Your Ultimate Guide to Sourcing Clipping Backpack

Guide to Clipping Backpack

- Introduction: Navigating the Global Market for clipping backpack

- Understanding clipping backpack Types and Variations

- Key Industrial Applications of clipping backpack

- Strategic Material Selection Guide for clipping backpack

- In-depth Look: Manufacturing Processes and Quality Assurance for clipping backpack

- Comprehensive Cost and Pricing Analysis for clipping backpack Sourcing

- Spotlight on Potential clipping backpack Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for clipping backpack

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the clipping backpack Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of clipping backpack

- Strategic Sourcing Conclusion and Outlook for clipping backpack

Introduction: Navigating the Global Market for clipping backpack

In today’s competitive landscape, the clipping backpack stands out as an essential product for various sectors, from outdoor activities to urban commuting. As a versatile and functional accessory, these backpacks cater to a wide range of consumers, making them a lucrative opportunity for international B2B buyers. The global bags and luggage market is projected to soar to $85 billion by 2030, and the demand for innovative, high-quality backpacks is a significant driver of this growth.

This comprehensive guide delves into the multifaceted world of clipping backpacks, offering insights into their diverse types, materials, and manufacturing processes. It emphasizes the importance of quality control and supplier reliability, which are crucial for maintaining brand reputation and ensuring customer satisfaction. Buyers will find valuable information on sourcing strategies, including cost considerations and market trends across different regions, specifically tailored for emerging markets in Africa, South America, the Middle East, and Europe.

By addressing frequently asked questions and providing actionable insights, this guide empowers international B2B buyers to make informed sourcing decisions. Whether you are looking to enhance your product offerings or streamline your supply chain, understanding the intricacies of the clipping backpack market will equip you with the tools needed to succeed in a dynamic and evolving global marketplace.

Understanding clipping backpack Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Clipping Backpack | Basic design with a single compartment and clips | School supplies, corporate gifts | Pros: Cost-effective, widely available. Cons: Limited features for specialized needs. |

| Tactical Clipping Backpack | Rugged, multi-pocket design for durability | Military, outdoor activities | Pros: High durability, versatile use. Cons: Higher cost, may be overbuilt for casual use. |

| Eco-Friendly Clipping Backpack | Made from sustainable materials | Eco-conscious brands, promotional items | Pros: Appeals to green consumers, unique branding potential. Cons: Potentially higher cost due to materials. |

| Child-Specific Clipping Backpack | Smaller sizes with safety features | Education, child care centers | Pros: Designed for safety, attractive to parents. Cons: Limited adult appeal, may lack durability. |

| Tech-Savvy Clipping Backpack | Compartments for tech gadgets and cables | Corporate, tech startups | Pros: Convenient for tech users, organized storage. Cons: Higher price point, may not appeal to non-tech users. |

Standard Clipping Backpack

The standard clipping backpack is characterized by its straightforward design, typically featuring a single large compartment secured with clips. This type is ideal for bulk purchases, such as school supplies or corporate gifts, due to its cost-effectiveness and availability. B2B buyers should consider the total cost of ownership, including shipping and potential customization options, to enhance branding.

Tactical Clipping Backpack

Tactical clipping backpacks are designed for rugged use, often equipped with multiple pockets and reinforced stitching. They are commonly used in military applications and outdoor activities, appealing to buyers looking for durability and versatility. When sourcing tactical backpacks, B2B buyers should evaluate the supplier’s reliability and the product’s compliance with quality standards.

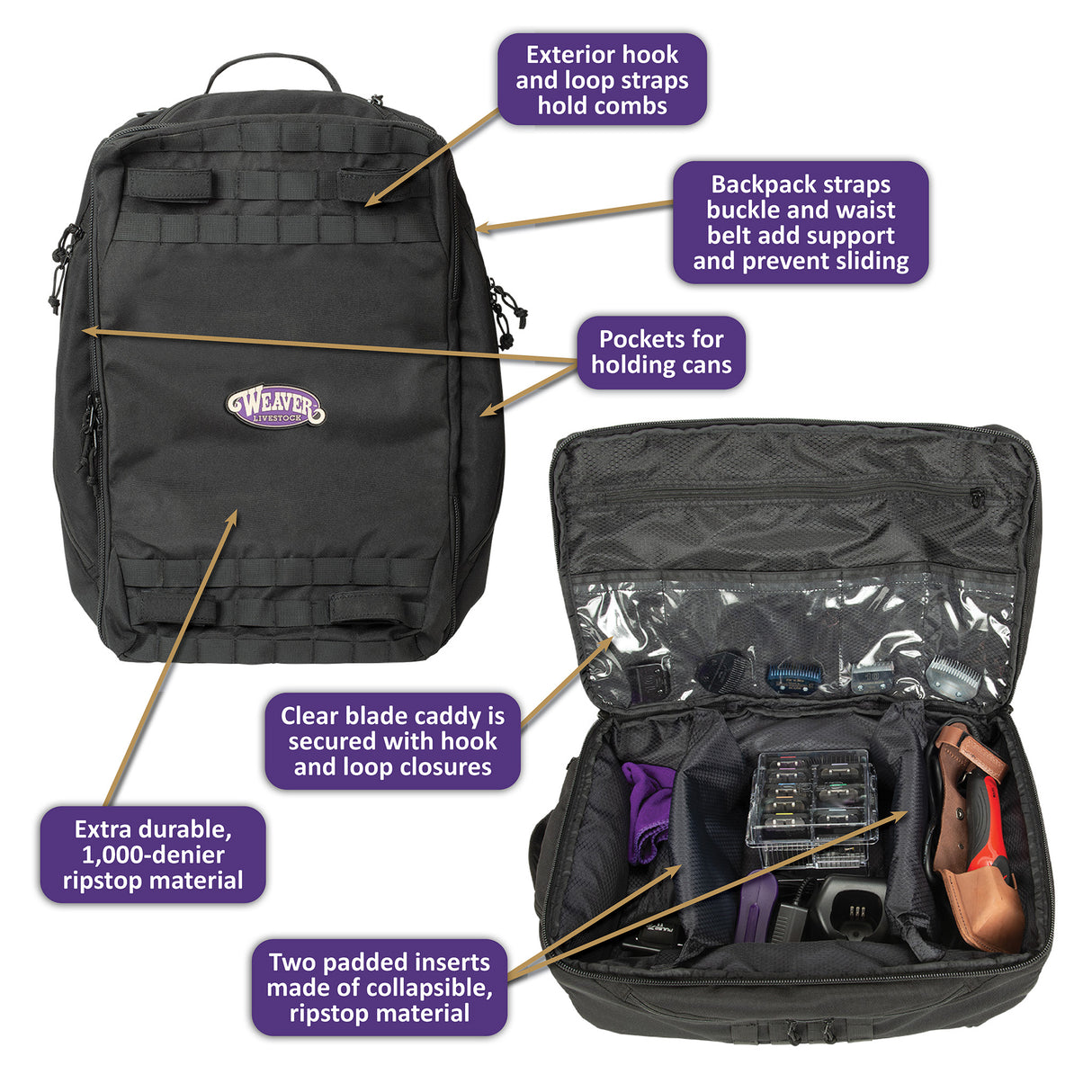

Illustrative Image (Source: Google Search)

Eco-Friendly Clipping Backpack

These backpacks are constructed from sustainable materials, making them appealing to brands focused on environmental responsibility. They are often used for promotional items targeting eco-conscious consumers. B2B buyers should assess the supplier’s commitment to sustainability and the potential for unique branding opportunities, which can enhance market appeal.

Child-Specific Clipping Backpack

Designed with children’s safety in mind, these backpacks feature smaller sizes and additional safety features. They are commonly used in educational settings and childcare centers. B2B buyers in this sector should prioritize quality and safety certifications while considering the appeal of the design to parents and guardians.

Tech-Savvy Clipping Backpack

This variation includes specialized compartments for storing tech gadgets and cables, making it popular among corporate clients and tech startups. Buyers should evaluate the backpack’s organizational features and durability, as well as the potential for customization to reflect brand identity. The higher price point may be justified by the added functionality and appeal to tech-savvy users.

Related Video: What Makes Large Language Models Expensive?

Key Industrial Applications of clipping backpack

| Industry/Sector | Specific Application of Clipping Backpack | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Outdoor Recreation | Hiking and Camping Gear | Enhanced convenience and accessibility for users | Durability, weather resistance, and ergonomic design |

| Logistics and Transport | Cargo Handling and Transport | Improved organization and ease of transport | Load capacity, weight distribution, and material strength |

| Education and Training | School and Training Supplies | Facilitates easy carrying of educational materials | Customization options, safety features, and compliance |

| Military and Tactical | Tactical Gear for Operations | Provides reliable storage and quick access to gear | Material durability, camouflage options, and modularity |

| Emergency Services | First Aid and Rescue Operations | Quick access to essential equipment in emergencies | Lightweight design, easy access pockets, and visibility |

Outdoor Recreation

In the outdoor recreation industry, clipping backpacks serve as essential gear for hiking and camping. They provide users with a convenient way to carry necessary supplies, such as water, food, and tools. Buyers in this sector should prioritize durability and weather resistance, as these backpacks often face harsh conditions. Ergonomic designs that promote comfort during long hikes are also crucial. For international buyers, understanding local preferences in style and functionality can enhance market acceptance and ensure product relevance.

Logistics and Transport

In logistics, clipping backpacks are utilized for cargo handling and transport, allowing workers to organize tools and equipment efficiently. They enhance productivity by making it easy to carry items without compromising mobility. Businesses should focus on sourcing backpacks with high load capacities and strong material strength to withstand heavy use. Additionally, weight distribution features can significantly improve worker comfort. International buyers should consider regional shipping regulations and material standards to ensure compliance.

Education and Training

Clipping backpacks are widely used in educational settings, providing students and trainers with a practical solution for carrying books, laptops, and training materials. They facilitate easy organization and access to supplies, which is essential for effective learning. Buyers should look for backpacks that offer customization options to reflect school branding and safety features, such as reflective materials. For international buyers, compliance with safety standards and preferences in design can impact purchasing decisions.

Military and Tactical

In military and tactical applications, clipping backpacks are designed for operational efficiency, allowing personnel to store and access gear quickly. These backpacks often feature modular designs to accommodate various equipment needs, from communication devices to survival kits. Buyers should prioritize material durability and camouflage options to meet operational requirements. International buyers must also consider the geopolitical context, ensuring compliance with local regulations and standards for tactical gear.

Emergency Services

For emergency services, clipping backpacks are vital for first aid and rescue operations, providing quick access to essential tools and supplies. The design must allow for lightweight carrying while ensuring visibility in critical situations. Buyers should focus on features that enhance accessibility, such as easy access pockets and bright colors for visibility. International buyers should also evaluate the need for compliance with local safety and medical equipment regulations to ensure effective deployment in emergencies.

Related Video: LABORATORY APPARATUS AND THEIR USES

Strategic Material Selection Guide for clipping backpack

When selecting materials for a clipping backpack, international B2B buyers must consider various factors that influence product performance, durability, and cost. Below, we analyze four common materials used in the production of clipping backpacks, highlighting their properties, advantages, disadvantages, and specific considerations for buyers in Africa, South America, the Middle East, and Europe.

1. Nylon

Key Properties:

Nylon is a synthetic polymer known for its high tensile strength and abrasion resistance. It performs well under a wide range of temperatures, typically from -40°C to 120°C, making it suitable for various climates.

Pros & Cons:

Nylon is lightweight and durable, which enhances the overall performance of the backpack. However, it can be susceptible to UV degradation over time and may not be as environmentally friendly as natural fibers. Manufacturing complexity can vary based on the weave and finish.

Impact on Application:

Nylon is compatible with various media, including water and dirt, making it ideal for outdoor applications. Its water-resistant properties can be enhanced with coatings.

Considerations for International Buyers:

Compliance with environmental standards is increasingly important, especially in Europe. Buyers should verify that the nylon used meets ASTM or similar standards for durability and safety.

2. Polyester

Key Properties:

Polyester is another synthetic material, known for its resistance to shrinking and stretching. It has a temperature tolerance similar to nylon and offers good moisture-wicking properties.

Pros & Cons:

Polyester is generally more cost-effective than nylon and is less prone to fading. However, it is not as strong as nylon, which may affect the backpack’s longevity under heavy use. Manufacturing processes are well-established, making it easier to source.

Impact on Application:

Polyester is often used in urban and casual backpacks, where style and affordability are priorities. Its compatibility with dyes allows for vibrant colors and patterns.

Considerations for International Buyers:

Buyers should ensure that polyester meets global safety standards, especially regarding chemical treatments. In regions like Africa and South America, local sourcing may also be beneficial for cost control.

3. Leather

Key Properties:

Leather is a natural material known for its durability and aesthetic appeal. It can withstand high pressure and has good temperature resistance, although it is less effective in extreme wet conditions.

Pros & Cons:

Leather offers a premium look and feel, making it suitable for high-end backpacks. However, it is more expensive and requires more complex manufacturing processes, including tanning and finishing. It can also be heavy compared to synthetic alternatives.

Impact on Application:

Leather is often used in fashion-forward backpacks and those intended for professional settings. It is less suited for rugged outdoor use unless treated for water resistance.

Considerations for International Buyers:

Ethical sourcing and compliance with environmental standards are critical, especially in Europe. Buyers should look for certifications that guarantee sustainable practices in leather production.

4. Canvas

Key Properties:

Canvas is a heavy-duty fabric, typically made from cotton or a cotton-polyester blend. It offers good breathability and is relatively resistant to wear and tear.

Pros & Cons:

Canvas is durable and provides a classic aesthetic, making it popular for casual and outdoor backpacks. However, it can be heavier than synthetic materials and may require additional treatment for water resistance.

Impact on Application:

Canvas backpacks are often used for school and casual outings. They can be treated to improve water resistance, but they are not ideal for extreme weather conditions without additional coatings.

Considerations for International Buyers:

Buyers should check for compliance with textile standards and certifications, particularly in Europe, where eco-friendly materials are increasingly preferred.

Summary Table

| Material | Typical Use Case for clipping backpack | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | Outdoor and technical backpacks | High tensile strength and abrasion resistance | Susceptible to UV degradation | Medium |

| Polyester | Urban and casual backpacks | Cost-effective and good moisture-wicking | Not as strong as nylon | Low |

| Leather | Fashion and professional backpacks | Premium look and durability | Expensive and complex manufacturing | High |

| Canvas | School and casual backpacks | Durable and breathable | Heavier and requires treatment for water resistance | Medium |

By carefully considering these materials and their properties, B2B buyers can make informed decisions that align with their product requirements, market demands, and sustainability goals.

In-depth Look: Manufacturing Processes and Quality Assurance for clipping backpack

Manufacturing Processes for Clipping Backpacks

The production of clipping backpacks involves several critical stages that ensure the final product meets both functionality and aesthetic standards. Understanding these processes is essential for B2B buyers, especially when sourcing from international manufacturers.

1. Material Preparation

The first step in manufacturing clipping backpacks is the selection and preparation of materials. Common materials used include nylon, polyester, canvas, and leather. Each material has distinct characteristics affecting durability, weight, and cost.

- Material Sourcing: Buyers should ensure that suppliers source materials from reputable vendors, prioritizing quality and sustainability.

- Cutting: Once materials are selected, they are cut into specific shapes using automated cutting machines or manual tools. Precision in this stage is crucial to minimize waste and ensure uniformity.

2. Forming

In this phase, the cut materials are shaped to form the various components of the backpack, such as the main body, straps, and pockets.

- Techniques: Common techniques include heat sealing, stitching, and welding. Heat sealing is often used for waterproof backpacks, while stitching is preferred for durability.

- Machinery: Advanced sewing machines, including those with multiple needle options, are employed to enhance stitching strength and design complexity.

3. Assembly

After forming the individual components, the next step is assembly.

- Joining Components: This involves sewing or attaching parts such as zippers, buckles, and straps. Quality control checks at this stage can prevent defects that could compromise the product’s integrity.

- Customization Options: Many manufacturers offer customization, allowing buyers to specify design elements that meet their branding needs.

4. Finishing

The final stage is finishing, where the backpack undergoes several processes to ensure it is ready for the market.

- Quality Checks: Each backpack is inspected for defects, ensuring that stitching is secure, zippers function correctly, and there are no material flaws.

- Packaging: Proper packaging is vital to protect the backpacks during transportation. Sustainable packaging options are increasingly popular, reflecting the growing emphasis on environmental responsibility.

Quality Assurance in Clipping Backpack Manufacturing

Quality assurance (QA) is a critical component of the manufacturing process, ensuring that each product meets international standards and buyer specifications.

International Standards

B2B buyers should prioritize suppliers that adhere to recognized quality standards:

- ISO 9001: This standard focuses on quality management systems and is applicable across industries. It ensures that manufacturers maintain consistent quality in their processes.

- CE Marking: Particularly relevant for products sold in the European market, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: For products intended for specific industries (e.g., outdoor or military), adherence to API standards can be crucial for ensuring product reliability.

Quality Control Checkpoints

Effective quality control involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial inspection focuses on raw materials to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): Regular inspections during the manufacturing process help catch defects early, minimizing the risk of large-scale issues.

- Final Quality Control (FQC): The final inspection involves a comprehensive review of the completed backpacks to ensure they meet all quality specifications and standards.

Common Testing Methods

To verify quality, manufacturers employ various testing methods, including:

- Tensile Strength Testing: Measures the strength of materials under tension, crucial for straps and seams.

- Water Resistance Testing: For backpacks marketed as waterproof, testing ensures they can withstand exposure to water without leaking.

- Color Fastness Testing: Ensures that colors do not fade or bleed during use or washing.

Verifying Supplier Quality Control

B2B buyers must actively verify the quality control processes of potential suppliers:

- Audits: Conducting on-site audits allows buyers to assess the manufacturing environment, equipment, and adherence to quality standards.

- Quality Reports: Requesting detailed quality reports can provide insights into a manufacturer’s processes and past performance.

- Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased assessment of the supplier’s quality control measures, ensuring compliance with international standards.

Quality Control Nuances for International Buyers

For B2B buyers from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential:

- Regulatory Compliance: Different regions have varying regulations regarding product safety and environmental impact. Buyers must ensure that their suppliers comply with local laws in their target markets.

- Cultural Considerations: Communication styles and business practices may differ. Establishing clear expectations and maintaining open lines of communication can help mitigate misunderstandings.

- Supply Chain Resilience: Diversifying suppliers across different regions can enhance supply chain resilience, minimizing risks associated with political instability or natural disasters.

Conclusion

Understanding the manufacturing processes and quality assurance measures for clipping backpacks is vital for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing, alongside robust quality control practices, buyers can ensure they source high-quality products that meet their market demands. Emphasizing these factors not only enhances product reliability but also strengthens brand reputation in competitive markets.

Related Video: How a Backpack is Made : Every Step on the Production Line

Comprehensive Cost and Pricing Analysis for clipping backpack Sourcing

When sourcing clipping backpacks, understanding the comprehensive cost structure and pricing dynamics is critical for B2B buyers, especially those operating across diverse markets like Africa, South America, the Middle East, and Europe. Here’s a detailed analysis of the cost components, price influencers, and practical tips for negotiating better deals.

Cost Components

-

Materials: The choice of materials significantly impacts the overall cost. Common materials for clipping backpacks include nylon, polyester, canvas, and leather. High-quality fabrics may come at a premium, but they can enhance product durability and appeal, justifying higher price points.

-

Labor: Labor costs vary widely by region. Countries like China and Vietnam offer competitive labor rates, but rising wages and labor laws can affect pricing. In contrast, countries such as India may provide skilled artisans at a reasonable cost, especially for handcrafted items, which can increase the price but add unique value.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and administrative expenses. Buyers should look for manufacturers with efficient operations to minimize overhead costs, which can be reflected in the final pricing.

-

Tooling: Tooling costs are essential for producing customized or specialized backpacks. This cost varies based on the complexity of the design and the need for molds or specialized machinery. For large orders, tooling costs can be amortized over the production run, reducing the per-unit price.

-

Quality Control (QC): Implementing robust QC processes is vital to ensure product consistency and quality. While this may increase initial costs, it reduces the risk of returns and enhances brand reputation, ultimately proving cost-effective.

-

Logistics: Shipping costs, including freight, customs duties, and insurance, can be substantial. Selecting the right Incoterms (e.g., FOB, CIF) can help manage these costs effectively. Buyers should consider logistics when assessing supplier quotes to avoid unexpected expenses.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. Understanding the industry norms for margins can help buyers evaluate whether a quoted price is competitive.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQs) play a significant role in pricing. Larger orders often lead to lower per-unit costs, but buyers must balance this against their inventory needs and cash flow.

-

Specifications/Customization: Custom designs and specifications can elevate costs. Buyers should clearly define their requirements to avoid unexpected charges and ensure that they receive the desired quality.

-

Materials and Quality Certifications: Premium materials and certifications (e.g., ISO, Fair Trade) can increase production costs. Buyers focused on sustainability or brand reputation may need to factor these into their budget.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may command higher prices due to their experience and quality assurance processes.

Buyer Tips

-

Negotiate Wisely: Leverage your position as a buyer by negotiating volume discounts, favorable payment terms, and flexible MOQs. Building a long-term relationship with suppliers can also yield better pricing over time.

-

Focus on Total Cost of Ownership (TCO): Look beyond the initial purchase price to consider all associated costs, including shipping, duties, and potential returns. A higher upfront cost may lead to lower overall expenses if the product quality is superior.

-

Understand Pricing Nuances: Different regions have varying pricing structures due to labor costs, material availability, and economic conditions. Buyers in Africa or South America may find different cost dynamics compared to those in Europe or the Middle East.

Disclaimer

Prices can fluctuate based on market conditions, material availability, and geopolitical factors. Buyers are encouraged to conduct thorough market research and obtain multiple quotes to ensure they receive competitive pricing tailored to their specific needs.

Spotlight on Potential clipping backpack Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘clipping backpack’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for clipping backpack

When sourcing clipping backpacks, understanding the critical technical properties and industry terminology is essential for making informed purchasing decisions. This section will outline key specifications that impact product quality and performance, as well as important trade terms that facilitate smoother transactions.

Key Technical Properties

-

Material Grade

– The material grade refers to the quality and type of fabric used in the construction of the backpack. Common materials include nylon, polyester, and canvas, each offering different levels of durability, weight, and water resistance. For B2B buyers, selecting the right material grade is crucial for ensuring the product meets the intended use, whether for outdoor activities or everyday commuting. -

Weight Capacity

– This specification indicates the maximum load the backpack can safely carry. It is essential for determining the suitability of the backpack for specific activities, such as hiking or traveling. Buyers should consider the weight capacity in relation to target customers’ needs to avoid product returns and dissatisfaction. -

Dimensions and Volume

– The size of the backpack, often measured in liters, affects its usability. Buyers should ensure that the dimensions align with market preferences, whether for compact daypacks or larger travel backpacks. This specification is vital for inventory management and meeting customer expectations regarding storage capacity. -

Zipper Quality and Type

– The quality of zippers can significantly affect the longevity and functionality of a backpack. Buyers should inquire about the zipper type (e.g., YKK, waterproof) and its durability under various conditions. A high-quality zipper prevents issues such as snagging or breaking, which can lead to customer dissatisfaction. -

Strap Design and Comfort

– The design of the straps, including padding and adjustability, plays a critical role in user comfort. Straps should be ergonomically designed to distribute weight evenly and reduce strain during use. For B2B buyers, understanding the importance of comfort can lead to better product reviews and repeat business. -

Tolerances

– Tolerances refer to the acceptable limits of variation in product dimensions and specifications during manufacturing. Tight tolerances ensure consistency and quality across batches. Buyers should prioritize manufacturers who adhere to strict tolerance standards to avoid discrepancies that could affect product performance.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– An OEM produces components or products that are used in another company’s end product. In the context of clipping backpacks, buyers may work with OEMs to customize designs or materials. Understanding OEM relationships can lead to better pricing and product quality. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest number of units a supplier is willing to sell. It is a critical factor in supply chain management, as it influences inventory costs and production planning. Buyers should negotiate MOQs that align with their sales forecasts to optimize cash flow.

Illustrative Image (Source: Google Search)

-

RFQ (Request for Quotation)

– An RFQ is a formal document sent to suppliers asking for pricing and terms for specific products. It is essential for comparing supplier offerings and ensuring competitive pricing. A well-prepared RFQ can streamline the procurement process and lead to better supplier relationships. -

Incoterms (International Commercial Terms)

– Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and duties. Familiarity with Incoterms helps buyers mitigate risks and clarify terms of shipment, ensuring smooth transactions and delivery. -

Lead Time

– Lead time refers to the amount of time it takes from placing an order until the product is delivered. Understanding lead times is vital for effective inventory management and meeting customer demands. Buyers should communicate clearly with suppliers to establish realistic lead times. -

Quality Assurance (QA)

– QA encompasses the processes and procedures that ensure products meet specified standards before they reach the market. For B2B buyers, establishing robust QA measures with suppliers can prevent costly returns and enhance brand reputation.

By mastering these technical properties and trade terms, B2B buyers can make informed decisions that align with their business goals and customer expectations. This knowledge not only facilitates smoother transactions but also contributes to long-term success in the competitive market for clipping backpacks.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the clipping backpack Sector

Market Overview & Key Trends

The global bags and luggage market, including the clipping backpack sector, has witnessed significant growth, with projections estimating it will reach $85 billion by 2030. This surge is driven by rising consumer demand for functional and stylish products, as well as the increasing popularity of outdoor and travel activities. For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, understanding key sourcing trends is crucial.

Emerging B2B Tech Trends:

1. Smart Manufacturing: Adoption of Industry 4.0 technologies, such as IoT and AI, is enhancing production efficiency and quality control.

2. E-commerce Integration: Companies are increasingly leveraging online platforms to reach global markets, making it essential for buyers to consider suppliers who can support e-commerce logistics.

3. Multi-Country Sourcing: The “China Plus One” strategy encourages diversification of suppliers to mitigate risks associated with geopolitical tensions and supply chain disruptions. This approach is particularly beneficial for brands looking to balance cost with quality.

Market Dynamics:

International buyers must navigate varying manufacturing capabilities across regions. Countries like Vietnam and India are emerging as strong alternatives to China, offering competitive pricing and quality. For instance, Vietnam excels in technical backpacks, while India is renowned for craftsmanship and sustainable materials. Understanding local market dynamics, including lead times and minimum order quantities (MOQs), is essential for optimizing supply chains.

Sustainability & Ethical Sourcing in B2B

The demand for sustainable products is reshaping the clipping backpack market. Buyers are increasingly prioritizing suppliers who adhere to ethical practices and demonstrate a commitment to reducing environmental impact. This shift is not merely a trend but a necessity for maintaining brand reputation in developed markets.

Key Environmental Considerations:

– Material Selection: Opting for eco-friendly materials, such as recycled polyester, organic cotton, or biodegradable materials, can significantly reduce a product’s carbon footprint.

– Certifications: Look for suppliers who hold relevant certifications, such as Global Recycled Standard (GRS), OEKO-TEX, or Fair Trade, which indicate adherence to environmental and social standards.

Importance of Ethical Supply Chains:

Ethical sourcing not only mitigates risks associated with reputational damage but also enhances consumer trust. Brands that transparently communicate their sustainability efforts are more likely to resonate with environmentally-conscious consumers. Thus, aligning with suppliers who prioritize ethical labor practices and sustainable sourcing can lead to long-term partnerships and market differentiation.

Brief Evolution/History

The clipping backpack, a versatile accessory that integrates functionality with style, has evolved significantly over the decades. Originally designed for outdoor enthusiasts, these backpacks have now permeated urban fashion, appealing to a broader consumer base. The rise of technology has also influenced design, with many modern clipping backpacks featuring smart compartments for devices and enhanced ergonomic support. As the market continues to evolve, B2B buyers must stay attuned to design innovations and consumer preferences to remain competitive.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of clipping backpack

-

What should I consider when vetting suppliers for clipping backpacks?

When vetting suppliers, prioritize their experience in the backpack market, particularly in clipping designs. Check for certifications that indicate compliance with international quality standards, such as ISO 9001. Request references from past clients to gauge reliability and performance. Additionally, assess their production capacity and flexibility to meet your demand fluctuations. Lastly, evaluate their communication responsiveness, as this is crucial for ongoing collaboration. -

Can I customize my order of clipping backpacks?

Yes, most reputable suppliers offer customization options. This can include variations in material, color, size, and design features. When discussing customization, clarify your specifications and request prototypes to ensure they meet your expectations. Be mindful that customization may affect lead times and minimum order quantities (MOQs). Communicate clearly about your brand requirements to avoid misunderstandings during production. -

What are the typical minimum order quantities (MOQs) and lead times for clipping backpacks?

MOQs for clipping backpacks typically range from 500 to 5,000 units, depending on the supplier and the complexity of the design. Lead times can vary, generally ranging from 4 to 8 weeks. Factors such as supplier location, order size, and customization requirements can influence these timelines. It’s advisable to discuss these details upfront and plan your inventory accordingly to avoid stock shortages. -

What payment terms should I expect when sourcing clipping backpacks?

Payment terms can vary significantly among suppliers. Common practices include a 30% deposit upon order confirmation, with the remaining 70% due before shipping. Some suppliers may also offer letter of credit options for larger orders. Ensure you discuss payment terms early in negotiations to avoid surprises. Additionally, consider using secure payment methods to safeguard your transactions. -

How can I ensure quality assurance (QA) and certifications for my order?

To ensure quality assurance, request samples before committing to large orders. Establish clear quality control standards and ask suppliers about their QA processes. Look for certifications that demonstrate adherence to environmental and safety standards, such as OEKO-TEX or GOTS for sustainable materials. Regular audits and inspections during production can also help maintain quality and adherence to your specifications.

Illustrative Image (Source: Google Search)

-

What logistics considerations should I keep in mind when importing clipping backpacks?

When importing, consider shipping methods, costs, and timelines. Sea freight is often more economical for large shipments, while air freight is faster but pricier. Ensure that your supplier can handle logistics and provide necessary documentation, such as bills of lading and customs declarations. Be aware of import duties and tariffs that may apply in your region, which can significantly impact total costs. -

What steps should I take if a dispute arises with my supplier?

In the event of a dispute, first attempt to resolve the issue through direct communication with the supplier. Document all correspondence and agreements to support your case. If informal negotiations fail, refer to your contract for dispute resolution clauses, which may include mediation or arbitration. Engaging a legal expert familiar with international trade can also provide guidance on the best course of action. -

How can I stay updated on trends in the clipping backpack market?

Staying informed about market trends can be achieved through industry reports, trade shows, and networking with other B2B buyers. Subscribe to industry publications and participate in online forums to gain insights into emerging materials, designs, and consumer preferences. Additionally, follow key players in the backpack industry on social media and attend webinars to keep abreast of innovations and market shifts.

Strategic Sourcing Conclusion and Outlook for clipping backpack

The landscape of strategic sourcing for clipping backpacks is rapidly evolving, driven by a combination of market demand, cost optimization, and geopolitical factors. For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing from diverse regions is crucial.

Key Takeaways:

-

Diversification is Essential: Embracing a “China Plus One” strategy allows businesses to mitigate risks associated with relying solely on one supplier or region. Countries like Vietnam, India, and Bangladesh offer competitive pricing and unique craftsmanship that can enhance product offerings.

-

Quality and Compliance Matter: Buyers must prioritize quality and adherence to social and environmental standards. This not only protects brand reputation but also ensures access to developed markets where compliance is increasingly scrutinized.

-

Cost Considerations: Evaluate the total cost of ownership, including shipping and quality control, rather than focusing solely on unit prices. This holistic approach will lead to better financial outcomes in the long term.

Looking ahead, the demand for innovative and sustainable products is set to grow. By leveraging a strategic sourcing framework that emphasizes quality, reliability, and ethical practices, B2B buyers can position themselves for success in a competitive market. Engage proactively with suppliers to explore these opportunities and ensure your business remains at the forefront of industry trends.