Your Ultimate Guide to Sourcing Large Clear Backpack

Guide to Large Clear Backpack

- Introduction: Navigating the Global Market for large clear backpack

- Understanding large clear backpack Types and Variations

- Key Industrial Applications of large clear backpack

- Strategic Material Selection Guide for large clear backpack

- In-depth Look: Manufacturing Processes and Quality Assurance for large clear backpack

- Comprehensive Cost and Pricing Analysis for large clear backpack Sourcing

- Spotlight on Potential large clear backpack Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for large clear backpack

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the large clear backpack Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of large clear backpack

- Strategic Sourcing Conclusion and Outlook for large clear backpack

Introduction: Navigating the Global Market for large clear backpack

Navigating the global market for large clear backpacks presents unique opportunities and challenges for international B2B buyers. As regulations around security and transparency in various sectors, including education, events, and travel, become increasingly stringent, the demand for clear backpacks has surged. These backpacks not only comply with security protocols but also cater to a growing consumer preference for stylish yet functional designs.

This comprehensive guide is tailored to empower international buyers, particularly from Africa, South America, the Middle East, and Europe, by providing a thorough understanding of the large clear backpack landscape. It covers essential topics such as different types of backpacks, the materials used in their construction, and best practices for manufacturing and quality control. Furthermore, we delve into supplier options, cost considerations, market trends, and frequently asked questions, equipping you with the insights needed to make informed sourcing decisions.

By understanding the dynamics of the global backpack market, you can strategically select suppliers that align with your quality expectations and budget constraints. Whether you are sourcing for educational institutions, corporate events, or retail purposes, this guide serves as a valuable resource to navigate the complexities of international procurement, ensuring your business remains competitive and compliant in an evolving market landscape.

Understanding large clear backpack Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Clear Backpack | Transparent material, spacious compartments | Schools, universities, events | Pros: Easy to inspect contents; Cons: Limited privacy for users. |

| Heavy-Duty Clear Backpack | Reinforced seams, durable materials | Industrial use, outdoor activities | Pros: High durability; Cons: Heavier, may be pricier. |

| Fashionable Clear Backpack | Trendy designs, various colors and styles | Retail, promotional giveaways | Pros: Appeals to younger demographics; Cons: May sacrifice durability for style. |

| Clear Security Backpack | Special features for security compliance (e.g., RFID-blocking) | Airports, concerts, stadiums | Pros: Enhanced security features; Cons: Higher cost due to added features. |

| Multi-Compartment Clear Backpack | Multiple pockets for organization | Corporate events, trade shows | Pros: Better organization; Cons: Can be bulkier and heavier. |

Standard Clear Backpack

The Standard Clear Backpack is designed primarily for educational institutions and events where security checks are common. Its transparent material allows for easy inspection of contents, making it a popular choice in schools and universities. When purchasing, buyers should consider the quality of the zippers and straps, as these components can significantly affect durability.

Heavy-Duty Clear Backpack

The Heavy-Duty Clear Backpack is constructed with reinforced seams and robust materials, making it suitable for industrial applications and outdoor activities. These backpacks are designed to withstand harsh conditions, appealing to businesses that require reliable gear for their employees. Buyers should evaluate the weight and comfort of the backpack, especially if it is intended for long-term use in rugged environments.

Fashionable Clear Backpack

The Fashionable Clear Backpack combines functionality with style, featuring trendy designs and vibrant colors. This type is particularly appealing to younger demographics and is often used in retail settings or as promotional giveaways. While they attract attention, buyers should be aware that these backpacks may not be as durable as their heavy-duty counterparts. Assessing the balance between aesthetics and practicality is crucial for B2B buyers in this segment.

Clear Security Backpack

The Clear Security Backpack is tailored for environments with strict security requirements, such as airports, concerts, and stadiums. These backpacks often include features like RFID-blocking technology to protect sensitive information. While they provide enhanced security, buyers should consider the higher cost associated with these additional features, as well as the potential limitations in style and design.

Multi-Compartment Clear Backpack

The Multi-Compartment Clear Backpack is designed for organization, offering multiple pockets and compartments for better storage solutions. This type is ideal for corporate events and trade shows where attendees need to carry various items efficiently. Buyers should evaluate the overall size and weight of the backpack, as these features can impact user comfort and portability.

Related Video: Large Language Models (LLMs) – Everything You NEED To Know

Key Industrial Applications of large clear backpack

| Industry/Sector | Specific Application of Large Clear Backpack | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Education | Student and Teacher Use | Enhanced visibility for security and easy access to materials | Durability, size variations, and compliance with school regulations |

| Event Management | Attendee Bags for Festivals and Concerts | Streamlined security checks and brand visibility | Customization options, lead times, and bulk pricing |

| Retail | Promotional Giveaways | Increased brand exposure and customer engagement | Material quality, eco-friendliness, and design flexibility |

| Sports and Recreation | Gear for Outdoor Activities | Lightweight, transparent storage for easy item identification | Weather resistance, comfort features, and compliance with safety standards |

| Healthcare | Patient Transport Bags | Easy identification of personal items and medical supplies | Compliance with health regulations, material safety, and hygiene standards |

Education

In educational settings, large clear backpacks are increasingly being adopted for both students and teachers. Their transparent design allows for easy visibility of contents, aiding in security protocols while also promoting a clutter-free environment. International buyers should consider durability and size variations to meet specific school regulations in different regions. Compliance with local educational standards is also crucial to ensure acceptance and utility.

Event Management

For event management, large clear backpacks serve as practical solutions for festivals, concerts, and other large gatherings. They facilitate streamlined security checks, enabling quick identification of prohibited items, thereby enhancing safety. Additionally, these backpacks can be customized with event branding, increasing visibility. Buyers should focus on customization options, lead times for large orders, and bulk pricing to maximize profitability.

Retail

In the retail sector, large clear backpacks are effective promotional tools. They can be used as giveaway items during marketing campaigns, helping to increase brand exposure and customer engagement. Their transparent nature allows consumers to see what they are carrying, which can be a selling point. When sourcing, businesses should prioritize material quality, eco-friendliness, and the flexibility to design unique styles that reflect their brand identity.

Sports and Recreation

In the sports and recreation industry, large clear backpacks are ideal for outdoor activities. They provide lightweight and transparent storage solutions that allow for easy identification of gear and personal items. This feature is particularly beneficial during team sports or group outings where organization is key. Buyers should ensure that the backpacks are weather-resistant, comfortable to carry, and compliant with any safety standards relevant to their specific activities.

Healthcare

In healthcare settings, large clear backpacks are utilized for patient transport and the organization of medical supplies. Their transparent design allows healthcare professionals to quickly identify essential items, improving efficiency in patient care. Buyers in this sector should pay attention to compliance with health regulations, material safety, and hygiene standards to ensure that the backpacks meet stringent healthcare requirements.

Related Video: 10 Nifty Uses for Oscillating Multitool Saws

Strategic Material Selection Guide for large clear backpack

When selecting materials for large clear backpacks, international B2B buyers must consider various factors that influence product performance, manufacturing complexity, and compliance with regional standards. Below is an analysis of four common materials used in the production of large clear backpacks, focusing on their properties, advantages and disadvantages, and implications for specific markets.

Polyvinyl Chloride (PVC)

Key Properties:

PVC is a synthetic plastic polymer known for its durability and flexibility. It can withstand temperatures ranging from -10°C to 60°C and is resistant to UV light, making it suitable for outdoor use. PVC is also waterproof, which is beneficial for protecting contents from moisture.

Pros & Cons:

PVC is relatively low-cost and easy to manufacture, making it a popular choice for large clear backpacks. However, it can be less durable than other materials, particularly under extreme conditions, and may become brittle over time. Additionally, PVC can release harmful chemicals during production and disposal, raising environmental concerns.

Impact on Application:

PVC is compatible with a wide range of media, including liquids and solids, making it versatile for various uses. However, its environmental impact could limit its acceptance in markets with strict sustainability regulations.

Considerations for International Buyers:

Buyers must ensure compliance with local regulations regarding PVC use, particularly in Europe, where restrictions on certain chemicals (REACH) are stringent. Understanding local recycling capabilities is also essential.

Thermoplastic Polyurethane (TPU)

Key Properties:

TPU is known for its excellent elasticity, transparency, and resistance to abrasion and oil. It can handle temperatures from -40°C to 80°C, making it suitable for diverse climates. TPU also offers good chemical resistance, enhancing its longevity.

Pros & Cons:

While TPU is more expensive than PVC, its durability and performance justify the cost for many applications. The manufacturing process can be more complex due to the need for specialized equipment. However, TPU is considered more environmentally friendly, as it can be recycled.

Impact on Application:

TPU’s resistance to chemicals makes it ideal for environments where exposure to oils or solvents is a concern. Its flexibility and strength ensure that the backpack maintains its shape under various loads.

Considerations for International Buyers:

Buyers should look for suppliers who adhere to international standards such as ASTM and ISO for TPU products. Additionally, the higher cost may influence pricing strategies in price-sensitive markets like South America.

Nylon

Key Properties:

Nylon is a synthetic fiber known for its strength, elasticity, and resistance to wear and tear. It performs well in a temperature range of -40°C to 90°C and is resistant to mildew and UV light, making it suitable for outdoor backpacks.

Pros & Cons:

Nylon is lightweight and durable, making it a preferred choice for many backpack manufacturers. However, it can be more expensive than PVC and may require additional treatments to enhance water resistance. Its production process can also be energy-intensive.

Impact on Application:

Nylon’s lightweight nature makes it ideal for applications requiring mobility, such as travel and outdoor activities. Its durability ensures that it can withstand heavy use without significant wear.

Considerations for International Buyers:

Buyers should ensure that the nylon used meets local environmental standards, especially in regions like Europe, where sustainability is increasingly prioritized. The cost may also affect market competitiveness in regions with lower purchasing power.

Polyester

Key Properties:

Polyester is a synthetic fabric known for its resistance to shrinking and stretching, as well as its quick-drying properties. It can withstand temperatures from -20°C to 80°C and offers good UV resistance.

Pros & Cons:

Polyester is relatively inexpensive and widely available, making it a common choice for large clear backpacks. However, it is less durable than nylon and may not hold up as well under heavy loads. Additionally, polyester is not as environmentally friendly as some other materials.

Impact on Application:

Polyester’s quick-drying feature makes it suitable for environments where moisture is a concern, such as schools or outdoor events. However, its lower durability may limit its suitability for heavy-duty applications.

Considerations for International Buyers:

Buyers should be aware of the environmental impact of polyester production and consider sourcing from manufacturers that utilize recycled materials. Compliance with international standards for textile products is also essential.

| Material | Typical Use Case for large clear backpack | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Budget-friendly promotional backpacks | Low cost, easy to manufacture | Less durable, environmental concerns | Low |

| TPU | High-performance, eco-friendly backpacks | Excellent durability and chemical resistance | Higher cost, complex manufacturing | High |

| Nylon | Lightweight outdoor and travel backpacks | Strong and durable | More expensive, energy-intensive production | Medium |

| Polyester | Everyday use and school backpacks | Quick-drying, cost-effective | Less durable than nylon | Low |

This strategic material selection guide provides international B2B buyers with critical insights into the materials available for large clear backpacks, enabling informed decision-making that aligns with market demands and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for large clear backpack

The production of large clear backpacks involves several key manufacturing processes and stringent quality assurance measures to ensure that the final product meets international standards and buyer expectations. This guide provides an in-depth look into these processes, with actionable insights for B2B buyers, particularly from Africa, South America, the Middle East, and Europe.

Manufacturing Processes

1. Material Preparation

The first stage of manufacturing large clear backpacks involves sourcing and preparing the materials. Key materials typically include:

- PVC or TPU: Transparent materials that provide durability and visibility.

- Fabric: Reinforcement materials like nylon or polyester for straps and pockets.

- Zippers and Fasteners: High-quality, weather-resistant components to ensure longevity.

During this stage, materials are tested for compliance with regulations, such as REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) in Europe, to ensure they are safe for consumer use.

2. Forming

Once materials are prepared, the next step is forming the components of the backpack. This includes:

- Cutting: Sheets of PVC or TPU are cut into the required shapes using precision cutting machines to minimize waste.

- Heat Sealing or Welding: To join the clear panels, manufacturers often use heat sealing or ultrasonic welding techniques. This ensures that the seams are watertight and durable.

Manufacturers may also employ laser cutting for intricate designs, which allows for precision and reduces the risk of fraying edges.

3. Assembly

After forming the components, the assembly process begins. This stage involves:

- Sewing: Skilled workers or automated machines stitch together the different components, including attaching straps, pockets, and closures.

- Attachment of Accessories: Features such as logos, reflective strips, and additional pockets are added during this stage.

Efficient assembly lines are crucial for maintaining production speed while ensuring quality. Manufacturers often implement lean manufacturing techniques to optimize workflow and reduce lead times.

4. Finishing

The finishing stage involves final touches to enhance the product’s appeal and functionality. Key activities include:

- Quality Inspection: Each backpack undergoes an initial quality check to identify defects in stitching or material.

- Cleaning: Backpacks are cleaned to remove any residues from the manufacturing process.

- Packaging: The final product is carefully packaged, often using eco-friendly materials to appeal to environmentally conscious consumers.

Quality Assurance

Quality assurance is critical in the manufacturing of large clear backpacks. Buyers should be aware of various international standards and industry-specific certifications that affect product quality.

International Standards

- ISO 9001: This standard outlines criteria for a quality management system and is crucial for ensuring consistent quality in production.

- CE Marking: In Europe, this indicates that the product meets health, safety, and environmental protection standards.

Industry-Specific Certifications

- API (American Petroleum Institute): Relevant for backpacks designed for industrial use, ensuring they can withstand harsh environments.

- ASTM Standards: These provide guidelines for the performance and safety of consumer products, including backpacks.

Quality Control Checkpoints

To maintain high quality throughout the manufacturing process, several key checkpoints should be established:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the assembly process to identify defects early on.

- Final Quality Control (FQC): A thorough inspection of finished products to ensure they meet design specifications and quality standards.

Common Testing Methods

B2B buyers should be familiar with common testing methods used in quality assurance:

- Tensile Strength Testing: Measures the durability of straps and seams.

- Water Resistance Testing: Ensures that seams and materials can withstand exposure to moisture.

- Visual Inspection: A thorough visual check for cosmetic defects and overall appearance.

Verifying Supplier Quality Control

International B2B buyers should have a robust strategy for verifying supplier quality control processes. Key actions include:

- Conducting Audits: Regular audits of suppliers’ facilities to assess their adherence to quality standards and practices.

- Reviewing Quality Reports: Requesting and reviewing reports on quality control processes and outcomes.

- Engaging Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased evaluation of product quality and manufacturing practices.

Quality Control and Certification Nuances

When sourcing from different regions, particularly Africa, South America, the Middle East, and Europe, buyers must consider regional nuances in quality control and certifications:

- Cultural Awareness: Understanding regional attitudes towards quality can influence supplier relationships. For instance, some regions may prioritize cost over quality, leading to potential risks.

- Regulatory Compliance: Different countries have varying regulations regarding materials and safety standards. Buyers should ensure that suppliers are compliant with local regulations and international standards.

In summary, the manufacturing processes and quality assurance for large clear backpacks are critical components that significantly impact product quality and buyer satisfaction. By understanding these processes and implementing stringent quality checks, B2B buyers can ensure that they source high-quality products that meet both consumer expectations and regulatory requirements.

Related Video: How a Backpack is Made : Every Step on the Production Line

Comprehensive Cost and Pricing Analysis for large clear backpack Sourcing

When sourcing large clear backpacks, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis delves into the various cost components, price influencers, and actionable tips for optimizing sourcing strategies.

Cost Components

-

Materials: The primary cost driver for large clear backpacks is the material used. Common materials include PVC, vinyl, and polyester. The quality of these materials directly impacts durability and compliance with safety regulations. Higher-grade materials may increase upfront costs but can lead to lower return rates and better customer satisfaction.

-

Labor: Labor costs vary significantly by country. Regions with established manufacturing capabilities, such as China and Vietnam, may offer lower labor costs due to economies of scale. However, regions like India may provide skilled labor for specialized craftsmanship, potentially at a higher rate but with superior quality.

-

Manufacturing Overhead: Overhead costs include utilities, facility maintenance, and administrative expenses. These can vary based on the operational efficiency of the manufacturing facility. It’s essential to assess suppliers’ operational practices to gauge overhead costs accurately.

-

Tooling: If custom designs or specific features (like reinforced seams or additional pockets) are required, tooling costs can add substantially to the initial investment. Discuss these upfront to avoid unexpected expenses later.

-

Quality Control (QC): Implementing robust quality control processes is vital to ensure product consistency and compliance with international standards. QC costs can range from 2% to 10% of the total production cost, depending on the complexity and number of inspections required.

-

Logistics: Shipping costs are influenced by the weight, volume, and destination of the backpacks. Import duties and taxes should also be considered, particularly for buyers in Africa and South America, where tariffs can significantly impact the final cost.

-

Margin: Suppliers typically apply a margin ranging from 10% to 30%, influenced by market demand, competition, and brand positioning. Understanding this can help in negotiating better pricing.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQs) can greatly affect pricing. Higher volumes often lead to lower unit costs, but buyers should ensure they can sell the quantity ordered.

-

Specifications/Customization: Custom features can increase costs. Buyers should balance the desire for unique features with the impact on pricing.

-

Materials and Quality Certifications: Products that comply with international quality standards (e.g., ISO certifications) may command higher prices. However, these certifications can enhance brand reputation and marketability.

-

Supplier Factors: The reliability and reputation of the supplier can influence pricing. Established manufacturers with a track record of quality may charge more but offer greater assurance.

-

Incoterms: Understanding Incoterms (international commercial terms) is vital for cost management. They define responsibilities for shipping, insurance, and tariffs, which can significantly affect total costs.

Buyer Tips

-

Negotiate: Always negotiate on price, especially for larger orders. Suppliers often have flexibility, particularly when it comes to payment terms or additional services.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but the total cost over the product’s lifecycle, including shipping, duties, and potential return costs.

-

Pricing Nuances: For international buyers, currency fluctuations can impact pricing. Establishing contracts in stable currencies or hedging against currency risks can be beneficial.

-

Regional Considerations: Buyers from Africa and South America should be aware of regional trade agreements that might lower tariffs or provide incentives for sourcing from specific countries.

In summary, understanding the cost structure and pricing dynamics of large clear backpacks allows international B2B buyers to make informed sourcing decisions. By considering the outlined components and influencers, buyers can optimize their procurement strategies while ensuring product quality and cost efficiency. Remember, the prices and costs discussed are indicative and can vary based on specific circumstances and market conditions.

Spotlight on Potential large clear backpack Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘large clear backpack’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for large clear backpack

Key Technical Properties of Large Clear Backpacks

Understanding the essential technical properties of large clear backpacks is crucial for international B2B buyers. These specifications not only influence product quality but also affect pricing, compliance, and customer satisfaction. Here are the key properties to consider:

-

Material Grade

The material used in the construction of a large clear backpack typically includes PVC or TPU (thermoplastic polyurethane). PVC is a cost-effective option, while TPU is more durable and environmentally friendly. Selecting the right material affects transparency, flexibility, and longevity, which are vital for customer satisfaction and brand reputation. -

Thickness

Measured in millimeters, the thickness of the material impacts durability and weight. A common thickness for clear backpacks is 0.5mm to 1.0mm. Thicker materials provide better protection against wear and tear but may increase overall weight. Buyers should balance thickness with intended use and price sensitivity. -

Water Resistance

Water-resistant properties are essential, especially for outdoor use. This feature can be achieved through the choice of material and additional coatings. Understanding the level of water resistance helps buyers assess the backpack’s suitability for various environments, impacting customer satisfaction in regions with diverse climates.

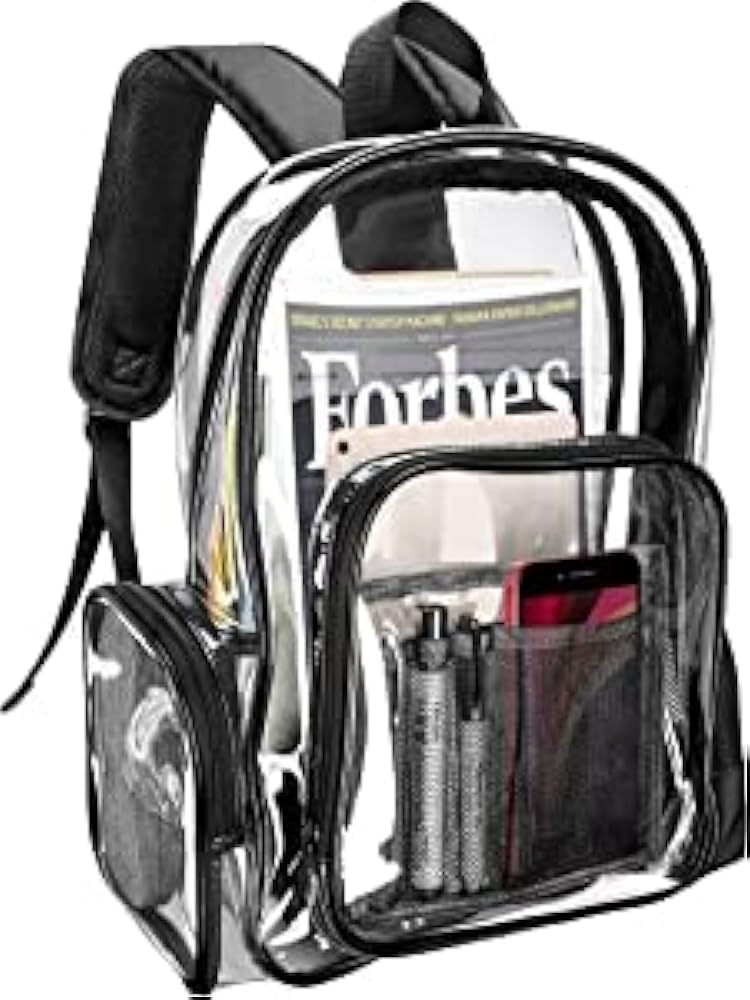

Illustrative Image (Source: Google Search)

-

Load Capacity

Load capacity, usually indicated in liters, defines how much weight the backpack can carry. A standard large clear backpack may have a capacity ranging from 20 to 30 liters. This specification is critical for buyers targeting specific customer needs, such as school use or outdoor activities. -

Compliance Standards

Many regions require compliance with safety and environmental standards. For instance, backpacks sold in the EU must adhere to REACH regulations regarding chemical safety. Understanding these compliance requirements is vital for avoiding legal issues and ensuring market access. -

Tolerances

Tolerances refer to the allowable variations in dimensions and material properties during manufacturing. Tight tolerances (e.g., ±5mm) ensure consistency and quality, which are crucial for maintaining brand integrity. Buyers should verify manufacturers’ capabilities to meet these specifications.

Common Trade Terminology in the Backpack Industry

Familiarity with industry jargon is essential for effective communication and negotiation with suppliers. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, partnering with an OEM can provide customized products that align with brand specifications without the need for extensive manufacturing investment. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest number of units a supplier is willing to produce or sell. Understanding MOQs helps buyers plan inventory levels and manage cash flow effectively. Suppliers often set MOQs based on production efficiency and cost considerations. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products. This process is essential for comparing offers and ensuring that all specifications are understood, allowing for better decision-making. -

Incoterms

Short for International Commercial Terms, Incoterms define the responsibilities of buyers and sellers in international trade. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who is responsible for costs and risks during transport. Understanding these terms helps buyers negotiate better shipping agreements. -

Lead Time

Lead time is the period between placing an order and receiving the goods. Knowing the lead time is vital for planning inventory and meeting market demands, especially for seasonal products. -

Customs Compliance

This refers to adhering to regulations governing the import and export of goods. For international buyers, understanding customs compliance is critical to avoid delays and additional costs during shipping.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, optimize their supply chain, and enhance their market competitiveness in the growing global backpack industry.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the large clear backpack Sector

Market Overview & Key Trends

The global market for large clear backpacks is experiencing significant growth, driven by increasing demand from educational institutions, corporate sectors, and event organizers. In 2023, the market size was valued at over $60 billion, with projections to reach $85 billion by 2030. This surge is attributed to heightened security protocols in schools and public venues, which necessitate transparent bags for easier inspection.

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, several sourcing trends are emerging. The “China Plus One” strategy is increasingly relevant, as companies diversify their supply chains to mitigate risks associated with reliance on a single manufacturing hub. Countries like Vietnam and India are gaining traction due to their competitive pricing, quality craftsmanship, and improved logistics. Buyers are advised to consider not just unit costs but the total cost of ownership, which includes shipping, duties, and potential quality control expenses.

Illustrative Image (Source: Google Search)

Technological advancements in manufacturing processes, such as automation and sustainable material usage, are also shaping the industry. Digital platforms are streamlining the sourcing process, enabling buyers to access a broader range of suppliers and facilitate easier communication. As demand for customization rises, manufacturers are adapting to offer personalized designs and features, which can enhance product appeal in various markets.

Sustainability & Ethical Sourcing in B2B

Sustainability is a critical consideration for B2B buyers in the large clear backpack sector. The environmental impact of production processes, material sourcing, and product lifecycle management has become increasingly scrutinized. Buyers should prioritize suppliers that adhere to sustainable practices, such as using recycled materials and minimizing waste throughout the production cycle.

Ethical supply chains are paramount, particularly as consumers become more aware of social issues related to manufacturing. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX provide assurance that products meet stringent environmental and social criteria. B2B buyers should seek partnerships with manufacturers who demonstrate compliance with these standards, ensuring their products not only meet market demand but also contribute positively to global sustainability goals.

Illustrative Image (Source: Google Search)

Incorporating eco-friendly materials, such as recycled plastics or organic cotton, can also enhance brand reputation and appeal to environmentally conscious consumers. Transparent communication regarding sourcing practices and materials used can further establish trust and loyalty among B2B partners.

Brief Evolution/History

The large clear backpack sector has evolved significantly over the past few decades. Initially popularized in the 1990s for school use, these bags have gained prominence due to security measures in public spaces. Major events like concerts and sports have mandated clear bags, propelling their demand.

In recent years, the evolution has been marked by a shift towards customization and eco-friendly materials. As consumers become more environmentally aware, brands are responding with sustainable options that align with modern values. This evolution not only addresses consumer preferences but also positions businesses to thrive in an increasingly competitive global market.

By understanding these dynamics, B2B buyers can make informed decisions that align with market trends while promoting sustainability and ethical practices within their supply chains.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of large clear backpack

-

What criteria should I use to vet suppliers for large clear backpacks?

When vetting suppliers, prioritize their manufacturing capabilities, quality control processes, and reputation in the industry. Request references and samples to assess the craftsmanship and material quality. Verify their compliance with international standards, such as ISO certifications, and ensure they follow ethical labor practices. Additionally, consider their capacity for customization and flexibility in meeting your specific needs, as well as their experience in exporting to your target market. -

Can I customize large clear backpacks according to my specifications?

Yes, many manufacturers offer customization options for large clear backpacks. You can specify design elements such as size, color, materials, and branding features. Discuss your requirements upfront to ensure the manufacturer can accommodate them. Be aware that customization may affect minimum order quantities (MOQs) and lead times, so plan accordingly to align with your project timelines. -

What are the typical MOQs and lead times for large clear backpacks?

Minimum order quantities (MOQs) can vary significantly by supplier and manufacturing location. Generally, you can expect MOQs to range from 500 to 5,000 pieces, depending on the complexity of the design. Lead times typically span from 4 to 8 weeks, influenced by factors like production schedules and shipping logistics. Always confirm these details with your supplier to avoid unexpected delays in your supply chain. -

What payment terms are common when sourcing from international suppliers?

Common payment terms include a deposit upfront (usually 30-50%) with the balance due before shipment. Some suppliers may offer letters of credit or escrow services for added security. It’s crucial to establish clear payment terms in your contract to protect your interests. Additionally, consider the impact of currency fluctuations and transaction fees when negotiating payment methods, especially if dealing with suppliers in different currencies. -

How can I ensure quality assurance and compliance with certifications?

To ensure quality assurance, request documentation of the supplier’s quality management systems and certifications, such as ISO 9001. Conduct pre-production inspections and consider third-party quality assurance firms for independent evaluations. Clearly outline your quality expectations in your contract, including acceptable defect rates. Regular communication throughout the production process will also help maintain standards and address issues promptly. -

What logistics considerations should I keep in mind when importing large clear backpacks?

When importing, factor in shipping costs, customs duties, and potential tariffs based on your country’s trade agreements. Choose reliable logistics partners experienced in international shipping to streamline the process. Understand the shipping terms (e.g., FOB, CIF) and their implications for liability and responsibility during transit. Additionally, plan for potential delays in customs clearance, especially during peak shipping seasons. -

How should I handle disputes with suppliers during the sourcing process?

Establish clear communication channels and a dispute resolution process in your contract. If issues arise, address them promptly and professionally to avoid escalation. Consider mediation or arbitration as alternatives to litigation, which can be costly and time-consuming. Document all communications and agreements, as this will provide a clear record should disputes need to be resolved formally. -

What should I do if there are quality issues after receiving the shipment?

Upon receipt of the shipment, conduct a thorough inspection to identify any quality issues. Document your findings with photos and detailed descriptions, and communicate these concerns to your supplier immediately. Most reputable suppliers will have procedures in place for handling quality complaints, which may include replacements or refunds. If the issue remains unresolved, refer to your contract’s dispute resolution clause for further action.

Strategic Sourcing Conclusion and Outlook for large clear backpack

In the dynamic landscape of the large clear backpack market, strategic sourcing remains a cornerstone for success. International B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, must prioritize sourcing strategies that encompass quality, reliability, and cost-effectiveness. By leveraging diversified manufacturing regions, such as China, Vietnam, and India, companies can enhance their supply chain resilience while optimizing production costs.

Key takeaways include understanding the importance of total cost of ownership rather than just unit price, ensuring supplier reliability, and complying with evolving social and environmental standards. As the demand for clear backpacks rises, particularly in educational and event settings, the ability to respond swiftly to market changes through scalable production will be crucial.

Looking ahead, the global backpack market is projected to reach $85 billion by 2030, presenting significant opportunities for growth. International buyers are encouraged to engage with multiple suppliers to foster innovation and maintain competitive advantages. By adopting these strategic sourcing practices, businesses can position themselves favorably in a thriving market, ready to meet the evolving needs of consumers. Embrace the future of sourcing and unlock new avenues for success.