Your Ultimate Guide to Sourcing Conceal Carry Backpack

Guide to Conceal Carry Backpack

- Introduction: Navigating the Global Market for conceal carry backpack

- Understanding conceal carry backpack Types and Variations

- Key Industrial Applications of conceal carry backpack

- Strategic Material Selection Guide for conceal carry backpack

- In-depth Look: Manufacturing Processes and Quality Assurance for conceal carry backpack

- Comprehensive Cost and Pricing Analysis for conceal carry backpack Sourcing

- Spotlight on Potential conceal carry backpack Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for conceal carry backpack

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the conceal carry backpack Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of conceal carry backpack

- Strategic Sourcing Conclusion and Outlook for conceal carry backpack

Introduction: Navigating the Global Market for conceal carry backpack

In today’s fast-paced world, conceal carry backpacks have emerged as essential accessories for both personal security and convenience. Designed to discreetly carry firearms while ensuring easy access, these backpacks cater to a growing demand among professionals, outdoor enthusiasts, and everyday users. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe—including key markets like Spain and Turkey—understanding the nuances of this product category is critical for making informed sourcing decisions.

This comprehensive guide explores the multifaceted landscape of conceal carry backpacks. It will delve into various types and designs, highlighting features that cater to different user needs. Additionally, we will examine materials used in manufacturing, focusing on durability, weight, and security. The guide will also cover the manufacturing and quality control processes, ensuring buyers can identify reliable suppliers who meet industry standards.

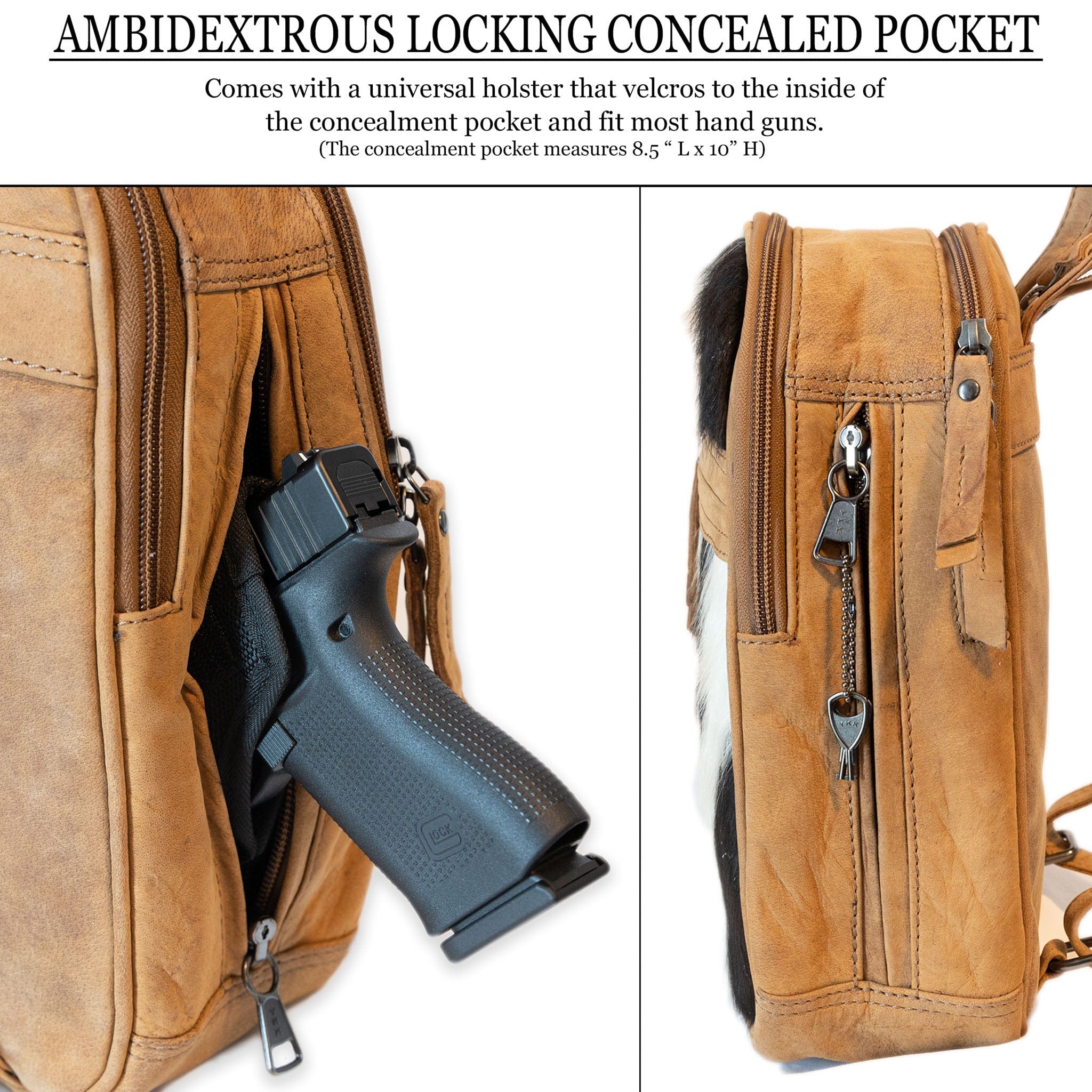

Illustrative Image (Source: Google Search)

Furthermore, we will provide insights into cost structures and market trends, empowering buyers to negotiate effectively and align their strategies with current consumer demands. To facilitate a thorough understanding, a dedicated FAQ section will address common inquiries that arise during the sourcing process.

By leveraging the information in this guide, B2B buyers can navigate the global market with confidence, ensuring they select the best conceal carry backpacks to meet their customers’ needs while maximizing profitability.

Understanding conceal carry backpack Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tactical Conceal Carry Backpack | Rugged design with MOLLE webbing, multiple compartments | Law enforcement, military, outdoor activities | Pros: High durability, versatile for gear; Cons: Heavier, may lack subtlety in urban settings. |

| Everyday Carry (EDC) Backpack | Sleek design, often made from lightweight materials | Daily commuting, urban use | Pros: Lightweight, discreet; Cons: Limited space for larger items. |

| Laptop Conceal Carry Backpack | Padded compartments for electronics, often includes concealment pocket | Corporate professionals, students | Pros: Protects electronics, dual functionality; Cons: May compromise on concealment space. |

| Travel Conceal Carry Backpack | Designed for travel, includes anti-theft features | Travel agencies, tourism operators | Pros: Security features, spacious; Cons: Bulkier, can be expensive. |

| Specialized Conceal Carry Backpack | Custom-designed for specific needs (e.g., medical kits) | Specialized industries, emergency services | Pros: Tailored functionality; Cons: Higher cost, may require longer lead times for production. |

Tactical Conceal Carry Backpack

This type of backpack is characterized by its rugged construction and tactical features, including MOLLE webbing for attaching additional gear. It’s primarily used by law enforcement and military personnel, making it suitable for outdoor activities as well. When purchasing, consider the durability of materials and the backpack’s ability to carry essential gear. While these backpacks are built to withstand harsh conditions, their weight may be a consideration for urban users seeking a more discreet option.

Everyday Carry (EDC) Backpack

EDC backpacks are designed for daily use, featuring a sleek profile and lightweight materials. They cater to urban commuters and individuals who prefer a low-key style. Buyers should evaluate the balance between size and functionality, as these bags typically prioritize convenience over large storage capacity. While they are perfect for everyday essentials, they may not provide enough space for larger items or tactical gear.

Laptop Conceal Carry Backpack

These backpacks are specifically designed to accommodate laptops and other electronics, often featuring padded compartments for protection. They are ideal for corporate professionals and students who need to transport tech securely while maintaining a concealment option. When sourcing these products, focus on the quality of the padding and the accessibility of the concealment pocket. However, potential buyers should be aware that the design may limit the amount of space available for other items.

Travel Conceal Carry Backpack

Travel backpacks combine concealment features with anti-theft designs, making them suitable for tourists and travel agencies. They often include multiple compartments for organizing travel essentials while ensuring security. When selecting these backpacks, consider the size, weight, and security features, as they can be bulkier than everyday options. While they offer ample space for travel needs, their cost and weight may deter some buyers.

Specialized Conceal Carry Backpack

Specialized backpacks are customized for specific industries or needs, such as medical kits for first responders. These bags typically feature tailored compartments and functionalities to meet unique requirements. B2B buyers should assess the customization options and lead times, as these backpacks may come at a higher price point. While they provide specialized solutions, the investment might be justified by their enhanced functionality and purpose-driven design.

Related Video: Large Language Models (LLMs) – Everything You NEED To Know

Key Industrial Applications of conceal carry backpack

| Industry/Sector | Specific Application of Conceal Carry Backpack | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Security Services | Personal protection for security personnel | Enhanced safety for staff in high-risk environments | Material durability, weight, and comfort for extended wear |

| Law Enforcement | Off-duty carry for law enforcement officers | Discreet firearm access while maintaining professionalism | Compliance with local laws, quality of stitching, and waterproofing |

| Outdoor Recreation | Concealed carry for outdoor enthusiasts | Protection while hiking or camping in remote areas | Weather resistance, lightweight materials, and ergonomic design |

| Corporate Training | Self-defense training gear for corporate events | Promotes safety awareness among employees | Custom branding options, ease of use, and storage capacity |

| Travel & Tourism | Safety for travelers in high-risk areas | Peace of mind for clients in unfamiliar environments | Compact design, RFID protection, and accessibility |

Security Services

In the security sector, conceal carry backpacks are essential for personnel who need to maintain a low profile while ensuring their safety. These backpacks allow security staff to carry necessary self-defense tools discreetly, especially in high-risk environments such as events or corporate settings. For international buyers, factors like durability and comfort are crucial since personnel may need to wear these bags for extended periods. Additionally, sourcing backpacks that meet specific safety standards can enhance the credibility of the security service.

Law Enforcement

For law enforcement officers, conceal carry backpacks serve as an effective means of carrying personal firearms while off-duty. These backpacks provide quick access to weapons without drawing attention, maintaining professionalism in public spaces. International B2B buyers in this sector should focus on compliance with local regulations regarding firearm storage and transportation. Quality stitching and waterproof materials are also vital to ensure longevity and reliability in various environments.

Outdoor Recreation

Outdoor enthusiasts often require reliable gear that accommodates concealed carry without sacrificing comfort. Conceal carry backpacks are ideal for hikers and campers who may need to protect themselves in remote areas. These backpacks must be lightweight yet durable, with weather-resistant features to withstand outdoor conditions. Buyers from regions with diverse terrains, such as Africa and South America, should prioritize sourcing materials that offer both protection and ease of movement during outdoor activities.

Corporate Training

In the corporate sector, conceal carry backpacks can be utilized during self-defense training sessions. Companies may offer training to employees as part of their safety programs, and having the right gear can enhance the training experience. Buyers should consider backpacks that allow for easy access to training tools while being comfortable enough for prolonged use. Custom branding options can also be a significant factor for businesses looking to promote their commitment to employee safety.

Travel & Tourism

For travelers, especially in regions known for safety concerns, conceal carry backpacks provide peace of mind. These bags allow tourists to carry personal safety items discreetly while exploring unfamiliar areas. Features such as RFID protection and compact designs are essential for enhancing security and convenience. International buyers in the travel industry should focus on sourcing backpacks that combine practicality with style, catering to the preferences of a diverse clientele.

Related Video: LABORATORY APPARATUS AND THEIR USES

Strategic Material Selection Guide for conceal carry backpack

When selecting materials for a conceal carry backpack, it’s essential to consider their performance characteristics, durability, and suitability for the intended market. Below, we analyze four common materials used in the manufacturing of conceal carry backpacks, providing insights relevant to international B2B buyers.

1. Nylon

Key Properties: Nylon is known for its high tensile strength and resistance to abrasion. It typically performs well in a range of temperatures and is resistant to mildew and UV light, making it ideal for outdoor use.

Pros & Cons: The advantages of nylon include its durability and lightweight nature, which is crucial for comfort during carry. However, it can be more expensive than other fabrics and may require specialized manufacturing processes to ensure waterproofing or additional features.

Impact on Application: Nylon’s compatibility with water-resistant coatings makes it suitable for environments where moisture is a concern. It is also easy to dye, allowing for various color options that appeal to different markets.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that suppliers adhere to international standards such as ASTM for textile safety. Additionally, the availability of nylon can vary by region, impacting lead times and costs.

2. Polyester

Key Properties: Polyester is resistant to shrinking and stretching, maintaining its shape over time. It has a good resistance to UV light and is generally more affordable than nylon.

Pros & Cons: The main advantage of polyester is its cost-effectiveness, making it a popular choice for budget-conscious buyers. However, it may not be as durable as nylon and can be prone to wear in high-friction areas.

Impact on Application: Polyester’s water-resistant properties make it suitable for conceal carry backpacks used in various climates. Its lightweight nature also contributes to the overall comfort of the backpack.

Considerations for International Buyers: For buyers in Europe, compliance with EU regulations on chemical safety in textiles (REACH) is essential. Understanding the local market preferences for material feel and performance can also guide purchasing decisions.

3. Cordura Fabric

Key Properties: Cordura is a brand of nylon fabric known for its exceptional durability and resistance to abrasions, tears, and scuffs. It is often treated for water resistance, enhancing its performance in wet conditions.

Pros & Cons: The key advantage of Cordura is its strength, making it ideal for rugged use. However, it tends to be more expensive than standard nylon or polyester, which can be a limiting factor for some buyers.

Impact on Application: Cordura is particularly suitable for tactical and outdoor applications, where durability is paramount. Its heavy-duty nature supports the weight of concealed items without compromising the backpack’s integrity.

Considerations for International Buyers: Buyers should verify that Cordura meets specific industry standards, such as those set by the American National Standards Institute (ANSI). Additionally, the availability of Cordura may be limited in some regions, necessitating careful supplier selection.

4. Leather

Key Properties: Leather offers natural durability and aesthetic appeal. It is resistant to wear and tear and can provide a sophisticated look, which is appealing in certain markets.

Pros & Cons: The primary advantage of leather is its longevity and timeless style. However, it can be heavy, expensive, and requires more maintenance compared to synthetic materials.

Impact on Application: Leather is often used in high-end conceal carry backpacks aimed at professionals or fashion-conscious consumers. Its weight can be a drawback for everyday carry, but its durability can be a selling point.

Considerations for International Buyers: Buyers in the Middle East and Europe should consider local leather sourcing standards and regulations concerning animal welfare and environmental impact. Understanding consumer preferences for leather finishes and treatments is also crucial.

Summary Table

| Material | Typical Use Case for conceal carry backpack | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | General purpose, outdoor activities | High durability and lightweight | Higher cost, specialized processes | High |

| Polyester | Budget-friendly options | Cost-effective, shape retention | Less durable than nylon | Med |

| Cordura Fabric | Tactical and rugged use | Exceptional durability | Higher cost | High |

| Leather | High-end, fashion-oriented markets | Longevity and aesthetic appeal | Heavy, requires maintenance | High |

This material selection guide provides a comprehensive overview for international B2B buyers, emphasizing the importance of material choice in meeting market demands and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for conceal carry backpack

In the competitive landscape of B2B sourcing for conceal carry backpacks, understanding the manufacturing processes and quality assurance protocols is crucial for international buyers. This knowledge not only helps in assessing product quality but also in establishing reliable supplier relationships. Below is a detailed overview of the typical manufacturing processes, quality control measures, and actionable insights for buyers from Africa, South America, the Middle East, and Europe.

Manufacturing Processes

The production of conceal carry backpacks involves several key stages: material preparation, forming, assembly, and finishing. Each stage is vital for ensuring that the final product meets both functional and aesthetic requirements.

1. Material Preparation

The first step in manufacturing a conceal carry backpack is sourcing high-quality materials. Manufacturers typically select durable fabrics such as nylon or polyester, which offer water resistance and wear resistance. Additionally, specialized materials like ballistic nylon or Kevlar may be used for added protection.

- Sourcing Tips: Buyers should visit local fabric markets or established suppliers known for quality. Establishing relationships with trusted fabric vendors can lead to better pricing and access to innovative materials.

2. Forming

Once materials are secured, the next step involves creating patterns and templates. This is done using computer-aided design (CAD) software to ensure precision in cutting.

- Key Techniques: Automated cutting machines are often employed for larger batches, allowing for consistent shapes and sizes. For small runs, manual cutting may still be utilized, but precision remains critical.

3. Assembly

During the assembly stage, the cut fabric pieces are stitched together. This process is typically performed in an assembly line format to maximize efficiency.

- Sewing Techniques: Skilled workers use industrial sewing machines to assemble the bags, ensuring that seams are reinforced. Techniques such as double stitching are often employed to enhance durability, especially in high-stress areas.

4. Finishing

The final stage involves adding any additional features, such as straps, zippers, or pockets. Each backpack is then inverted, tidied up, and prepared for quality checks.

- Finishing Touches: This may include adding branding elements or custom embroidery, which can enhance the product’s marketability.

Quality Assurance Protocols

Quality control (QC) is paramount in the production of conceal carry backpacks to ensure safety, durability, and compliance with international standards. Here are the key aspects of QC that B2B buyers should consider:

Illustrative Image (Source: Google Search)

International Standards

Familiarity with relevant standards such as ISO 9001 is essential. This standard focuses on quality management systems and can help buyers assess a supplier’s commitment to quality.

- Industry-Specific Certifications: Depending on the market, certifications like CE (Conformité Européenne) for European markets or API (American Petroleum Institute) for specialized applications may also be relevant.

QC Checkpoints

Effective quality assurance should incorporate several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during production helps catch defects early. This can include regular inspections of stitching and material integrity.

- Final Quality Control (FQC): Before shipping, a thorough inspection is conducted on finished products to ensure they meet quality and safety standards.

Common Testing Methods

Testing methods used in the quality assurance of conceal carry backpacks may include:

- Abrasion Resistance Testing: Ensures the fabric can withstand wear and tear.

- Water Resistance Testing: Checks the effectiveness of water-repellent coatings.

- Load Testing: Assesses the backpack’s ability to hold weight without structural failure.

Verifying Supplier Quality Control

For international buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are actionable steps:

Conduct Supplier Audits

Regular audits of potential suppliers can provide insight into their manufacturing processes and quality control measures. Buyers should look for suppliers who are willing to share their quality management system documentation and certification results.

Request Quality Reports

Ask suppliers for detailed quality reports that include information on testing methods, results, and any corrective actions taken for defects. These reports should be transparent and readily available.

Utilize Third-Party Inspections

Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing process. These services often include pre-production inspections, in-line inspections, and final inspections, ensuring that the products meet agreed-upon specifications.

Regional Considerations

Understanding regional nuances in quality assurance is essential for successful international B2B transactions. For example:

- Africa: Buyers should consider the impact of local regulations on product safety and quality. Engaging with suppliers who understand these regulations can mitigate risks.

- South America: Due diligence in supplier selection is critical due to varying standards across countries. Establishing clear communication and expectations can enhance supplier relationships.

- Middle East: Cultural considerations may affect negotiations and quality expectations. Building rapport with suppliers can lead to better cooperation on quality assurance.

- Europe (e.g., Spain, Turkey): Familiarity with EU regulations on product safety is vital. Suppliers should be equipped to demonstrate compliance with CE marking and other relevant standards.

Conclusion

For B2B buyers seeking to source conceal carry backpacks, a thorough understanding of manufacturing processes and quality assurance is essential. By focusing on material quality, employing rigorous QC measures, and conducting diligent supplier evaluations, buyers can ensure that they receive high-quality products that meet international standards. This not only safeguards investments but also enhances brand reputation in competitive markets.

Related Video: How a Backpack is Made : Every Step on the Production Line

Comprehensive Cost and Pricing Analysis for conceal carry backpack Sourcing

When sourcing conceal carry backpacks, understanding the comprehensive cost structure is essential for international B2B buyers, especially those from Africa, South America, the Middle East, and Europe. The cost components involved in manufacturing these specialized backpacks can significantly influence pricing and overall procurement strategy.

Cost Components

-

Materials: The choice of materials is critical in determining the cost of a conceal carry backpack. High-quality fabrics such as ballistic nylon or waterproof materials will increase costs but enhance durability and functionality. Additionally, specialized materials for concealment can add to expenses.

-

Labor: Labor costs vary by region and can impact the final price. Countries with lower labor costs, such as some in Southeast Asia, may offer more competitive pricing, while skilled labor in Europe might command higher wages but can ensure better craftsmanship.

-

Manufacturing Overhead: This includes expenses related to factory operation, utilities, and equipment maintenance. These overheads are typically factored into the per-unit cost and can vary widely based on the location and efficiency of the manufacturing facility.

-

Tooling: For customized designs, tooling costs can be significant. This encompasses the creation of molds and cutting dies specific to the conceal carry backpack design. Initial tooling investments can be amortized over larger production runs, making it essential to consider minimum order quantities (MOQs).

-

Quality Control (QC): Implementing rigorous quality control processes ensures that the backpacks meet safety and performance standards. This can add to the overall cost but is crucial for maintaining brand reputation and compliance with local regulations.

-

Logistics: Shipping costs can fluctuate based on the Incoterms negotiated with suppliers. International shipping rates, customs duties, and tariffs can significantly affect the total cost of ownership for buyers.

-

Margin: Suppliers will typically add a margin to cover their costs and profit. Understanding the margin expectations can help buyers negotiate better terms.

Price Influencers

-

Volume/MOQ: Higher order volumes generally lead to lower unit prices. Manufacturers often provide discounts for larger orders, making it advantageous for buyers to consolidate purchases.

-

Specifications/Customization: Custom features, such as specific compartments or branding, can increase costs. Buyers should weigh the benefits of customization against the added expenses.

-

Material Quality/Certifications: Certifications for materials (e.g., fire-retardant or waterproof) can influence pricing. Higher-quality materials not only increase the upfront cost but can also enhance the product’s longevity.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established manufacturers with a proven track record may charge more due to their quality assurance processes.

-

Incoterms: Different shipping terms (e.g., FOB, CIF) can change the cost structure. Understanding these terms can help buyers manage logistics costs effectively.

Buyer Tips

-

Negotiation: Develop strong negotiation skills. Leverage your knowledge of the market and competitor pricing to secure favorable terms.

-

Cost-Efficiency: Consider the total cost of ownership, which includes initial purchase price, shipping, and expected lifespan. Investing in higher-quality backpacks may result in lower overall costs due to less frequent replacements.

-

Pricing Nuances: Be aware of regional pricing differences. For example, suppliers in Turkey might offer competitive pricing for European buyers due to geographical proximity and lower shipping costs.

In conclusion, while sourcing conceal carry backpacks, international B2B buyers should conduct thorough research on cost components and pricing influencers to make informed purchasing decisions. Understanding the nuances of pricing and the total cost of ownership will enable buyers to optimize their procurement strategy effectively. Always remember that the prices discussed should be viewed as indicative, as they can vary widely based on market conditions and individual supplier negotiations.

Spotlight on Potential conceal carry backpack Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘conceal carry backpack’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for conceal carry backpack

When sourcing or manufacturing conceal carry backpacks, international B2B buyers need to understand key technical properties and trade terminology that influence product quality, pricing, and supplier relationships. This understanding is vital to making informed purchasing decisions and ensuring compliance with various market standards.

Essential Technical Properties

-

Material Grade

– The choice of material significantly affects durability, weight, and functionality. Common materials for conceal carry backpacks include high-denier nylon, polyester, and ballistic fabric. A higher denier indicates a thicker, more durable material, which is essential for carrying heavier items and ensuring longevity.

– B2B Importance: Selecting the appropriate material grade can influence production costs and the perceived value of the product in the market. -

Weight Capacity

– This refers to the maximum load that the backpack can carry without compromising its structural integrity. Weight capacity is often tested to ensure that the seams, straps, and zippers can handle the specified load.

– B2B Importance: Knowing the weight capacity is crucial for targeting the right customer segments, especially in outdoor and tactical markets where heavy gear is common. -

Water Resistance

– Many conceal carry backpacks incorporate water-resistant or waterproof materials to protect contents from moisture. This property is often measured by a hydrostatic head test, indicating how much water pressure the fabric can withstand.

– B2B Importance: For buyers in regions with high rainfall or humidity, this feature can be a significant selling point, enhancing customer satisfaction and reducing returns. -

Concealment Features

– Specific design elements such as hidden compartments, lockable zippers, and reinforced stitching are critical for ensuring the safety and discretion of concealed items. These features must meet legal standards and user expectations.

– B2B Importance: Understanding these features allows buyers to differentiate their products in a competitive market, appealing to consumers’ safety and security concerns. -

Tolerance Levels

– Tolerance refers to the acceptable limits of variation in the dimensions of the backpack components. For example, a tolerance of ±1mm on zipper lengths ensures that all zippers fit perfectly during assembly.

– B2B Importance: Maintaining strict tolerance levels is essential for quality control and can significantly affect production efficiency and product durability.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– An OEM produces parts and equipment that may be marketed by another manufacturer. In the context of conceal carry backpacks, an OEM may create custom designs based on a buyer’s specifications.

– Importance: Understanding OEM relationships can help buyers negotiate better terms and ensure they receive tailored products that meet their specific needs. -

MOQ (Minimum Order Quantity)

– This is the smallest quantity of a product that a supplier is willing to sell. For backpacks, the MOQ can vary based on the manufacturer and the complexity of the design.

– Importance: Knowing the MOQ is critical for budgeting and inventory management, particularly for new businesses or those testing market demand. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing and terms for a specific quantity of goods. For conceal carry backpacks, an RFQ should detail specifications, materials, and delivery timelines.

– Importance: A well-prepared RFQ can lead to competitive pricing and better supplier relationships. -

Incoterms (International Commercial Terms)

– These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight).

– Importance: Familiarity with Incoterms helps buyers understand shipping costs, risk management, and the logistics of their purchases. -

Lead Time

– This refers to the time taken from placing an order until its delivery. For backpacks, lead time can be affected by production schedules, material availability, and shipping conditions.

– Importance: Recognizing lead times is essential for planning inventory and meeting customer demand, particularly in fast-paced markets.

By grasping these essential properties and terminology, B2B buyers can make more strategic purchasing decisions, ensuring that their conceal carry backpacks meet market demands while maintaining quality and compliance.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the conceal carry backpack Sector

Market Overview & Key Trends

The global market for conceal carry backpacks is witnessing significant growth driven by increasing personal safety concerns and a rise in outdoor activities. In regions like Africa, South America, the Middle East, and Europe, consumers are seeking functional yet stylish options that cater to their security needs. Emerging trends include the integration of technology, such as RFID-blocking compartments and built-in charging ports, which appeal to tech-savvy consumers. Additionally, the demand for modular designs that allow users to customize their bags for various purposes is on the rise.

Sourcing trends are increasingly influenced by digital platforms that enable B2B buyers to connect with manufacturers directly. However, international buyers must navigate challenges such as fluctuating currency rates and varying quality standards. Leveraging platforms like Alibaba or TradeKey can facilitate sourcing, but buyers should conduct thorough due diligence to avoid pitfalls associated with pricing unpredictability. Collaborating with consultancy firms can offer valuable insights into local markets, ensuring that brands align their products with consumer preferences and regulatory requirements.

As the market evolves, sustainability is becoming a critical factor. Buyers are increasingly prioritizing products made from eco-friendly materials, which enhances brand image and appeals to environmentally conscious consumers. Understanding these dynamics will empower B2B buyers to make informed decisions and stay competitive in the growing conceal carry backpack sector.

Sustainability & Ethical Sourcing in B2B

The environmental impact of the backpack industry is substantial, with concerns ranging from resource depletion to pollution caused by manufacturing processes. For B2B buyers, prioritizing sustainability is not just an ethical choice; it is increasingly becoming a market demand. Incorporating sustainable practices into sourcing strategies can enhance brand reputation and appeal to a growing segment of eco-conscious consumers.

Ethical sourcing involves ensuring that materials are obtained responsibly, with consideration for labor conditions and environmental standards. Buyers should look for suppliers who adhere to international labor laws and environmental regulations. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® can serve as benchmarks for sustainable practices. Additionally, using recycled materials or biodegradable fabrics for conceal carry backpacks not only reduces environmental impact but also attracts consumers who prioritize sustainability in their purchasing decisions.

By fostering transparency in the supply chain and prioritizing ethical sourcing, B2B buyers can build trust with their customers and contribute positively to the planet.

Brief Evolution/History

The concept of conceal carry backpacks has evolved significantly over the past few decades. Initially designed for military and tactical use, these backpacks have transitioned into mainstream consumer products, reflecting changing societal attitudes towards personal safety and self-defense. The introduction of innovative materials and designs has expanded their functionality beyond mere concealment; today’s backpacks are equipped with features such as water resistance, ergonomic designs, and modular compartments.

This evolution has been driven by increased consumer awareness and demand for products that combine safety with practicality. As a result, the conceal carry backpack market is now characterized by diverse offerings that cater to various consumer needs, from urban commuting to outdoor adventures, positioning it as a vital segment within the broader backpack industry.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of conceal carry backpack

-

What should I consider when vetting suppliers for conceal carry backpacks?

When vetting suppliers, assess their reputation through reviews and industry references. Verify their certifications, such as ISO or other relevant quality management standards. Request samples to evaluate product quality firsthand, and inquire about their production capacity to ensure they can meet your demand. Additionally, consider their experience in producing conceal carry backpacks specifically, as this niche requires specialized knowledge in materials and design. -

Can I customize the design and features of the conceal carry backpack?

Yes, many manufacturers offer customization options, allowing you to tailor the design, materials, and features of the backpack to meet your market’s needs. When discussing customization, provide clear specifications and be prepared for possible minimum order quantities (MOQs). It’s essential to communicate your brand vision and any specific functionalities you require, such as additional compartments or unique fabric choices. -

What are typical minimum order quantities (MOQs) and lead times for conceal carry backpacks?

MOQs for conceal carry backpacks can vary widely depending on the manufacturer and the level of customization required. Generally, expect MOQs ranging from 100 to 1,000 units. Lead times typically range from 30 to 90 days, influenced by factors such as order size, complexity, and the manufacturer’s production schedule. Always confirm these details upfront to ensure they align with your business plan and timelines. -

What payment methods are commonly accepted by suppliers?

Most suppliers accept a variety of payment methods, including bank transfers, PayPal, and letters of credit. For larger orders, a letter of credit is often recommended as it provides security for both parties. Establish clear payment terms upfront, including deposits and payment schedules, to avoid any misunderstandings later. It’s also advisable to confirm any currency exchange rates if dealing with international suppliers. -

How do I ensure quality assurance and compliance with certifications?

To ensure quality, request documentation of certifications relevant to the conceal carry backpacks, such as safety standards or material specifications. Establish a quality assurance process that includes pre-production samples, in-line inspections, and final product audits. Working with suppliers that have a solid QA process in place can significantly reduce the risk of receiving subpar products. -

What logistics considerations should I keep in mind when importing backpacks?

Consider the total landed cost, which includes product cost, shipping, customs duties, and taxes. Engage a reliable freight forwarder familiar with international shipping regulations, especially for specialized items like conceal carry backpacks. Ensure all shipping documentation is accurate to avoid delays at customs, and be aware of any import restrictions or requirements specific to your target market. -

How can I handle disputes or quality issues with a supplier?

To manage disputes effectively, maintain clear documentation of all communications and agreements with the supplier. Address issues promptly and professionally, outlining specific concerns and proposed resolutions. If necessary, involve a third-party mediator or legal counsel familiar with international trade laws to facilitate a resolution. Establishing a solid contract with defined terms can also help mitigate potential disputes.

Illustrative Image (Source: Google Search)

- What trends should I be aware of in the conceal carry backpack market?

Trends in the conceal carry backpack market include a growing emphasis on sustainable materials and multifunctional designs. Consumers are increasingly looking for backpacks that blend style with practicality. Additionally, advancements in fabric technology, such as water-resistant and lightweight materials, are gaining popularity. Staying informed about these trends will help you align your product offerings with market demands and enhance your competitive edge.

Strategic Sourcing Conclusion and Outlook for conceal carry backpack

In summary, the strategic sourcing of conceal carry backpacks involves a nuanced understanding of the manufacturing process and market dynamics. Key takeaways include the importance of selecting reliable suppliers, ensuring high-quality materials, and understanding the regional preferences that can influence purchasing decisions. By leveraging platforms like Alibaba cautiously and investing in expert consultancy services, buyers can avoid common pitfalls and secure favorable terms.

Strategic sourcing not only enhances product quality but also strengthens supplier relationships, ultimately leading to better pricing and innovation. As international buyers from Africa, South America, the Middle East, and Europe (including Spain and Turkey) navigate this growing market, they should prioritize transparency and due diligence in their supplier evaluations.

Looking forward, the demand for conceal carry backpacks is set to rise, driven by increasing safety awareness and lifestyle needs. Now is the time to act—engage with trusted manufacturers, explore diverse materials, and adapt to evolving consumer preferences. By positioning themselves strategically, buyers can capitalize on this opportunity and drive sustainable growth in their respective markets.