Your Ultimate Guide to Sourcing Gomatic 30L Backpack

Guide to Gomatic 30L Backpack

- Introduction: Navigating the Global Market for gomatic 30l backpack

- Understanding gomatic 30l backpack Types and Variations

- Key Industrial Applications of gomatic 30l backpack

- Strategic Material Selection Guide for gomatic 30l backpack

- In-depth Look: Manufacturing Processes and Quality Assurance for gomatic 30l backpack

- Comprehensive Cost and Pricing Analysis for gomatic 30l backpack Sourcing

- Spotlight on Potential gomatic 30l backpack Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for gomatic 30l backpack

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the gomatic 30l backpack Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of gomatic 30l backpack

- Strategic Sourcing Conclusion and Outlook for gomatic 30l backpack

Introduction: Navigating the Global Market for gomatic 30l backpack

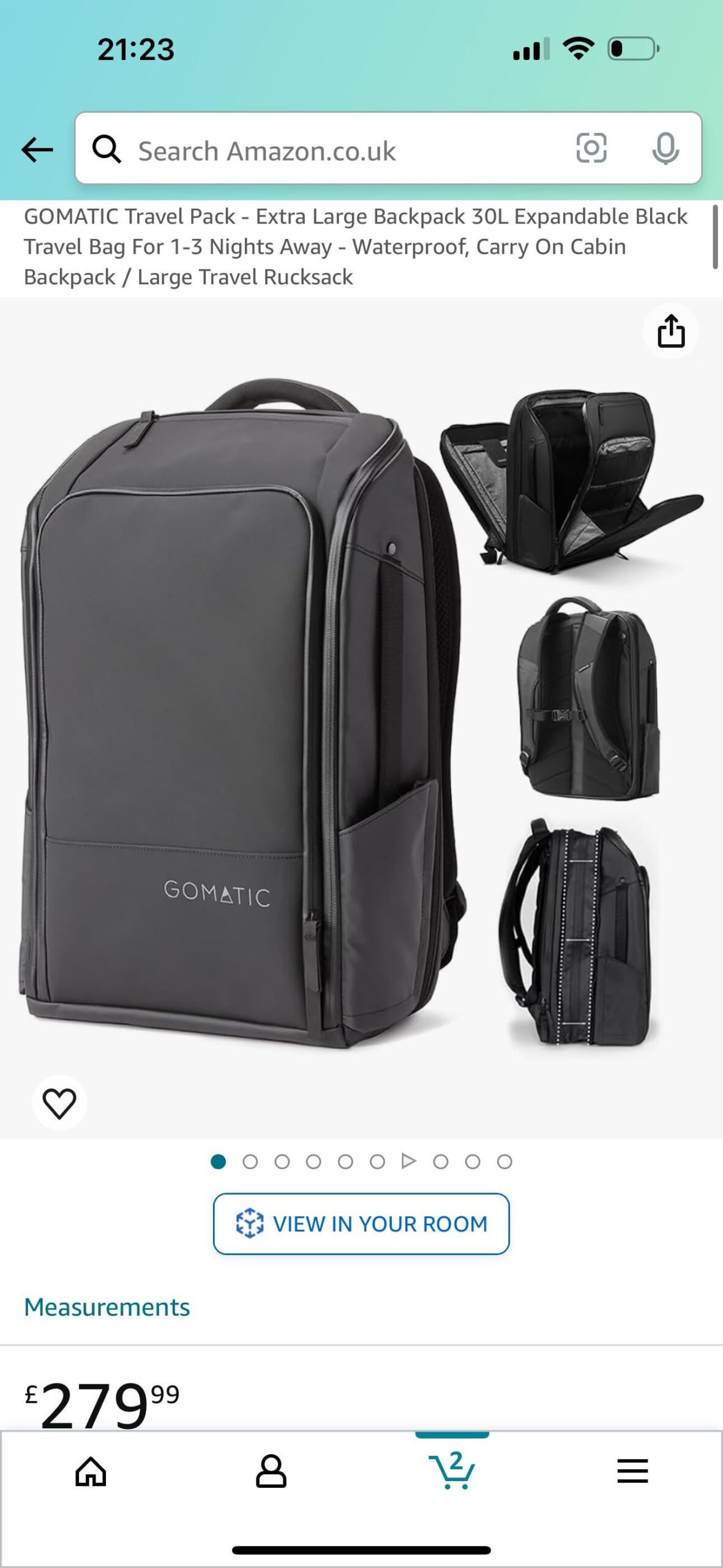

In an era defined by global connectivity and mobility, the Gomatic 30L backpack emerges as an indispensable asset for businesses seeking to enhance their travel gear offerings. This premium backpack combines functionality and style, making it the perfect choice for organizations aiming to boost employee satisfaction and streamline logistics. With its robust design, versatile carry options, and intelligent compartmentalization, the Gomatic 30L backpack meets the diverse needs of professionals across various sectors, from corporate travel to adventure tourism.

This comprehensive guide serves as an essential resource for B2B buyers from Africa, South America, the Middle East, and Europe. It delves into the critical aspects of sourcing the Gomatic 30L backpack, providing actionable insights on types and features, materials and manufacturing practices, supplier evaluation and quality control, cost structures, and market positioning. Understanding these elements is crucial for making informed purchasing decisions, ensuring that buyers not only meet their specific needs but also align with evolving consumer preferences.

By equipping decision-makers with in-depth knowledge and practical tools, this guide empowers businesses to navigate the complexities of the global market confidently. Whether you are sourcing for corporate gifts, retail distribution, or team travel, the Gomatic 30L backpack represents a strategic investment that can enhance your brand image and operational efficiency.

Understanding gomatic 30l backpack Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 30L Travel Duffel Bag | Converts between duffel and backpack; ventilated shoe pocket; water-resistant | Corporate gifting, travel agencies, distribution | Versatile and spacious but bulkier than traditional backpacks |

| 30L Travel Pack | Expands from 20L to 30L; slim design; RFID-safe pockets | Business travel, retail channels, corporate clients | Professional look but limited capacity when not expanded |

| 30L Camera Backpack | Customizable compartments for tech gear; water-resistant shell | Photography/videography, media production | Highly specialized but premium-priced and less multipurpose |

| 30L Collapsible Backpack | Lightweight, foldable design; compact storage | Travel/tour operators, adventure outfitting | Space-saving and convenient but less structured for heavy loads |

| 30L Branded/Custom Bag | Corporate branding options; tailored features/materials | Promotional, corporate gifting, secondary branding | Differentiated branding but longer lead times and higher MOQ |

30L Travel Duffel Bag

The 30L Travel Duffel Bag is designed for versatility, allowing users to easily switch between duffel and backpack styles. It features a ventilated shoe compartment and robust water-resistant materials, making it ideal for corporate gifting and travel agencies. B2B buyers should consider the potential for volume discounts and customization options to enhance brand visibility. While it offers ample space, its bulkier design may not appeal to all users, particularly those seeking a more streamlined option.

30L Travel Pack

The 30L Travel Pack is optimized for business professionals, featuring an expandable design that adjusts from 20L to 30L. Its sleek, minimalist aesthetic and RFID-safe pockets cater to urban travelers and corporate clients. This model is especially suitable for retail channels focused on frequent travelers. Buyers should weigh the professional appearance against its limited capacity when not expanded, ensuring it aligns with customer needs for both style and functionality.

30L Camera Backpack

Tailored for photographers and content creators, the 30L Camera Backpack includes dedicated compartments for cameras and accessories, with customizable dividers for organization. Its water-resistant shell ensures protection for valuable gear, making it a strong choice for media production companies and camera retailers. However, its specialized nature comes with a premium price tag, which may limit appeal to broader markets. B2B buyers should assess the size of their target market for such specialized products.

30L Collapsible Backpack

The 30L Collapsible Backpack is engineered for lightweight portability and ease of storage, folding into a compact pouch. This backpack is particularly appealing to travel operators and adventure brands, as it facilitates easy transport for tours or promotional events. While it offers significant convenience, it may lack the structure needed for carrying heavy loads or professional equipment. Buyers should consider the balance between space-saving features and the intended use case when selecting this model.

30L Branded/Custom Bag

The 30L Branded/Custom Bag provides opportunities for corporate branding and tailored features, appealing to companies looking to enhance brand visibility through promotional items. This option allows for customization in materials and design, making it suitable for corporate gifting and secondary branding. However, longer lead times and higher minimum order quantities (MOQs) may be a consideration for buyers. Evaluating the potential return on investment for branded items is crucial for effective purchasing decisions.

Related Video: Gomatic The Navigator Backpack 15L Review – 2024 – Expandable to 21L Capacity Futureproof Backpack

Key Industrial Applications of gomatic 30l backpack

| Industry/Sector | Specific Application of gomatic 30l backpack | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Corporate Travel | Employee travel gear for business trips | Enhances employee satisfaction and productivity | MOQ flexibility, customization options for branding |

| Outdoor Adventure | Equipment for tour guides and adventure outfits | Durable and versatile for varied outdoor conditions | Material quality, weather resistance, local sourcing |

| Photography and Media | Equipment transport for photographers | Secure storage for valuable gear, easy portability | Customization for dividers, compatibility with tech |

| Retail and Distribution | Retail display and promotional items | Attracts customers with branded, high-quality products | Lead times, bulk pricing, and packaging requirements |

| Education | Gear for educational trips and field studies | Practical and organized storage for student supplies | Cost efficiency, durability, and volume discounts |

Corporate Travel

The gomatic 30L backpack serves as an essential travel accessory for corporate employees on business trips. Its sleek design and organizational features ensure that professionals can carry their tech, documents, and personal items efficiently. By providing high-quality travel gear, companies can enhance employee satisfaction and productivity, leading to improved performance. International buyers should consider customization options for branding, as well as minimum order quantities (MOQs) that align with their organizational needs.

Outdoor Adventure

For businesses in the outdoor adventure sector, the gomatic 30L backpack is a reliable choice for tour guides and adventure outfitters. Its durable, water-resistant materials and versatile compartments make it ideal for carrying essential gear in diverse environments. This versatility not only meets the demands of various outdoor conditions but also enhances the customer experience. Buyers should focus on sourcing materials that ensure longevity and resistance to harsh weather, while also considering local suppliers to reduce shipping costs and times.

Photography and Media

In the photography and media industry, the gomatic 30L backpack is tailored to securely transport cameras, lenses, and other equipment. Its customizable internal dividers allow photographers to organize their gear efficiently, ensuring quick access during shoots. This backpack addresses the specific needs of professionals who require reliable and portable storage solutions. B2B buyers should prioritize customization options and ensure compatibility with various tech equipment when sourcing, as well as consider the higher price point associated with specialized features.

Retail and Distribution

Retailers can leverage the gomatic 30L backpack as a promotional item or display product, enhancing their brand visibility. Its premium quality and modern design attract customers, making it an effective tool for driving sales. When sourcing for retail, businesses should negotiate bulk pricing and consider lead times that align with marketing campaigns. Additionally, they should evaluate packaging requirements to ensure that the product is presented attractively to consumers.

Education

Educational institutions can utilize the gomatic 30L backpack for field trips and outdoor learning experiences. Its spacious compartments provide practical storage for student supplies, while its durable construction ensures it withstands frequent use. By investing in high-quality backpacks, schools can enhance the educational experience and promote responsible gear ownership among students. B2B buyers in this sector should focus on cost efficiency and durability, as well as explore volume discounts to accommodate larger groups of students.

Related Video: Uses of Metals and Non Metals

Strategic Material Selection Guide for gomatic 30l backpack

When selecting materials for the Gomatic 30L backpack, it’s essential to consider the properties, advantages, and limitations of each option. This analysis will focus on four common materials used in the production of the Gomatic 30L backpack: nylon, polyester, leather, and ripstop fabric. Each material has distinct characteristics that can impact product performance, cost, and suitability for various applications.

Nylon

Nylon is a synthetic polymer known for its durability and strength. It exhibits excellent resistance to abrasion and is lightweight, making it a popular choice for high-performance backpacks.

- Key Properties: Nylon can withstand significant tensile strength and is resistant to mildew and UV damage. It performs well under various temperatures and is less prone to tearing compared to other materials.

- Pros & Cons: While nylon is incredibly durable, it can be more expensive than other materials like polyester. Manufacturing complexity is moderate, as it requires specialized sewing techniques to ensure seams are secure. Nylon is suitable for rugged outdoor use but may not be the best choice for luxury applications due to its synthetic feel.

- Impact on Application: Nylon’s water-resistant properties make it ideal for environments where moisture is a concern, such as in tropical climates in Africa or humid regions in South America.

- Considerations for Buyers: International buyers should ensure compliance with local regulations regarding synthetic materials and check for certifications like OEKO-TEX, which ensures the absence of harmful substances.

Polyester

Polyester is another synthetic material often used in backpack manufacturing. It is known for its resistance to shrinking and stretching, making it a reliable choice for everyday use.

- Key Properties: Polyester is lightweight, quick-drying, and resistant to wrinkles and fading. It has moderate strength and can withstand various environmental conditions.

- Pros & Cons: The primary advantage of polyester is its cost-effectiveness, making it an attractive option for bulk orders. However, it is generally less durable than nylon and may not hold up as well under heavy use. Manufacturing complexity is low, allowing for efficient production.

- Impact on Application: Polyester is suitable for urban settings and corporate environments, appealing to buyers in Europe and the Middle East who prioritize aesthetics alongside functionality.

- Considerations for Buyers: Buyers should verify that polyester meets international standards for flammability and durability, such as ASTM D6413 for flame resistance.

Leather

Leather is a traditional material that offers a premium look and feel. It is often used in high-end backpacks for its aesthetic appeal and durability.

- Key Properties: Leather is naturally strong and resistant to wear and tear. It also has a unique ability to age gracefully, developing a patina over time.

- Pros & Cons: The main advantage of leather is its luxurious appearance, which can enhance brand image. However, it is significantly more expensive than synthetic materials and requires careful maintenance to prevent damage from moisture and UV exposure. Manufacturing complexity is high, as leather requires specialized techniques for cutting and stitching.

- Impact on Application: Leather backpacks are particularly appealing in corporate gifting and luxury markets, making them suitable for buyers in Europe and affluent regions of the Middle East.

- Considerations for Buyers: Buyers should ensure that the leather used is sourced sustainably and complies with environmental regulations, including REACH compliance in the EU.

Ripstop Fabric

Ripstop fabric is a type of nylon or polyester that incorporates a special reinforcing technique to prevent tears from spreading.

- Key Properties: This material is lightweight yet incredibly strong, featuring a grid pattern that enhances durability. It is also water-resistant, making it suitable for various weather conditions.

- Pros & Cons: The primary advantage of ripstop fabric is its resistance to ripping and tearing, making it ideal for outdoor and adventure applications. However, it can be more expensive than standard nylon or polyester due to its specialized manufacturing process.

- Impact on Application: Ripstop fabric is particularly well-suited for adventure travel and outdoor activities, appealing to buyers in South America and Africa, where rugged conditions are common.

- Considerations for Buyers: Buyers should look for certifications that ensure the material’s performance under extreme conditions, such as ISO 13934 for tensile strength.

Summary Table

| Material | Typical Use Case for gomatic 30l backpack | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | High-performance outdoor use | Excellent durability and strength | Higher cost compared to polyester | High |

| Polyester | Everyday urban and corporate use | Cost-effective and lightweight | Less durable than nylon | Medium |

| Leather | Luxury and corporate gifting | Premium aesthetic and durability | High maintenance and cost | High |

| Ripstop Fabric | Adventure travel and outdoor applications | Tear-resistant and lightweight | More expensive due to manufacturing | Medium |

This strategic material selection guide provides international B2B buyers with a comprehensive overview of the materials used in the Gomatic 30L backpack, enabling them to make informed decisions that align with their market needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for gomatic 30l backpack

The manufacturing process of the gomatic 30L backpack is a comprehensive and intricate operation that ensures high-quality standards are met at every stage. For B2B buyers, understanding this process is crucial to making informed sourcing decisions. This guide outlines the main manufacturing stages, key techniques used, and the quality assurance measures that align with international standards.

Manufacturing Process

1. Material Preparation

The first step in the manufacturing of the gomatic 30L backpack involves sourcing high-quality materials. Key materials include durable nylon, water-resistant fabrics, and lightweight components that contribute to the backpack’s overall functionality and aesthetic appeal. Manufacturers often visit fabric markets or partner with reliable suppliers to procure specialized textiles that meet specific performance criteria, such as water resistance and durability.

- Sourcing Locations: Common sourcing hubs include Guangzhou International Textile City and other textile markets in Asia, which provide a wide range of materials suitable for various backpack styles.

2. Forming

Once materials are sourced, the next stage is forming, which includes creating patterns and templates for the backpack. This involves drafting blueprints for the bag’s components, including the main body, pockets, and straps.

- Key Techniques: Computer-Aided Design (CAD) software is frequently utilized to create precise templates. This technology allows manufacturers to ensure accuracy in cutting, which minimizes waste and maximizes efficiency.

3. Assembly

The assembly phase is where the backpack starts to take shape. This process includes cutting the fabric, organizing accessories (like zippers and buckles), and sewing the various components together.

-

Cutting: Automated cutting machines are used for large production runs, while manual cutting may be employed for smaller batches. Precision cutting is vital to ensure all components fit together seamlessly.

-

Sewing: Skilled workers use industrial sewing machines for stitching the pieces together. The sewing process is often organized into assembly lines, with each worker specializing in specific tasks to enhance efficiency.

4. Finishing

After assembly, the backpack undergoes several finishing processes. This includes inverting the bag to reveal its final shape and adding any additional features such as branding, labels, or decorative elements.

- Quality Checks: Throughout the finishing stage, manufacturers conduct visual inspections to ensure that there are no defects in the product and that all features meet the design specifications.

Quality Assurance

Ensuring the quality of the gomatic 30L backpack is a critical aspect of the manufacturing process. B2B buyers must be aware of the international and industry-specific standards that govern product quality.

Relevant International Standards

-

ISO 9001: This standard outlines the criteria for a quality management system and is essential for manufacturers aiming to ensure consistent quality in their products. Compliance with ISO 9001 indicates that a supplier is committed to meeting customer requirements and enhancing satisfaction.

-

CE Marking: For products sold within the European Economic Area (EEA), compliance with CE marking indicates that the product meets EU safety, health, and environmental protection standards.

-

API Standards: For specialized backpacks, such as those used in photography or outdoor activities, adherence to American Petroleum Institute (API) standards may apply, particularly if the product is intended for rugged environments.

Quality Control Checkpoints

Quality control (QC) is conducted at various checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials and components upon arrival at the manufacturing facility. This ensures that all materials meet specified quality standards before production begins.

-

In-Process Quality Control (IPQC): During the assembly process, ongoing inspections are conducted to identify any defects or inconsistencies. This proactive approach helps to catch issues early, reducing waste and rework.

-

Final Quality Control (FQC): Once the backpacks are fully assembled, a final inspection is carried out. This includes testing the functionality of zippers, checking for stitching errors, and ensuring overall quality before the product is packaged and shipped.

Common Testing Methods

To verify product quality, manufacturers often employ various testing methods, including:

-

Tensile Testing: This assesses the strength of materials used in the backpack, ensuring they can withstand expected loads.

-

Water Resistance Testing: For backpacks designed to be water-resistant, testing involves simulating exposure to water to ensure performance claims are met.

-

Durability Testing: This includes stress tests that simulate wear and tear over time, ensuring that the backpack remains functional and intact under regular use.

Verifying Supplier Quality Control

For B2B buyers, verifying a supplier’s quality control practices is crucial to ensuring product reliability. Here are several strategies:

-

Supplier Audits: Conducting regular audits of potential suppliers can provide insight into their manufacturing processes and quality management systems. Buyers should request documentation demonstrating compliance with international standards.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers assess the consistency of product quality over time.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturer’s quality control processes and product quality.

Conclusion

Understanding the manufacturing processes and quality assurance measures for the gomatic 30L backpack is essential for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing, and by ensuring compliance with relevant quality standards, buyers can make informed decisions that enhance their supply chain efficiency and product offerings. Engaging in thorough supplier verification practices not only mitigates risks but also fosters long-term partnerships that contribute to success in the competitive global market.

Related Video: How a Backpack is Made : Every Step on the Production Line

Comprehensive Cost and Pricing Analysis for gomatic 30l backpack Sourcing

Understanding the cost structure and pricing dynamics for the Gomatic 30L backpack is essential for international B2B buyers aiming to make informed purchasing decisions. This analysis covers the key components of costs, the factors influencing pricing, and practical tips for negotiating effectively in the global market.

Cost Components

- Materials: The choice of fabrics, zippers, and other components directly impacts the base cost of the Gomatic 30L backpack. High-quality materials such as durable nylon or eco-friendly alternatives are likely to be more expensive but can enhance product longevity and appeal.

Illustrative Image (Source: Google Search)

-

Labor: Labor costs vary significantly across regions. Countries like Vietnam and China may offer competitive labor rates, while European countries might have higher costs due to stricter labor laws. Understanding the labor market in the supplier’s location is crucial for estimating overall costs.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and administrative costs. Efficient factories can minimize overhead, which can be reflected in more competitive pricing for buyers.

-

Tooling: Initial tooling costs for custom designs or variations can be substantial. Buyers should account for these in their total cost calculations, especially if they require unique branding or specialized features.

-

Quality Control (QC): Implementing QC processes ensures product integrity but adds to the overall cost. Investing in rigorous QC can prevent issues down the line, potentially saving costs associated with returns or dissatisfaction.

Illustrative Image (Source: Google Search)

-

Logistics: Shipping costs can fluctuate based on the chosen Incoterms, shipping method, and distance. Air freight is faster but more expensive than sea freight, which is often preferred for bulk orders.

-

Margin: Suppliers will add a profit margin to cover their costs and ensure profitability. This margin can vary based on the supplier’s market position and competitiveness.

Price Influencers

-

Volume/MOQ: Minimum Order Quantities (MOQs) significantly impact pricing. Higher volume orders often lead to lower per-unit costs. Buyers should evaluate their needs against the supplier’s MOQ to optimize cost efficiency.

-

Specifications/Customization: Custom features, such as unique colors or added compartments, can increase costs. Buyers must weigh the benefits of customization against the additional expenses.

-

Materials: The quality and type of materials selected will directly influence the final price. Sustainable materials may come at a premium but can attract environmentally conscious consumers.

-

Quality/Certifications: Certifications (e.g., ISO, eco-labels) can enhance product credibility but may also increase costs. Buyers should consider whether these certifications are necessary for their target market.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their proven track record, while newer suppliers might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is vital for calculating total costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) determine who bears shipping costs, insurance, and risk during transport.

Buyer Tips

-

Negotiation: Leverage volume and long-term relationships to negotiate better pricing. Building rapport with suppliers can lead to more favorable terms.

-

Cost Efficiency: Assess the Total Cost of Ownership (TCO), which includes acquisition costs, maintenance, and operational expenses over time. A lower initial price might not always equate to better value.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations and import tariffs that can affect overall costs.

-

Research and Benchmarking: Conduct thorough market research to benchmark prices against competitors. This knowledge can empower buyers during negotiations.

In conclusion, understanding the comprehensive cost structure and pricing dynamics of the Gomatic 30L backpack is essential for making informed sourcing decisions. By considering all cost components and influencers, international B2B buyers can optimize their purchasing strategies, ensuring they achieve the best possible value for their investments. Always remember that prices can vary, and it is advisable to consult with suppliers for the most current pricing information.

Spotlight on Potential gomatic 30l backpack Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘gomatic 30l backpack’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for gomatic 30l backpack

Understanding the critical technical properties and trade terminology associated with the gomatic 30L backpack is essential for international B2B buyers. This knowledge not only aids in sourcing decisions but also enhances negotiation and supplier relationships.

Key Technical Properties

-

Material Grade

– Definition: This refers to the quality and type of fabric used in the backpack, such as high-denier nylon or polyester.

– B2B Importance: Higher material grades often indicate better durability and water resistance, which are crucial for professional users who require reliability in various environments. Selecting the right material can also influence branding and market positioning. -

Water Resistance Rating

– Definition: This specification measures the degree to which the backpack can repel water, typically rated in millimeters (e.g., 1000mm, 2000mm).

– B2B Importance: A higher water resistance rating is vital for buyers in regions prone to rain or humidity, such as parts of Africa and South America. This feature enhances the product’s appeal to consumers and can justify a premium price point. -

Capacity and Dimensions

– Definition: Refers to the volume of the backpack (30L) and its physical dimensions, including height, width, and depth.

– B2B Importance: Understanding capacity is crucial for buyers who need to ensure that the backpack meets specific use cases, such as business travel or outdoor adventures. Accurate dimensions help in logistics planning and storage considerations. -

Weight Tolerance

– Definition: This property indicates the maximum weight the backpack can safely carry without compromising its structure.

– B2B Importance: Buyers must consider weight tolerance for user safety and comfort. This is particularly relevant for organizations in the adventure tourism sector or for corporate clients who require durable travel gear.

Illustrative Image (Source: Google Search)

- Zipper Quality and Type

– Definition: The specifications of zippers used, such as YKK or waterproof zippers, which can significantly impact usability and longevity.

– B2B Importance: High-quality zippers reduce the likelihood of failure and enhance user experience. B2B buyers should prioritize backpacks that feature durable hardware, as it reflects the overall quality of the product.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Context: Buyers often work with OEMs to customize products like the gomatic 30L backpack, ensuring alignment with specific brand requirements or customer preferences. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Context: Understanding MOQ is essential for B2B buyers to manage inventory costs effectively. Negotiating MOQs can lead to better pricing structures, especially when sourcing for larger organizations. -

RFQ (Request for Quotation)

– Definition: A standard business process to invite suppliers to bid on specific products or services.

– Context: Utilizing RFQs allows buyers to gather competitive pricing and terms from multiple suppliers, ensuring they make informed sourcing decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international rules that clarify the responsibilities of buyers and sellers in international transactions.

– Context: Familiarity with Incoterms is crucial for B2B transactions, as they dictate shipping costs, risks, and liabilities. Knowing these terms can help buyers negotiate better shipping agreements and avoid unexpected costs. -

Customization

– Definition: The process of modifying a product to meet specific customer requirements.

– Context: Many B2B buyers seek customizable features in products like the gomatic 30L backpack to enhance brand visibility and meet market demands. Understanding customization options can lead to unique offerings that stand out in competitive markets.

By mastering these technical properties and trade terms, B2B buyers can enhance their sourcing strategies and build stronger supplier partnerships, ultimately leading to more successful procurement processes in the global market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the gomatic 30l backpack Sector

In the current global landscape, the demand for high-quality travel gear is spurred by increasing mobility and evolving consumer preferences. The gomatic 30L backpack sector is influenced by several key drivers, including the rise of remote work, the growth of the adventure tourism market, and an emphasis on multifunctional products. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking backpacks that offer versatility, durability, and a contemporary aesthetic, aligning with the needs of both corporate clients and end-users.

Market Overview & Key Trends

The global market for travel gear, including backpacks, is experiencing significant growth, driven by technological advancements and changing consumer behaviors. Key trends include:

- Technological Integration: Modern backpacks are incorporating smart features such as USB charging ports and RFID-blocking compartments, appealing to tech-savvy professionals.

- Customization and Branding: B2B buyers are leaning towards options that allow for personalization, such as branded bags that enhance corporate identity during events and promotions.

- Sourcing Strategies: Buyers are increasingly using digital platforms for sourcing, enabling access to a broader range of suppliers. However, this shift necessitates a deeper understanding of supplier reliability and compliance with international standards.

Emerging markets, particularly in Africa and South America, are recognizing the potential of travel gear as a lucrative investment. As urbanization increases, the demand for stylish yet functional backpacks is projected to rise. Buyers should prioritize partnerships with manufacturers who demonstrate agility in adapting to these market dynamics while maintaining quality and affordability.

Sustainability & Ethical Sourcing in B2B

Sustainability is a crucial consideration in the sourcing of the gomatic 30L backpack. The environmental impact of production processes can be significant, making it imperative for B2B buyers to prioritize ethical supply chains. The following factors are essential:

- Material Selection: Buyers should look for backpacks made from recycled or sustainably sourced materials, such as recycled polyester or organic cotton, which minimize environmental footprints.

- Certifications: Opting for products with certifications like Global Recycle Standard (GRS) or OEKO-TEX can assure buyers of adherence to environmental and social standards during production.

- Supplier Transparency: Engaging with suppliers who provide clear insights into their manufacturing processes and labor practices can foster trust and ensure compliance with ethical sourcing standards.

Investing in sustainable products not only benefits the environment but can also enhance brand loyalty among consumers who prioritize eco-friendly practices.

Brief Evolution/History

The evolution of the gomatic 30L backpack reflects broader trends in travel gear, emphasizing adaptability and user-centered design. Initially designed as utilitarian bags for outdoor enthusiasts, backpacks have transitioned into essential tools for urban professionals. The introduction of innovative features—such as modular compartments and water-resistant materials—has broadened their appeal across various sectors. As the market continues to evolve, the gomatic 30L backpack stands as a testament to the blend of functionality, style, and sustainability that modern consumers demand. This evolution presents significant opportunities for B2B buyers to align their product offerings with current market needs.

Frequently Asked Questions (FAQs) for B2B Buyers of gomatic 30l backpack

-

How can I effectively vet suppliers for the gomatic 30L backpack?

When vetting suppliers, prioritize those with a proven track record in manufacturing quality backpacks. Review their certifications (such as ISO standards) and request references from other B2B clients. It’s beneficial to conduct factory visits, if possible, or utilize third-party inspection services to assess production capabilities. Additionally, consider suppliers who specialize in your region’s market, as they will better understand local preferences and regulations. -

What customization options are available for the gomatic 30L backpack?

Customization options typically include branding (such as logo placement), color choices, and specific feature alterations to meet your business needs. Discuss these options with your supplier early in the process to ensure they can accommodate your requests without significant lead time increases. Be prepared to meet minimum order quantities (MOQs) for custom designs, and confirm the implications for pricing and delivery timelines. -

What are the standard minimum order quantities (MOQs) and lead times for the gomatic 30L backpack?

MOQs can vary significantly based on the supplier and the level of customization required. Generally, expect MOQs to range from 100 to 500 units for standard orders, while customized orders may require higher quantities. Lead times typically span 30 to 90 days, depending on the complexity of the order and the supplier’s production capacity. Always confirm these details upfront to align your inventory planning with supplier capabilities. -

What payment terms should I expect when sourcing the gomatic 30L backpack?

Payment terms often vary by supplier, but common practices include a 30% deposit upon order confirmation and the remaining balance before shipment. Some suppliers may offer payment via letters of credit, which can provide additional security. Be clear about your preferred payment methods and negotiate terms that suit your cash flow while ensuring supplier trust and commitment to quality. -

How can I ensure quality assurance for the gomatic 30L backpack?

To ensure quality, implement a robust quality assurance (QA) process that includes pre-production samples, in-line inspections, and final product assessments. Request certifications such as ISO 9001 or compliance with specific safety standards relevant to your market. Establish clear communication with your supplier regarding your quality expectations and consider third-party inspection services for unbiased evaluations. -

What logistics considerations should I keep in mind when importing the gomatic 30L backpack?

Logistics for importing the gomatic 30L backpack involve understanding shipping options, customs regulations, and potential tariffs. Work with a freight forwarder who has experience with your target markets to navigate these complexities. Ensure that your supplier provides the necessary documentation for customs clearance, including commercial invoices and packing lists, to avoid delays and additional costs. -

How can disputes with suppliers be effectively managed?

To manage disputes with suppliers, establish clear terms and conditions in your contract, including quality standards, delivery timelines, and payment terms. Maintain open lines of communication and document all interactions to provide a clear record if issues arise. In the event of a dispute, consider mediation or arbitration as a first step before escalating to legal proceedings, as these methods can save time and costs. -

What certifications should I look for when sourcing the gomatic 30L backpack?

Look for certifications that indicate quality and safety compliance, such as ISO 9001 for quality management and OEKO-TEX for non-toxic materials. If your market has specific regulations (e.g., REACH in Europe), ensure the supplier’s products meet these standards. Certifications not only enhance product credibility but can also positively influence your brand image in the competitive marketplace.

Strategic Sourcing Conclusion and Outlook for gomatic 30l backpack

As international B2B buyers consider the gomatic 30L backpack, strategic sourcing emerges as a critical component for success. By focusing on quality, functionality, and market adaptability, businesses can leverage the backpack’s robust features—such as water resistance and intelligent compartmentalization—to enhance their offerings. Buyers from Africa, South America, the Middle East, and Europe must evaluate supplier reliability and manufacturing processes, ensuring they select partners who can deliver consistent quality while meeting regional demands.

Key takeaways include understanding the diverse types of backpacks available, recognizing the importance of material selection, and negotiating effectively with suppliers to achieve favorable pricing structures. Additionally, incorporating branding opportunities can significantly enhance market presence and customer loyalty.

Looking ahead, the demand for versatile travel gear will continue to grow, driven by an increasingly mobile workforce. International B2B buyers are encouraged to act now—evaluate your sourcing strategies, engage with reliable suppliers, and position your business to capture emerging opportunities within the global market. By prioritizing strategic sourcing, you can not only meet current consumer demands but also set the stage for future growth and innovation in your product lineup.