Your Ultimate Guide to Sourcing Mushroom Backpack

Guide to Mushroom Backpack

- Introduction: Navigating the Global Market for mushroom backpack

- Understanding mushroom backpack Types and Variations

- Key Industrial Applications of mushroom backpack

- Strategic Material Selection Guide for mushroom backpack

- In-depth Look: Manufacturing Processes and Quality Assurance for mushroom backpack

- Comprehensive Cost and Pricing Analysis for mushroom backpack Sourcing

- Spotlight on Potential mushroom backpack Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for mushroom backpack

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the mushroom backpack Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of mushroom backpack

- Strategic Sourcing Conclusion and Outlook for mushroom backpack

Introduction: Navigating the Global Market for mushroom backpack

In the ever-evolving landscape of outdoor and lifestyle products, the mushroom backpack stands out as a versatile solution for various consumer needs, particularly in regions rich in outdoor activities. Designed to cater to the growing demand for functional and stylish carrying solutions, the mushroom backpack not only serves as a practical accessory but also embodies a commitment to sustainability through the use of eco-friendly materials. For B2B buyers, understanding the intricacies of this product is crucial for making informed sourcing decisions that align with market trends and consumer preferences.

This comprehensive guide delves into the critical aspects of the mushroom backpack, covering its diverse types, material options, manufacturing processes, quality control measures, and pricing strategies. Furthermore, it highlights key suppliers and market insights across continents, including Africa, South America, the Middle East, and Europe, with a particular focus on countries like Italy and the UK.

By equipping international B2B buyers with actionable insights and a thorough understanding of the mushroom backpack market, this guide empowers businesses to navigate sourcing effectively. From selecting the right materials to understanding manufacturing nuances, buyers will gain the knowledge needed to optimize their purchasing strategies and meet the evolving demands of their customers. Embrace the opportunity to enhance your product offerings and tap into the growing market for sustainable and functional backpacks.

Understanding mushroom backpack Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Mushroom Backpack | Basic design, lightweight, often with drawstring closure | General mushroom foraging | Pros: Cost-effective, easy to use. Cons: Limited durability and features. |

| Heavy-Duty Mushroom Backpack | Reinforced stitching, waterproof materials, larger capacity | Professional foragers, commercial use | Pros: High durability, weather-resistant. Cons: Higher cost, bulkier. |

| Insulated Mushroom Backpack | Thermal lining, compartments for temperature-sensitive fungi | Specialty foraging, gourmet markets | Pros: Maintains freshness, versatile. Cons: More expensive, heavier. |

| Modular Mushroom Backpack | Customizable compartments, adjustable straps | Research, educational purposes | Pros: Versatile, can adapt to various needs. Cons: Complexity may deter some users. |

| Eco-Friendly Mushroom Backpack | Made from sustainable materials, biodegradable options | Eco-conscious markets | Pros: Environmentally friendly, appealing to niche markets. Cons: Often pricier, limited availability. |

Standard Mushroom Backpack

The standard mushroom backpack is typically characterized by its simple, lightweight design, often featuring a drawstring closure. It is primarily used by casual foragers or hobbyists seeking an affordable option for gathering mushrooms. When considering a purchase, buyers should evaluate factors such as fabric quality and comfort, as these backpacks may lack advanced features like waterproofing or reinforced stitching.

Heavy-Duty Mushroom Backpack

Designed for professional foragers and commercial applications, heavy-duty mushroom backpacks offer enhanced durability through reinforced stitching and waterproof materials. These backpacks are larger, accommodating more significant quantities of harvested fungi. Buyers should consider the balance between cost and longevity, as these options tend to be more expensive but provide superior protection against the elements.

Insulated Mushroom Backpack

Insulated mushroom backpacks feature thermal linings and specialized compartments to keep temperature-sensitive fungi fresh during transport. This type is ideal for gourmet markets and specialty foraging where quality preservation is critical. B2B buyers should assess the insulation performance and weight, as these backpacks are typically heavier and come at a higher price point.

Modular Mushroom Backpack

The modular mushroom backpack is designed with customizable compartments and adjustable straps, making it suitable for research and educational purposes. This flexibility allows users to adapt the backpack for various foraging scenarios. Buyers should evaluate the ease of customization and overall design complexity, as some may find the intricate setup challenging.

Eco-Friendly Mushroom Backpack

Eco-friendly mushroom backpacks are constructed from sustainable materials, appealing to environmentally conscious consumers and businesses. These backpacks often feature biodegradable options and are marketed towards niche markets focused on sustainability. Buyers should weigh the benefits of supporting eco-friendly practices against the typically higher costs and potential availability issues in the market.

Related Video: Large Language Models (LLMs) – Everything You NEED To Know

Key Industrial Applications of mushroom backpack

| Industry/Sector | Specific Application of Mushroom Backpack | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Transporting mushroom spores and cultivation kits | Efficient handling and protection of sensitive materials | Durability, moisture resistance, and weight capacity |

| Food & Beverage | Delivery of fresh mushrooms to markets | Preserves product integrity and freshness during transit | Insulation properties, breathable materials, and hygiene standards |

| Outdoor Recreation | Carrying foraging equipment in eco-tourism | Enhances customer experience and promotes sustainable practices | Lightweight design, comfort, and ergonomic features |

| Healthcare | Storage for medicinal mushrooms in laboratories | Ensures safe transport and storage of sensitive specimens | Sterilization capabilities, material safety, and compliance with health regulations |

| Retail | Point-of-sale display for mushroom products | Attracts customers and promotes brand visibility | Customizable designs, branding opportunities, and durability |

Agriculture

In the agriculture sector, mushroom backpacks are utilized for the transport of mushroom spores and cultivation kits. These backpacks are designed to protect sensitive materials from environmental factors, ensuring that the spores remain viable during transit. For international buyers, particularly from regions like Africa and South America, sourcing durable materials that can withstand various climates is crucial. Additionally, the weight capacity of the backpack is a significant consideration, as it needs to accommodate heavy loads without compromising comfort.

Food & Beverage

Within the food and beverage industry, mushroom backpacks serve as an effective solution for the delivery of fresh mushrooms to markets. These backpacks are engineered to preserve product integrity and freshness during transit, which is vital for maintaining quality and customer satisfaction. Buyers in Europe, such as those in Italy and the UK, should prioritize sourcing backpacks with excellent insulation properties and breathable materials to prevent spoilage. Hygiene standards are also essential, as food safety regulations must be adhered to.

Outdoor Recreation

In the outdoor recreation industry, mushroom backpacks are increasingly used to carry foraging equipment as part of eco-tourism activities. These backpacks enhance the customer experience by allowing for easy access to tools while promoting sustainable practices. B2B buyers in the Middle East and Europe should focus on lightweight designs that offer comfort and ergonomic features, ensuring that users can carry their gear over long distances without fatigue. The ability to customize these backpacks for branding purposes can also provide an added marketing advantage.

Healthcare

The healthcare sector employs mushroom backpacks for the safe transport and storage of medicinal mushrooms in laboratories. These backpacks ensure that sensitive specimens are stored securely and transported without contamination. International buyers must consider the sterilization capabilities of the materials used, as well as compliance with health regulations. Sourcing backpacks that are made from safe, non-toxic materials will be critical in meeting industry standards and ensuring patient safety.

Retail

In the retail sector, mushroom backpacks can be utilized as a point-of-sale display for mushroom products. They not only attract customers but also promote brand visibility in a competitive market. B2B buyers should consider sourcing customizable designs that allow for branding opportunities, ensuring that the backpack stands out in retail environments. Durability is also key, as the backpacks will be subjected to frequent handling and must maintain their appearance and functionality over time.

Related Video: SCIENCE LAB EQUIPMENT🔬🧪⚗🧫🧲🔎 and their uses-(A to Z) school video

Strategic Material Selection Guide for mushroom backpack

When selecting materials for manufacturing mushroom backpacks, it’s crucial to consider various factors that affect performance, durability, and cost. Below, we analyze four common materials used in the production of mushroom backpacks, focusing on their properties, advantages and disadvantages, and specific considerations for international B2B buyers.

1. Nylon

Key Properties: Nylon is known for its high tensile strength and resistance to abrasion. It performs well under varying temperatures and is inherently resistant to mold and mildew, making it suitable for outdoor applications.

Pros & Cons: The primary advantage of nylon is its durability and lightweight nature, which is essential for backpacks that may carry heavy loads. However, it can be more expensive than other materials, and its production process can be complex due to the need for specialized manufacturing techniques.

Impact on Application: Nylon is particularly compatible with moisture-rich environments, making it ideal for mushroom harvesting in humid conditions. Its ability to withstand wear and tear ensures that the backpack will last through multiple seasons.

Considerations for Buyers: International buyers should ensure compliance with standards such as ASTM D751 for fabric strength. Additionally, sourcing from manufacturers that adhere to sustainable practices can enhance brand reputation in eco-conscious markets.

2. Polyester

Key Properties: Polyester offers excellent resistance to UV rays and water, making it suitable for various environmental conditions. It has a lower temperature resistance compared to nylon but maintains structural integrity under pressure.

Pros & Cons: Polyester is generally more cost-effective than nylon, providing a good balance between durability and affordability. However, it may not be as strong as nylon and can be prone to fading over time.

Impact on Application: Polyester is effective for backpacks used in moderate climates, where exposure to sunlight and moisture is a concern. Its lightweight nature makes it suitable for casual use and everyday carry.

Considerations for Buyers: Buyers should look for compliance with ISO 105-B02 for colorfastness and consider sourcing from regions with established textile standards to ensure quality.

3. Canvas

Key Properties: Canvas is a heavy-duty fabric known for its durability and resistance to tearing. It can withstand significant wear and is often treated for water resistance.

Pros & Cons: The main advantage of canvas is its robustness and classic aesthetic appeal, making it popular for fashion-oriented backpacks. However, it is heavier than nylon and polyester, which may not be ideal for all users.

Impact on Application: Canvas backpacks are suitable for urban environments and casual outings, where style and durability are prioritized. They are less ideal for extreme outdoor conditions due to their weight and potential for water absorption.

Considerations for Buyers: Buyers should ensure that the canvas is treated for water resistance and complies with relevant safety standards, such as EN 71 for non-toxic materials, especially if targeting markets in Europe.

4. Recycled PET Fabric

Key Properties: Recycled PET (rPET) fabric is made from post-consumer plastic bottles. It offers good tensile strength and is resistant to UV rays and moisture.

Pros & Cons: The key advantage of rPET is its environmental benefits, appealing to eco-conscious consumers. However, its performance may vary based on the recycling process and the quality of the original plastics used.

Impact on Application: rPET is suitable for consumers looking for sustainable options in their outdoor gear. It performs well in various conditions but may not match the durability of virgin materials.

Considerations for Buyers: Buyers should verify certifications such as Global Recycled Standard (GRS) to ensure the authenticity of recycled claims. Understanding local regulations regarding recycled materials can also aid in compliance.

Summary Table

| Material | Typical Use Case for mushroom backpack | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | Outdoor and heavy-duty applications | High durability and lightweight | Higher cost and complex manufacturing | High |

| Polyester | Everyday and moderate climate use | Cost-effective and versatile | Less durable than nylon | Medium |

| Canvas | Urban and fashion-oriented applications | Robustness and aesthetic appeal | Heavier and less water-resistant | Medium |

| Recycled PET Fabric | Eco-friendly options for outdoor use | Environmental sustainability | Variable performance based on quality | Medium |

This guide provides B2B buyers with essential insights into material selection for mushroom backpacks, ensuring informed decisions that align with market demands and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for mushroom backpack

The manufacturing process for a mushroom backpack involves several critical stages that ensure the final product is durable, functional, and of high quality. This section provides an in-depth look into these processes and the associated quality assurance measures that international B2B buyers, especially from Africa, South America, the Middle East, and Europe, should consider.

Manufacturing Process

1. Material Preparation

The first step in manufacturing a mushroom backpack is selecting the right materials. This type of backpack often uses high-performance fabrics such as nylon or polyester, which are favored for their lightweight properties and durability.

- Sourcing Materials: Buyers should seek out suppliers who have access to reputable fabric markets. For instance, sourcing from established textile hubs can ensure that the materials meet international standards.

- Sustainability Considerations: As environmental concerns rise, using recycled or eco-friendly materials is becoming increasingly important. Look for suppliers who can provide certifications for sustainable practices.

2. Forming

Once the materials are procured, the next stage is forming, which includes cutting and shaping the fabric.

- Pattern Creation: Using CAD (Computer-Aided Design) software, manufacturers create precise patterns that dictate the shape and size of the backpack components.

- Cutting Techniques: For efficiency and accuracy, automated cutting machines are often employed. This reduces waste and ensures that all pieces are cut to exact specifications.

3. Assembly

The assembly stage is where the backpack starts to take its final shape.

- Sewing: Skilled workers use industrial sewing machines to stitch the various components together. This includes attaching straps, pockets, and zippers. The quality of stitching is vital; double stitching and reinforced seams are common practices to enhance durability.

- Quality Control during Assembly: Implementing in-process quality control (IPQC) during assembly helps catch defects early. Each worker should be trained to identify common issues, which can save time and costs later in the production process.

4. Finishing

The finishing stage encompasses final touches that enhance the aesthetic and functional qualities of the backpack.

- Adding Hardware: This includes attaching buckles, zippers, and any additional features like hydration compartments. Ensure that all hardware meets durability standards.

- Final Inspections: Before packaging, a thorough inspection is conducted to ensure all components are securely attached and functioning as intended. This is typically the final quality control checkpoint known as Final Quality Control (FQC).

Quality Assurance

Quality assurance (QA) is essential to ensure that the mushroom backpacks meet both industry and international standards.

International Standards

- ISO 9001: This standard focuses on quality management systems and is critical for manufacturers aiming for international credibility. It ensures that products are consistent and meet customer satisfaction.

- CE Marking: For European buyers, CE marking indicates that the product complies with health, safety, and environmental protection standards.

Industry-Specific Standards

- API Standards: Depending on the intended use (e.g., tactical or outdoor), certain API (American Petroleum Institute) standards may apply, particularly if the backpack is designed for rugged environments.

Quality Control Checkpoints

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): Regular checks during the assembly process to catch defects early.

- Final Quality Control (FQC): A comprehensive inspection conducted before the product is packed and shipped.

Common Testing Methods

- Material Testing: Tests for tensile strength, abrasion resistance, and waterproofing can be conducted to ensure that materials perform under expected conditions.

- Functional Testing: This includes testing zippers, buckles, and overall backpack functionality under various load conditions to verify performance.

Verifying Supplier Quality Control

For B2B buyers, particularly those operating internationally, it is crucial to verify the quality assurance practices of suppliers.

- Audits: Regular audits of suppliers can help ensure compliance with quality standards. Buyers should consider conducting both announced and unannounced audits to gauge true compliance.

- Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their QC processes and any issues encountered during production.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of product quality. This is particularly important for buyers who may not have the capacity to conduct thorough inspections themselves.

Quality Control Nuances for International Buyers

Understanding regional regulations and standards is vital for international B2B buyers. For instance:

- Cultural Differences: Different regions may have varying perceptions of quality. Buyers from Europe may expect stricter adherence to environmental standards compared to those in Africa or South America.

- Logistics Considerations: Shipping times and customs regulations can impact product quality. Ensuring that products are stored and transported under proper conditions is essential to maintain quality.

In conclusion, the manufacturing processes and quality assurance measures for mushroom backpacks are critical to delivering a high-quality product. International B2B buyers must be diligent in selecting suppliers who adhere to both local and international standards while ensuring robust QC practices are in place. This diligence not only protects the buyer’s investment but also ensures customer satisfaction in the end product.

Related Video: How a Backpack is Made : Every Step on the Production Line

Comprehensive Cost and Pricing Analysis for mushroom backpack Sourcing

Understanding the cost structure and pricing dynamics of sourcing mushroom backpacks is essential for international B2B buyers. This analysis delves into the critical components that contribute to the overall cost, factors that influence pricing, and actionable tips for buyers, particularly from Africa, South America, the Middle East, and Europe.

Cost Components of Mushroom Backpack Sourcing

-

Materials

The choice of materials significantly impacts the cost. High-quality fabrics such as nylon, polyester, or eco-friendly alternatives like recycled PET can vary in price. The cost will also fluctuate based on whether the materials are sourced locally or imported. -

Labor

Labor costs are influenced by the manufacturing location. Countries with lower labor costs, such as those in Southeast Asia, may offer better pricing, but this can affect quality. Skilled labor for specialized tasks (like embroidery or advanced sewing techniques) can also drive up costs. -

Manufacturing Overhead

This includes utilities, rent, and other operational expenses associated with the manufacturing facility. Overhead costs may vary significantly depending on the region and the factory’s efficiency. -

Tooling

Initial tooling costs can be substantial, especially for custom designs. This includes the costs of creating molds, dies, and any specific machinery needed for production. Buyers should consider these costs when estimating the total investment required for launching a new product line. -

Quality Control (QC)

Implementing robust quality control processes is vital to ensure that the final product meets specifications and standards. This may involve additional labor costs and the use of specialized testing equipment, which can add to the overall cost. -

Logistics

Transporting materials to the manufacturing site and shipping finished products to the buyer involves considerable expense. Factors such as distance, shipping method, and customs duties can significantly influence logistics costs. -

Margin

Manufacturers will typically add a profit margin to the production cost. This margin can vary widely based on the brand’s positioning, market demand, and competitive landscape.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity)

Higher order volumes typically lead to lower per-unit costs. Establishing relationships with suppliers that allow flexibility in MOQs can be beneficial for smaller businesses. -

Specifications and Customization

Custom designs or specific features will generally increase costs. Buyers should clearly communicate their requirements to avoid unexpected pricing increases later in the process. -

Quality and Certifications

Products that require specific certifications (e.g., eco-friendly materials, safety standards) may incur additional costs. Ensure that suppliers can meet these certifications to avoid delays and extra expenses. -

Supplier Factors

The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their quality assurance processes, but they can also save costs in the long run by minimizing defects and returns. -

Incoterms

Understanding shipping terms is crucial. For instance, FOB (Free on Board) means the seller pays for transportation to the port, whereas CIF (Cost, Insurance, and Freight) includes additional shipping costs. These terms can significantly impact the total cost.

Buyer Tips

-

Negotiate

Effective negotiation can lead to better pricing. Understand the supplier’s cost structure and leverage volume commitments or long-term contracts to secure favorable terms. -

Focus on Cost-Efficiency

Consider total cost of ownership rather than just upfront costs. Evaluate durability, maintenance, and potential for returns when assessing the price. -

Understand Pricing Nuances

International buyers should be aware of currency fluctuations, tariffs, and trade regulations that can affect pricing. Staying informed about these factors can help in making better purchasing decisions. -

Conduct Market Research

Researching local and international market trends can provide insights into pricing standards. This knowledge can empower buyers during negotiations and sourcing decisions. -

Request Multiple Quotes

Always seek quotes from multiple suppliers to compare prices and services. This practice can reveal significant discrepancies and provide leverage in negotiations.

Disclaimer

Prices can vary widely based on numerous factors, including market conditions and specific buyer requirements. Therefore, it is advisable to obtain detailed quotes tailored to your specific needs.

Spotlight on Potential mushroom backpack Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘mushroom backpack’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for mushroom backpack

Understanding the essential technical properties and trade terminology associated with mushroom backpacks is crucial for international B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. This section outlines key specifications and common industry terms that will aid in making informed purchasing decisions.

Key Technical Properties

-

Material Grade

– Definition: Refers to the quality and type of fabric used in the backpack, such as nylon, polyester, or canvas.

– Importance: The choice of material impacts durability, weight, and water resistance. For mushroom backpacks, which may be used in varying climates, selecting a high-grade material ensures longevity and performance. -

Weight Capacity

– Definition: The maximum weight the backpack can safely carry, typically expressed in kilograms or pounds.

– Importance: Understanding weight capacity is essential for buyers targeting specific user groups, such as hikers or travelers, to ensure that the backpack can handle the intended load without compromising comfort or safety. -

Water Resistance Rating (WR)

– Definition: A measure of the backpack’s ability to resist water penetration, often expressed in millimeters (mm) of water column pressure.

– Importance: A higher WR indicates better water resistance, which is particularly important for users who may encounter wet conditions while foraging or traveling. This property can influence marketability in regions prone to rain. -

Zipper Quality

– Definition: Refers to the durability and functionality of the zippers used in the backpack, including types such as YKK or waterproof zippers.

– Importance: High-quality zippers enhance the backpack’s usability and lifespan. Buyers should ensure that zippers can withstand frequent use and environmental conditions, as failures can lead to product returns and dissatisfaction.

-

Ergonomics

– Definition: The design features that contribute to user comfort, such as padded straps, adjustable harness systems, and back ventilation.

– Importance: Ergonomically designed backpacks reduce strain on the user’s body, making them more appealing to consumers. This is especially relevant for long-duration activities like hiking or traveling. -

Sustainability Certifications

– Definition: Certifications that indicate the backpack is made from environmentally friendly materials and processes, such as GRS (Global Recycled Standard) or OEKO-TEX.

– Importance: As sustainability becomes a priority for consumers, having certified products can enhance brand reputation and marketability. Buyers from regions with a strong eco-conscious consumer base should prioritize suppliers who offer sustainable options.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships is crucial for buyers seeking customization or specific branding on their mushroom backpacks. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Buyers must be aware of MOQ requirements to ensure they can meet purchasing commitments without overextending their budgets. -

RFQ (Request for Quotation)

– Definition: A document used to solicit quotes from suppliers for specific products or services.

– Relevance: Crafting a clear RFQ can help buyers receive accurate pricing and terms, facilitating better negotiations and decision-making. -

Incoterms (International Commercial Terms)

– Definition: A set of rules that define the responsibilities of sellers and buyers in international transactions.

– Relevance: Familiarity with Incoterms helps buyers understand shipping responsibilities, costs, and risks, which is essential for effective logistics management. -

Lead Time

– Definition: The time it takes from placing an order to receiving the goods.

– Relevance: Knowing lead times is vital for inventory planning and ensuring timely delivery to customers, especially in markets with fluctuating demand. -

Sample Approval

– Definition: The process of reviewing and approving a prototype or sample before mass production begins.

– Relevance: This step is crucial for ensuring that the final product meets quality standards and design specifications, reducing the risk of costly production errors.

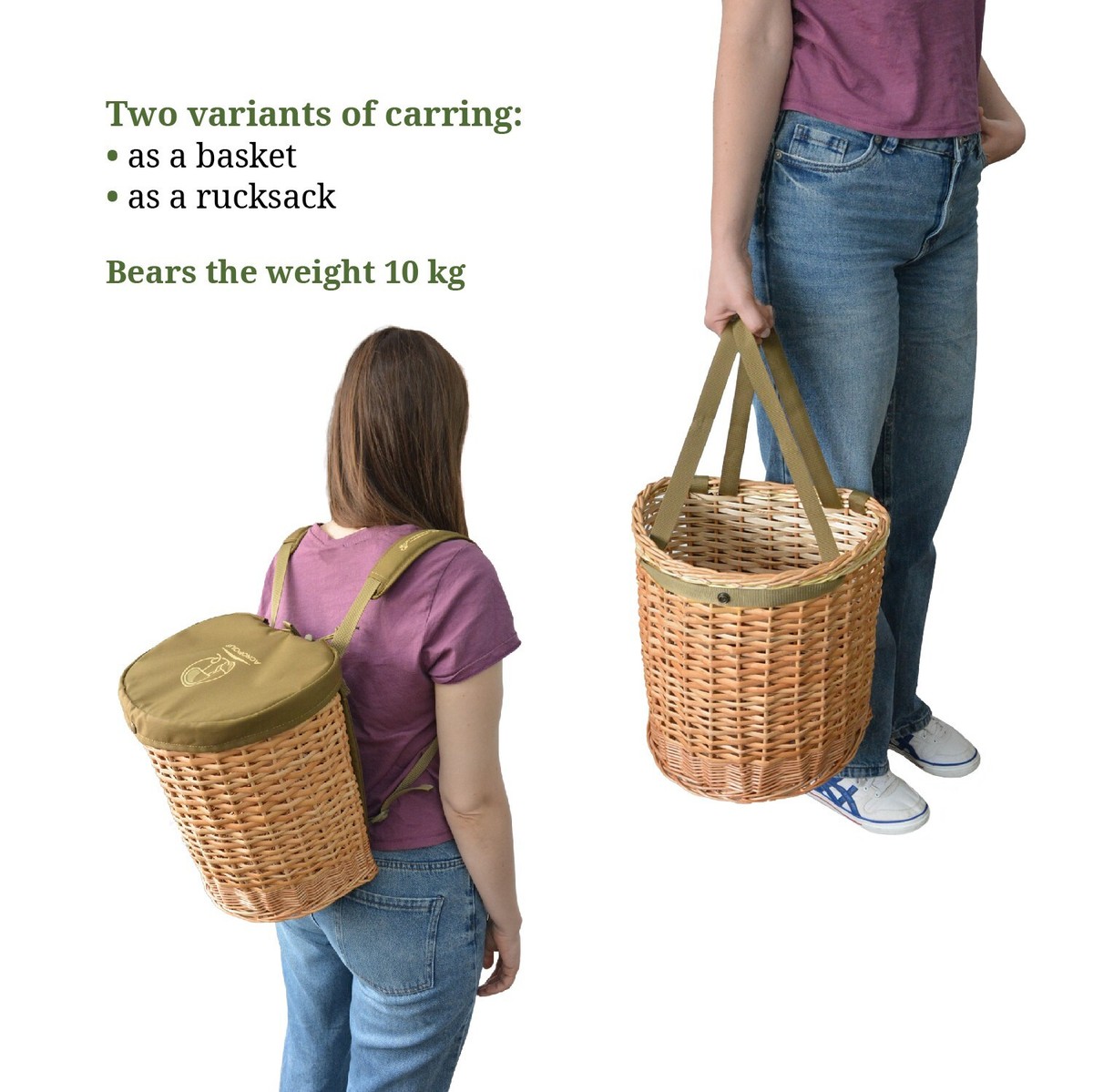

Illustrative Image (Source: Google Search)

By understanding these technical properties and trade terms, B2B buyers can navigate the complexities of sourcing mushroom backpacks more effectively, ensuring they make informed purchasing decisions that align with their business objectives.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the mushroom backpack Sector

Market Overview & Key Trends

The global market for mushroom backpacks, which cater to both outdoor enthusiasts and urban commuters, is witnessing significant growth driven by several factors. Increasing consumer interest in sustainable and eco-friendly products has created a niche for backpacks made from alternative materials, such as mycelium-based fabrics. This trend resonates particularly well in regions like Europe, where sustainability is a strong purchasing criterion among consumers. Additionally, the rise of outdoor activities, particularly post-pandemic, has spurred demand for functional and stylish backpacks that can handle various environments.

Emerging technologies are also shaping the sourcing landscape. B2B buyers are increasingly leveraging digital platforms for sourcing, allowing them to compare prices, quality, and supplier capabilities efficiently. Platforms such as Alibaba, while useful, require careful navigation to avoid unpredictable pricing. Buyers are encouraged to engage in thorough market research and consider consulting services to ensure they select suppliers that align with their quality and sustainability standards.

Moreover, the competitive landscape is evolving, with manufacturers focusing on innovative designs that incorporate features like modular components and enhanced ergonomics. This focus on versatility caters to a diverse consumer base, from casual users to serious adventurers, and presents opportunities for international buyers to differentiate their offerings in local markets.

Sustainability & Ethical Sourcing in B2B

Sustainability in the mushroom backpack sector is not merely a trend; it is becoming a necessity as consumers demand greater transparency and accountability from brands. The environmental impact of traditional materials, such as polyester and nylon, has prompted manufacturers to explore eco-friendly alternatives. Materials derived from mycelium, recycled plastics, and organic cotton are gaining traction, reducing the carbon footprint associated with production.

Illustrative Image (Source: Google Search)

For B2B buyers, understanding the importance of ethical supply chains is paramount. Working with suppliers who prioritize fair labor practices and environmental stewardship not only enhances brand reputation but also aligns with the values of increasingly conscious consumers. Certifications such as Global Organic Textile Standard (GOTS) or OEKO-TEX can serve as indicators of a supplier’s commitment to sustainability, providing buyers with assurance regarding the quality and ethical standards of the materials used.

Additionally, adopting a circular economy model—where products are designed for longevity and recyclability—can significantly mitigate waste and foster brand loyalty. As sustainability becomes central to purchasing decisions, buyers who prioritize these values will likely see increased demand for their products.

Brief Evolution/History

The concept of the mushroom backpack is relatively recent, emerging from a broader trend towards sustainable fashion and outdoor equipment. Initially, traditional backpacks relied heavily on synthetic materials that posed environmental challenges. However, with the rise of eco-conscious consumers and advancements in material science, manufacturers began experimenting with biodegradable and sustainable materials, particularly mycelium-based fabrics.

This evolution reflects a shift in consumer expectations, where functionality meets sustainability. As buyers in Africa, South America, the Middle East, and Europe increasingly seek products that align with their values, the mushroom backpack sector is positioned to grow, offering unique opportunities for differentiation in the competitive B2B landscape.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of mushroom backpack

-

How can I effectively vet suppliers for mushroom backpacks?

To vet suppliers, start by checking their business credentials, including registration and certifications. Use platforms like Alibaba, Global Sources, or local trade fairs to find potential suppliers. Request references from their previous clients to gauge reliability. Ensure they have experience in manufacturing mushroom backpacks specifically, as this niche may require unique materials or designs. Conduct a factory visit or request a video tour if possible to assess their production capabilities, quality control processes, and working conditions. -

What customization options are typically available for mushroom backpacks?

Most manufacturers offer various customization options, including size, color, materials, and branding. You can specify features such as pockets, straps, and insulation to cater to your target market. Some suppliers may also provide design services to help create unique styles that stand out. Be clear about your requirements and provide detailed specifications to avoid misunderstandings. Always request samples before committing to a large order to ensure the final product meets your expectations. -

What are the typical minimum order quantities (MOQs) and lead times for mushroom backpacks?

MOQs for mushroom backpacks can vary widely depending on the supplier and the complexity of the design. Generally, you may encounter MOQs ranging from 100 to 1,000 units. Lead times typically range from 4 to 12 weeks, depending on production schedules and customization requirements. It’s essential to communicate your needs upfront and negotiate terms that align with your business strategy. Consider establishing a long-term relationship with suppliers to potentially lower MOQs in future orders. -

What payment terms should I expect when sourcing mushroom backpacks?

Payment terms can vary by supplier but typically include options like a 30% deposit upfront and the remaining 70% before shipping. Some suppliers may offer credit terms for established businesses. Ensure you understand the payment methods accepted, such as bank transfers or platforms like PayPal. Always use secure payment methods to protect your funds. It’s also advisable to include terms in the contract that outline payment schedules and consequences for late payments. -

How can I ensure quality assurance (QA) and certifications for mushroom backpacks?

Request copies of any quality certifications the supplier holds, such as ISO 9001 or specific industry standards for textiles. Conducting third-party inspections before shipment is another effective way to ensure product quality. Define your quality expectations in detail, including materials, stitching, and functionality. Consider implementing a quality control checklist that the manufacturer must follow during production. Regular communication throughout the manufacturing process can help address any issues before they become significant problems. -

What logistics considerations should I keep in mind when importing mushroom backpacks?

When importing, consider shipping methods (air vs. sea), as they will affect delivery times and costs. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments. Research customs regulations in your country to ensure compliance and avoid delays. Work with a freight forwarder who understands the nuances of importing textiles to navigate paperwork efficiently. Be aware of additional costs such as duties and taxes, which can impact your overall budget. -

How can I handle disputes with suppliers when sourcing mushroom backpacks?

To handle disputes effectively, maintain clear communication from the outset. Document all agreements in writing, including specifications, timelines, and payment terms. If a dispute arises, first attempt to resolve it amicably through direct communication. If necessary, refer to the contract for dispute resolution clauses, which may involve mediation or arbitration. Consider engaging a local legal expert familiar with international trade laws to assist in resolving complex disputes. -

What market trends should I be aware of when sourcing mushroom backpacks?

Stay informed about trends such as sustainable materials and eco-friendly production methods, as consumers increasingly favor environmentally conscious products. Additionally, monitor consumer preferences for multifunctional designs and innovative features that enhance usability. Understanding regional market demands is crucial; for example, buyers in Europe may prioritize quality and sustainability, while those in Africa might focus on affordability and durability. Conducting market research can help you align your product offerings with current trends, ensuring competitiveness in the market.

Strategic Sourcing Conclusion and Outlook for mushroom backpack

The strategic sourcing of mushroom backpacks is pivotal for international B2B buyers looking to establish a competitive edge in their markets. By focusing on high-quality materials such as nylon and recycled fabrics, businesses can enhance product durability and appeal to eco-conscious consumers. Understanding the intricacies of manufacturing—from material sourcing to assembly—ensures that buyers can make informed decisions that align with their brand values and customer expectations.

Key takeaways include:

- Research and Relationships: Establish strong connections with manufacturers to negotiate favorable terms and ensure quality control.

- Market Knowledge: Familiarize yourself with regional preferences and trends, particularly in Africa, South America, the Middle East, and Europe, to tailor your product offerings.

- Sustainability Focus: Leverage sustainable practices in sourcing to meet the growing demand for environmentally friendly products.

As the global market for backpacks continues to evolve, now is the time for international buyers to act. By adopting a strategic sourcing approach, businesses can not only meet customer needs but also position themselves for future growth. Engage with reliable suppliers today to explore innovative designs and materials that will set your brand apart in an increasingly competitive landscape.

Illustrative Image (Source: Google Search)