication and negotiation in the B2B space. Here are some common terms relevant to sourcing Spongebob backpacks:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or products that may be marketed by another company. In the context of backpacks, this means sourcing manufacturers that create Spongebob designs under a brand’s specifications. Understanding OEM relationships can help buyers negotiate better pricing and customizations. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers as it affects initial investment and inventory management. Buyers should negotiate MOQs that align with their sales forecasts to avoid overstocking or stockouts. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. This process helps buyers compare offers from multiple suppliers, ensuring they get the best deal. A well-structured RFQ can streamline sourcing and lead to better purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for B2B buyers to manage shipping costs and risks effectively. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight), which dictate who bears shipping and insurance costs. -

Lead Time

Lead time refers to the time taken from placing an order until the product is delivered. This term is crucial for inventory planning and customer satisfaction. B2B buyers should consider lead times when negotiating with suppliers to ensure timely availability of Spongebob backpacks in their market.

By understanding these technical properties and trade terms, B2B buyers can navigate the sourcing process more effectively, ensuring they select high-quality products that meet their market demands.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the spongebob backpack Sector

Market Overview & Key Trends

The global market for SpongeBob backpacks is experiencing dynamic growth, fueled by various factors including the enduring popularity of the SpongeBob franchise and increasing demand for character-themed products among younger consumers. Key drivers in this market include the rise of e-commerce, which has simplified access for international B2B buyers, and the growing trend of customization in product offerings. B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should note that local preferences significantly influence purchasing decisions. For instance, vibrant designs and functionality are crucial in markets like Colombia and Egypt, where school-aged children are the primary consumers.

Illustrative Image (Source: Google Search)

Emerging technologies such as supply chain digitization and data analytics are reshaping sourcing strategies. Buyers can leverage these technologies to streamline procurement processes, enhance inventory management, and gain insights into consumer trends. Furthermore, the shift towards sustainable production practices is becoming a focal point. As consumers increasingly prioritize eco-friendly products, international buyers must consider sourcing from manufacturers that employ sustainable materials and practices. This not only meets consumer demand but also aligns with global sustainability goals, making it a strategic advantage in competitive markets.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer a mere trend; it has become an essential aspect of sourcing strategies for SpongeBob backpacks. The environmental impact of production processes, particularly in the textile industry, necessitates a careful evaluation of suppliers. Buyers should seek manufacturers that prioritize ethical supply chains, ensuring fair labor practices and minimal environmental degradation. This includes evaluating the use of harmful chemicals and energy-intensive processes in backpack production.

Incorporating green certifications into sourcing decisions can enhance brand reputation and consumer trust. Certifications such as Global Organic Textile Standard (GOTS) or OEKO-TEX indicate that materials used in the backpacks are sourced sustainably and are free from harmful substances. Furthermore, opting for recycled materials or organic cotton can significantly reduce the ecological footprint of SpongeBob backpacks. International buyers should prioritize partnerships with suppliers who are committed to sustainable practices, as this not only contributes to environmental conservation but also caters to a growing consumer base that values corporate responsibility.

Brief Evolution/History

The SpongeBob backpack has evolved alongside the franchise itself, which debuted in 1999. Initially aimed at children, these backpacks quickly became popular among collectors and fans of all ages. Over the years, they have diversified in design and functionality, adapting to changing consumer preferences and technological advancements. The incorporation of materials such as durable polyester and eco-friendly options reflects a broader trend within the industry toward sustainability. As the brand continues to engage new generations, the evolution of SpongeBob backpacks presents ongoing opportunities for B2B buyers to tap into a vibrant market that celebrates nostalgia while embracing modern values.

Related Video: What Is International Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of spongebob backpack

-

What should I consider when vetting suppliers for SpongeBob backpacks?

When vetting suppliers, prioritize their experience in producing licensed merchandise and their adherence to quality standards. Request references from other international buyers and assess their manufacturing capabilities. Verify their compliance with safety regulations in your target markets, such as CE certification in Europe or CPSIA in the U.S. Additionally, consider suppliers with a strong track record in logistics and on-time delivery, which is crucial for maintaining your inventory levels. -

Can I customize SpongeBob backpacks for my brand?

Yes, many manufacturers offer customization options for SpongeBob backpacks, including fabric choices, colors, and branding elements like logos or taglines. When discussing customization, clarify the extent of alterations allowed under the licensing agreement. Ensure that the supplier can accommodate your design specifications and has the necessary equipment for high-quality printing or embroidery, as well as the ability to meet your target market’s preferences. -

What are the typical minimum order quantities (MOQs) and lead times?

MOQs for SpongeBob backpacks can vary widely based on the supplier and the complexity of your order. Generally, expect MOQs to range from 500 to 1,000 units. Lead times typically range from 30 to 90 days, depending on factors such as customization, production schedules, and shipping methods. It’s essential to discuss these details upfront with your supplier to align your production timelines with your sales forecasts and marketing campaigns.

Illustrative Image (Source: Google Search)

-

What payment terms are standard for international purchases?

Payment terms can vary based on the supplier’s policies and your negotiation leverage. Common arrangements include a 30% deposit upfront with the balance due before shipping or upon delivery. For first-time transactions, suppliers may prefer secure methods such as letter of credit or PayPal to mitigate risk. Always clarify payment terms in your contract and consider using escrow services for larger orders to protect both parties. -

How can I ensure quality assurance and certification for SpongeBob backpacks?

Request detailed information about the supplier’s quality assurance processes, including inspections during production and before shipment. Look for certifications such as ISO 9001, which indicates adherence to quality management systems. It’s also beneficial to ask for samples before placing a large order, allowing you to assess the product quality firsthand. Consider third-party quality inspections if you’re ordering in bulk from overseas suppliers. -

What logistics considerations should I keep in mind?

When sourcing SpongeBob backpacks, factor in shipping costs, import duties, and delivery timelines. Work with suppliers who have established logistics networks, as they can provide better rates and more reliable shipping options. If you’re importing from Asia or another region, consider the impact of customs clearance and ensure all paperwork is in order to avoid delays. Collaborating with a freight forwarder can help streamline the logistics process. -

How should I handle disputes with suppliers?

Establish clear communication channels and documentation practices from the outset to minimize disputes. In the event of a disagreement, attempt to resolve it amicably through direct negotiation. If necessary, refer to the contract terms, which should include clauses for dispute resolution, such as arbitration or mediation. Having a local legal expert in the supplier’s country can also provide valuable support in navigating legal issues. -

What are the key market trends affecting SpongeBob backpack sales?

Stay informed about trends in consumer preferences, such as the rising demand for eco-friendly materials and unique designs that cater to specific demographics. Monitor the popularity of licensed merchandise among younger consumers, especially in regions like Africa and South America, where character-based products can be especially appealing. Additionally, consider the impact of online retail growth, which may influence your distribution strategy and marketing efforts for SpongeBob backpacks.

Strategic Sourcing Conclusion and Outlook for spongebob backpack

In conclusion, the strategic sourcing of SpongeBob backpacks presents a unique opportunity for international B2B buyers to enhance their product offerings while tapping into a globally recognized brand. Key takeaways emphasize the importance of understanding market demands, supplier reliability, and product customization. By leveraging these insights, businesses can optimize their sourcing strategies to meet consumer preferences across diverse regions, including Africa, South America, the Middle East, and Europe.

The value of strategic sourcing cannot be overstated; it allows companies to reduce costs, improve quality, and foster long-term supplier relationships. As the demand for character-themed products continues to rise, aligning sourcing decisions with market trends will be crucial for success.

Looking ahead, international B2B buyers should actively engage with suppliers who can provide innovative designs and sustainable production methods. Embracing these strategies will not only enhance brand appeal but also position businesses favorably in competitive markets. Now is the time to take action—evaluate your sourcing strategies, explore potential partnerships, and capitalize on the growing demand for SpongeBob backpacks to ensure your business thrives in an evolving landscape.