Your Ultimate Guide to Sourcing Lion King Backpack

Guide to Lion King Backpack

- Introduction: Navigating the Global Market for lion king backpack

- Understanding lion king backpack Types and Variations

- Key Industrial Applications of lion king backpack

- Strategic Material Selection Guide for lion king backpack

- In-depth Look: Manufacturing Processes and Quality Assurance for lion king backpack

- Comprehensive Cost and Pricing Analysis for lion king backpack Sourcing

- Spotlight on Potential lion king backpack Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for lion king backpack

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the lion king backpack Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of lion king backpack

- Strategic Sourcing Conclusion and Outlook for lion king backpack

Introduction: Navigating the Global Market for lion king backpack

The Lion King backpack has transcended mere utility, evolving into a cultural icon that resonates with consumers across diverse markets. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe—including key regions like Spain and Poland—understanding the significance of this product is crucial. The Lion King backpack serves not just as a functional item for students and travelers but also as a beloved brand representation, making it a valuable addition to any retail portfolio.

This guide provides a comprehensive exploration of the Lion King backpack, covering essential aspects such as design variations, material selection, manufacturing processes, and quality control measures. Buyers will gain insights into sourcing from reliable suppliers, evaluating costs, and understanding market demand, empowering them to make informed purchasing decisions.

By delving into frequently asked questions and industry trends, this guide equips B2B buyers with the knowledge needed to navigate the complexities of the global backpack market. Whether you are looking to cater to a young audience in Africa or meet the demands of a competitive European market, this resource serves as a foundational tool for successful sourcing strategies. With the right information at your fingertips, you can confidently engage with suppliers and enhance your product offerings to meet consumer expectations.

Understanding lion king backpack Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Lion King Backpack | Iconic designs featuring characters and motifs from the Lion King franchise | Retail, merchandising, educational institutions | Pros: Strong brand appeal; Cons: Limited to niche markets |

| Themed Adventure Backpack | Rugged design with compartments for outdoor gear, featuring Lion King graphics | Outdoor retailers, adventure tourism | Pros: Versatile for outdoor use; Cons: May lack urban style |

| School Backpack | Spacious, ergonomic design with Lion King themes, often with additional pockets | Schools, educational supply distributors | Pros: Functional for students; Cons: Seasonal demand fluctuations |

| Eco-Friendly Backpack | Made from sustainable materials, featuring Lion King branding | Eco-conscious retailers, corporate gifting | Pros: Appeals to sustainability trends; Cons: Higher production costs |

| Luxury Collector’s Edition Backpack | Premium materials with exclusive Lion King designs, often limited edition | High-end retail, collectors’ markets | Pros: High profit margins; Cons: Limited target audience |

Classic Lion King Backpack

The Classic Lion King Backpack is characterized by its vibrant designs that prominently feature beloved characters from the franchise. These backpacks are primarily utilized in retail and merchandising, appealing to fans of all ages. For B2B buyers, the strong brand recognition can drive sales, but it’s important to consider the limitations in market reach, as these products cater to a niche audience.

Themed Adventure Backpack

Designed for outdoor enthusiasts, the Themed Adventure Backpack combines rugged functionality with Lion King aesthetics. This type is ideal for outdoor retailers and adventure tourism companies looking to attract customers with unique, themed products. Buyers should evaluate material durability and compartmentalization to ensure they meet the practical needs of outdoor activities, while also appealing to fans of the franchise.

School Backpack

The School Backpack offers spacious compartments and ergonomic designs, making it a practical choice for students. B2B applications include schools and educational supply distributors, particularly during back-to-school seasons. Buyers should consider the balance between functionality and design appeal, as well as the potential for fluctuating demand based on academic calendars.

Eco-Friendly Backpack

This variation is crafted from sustainable materials and features Lion King branding, appealing to eco-conscious consumers. Ideal for eco-friendly retailers and corporate gifting, these backpacks align with the growing trend towards sustainability. However, buyers must weigh the higher production costs against potential market demand, as eco-friendly products often command premium pricing.

Luxury Collector’s Edition Backpack

The Luxury Collector’s Edition Backpack is made from high-quality materials and features exclusive designs, often released in limited quantities. This type targets high-end retail and collectors’ markets, offering significant profit margins for B2B buyers. However, the limited audience means that companies should carefully assess their target market’s size and purchasing power before investing in inventory.

Related Video: Large Language Models (LLMs) – Everything You NEED To Know

Key Industrial Applications of lion king backpack

| Industry/Sector | Specific Application of lion king backpack | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Education | School and university supplies | Appeals to students with a recognizable theme | Durability, design customization, and safety compliance |

| Travel & Tourism | Travel gear for families and children | Enhances brand visibility and customer loyalty | Lightweight materials, water resistance, and storage options |

| Outdoor Recreation | Adventure and camping supplies | Attracts outdoor enthusiasts with fun designs | Quality of materials, comfort, and functional features |

| Retail | Merchandise for themed stores | Increases foot traffic and impulse purchases | Cost-effective production, branding opportunities, and seasonality |

| Event Management | Promotional giveaways at family-friendly events | Strengthens brand presence and customer engagement | Customization options, lead times, and minimum order quantities |

Education

In educational settings, the Lion King backpack serves as a popular choice among students. Its vibrant design resonates with children, making it an appealing option for parents looking for functional yet attractive school supplies. International buyers should consider durability and safety compliance, ensuring the backpack withstands daily use while meeting local regulations. Additionally, customization options can enhance brand visibility for educational institutions.

Travel & Tourism

The Lion King backpack is ideal for travel and tourism, especially for families. Its engaging design can captivate children, making it a sought-after item for family vacations. B2B buyers in this sector should focus on lightweight materials and water-resistant features, ensuring comfort and practicality during travel. Emphasizing storage options can also enhance customer satisfaction, making the backpack a versatile travel companion.

Outdoor Recreation

For the outdoor recreation industry, the Lion King backpack appeals to adventure enthusiasts, particularly families engaging in camping and hiking activities. The unique branding can attract a niche market, while the backpack’s durability and comfort are critical for prolonged use. Buyers should prioritize high-quality materials and functional features like adjustable straps and ample storage space to meet the demands of outdoor activities.

Retail

Retail businesses, especially themed stores, can leverage the Lion King backpack as a merchandise item. Its distinctive design can drive foot traffic and encourage impulse purchases among parents and children alike. B2B buyers in retail should consider cost-effective production methods and branding opportunities to maximize profit margins. Additionally, understanding seasonality trends can help retailers stock the backpacks at optimal times.

Event Management

Event managers can utilize the Lion King backpack as promotional giveaways at family-friendly events such as fairs and festivals. This strategy enhances brand presence and fosters customer engagement, particularly among families. Buyers should focus on customization options that allow for branding and messaging, along with lead times and minimum order quantities to ensure timely delivery for events.

Related Video: Farm tools and their uses

Strategic Material Selection Guide for lion king backpack

When selecting materials for the production of Lion King backpacks, it is crucial to consider various factors that impact performance, durability, and cost. Below, we analyze four common materials that are suitable for this application, providing insights tailored for international B2B buyers.

1. Nylon

Key Properties: Nylon is known for its excellent tensile strength, abrasion resistance, and lightweight nature. It performs well in a range of temperatures and is resistant to mold and mildew, making it suitable for outdoor use.

Pros & Cons: The primary advantage of nylon is its durability and resistance to wear and tear. It is also relatively lightweight, which is beneficial for backpack design. However, nylon can be more expensive than other materials like polyester and may not be as environmentally friendly due to its petroleum-based origins.

Impact on Application: Nylon is particularly effective in environments where moisture resistance is required, making it ideal for outdoor adventures.

Considerations for International Buyers: Buyers from regions such as Africa and South America should be aware of the varying quality standards for nylon. Compliance with international standards like ASTM for textile materials is essential to ensure product reliability.

2. Polyester

Key Properties: Polyester is strong, resistant to shrinking and stretching, and quick-drying. It offers moderate resistance to UV light, which helps in maintaining color and integrity over time.

Pros & Cons: Polyester is generally more cost-effective than nylon and offers good durability for everyday use. However, it is not as breathable or moisture-wicking as nylon, which may affect comfort in humid conditions.

Impact on Application: This material is suitable for casual use and school backpacks, where exposure to moisture is less of a concern.

Considerations for International Buyers: Buyers should ensure that the polyester used meets local and international textile regulations. In Europe, for example, compliance with REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) is crucial.

3. Canvas

Key Properties: Canvas is a heavy-duty fabric made from cotton or a blend of cotton and synthetic fibers. It is known for its sturdiness and ability to withstand rough handling.

Pros & Cons: The main advantage of canvas is its durability and classic aesthetic appeal, making it a popular choice for fashion-oriented backpacks. However, it can be heavier than nylon or polyester and may require more care to maintain its appearance, especially if it gets wet.

Impact on Application: Canvas is ideal for urban and casual backpacks, where style and durability are prioritized over lightweight design.

Considerations for International Buyers: Buyers in Europe and the Middle East should be aware of the environmental impact of cotton production. Sourcing organic or sustainably produced canvas may align better with consumer preferences in these regions.

4. Ripstop Nylon

Key Properties: Ripstop nylon features a grid pattern that enhances its tear resistance. It combines the lightweight characteristics of nylon with added durability.

Pros & Cons: The key advantage of ripstop nylon is its ability to withstand significant wear and tear without compromising weight. However, it can be more complex to manufacture, potentially increasing costs.

Impact on Application: This material is perfect for high-performance backpacks used in rugged outdoor settings, where durability is paramount.

Considerations for International Buyers: Buyers should ensure that ripstop nylon meets international standards for performance and safety, particularly in regions like Europe where stringent regulations may apply.

Summary Table

| Material | Typical Use Case for Lion King Backpack | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | Outdoor and travel backpacks | Excellent durability and moisture resistance | Higher cost than polyester | High |

| Polyester | Casual and school backpacks | Cost-effective and durable | Less breathable than nylon | Medium |

| Canvas | Urban and casual backpacks | Sturdy and aesthetically appealing | Heavier and requires maintenance | Medium |

| Ripstop Nylon | High-performance outdoor backpacks | Lightweight with enhanced tear resistance | More complex manufacturing process | High |

This guide provides a strategic overview of material selection for Lion King backpacks, helping international B2B buyers make informed decisions tailored to their specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for lion king backpack

The manufacturing process of a Lion King backpack involves several critical stages that ensure the product is both functional and visually appealing. Understanding these stages is vital for international B2B buyers who prioritize quality, reliability, and adherence to international standards.

Manufacturing Process

1. Material Preparation

Material selection is the foundational step in manufacturing a Lion King backpack. Common materials include:

- Nylon: Lightweight and water-resistant, ideal for everyday use.

- Polyester: Known for durability and easy maintenance, suitable for various designs.

- Canvas: Offers a heavier-duty option, often used for themed or artistic backpacks.

- Specialty Fabrics: Options such as ripstop or ballistic nylon can enhance durability and resistance to wear and tear.

Buyers should consider the intended use and market demands when selecting materials. For instance, a backpack aimed at outdoor enthusiasts might require water-resistant features, while a school backpack may prioritize lightweight design.

2. Forming

Once materials are selected, the next step is forming, which includes cutting and shaping the fabric into the desired components of the backpack. This stage involves:

- Cutting: Using precise templates to ensure uniformity in shapes and sizes.

- Heat Sealing: A technique that can be employed to create waterproof seams, especially around zippers and edges.

This stage is crucial for maintaining quality standards, as the precision in cutting can significantly affect the overall durability and appearance of the finished product.

3. Assembly

The assembly phase involves sewing the cut pieces together. Key techniques include:

- Heavy-Duty Sewing: Ensures that seams are strong enough to withstand stress, particularly at high-impact areas like strap attachments.

- Reinforced Stitching: Adding extra stitches in critical areas to prevent tearing.

- Quality Zippers and Buckles: Selecting high-quality hardware is essential for functionality and longevity.

Attention to detail during assembly is paramount, as it directly influences the backpack’s usability and aesthetic appeal.

4. Finishing

In the finishing stage, manufacturers add embellishments and branding elements, such as:

- Logos: Applied through methods like embroidery, screen printing, or heat transfer.

- Additional Features: Including pockets, straps, or decorative elements that enhance the product’s appeal.

This stage not only contributes to the backpack’s functionality but also its marketability, especially for themed products like those featuring characters from The Lion King.

Quality Assurance

Quality assurance is critical in ensuring that the Lion King backpacks meet both manufacturer and consumer expectations. The following international and industry-specific standards are commonly employed:

Relevant International Standards

- ISO 9001: A widely recognized standard that outlines requirements for a quality management system, ensuring consistent quality in products and services.

- CE Marking: Indicates compliance with health, safety, and environmental protection standards for products sold within the European Economic Area.

Quality Control Checkpoints

Quality control typically involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process to identify defects early.

- Final Quality Control (FQC): A comprehensive check of the finished product before shipment, ensuring all specifications are met.

Common Testing Methods

Testing methods for backpacks can include:

- Tensile Strength Testing: Measures the durability of seams and materials.

- Water Resistance Testing: Ensures that the backpack can withstand moisture without damage.

- Zipper and Buckle Testing: Assesses the reliability and functionality of hardware components.

Verifying Supplier Quality Control

For international B2B buyers, especially those from diverse markets like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential. Strategies include:

- Supplier Audits: Conducting on-site inspections to evaluate the manufacturing process and quality control systems.

- Quality Reports: Requesting documentation from suppliers that detail their quality control measures and results from various testing methods.

- Third-Party Inspections: Engaging independent inspection agencies to assess product quality before shipment, providing an unbiased evaluation.

QC and Certification Nuances for International Buyers

B2B buyers must be aware of the nuances of quality control and certifications when sourcing internationally. Here are a few considerations:

- Local Regulations: Understanding country-specific regulations and standards can help avoid compliance issues.

- Cultural Differences: Be mindful of how quality is perceived in different regions, as this may impact supplier negotiations and expectations.

- Communication: Establish clear communication channels with suppliers to ensure that quality standards are understood and met throughout the production process.

By comprehensively understanding the manufacturing processes and quality assurance measures in the production of Lion King backpacks, international B2B buyers can make informed decisions, ensuring they source high-quality products that meet market demands.

Related Video: How a Backpack is Made : Every Step on the Production Line

Comprehensive Cost and Pricing Analysis for lion king backpack Sourcing

When sourcing Lion King backpacks, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. Here’s a comprehensive analysis of the various components influencing costs, pricing factors, and actionable tips for effective sourcing.

Cost Components

-

Materials: The choice of materials significantly impacts the overall cost. High-quality fabrics such as nylon, polyester, or canvas can range from $2 to $10 per yard, depending on durability and water-resistance features. Special materials like ripstop or ballistic nylon will incur higher costs but offer enhanced durability.

-

Labor: Labor costs vary by region. For example, labor in Southeast Asia is generally cheaper than in Europe. On average, labor costs can account for 10-30% of the total manufacturing cost, influenced by the complexity of the backpack design and local wage standards.

-

Manufacturing Overhead: This includes factory utilities, equipment maintenance, and administrative costs. Overhead can typically represent 15-25% of the total production costs. Efficient factories with streamlined operations can lower this percentage.

-

Tooling: Initial tooling costs for molds and patterns can be substantial, often ranging from $500 to $5,000 depending on the complexity of the design. This is a one-time cost that should be amortized over the production run.

-

Quality Control (QC): Implementing a robust QC process is essential for ensuring product reliability. QC costs can add about 5-10% to the total manufacturing cost, depending on the rigor of the inspection processes.

Illustrative Image (Source: Google Search)

-

Logistics: Shipping costs can vary widely based on the destination, weight, and dimensions of the shipment. International freight costs are influenced by Incoterms, with DDP (Delivered Duty Paid) typically being more expensive due to included duties and taxes.

-

Margin: Suppliers typically add a profit margin of 10-30% on top of their costs. This margin can vary based on market demand and competition.

Price Influencers

-

Volume/MOQ: Higher order volumes generally lead to lower per-unit costs. Minimum order quantities (MOQs) can range from 300 to 1,000 units, depending on the supplier.

-

Specifications/Customization: Custom designs and features can significantly increase costs. Simple designs will be more economical, while intricate designs with multiple colors or specialized features will cost more.

-

Quality/Certifications: Certification for safety and quality standards (e.g., ISO, CE) can add to the cost but may be necessary for market entry in specific regions.

-

Supplier Factors: The supplier’s reputation, reliability, and location can influence costs. Established suppliers may charge more due to their proven track record.

-

Incoterms: Understanding Incoterms is crucial for international shipping. Options like FOB (Free on Board) may lower initial costs but could lead to higher overall expenses once logistics are factored in.

Buyer Tips

-

Negotiate: Always negotiate prices and terms. Suppliers may be willing to offer discounts for larger orders or early payment.

-

Cost Efficiency: Analyze the Total Cost of Ownership (TCO), which includes initial costs, maintenance, and logistics. Sometimes a higher upfront investment can lead to lower long-term costs.

-

Research: Understand regional market trends and pricing structures. Prices can fluctuate based on demand and economic conditions in your target market.

-

Quality Assurance: Prioritize quality to avoid costly returns and brand damage. Investing in QC processes can save money in the long run.

-

Stay Informed: Keep abreast of global supply chain disruptions, which can affect pricing and availability. Being proactive can help mitigate potential risks.

Disclaimer

Prices and costs mentioned are indicative and can vary significantly based on market conditions, supplier negotiations, and specific order requirements. Always conduct thorough due diligence before making purchasing decisions.

Spotlight on Potential lion king backpack Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘lion king backpack’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for lion king backpack

Essential Technical Properties

When selecting a “Lion King” backpack for your B2B needs, understanding the critical technical properties is essential for ensuring quality and suitability for your target market. Below are key specifications to consider:

-

Material Grade

The material grade refers to the quality and type of fabric used in the backpack. Common materials include nylon, polyester, and canvas, each offering varying degrees of durability, water resistance, and weight. Selecting the appropriate material is vital as it affects the backpack’s longevity and functionality, directly impacting customer satisfaction and return rates. -

Water Resistance Rating (WRR)

This specification indicates the level of water resistance the backpack can provide, often measured in millimeters. For example, a WRR of 1,500 mm means the fabric can withstand light rain. Understanding WRR is crucial for markets prone to wet conditions, ensuring that the backpacks meet consumer expectations for performance. -

Load-Bearing Capacity

This property refers to the maximum weight the backpack can safely carry without compromising its structure. It is typically measured in kilograms (kg) or pounds (lbs). For B2B buyers, knowing the load-bearing capacity is essential for aligning product offerings with customer needs, especially in sectors like education and outdoor activities. -

Strap and Zipper Quality

The durability of straps and zippers is critical for the overall performance of the backpack. High-quality materials such as YKK zippers and reinforced stitching on straps can enhance durability. Buyers should prioritize these components to minimize returns and warranty claims, ensuring a better customer experience. -

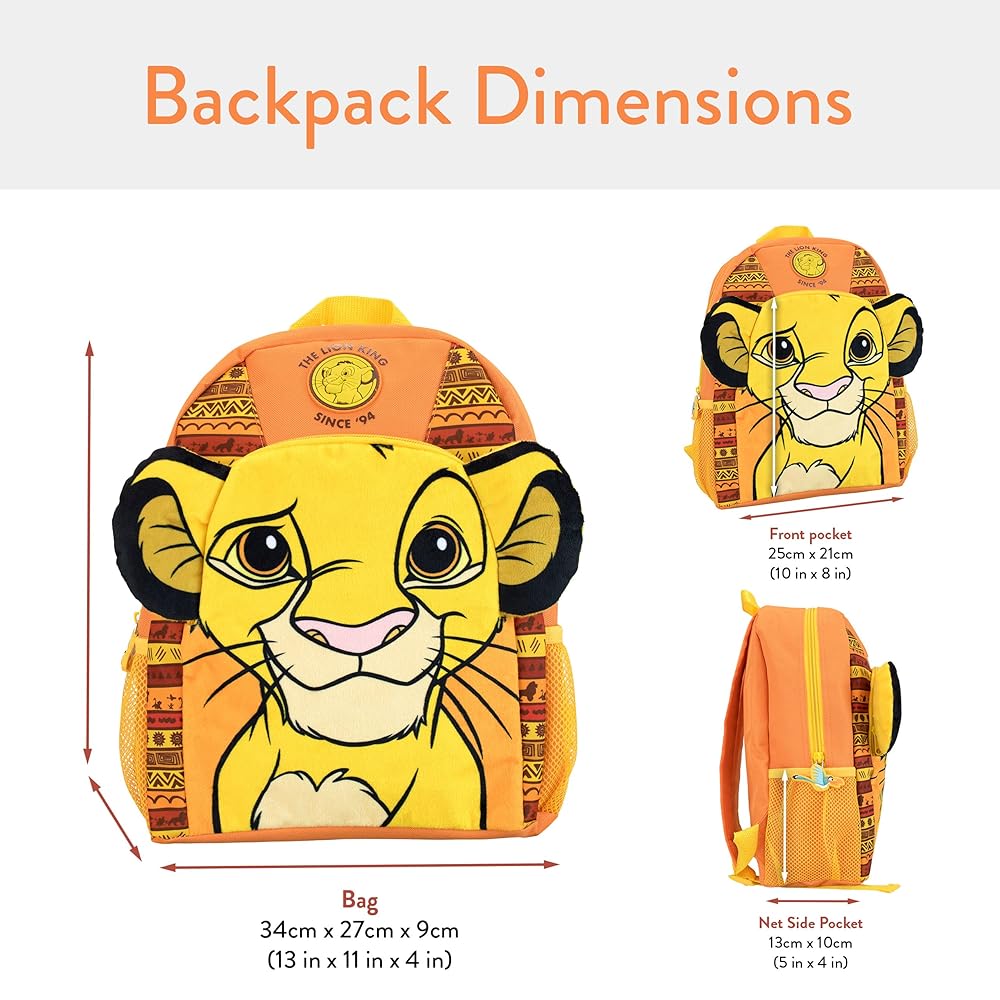

Size and Dimensions

Understanding the dimensions of the backpack is essential for market segmentation. For example, backpacks designed for children will differ significantly in size compared to those meant for adults or travelers. Specifying dimensions helps in targeting the right demographic and optimizing storage solutions. -

Reinforcement and Tolerance Levels

Reinforcement refers to additional stitching or fabric layers at stress points, while tolerance levels indicate the acceptable variation in manufacturing dimensions. These factors are critical for ensuring the backpack can withstand everyday use without failure, ultimately affecting brand reputation.

Common Trade Terminology

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B space. Here are some common terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces goods that are sold under another company’s brand name. In the context of backpacks, an OEM can create custom designs and specifications according to a buyer’s requirements. Understanding OEM relationships can lead to better pricing and product quality. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it helps in planning inventory and managing cash flow. Knowing the MOQ also allows buyers to assess whether a supplier can meet their scaling needs. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing for specific products or services. For B2B buyers, issuing RFQs enables comparison of prices and terms from multiple suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in international trade. Understanding Incoterms is critical for B2B transactions, as they clarify who is responsible for shipping, insurance, and tariffs during transportation, helping to avoid misunderstandings. -

Lead Time

Lead time refers to the time it takes from placing an order to the delivery of the product. This is a vital specification for B2B buyers to manage customer expectations and inventory levels effectively. -

AQL (Acceptable Quality Level)

AQL is a statistical measurement used to determine the maximum number of defective items considered acceptable in a batch. Understanding AQL helps B2B buyers set quality control standards and make informed decisions regarding supplier reliability.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing “Lion King” backpacks, ensuring they meet market demands and quality standards.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the lion king backpack Sector

Market Overview & Key Trends

The global market for Lion King backpacks is witnessing significant growth, driven by factors such as increasing brand recognition and the rising popularity of character-themed products among consumers. This segment is particularly appealing to children and young adults, making it a lucrative opportunity for B2B buyers. In regions like Africa and South America, where youth demographics are prominent, character-based merchandise is becoming a staple in retail offerings.

Current sourcing trends highlight a shift towards digital platforms for procurement. International buyers, particularly from Europe and the Middle East, are leveraging e-commerce platforms like Alibaba and specialized suppliers to source products efficiently. However, buyers must exercise caution; without a solid understanding of manufacturing processes and material costs, they may encounter unpredictable pricing.

Emerging technologies, such as 3D modeling and augmented reality, are becoming vital tools in backpack design and marketing. These innovations allow manufacturers to present realistic product representations, enhancing buyer confidence. Additionally, sustainable manufacturing practices are gaining traction, with buyers increasingly prioritizing suppliers that adhere to ethical standards and environmental guidelines.

Illustrative Image (Source: Google Search)

The competitive landscape is also evolving, with an emphasis on custom designs that cater to local tastes and preferences. This trend is particularly relevant in diverse markets, such as Spain and Poland, where cultural nuances influence consumer behavior. B2B buyers should focus on suppliers that offer flexibility in design and can adapt to regional market dynamics.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer a choice but a necessity in the backpack manufacturing sector. The environmental impact of conventional materials, such as plastic and non-biodegradable fabrics, has prompted B2B buyers to seek alternatives that minimize ecological footprints. For Lion King backpacks, materials like recycled polyester and organic cotton are becoming increasingly popular, aligning with global sustainability goals.

Ethical sourcing is paramount, particularly as consumers demand transparency from brands. Buyers should prioritize suppliers who can demonstrate ethical supply chains, ensuring fair labor practices and safe working conditions. Certifications such as Global Recycle Standard (GRS) and OEKO-TEX® provide credibility and assurance that the materials used are environmentally friendly and socially responsible.

Moreover, companies that adopt eco-friendly practices often gain a competitive advantage, appealing to the growing demographic of environmentally conscious consumers. This trend is evident in regions like Europe, where sustainability is a significant purchasing factor. B2B buyers should engage with suppliers who not only offer sustainable materials but also have a clear strategy for reducing waste and carbon emissions throughout the manufacturing process.

Brief Evolution/History

The Lion King backpack market has evolved significantly since the release of the original animated film in 1994. Initially, these products were simple, featuring basic designs that appealed primarily to children. Over the years, as the franchise expanded with sequels, merchandise diversification, and a live-action adaptation, the demand for branded backpacks surged.

Today, Lion King backpacks are not just functional items; they are fashion statements that resonate with nostalgia among adults and are highly sought after by younger generations. This evolution has prompted manufacturers to innovate continuously, integrating modern design elements and sustainable practices to cater to a broader audience while maintaining the beloved themes of the franchise. B2B buyers can leverage this rich history and brand loyalty to position their offerings effectively in the market.

Related Video: Inside the Global Underground Wildlife Trafficking Market

Frequently Asked Questions (FAQs) for B2B Buyers of lion king backpack

-

What should I consider when vetting suppliers for Lion King backpacks?

When vetting suppliers, focus on their manufacturing capabilities, experience in producing similar products, and certifications (e.g., ISO, CE). Request samples to assess quality and ensure they can meet your design specifications. It’s also essential to check their reputation through references and reviews from previous clients, particularly those in your target markets. Lastly, consider their communication responsiveness and willingness to provide transparent information regarding their production processes. -

Can I customize the Lion King backpack design?

Yes, most manufacturers offer customization options for designs, materials, and features. When discussing your requirements, provide detailed specifications, including dimensions, colors, and any unique functionalities you want to incorporate. Be aware that extensive customization may impact the minimum order quantity (MOQ) and lead time, so it’s essential to clarify these aspects with the supplier upfront. -

What are typical minimum order quantities (MOQ) and lead times for Lion King backpacks?

MOQs can vary significantly between manufacturers, typically ranging from 100 to 1,000 units, depending on the level of customization and material costs. Lead times usually fall between 30 to 90 days, influenced by the complexity of the design and the supplier’s production capacity. Always negotiate these terms before placing an order to ensure they align with your business needs and inventory management strategies. -

What payment terms should I expect when ordering Lion King backpacks?

Payment terms can vary widely by supplier but commonly include options such as a 30% deposit upfront with the balance due before shipping. Some suppliers may offer flexible terms, especially for larger orders or long-term partnerships. Always ensure that you have a clear agreement in writing regarding payment terms to avoid any misunderstandings and to protect your financial interests.

Illustrative Image (Source: Google Search)

-

How can I ensure quality assurance (QA) for the Lion King backpacks?

To ensure quality assurance, request a detailed QA process from the supplier, which should include inspections at various production stages. Inquire about their quality certifications and any third-party testing they may conduct. It’s advisable to arrange for pre-shipment inspections by independent quality control firms, especially if you cannot visit the factory. This proactive approach can help mitigate risks associated with product quality. -

What certifications should I look for in a Lion King backpack supplier?

Key certifications to look for include ISO 9001 for quality management systems, ISO 14001 for environmental management, and any relevant safety certifications, such as EN71 for toys or CPSIA for children’s products, if applicable. These certifications indicate that the supplier adheres to international standards for quality and safety, which is crucial for maintaining your brand’s reputation in the market. -

What logistics considerations should I keep in mind when sourcing Lion King backpacks?

Logistics play a critical role in international trade. Consider factors such as shipping methods (air vs. sea), associated costs, customs regulations, and import duties specific to your country. Establish a reliable logistics partner who can manage shipping and ensure timely delivery. Additionally, factor in potential delays due to customs clearance and plan your inventory accordingly to avoid stockouts. -

How should I handle disputes with suppliers?

To handle disputes effectively, maintain clear and consistent communication with your supplier from the beginning. Establish a written contract that outlines all terms, including quality expectations and delivery timelines. If a dispute arises, attempt to resolve it amicably through discussions. If necessary, refer to the contract’s dispute resolution clause, which may involve mediation or arbitration. Keeping detailed records of all communications can also support your case if formal actions are required.

Strategic Sourcing Conclusion and Outlook for lion king backpack

In conclusion, strategic sourcing for the Lion King backpack presents a unique opportunity for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Understanding the intricacies of the manufacturing process—from design and material selection to quality control—is essential for ensuring high-quality products that meet market demands.

Key Takeaways:

- Focus on Quality: Prioritize manufacturers that demonstrate strong quality control processes to ensure the durability and functionality of the backpacks.

- Material Choices Matter: Select materials that align with your target market’s needs, whether it’s lightweight nylon for casual users or heavy-duty canvas for outdoor enthusiasts.

- Cost Management: Engage with suppliers who provide transparent pricing and can offer flexible payment terms to manage costs effectively.

Looking ahead, the demand for innovative and themed backpacks, such as those inspired by beloved franchises like Lion King, is poised to grow. Buyers are encouraged to leverage this trend by forming strategic partnerships with reliable manufacturers. By doing so, you can not only enhance your product offerings but also strengthen your market position. Connect with trusted suppliers today to explore how you can capitalize on this exciting opportunity.