Your Ultimate Guide to Sourcing Backpack Weed Eater

Guide to Backpack Weed Eater

- Introduction: Navigating the Global Market for backpack weed eater

- Understanding backpack weed eater Types and Variations

- Key Industrial Applications of backpack weed eater

- Strategic Material Selection Guide for backpack weed eater

- In-depth Look: Manufacturing Processes and Quality Assurance for backpack weed eater

- Comprehensive Cost and Pricing Analysis for backpack weed eater Sourcing

- Spotlight on Potential backpack weed eater Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for backpack weed eater

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the backpack weed eater Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of backpack weed eater

- Strategic Sourcing Conclusion and Outlook for backpack weed eater

Introduction: Navigating the Global Market for backpack weed eater

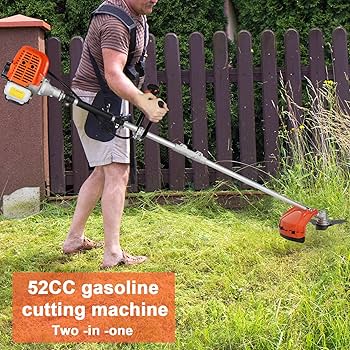

In an era where efficient landscaping and maintenance are paramount, the backpack weed eater emerges as an essential tool for businesses across various sectors, including agriculture, landscaping, and municipal services. These powerful machines not only enhance productivity but also offer a more ergonomic solution for tackling stubborn weeds in diverse environments. As international B2B buyers, understanding the nuances of backpack weed eaters can significantly impact sourcing decisions, ensuring that investments lead to optimal performance and cost-efficiency.

This comprehensive guide delves into the multifaceted world of backpack weed eaters, covering key topics such as types (gas-powered vs. electric), materials used in construction, and the importance of manufacturing quality control. Buyers will gain insights into the supplier landscape, with a focus on reputable manufacturers from Africa, South America, the Middle East, and Europe, including insights specific to regions like Spain and Nigeria. Additionally, we will explore cost considerations and market dynamics, helping businesses navigate pricing structures and value propositions.

Equipped with frequently asked questions (FAQs), this guide empowers B2B buyers to make informed decisions, minimizing risks and maximizing returns. By understanding the critical features and innovations in backpack weed eaters, businesses can enhance their operational efficiency and ensure sustainability in their landscaping practices. Dive into this essential resource to elevate your procurement strategy and drive success in the global market.

Understanding backpack weed eater Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gas-Powered Backpack | High power output, suitable for tough vegetation | Large-scale landscaping, agriculture | Pros: Powerful, long runtime; Cons: Heavier, noisy, higher emissions. |

| Electric Backpack | Battery-operated, quieter, eco-friendly | Residential landscaping, urban areas | Pros: Low emissions, quiet operation; Cons: Limited runtime, requires charging. |

| Commercial-Grade Backpack | Enhanced durability, designed for frequent use | Professional landscaping, municipal maintenance | Pros: Robust, designed for heavy use; Cons: Higher initial investment. |

| Multi-Function Backpack | Interchangeable heads for various tasks | Versatile landscaping, maintenance | Pros: Cost-effective, versatile; Cons: Potentially complex to use. |

| Lightweight Backpack | Designed for ease of use and portability | Small gardens, residential maintenance | Pros: Easy to handle, less fatigue; Cons: Less power for tough jobs. |

Gas-Powered Backpack Weed Eaters

Gas-powered backpack weed eaters are known for their high power output, making them ideal for tackling tough vegetation in large-scale landscaping and agricultural applications. These machines typically feature robust engines that can handle thick weeds and overgrown areas efficiently. When considering a gas-powered model, B2B buyers should evaluate fuel efficiency, weight, and maintenance requirements. While they offer long runtimes and significant cutting power, the trade-offs include increased noise levels and emissions, which may not align with eco-friendly initiatives.

Electric Backpack Weed Eaters

Electric backpack weed eaters are battery-operated, making them a quieter and more eco-friendly option compared to their gas-powered counterparts. They are particularly suitable for residential landscaping and urban maintenance, where noise restrictions may apply. Buyers should consider battery life, charging time, and power output when purchasing. Although these models are easier to handle and emit no emissions during operation, their runtime is limited by battery capacity, necessitating a charging strategy for extended use.

Commercial-Grade Backpack Weed Eaters

Commercial-grade backpack weed eaters are built for durability and frequent use, designed to withstand the rigors of professional landscaping and municipal maintenance. These machines often feature enhanced engine performance, advanced cooling systems, and ergonomic designs for comfort during long hours of operation. B2B buyers should focus on warranty options, service support, and parts availability. While the initial investment may be higher, the long-term cost-effectiveness and reliability make them a smart choice for businesses that prioritize efficiency and performance.

Multi-Function Backpack Weed Eaters

Multi-function backpack weed eaters come with interchangeable heads, allowing users to switch between tasks such as trimming, edging, and blowing. This versatility makes them suitable for various landscaping needs, providing a cost-effective solution for businesses that require multiple tools in one. When considering this option, buyers should assess the ease of head attachment, weight distribution, and overall design. Although they save on costs and storage space, the complexity of use may deter some operators who prefer straightforward machines.

Lightweight Backpack Weed Eaters

Lightweight backpack weed eaters are designed for ease of use and portability, making them an excellent choice for small gardens and residential maintenance. These models are typically less powerful but are favored for their maneuverability and reduced fatigue during operation. B2B buyers should consider the balance between power and weight, as well as the intended use scenario. While they are easy to handle and transport, their lower power output may limit effectiveness in larger or more challenging environments.

Related Video: GX35 honda backpack weed trimmer

Key Industrial Applications of backpack weed eater

| Industry/Sector | Specific Application of Backpack Weed Eater | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Weed management in crop fields | Enhances crop yield by reducing competition for nutrients | Engine power, weight for portability, fuel efficiency |

| Landscaping & Gardening | Maintenance of parks and recreational areas | Improves aesthetics and usability of outdoor spaces | Durability, ease of operation, noise levels |

| Municipal Services | Clearing overgrown vegetation in urban settings | Promotes safety and accessibility in public areas | Compliance with local regulations, service support availability |

| Forestry & Conservation | Underbrush clearing and habitat management | Supports biodiversity and forest health | Adaptability to various terrains, maintenance needs |

| Construction & Development | Site preparation and clearing | Ensures safety and efficiency in project timelines | Robust construction, fuel type options, warranty and support |

Detailed Applications

Agriculture

In agricultural settings, backpack weed eaters are essential for managing weeds in crop fields. By effectively reducing weed growth, these machines help enhance crop yield and minimize competition for nutrients and water. International buyers, especially in regions with diverse agricultural practices such as Africa and South America, should prioritize models that offer high engine power and fuel efficiency to withstand extensive use in large fields.

Landscaping & Gardening

Backpack weed eaters are widely used in landscaping to maintain parks, gardens, and other recreational areas. Their ability to quickly trim grass and weeds helps improve the aesthetic appeal and usability of outdoor spaces, making them attractive for community use. Buyers from Europe and the Middle East should consider the durability and ease of operation, particularly in urban environments where noise levels may be a concern.

Municipal Services

Municipalities utilize backpack weed eaters to clear overgrown vegetation in public areas, ensuring safety and accessibility for residents and visitors. This application is crucial in maintaining clean and navigable urban spaces. For international buyers, compliance with local regulations regarding noise and emissions is a critical consideration, as well as the availability of reliable after-sales support.

Forestry & Conservation

In forestry and conservation efforts, backpack weed eaters play a vital role in underbrush clearing and habitat management. This application supports biodiversity by allowing native plants to thrive while controlling invasive species. Buyers in regions like Africa and South America, where terrain can vary significantly, should seek equipment that is adaptable to different environments and has manageable maintenance needs.

Construction & Development

On construction sites, backpack weed eaters are used for site preparation and clearing, ensuring that the area is safe and ready for development. Their efficiency can significantly impact project timelines, making them a valuable asset for contractors. Key considerations for B2B buyers in this sector include the robustness of the equipment, options for different fuel types, and the warranty and support provided by manufacturers.

Related Video: Stihl FSA 130R Weed Eater Paired with MONSTER AR3000 Backpack Battery Review and Demo

Strategic Material Selection Guide for backpack weed eater

When selecting materials for backpack weed eaters, it is essential to consider properties that directly impact performance, durability, and user satisfaction. Below is an analysis of four common materials used in the construction of backpack weed eaters, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Aluminum Alloys

Key Properties: Aluminum alloys are lightweight, corrosion-resistant, and possess good thermal conductivity. They typically have a temperature rating of up to 150°C and can withstand moderate pressure, making them suitable for various outdoor applications.

Pros & Cons: The primary advantage of aluminum alloys is their lightweight nature, which enhances user comfort during extended use. They also resist rust, making them ideal for humid or wet environments. However, they can be more expensive than steel and may not have the same strength under heavy loads, leading to potential durability issues over time.

Impact on Application: Aluminum is compatible with various fuels and oils, making it suitable for diverse applications. However, it may not be ideal for extreme conditions where higher strength materials are required.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local regulations regarding metal recycling and environmental standards. Understanding local market preferences for lightweight equipment can also drive purchasing decisions.

2. High-Carbon Steel

Key Properties: High-carbon steel is known for its high tensile strength and hardness, with a temperature rating of up to 300°C. It is less resistant to corrosion unless treated with coatings.

Pros & Cons: The key advantage of high-carbon steel is its durability and ability to withstand heavy usage without deformation. However, it is heavier than aluminum, which may lead to user fatigue. Additionally, if not properly maintained, it can rust, necessitating protective coatings.

Impact on Application: This material is well-suited for heavy-duty applications, especially in rugged terrains. Its compatibility with various fuels makes it versatile, although its weight may be a drawback for some users.

Considerations for International Buyers: Compliance with ASTM standards for steel quality is crucial, particularly in Europe. Buyers should also consider the availability of maintenance services to ensure the longevity of high-carbon steel components.

3. Polypropylene (PP)

Key Properties: Polypropylene is a thermoplastic polymer that is lightweight, flexible, and resistant to chemical corrosion. It can withstand temperatures up to 100°C and is often used in components that require impact resistance.

Pros & Cons: The main advantage of polypropylene is its low weight and resistance to a wide range of chemicals, making it ideal for various outdoor applications. However, it may not withstand high temperatures as effectively as metals and can become brittle over time.

Impact on Application: Polypropylene is suitable for components like fuel tanks and covers, where chemical resistance is vital. Its lightweight nature enhances portability, but it may not be suitable for structural components requiring high strength.

Considerations for International Buyers: Buyers should ensure that polypropylene components meet local safety and environmental regulations, particularly in the Middle East where high temperatures can affect material performance.

4. Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance and high strength, with a temperature rating of up to 500°C. It is durable and can withstand harsh environmental conditions.

Pros & Cons: The primary advantage of stainless steel is its longevity and resistance to rust, making it ideal for outdoor equipment. However, it is heavier and more expensive than other materials, which can impact overall equipment cost.

Impact on Application: Stainless steel is suitable for high-stress components and those exposed to moisture. Its compatibility with various fuels makes it versatile, but weight considerations may deter some buyers.

Considerations for International Buyers: Compliance with DIN and JIS standards is essential for buyers in Europe and Asia. Additionally, understanding local preferences for durable materials can influence purchasing decisions.

Summary Table

| Material | Typical Use Case for backpack weed eater | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloys | Frames and housing | Lightweight, corrosion-resistant | Higher cost, less strength | Medium |

| High-Carbon Steel | Structural components | High durability | Heavier, susceptible to rust | Medium |

| Polypropylene (PP) | Fuel tanks and non-structural parts | Chemical resistance, lightweight | Limited high-temperature performance | Low |

| Stainless Steel | High-stress components | Excellent corrosion resistance | Heavier, more expensive | High |

This guide provides a comprehensive overview of material options for backpack weed eaters, allowing international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for backpack weed eater

In the realm of backpack weed eaters, understanding the manufacturing processes and quality assurance protocols is crucial for international B2B buyers. This knowledge not only aids in selecting reliable suppliers but also ensures that the products meet the necessary standards for performance and safety. Below is an in-depth exploration of the typical manufacturing stages and quality control measures relevant to backpack weed eaters.

Manufacturing Processes

The manufacturing of backpack weed eaters involves several key stages, each critical for ensuring the final product’s performance and durability.

1. Material Preparation

The first stage in the manufacturing process involves sourcing high-quality materials. Common materials used include:

- Engine Components: Aluminum and steel for durability and lightweight characteristics.

- Plastic Housing: High-density polyethylene (HDPE) or polycarbonate for impact resistance.

- String Trimmer Line: Nylon or other synthetic materials that offer strength and flexibility.

Suppliers should ensure that materials comply with international standards, such as ISO 14001 for environmental management, to demonstrate a commitment to sustainable practices.

2. Forming

In this stage, the prepared materials are shaped into components. Techniques commonly employed include:

- Injection Molding: Used for creating the plastic housing and components, allowing for precise shapes and designs.

- Stamping and Machining: Essential for forming metal parts, such as engine casings and frames, ensuring they meet specified tolerances.

Investing in advanced technology, such as Computer Numerical Control (CNC) machines, can enhance precision and reduce waste during this phase.

3. Assembly

The assembly process involves integrating the various components into a complete backpack weed eater. Key steps include:

- Sub-Assembly: Individual components, such as the engine, handles, and trimmer heads, are assembled separately before final assembly.

- Final Assembly: All sub-assemblies are brought together, typically involving the installation of the engine, attachment of the cutting head, and ensuring the harness and controls are properly fitted.

At this stage, it is essential to implement assembly line best practices, including ergonomic designs to enhance user comfort and efficiency.

4. Finishing

The finishing stage adds the final touches to the product. This may involve:

- Painting or Coating: Applying protective coatings to prevent corrosion and enhance aesthetics.

- Quality Checks: Conducting initial quality inspections to ensure that all components fit properly and the product functions as intended.

Investing in environmentally friendly coatings and finishes can also appeal to buyers focused on sustainability.

Quality Assurance

Quality assurance is a critical aspect of the manufacturing process, ensuring that backpack weed eaters meet both international and industry-specific standards.

International Standards

B2B buyers should familiarize themselves with relevant international quality standards, including:

- ISO 9001: Focuses on quality management systems, ensuring consistent product quality and continuous improvement.

- ISO 14001: Pertains to environmental management, crucial for companies aiming to minimize their ecological footprint.

Industry-Specific Standards

In addition to general standards, certain certifications are vital for specific markets:

- CE Marking: Required for products sold in the European Economic Area, ensuring compliance with safety and environmental requirements.

- API Standards: Relevant for products used in specific industrial applications, ensuring performance and safety.

Quality Control Checkpoints

Quality control is typically structured around several key checkpoints:

- Incoming Quality Control (IQC): Inspecting raw materials and components upon arrival at the manufacturing facility to ensure they meet specified criteria.

- In-Process Quality Control (IPQC): Conducting ongoing inspections during the manufacturing process to identify defects early and reduce waste.

- Final Quality Control (FQC): A comprehensive examination of the finished product before shipment, ensuring it meets all specifications and standards.

Common Testing Methods

Quality assurance involves various testing methods to verify product performance:

- Durability Testing: Assessing the product’s lifespan under simulated use conditions.

- Safety Testing: Ensuring compliance with electrical safety standards and testing for emissions, especially for gasoline-powered models.

- Noise Level Testing: Measuring operational noise to comply with regulations in different regions.

Verifying Supplier Quality Control

For international B2B buyers, verifying a supplier’s quality control measures is essential. Here are practical steps to ensure supplier reliability:

-

Conduct Audits: Perform on-site audits to assess the manufacturing processes and quality assurance practices. This provides firsthand insight into their operations.

-

Request Quality Reports: Ask suppliers for detailed quality assurance reports, including data on defect rates, testing outcomes, and compliance with standards.

-

Engage Third-Party Inspectors: Utilize third-party inspection services to evaluate product quality before shipment. This can mitigate risks associated with receiving substandard products.

Navigating QC and Certification Nuances

B2B buyers from regions such as Africa, South America, the Middle East, and Europe must be aware of the nuances in quality control and certification. Different countries may have specific regulatory requirements, so understanding local laws is vital.

-

Regional Compliance: Ensure that the products comply with local regulations and standards. For instance, certain African countries may have specific emissions standards that differ from those in Europe.

-

Cultural Considerations: Recognize that business practices and expectations may vary by region. Building strong relationships with suppliers can facilitate better communication and understanding of quality expectations.

-

Documentation: Maintain thorough documentation of all quality assurance processes, certifications, and inspections. This will facilitate smoother transactions and compliance with international trade regulations.

In conclusion, an in-depth understanding of the manufacturing processes and quality assurance protocols for backpack weed eaters is essential for international B2B buyers. By focusing on material quality, manufacturing techniques, and rigorous quality control measures, buyers can make informed decisions, ensuring they procure reliable and compliant products for their markets.

Related Video: How a Backpack is Made : Every Step on the Production Line

Comprehensive Cost and Pricing Analysis for backpack weed eater Sourcing

When sourcing backpack weed eaters, understanding the cost structure and pricing dynamics is essential for international B2B buyers. This section provides an in-depth analysis of the various cost components, price influencers, and practical tips for negotiating the best deals.

Cost Components

-

Materials: The primary materials used in backpack weed eaters include high-quality plastics, metals for the frame and cutting components, and durable rubber for grips. Sourcing materials locally can reduce costs, but importing high-quality components may be necessary for performance and durability.

-

Labor: Labor costs vary significantly based on the manufacturing location. Regions with lower labor costs, such as parts of Africa and South America, may offer competitive pricing. However, the skill level of the workforce can influence product quality, so it’s important to balance cost and expertise.

-

Manufacturing Overhead: This includes expenses such as utilities, rent, and administrative costs associated with production. Buyers should inquire about the supplier’s overhead costs, as they can influence the final pricing.

-

Tooling: Initial investment in tooling for production can be substantial. Custom tooling for specific designs can add to the initial costs but may provide long-term savings through efficiency and reduced defects.

-

Quality Control (QC): Investing in quality control processes ensures that the products meet international standards. This is particularly crucial for buyers in Europe and the Middle East, where regulatory compliance is stringent.

-

Logistics: Shipping costs, including freight, customs duties, and insurance, can significantly impact the total cost. Buyers should evaluate different Incoterms (International Commercial Terms) to determine who bears these costs and consider local logistics options to minimize expenses.

-

Margin: Manufacturers typically add a profit margin to cover their costs and ensure sustainability. Understanding the industry standard margins can provide insight into the pricing structure and help in negotiations.

Price Influencers

Several factors can influence the pricing of backpack weed eaters:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs. Buyers should consider their immediate needs and future demand to negotiate favorable pricing.

-

Specifications/Customization: Customized features, such as engine size or additional attachments, can increase costs. Clear specifications can streamline the manufacturing process and mitigate unexpected expenses.

-

Materials and Quality/Certifications: Higher quality materials and certifications (e.g., ISO, CE) can command premium prices. Buyers should assess the importance of these factors against their budget and intended use.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with a proven track record may charge higher prices, but they often provide better quality assurance and support.

-

Incoterms: The choice of Incoterms affects the total landed cost. For instance, using DDP (Delivered Duty Paid) terms means the supplier handles all shipping and customs costs, simplifying the buying process for the buyer.

Buyer Tips

-

Negotiation: Buyers should leverage their knowledge of market prices and cost structures during negotiations. Highlighting potential long-term partnerships can also incentivize suppliers to offer better pricing.

-

Cost Efficiency: Evaluate the Total Cost of Ownership (TCO), including maintenance and operational costs. A cheaper upfront price may result in higher long-term costs if the product is less durable or requires more maintenance.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import tariffs, and regional market trends that can influence pricing.

-

Disclaimer for Indicative Prices: Prices in the industry can fluctuate based on various factors, including raw material costs and geopolitical influences. Always request updated quotes and consider potential changes in pricing before finalizing orders.

By understanding these cost components and pricing influencers, international B2B buyers can make informed decisions when sourcing backpack weed eaters, ensuring they achieve the best value for their investment.

Spotlight on Potential backpack weed eater Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘backpack weed eater’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for backpack weed eater

When considering the purchase of a backpack weed eater, understanding its essential technical properties and trade terminology is vital for making informed decisions. This section outlines critical specifications and common industry terms that can significantly impact purchasing choices for international B2B buyers.

Key Technical Properties

-

Engine Type and Power Output

– Definition: Backpack weed eaters typically feature two-stroke or four-stroke engines. Power output is measured in horsepower (HP) or cubic centimeters (CC).

– B2B Importance: The engine type affects fuel efficiency, performance, and maintenance requirements. A higher CC generally indicates more power, which is crucial for commercial users requiring robust performance. -

Cutting Width

– Definition: This refers to the diameter of the cutting area, usually ranging from 12 to 30 inches.

– B2B Importance: A wider cutting width allows for more efficient weed clearing, reducing the time spent on tasks. For businesses, this translates to increased productivity and reduced labor costs. -

Weight and Ergonomics

– Definition: The weight of the unit impacts user comfort, typically ranging from 10 to 15 kg. Ergonomic features include padded straps and back support.

– B2B Importance: Lightweight models reduce fatigue during prolonged use, essential for commercial landscapers. Investing in ergonomic designs can lead to better employee satisfaction and efficiency. -

Fuel Tank Capacity

– Definition: Measured in liters, this indicates how much fuel the weed eater can hold.

– B2B Importance: Larger fuel tanks enable longer operational periods without refueling, crucial for businesses managing extensive landscaping projects. This can enhance productivity and minimize downtime. -

Durability and Material Grade

– Definition: Backpack weed eaters are often constructed from high-grade plastics or aluminum, affecting their longevity and resistance to wear.

– B2B Importance: Higher material grades ensure durability, reducing replacement costs and maintenance needs. This is particularly relevant for businesses operating in challenging environments.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships can help buyers identify quality parts and potential warranty issues. It also informs negotiations on pricing and product availability. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Knowing the MOQ is crucial for budgeting and inventory management. Buyers should negotiate MOQs to align with their operational needs without overcommitting capital. -

RFQ (Request for Quotation)

– Definition: A document used to invite suppliers to submit price quotes for a specific product or service.

– Relevance: RFQs streamline the purchasing process, allowing buyers to compare costs and services effectively. This is especially important for large-scale orders typical in B2B transactions. -

Incoterms (International Commercial Terms)

– Definition: A set of international rules that define the responsibilities of sellers and buyers in shipping contracts.

– Relevance: Understanding Incoterms is essential for managing shipping costs and responsibilities, especially for international buyers. It helps clarify who is liable for shipping, insurance, and customs duties. -

Warranty and After-Sales Support

– Definition: Warranty refers to the manufacturer’s guarantee covering repairs or replacements, while after-sales support includes services provided post-purchase.

– Relevance: A comprehensive warranty and robust after-sales support are critical for minimizing operational disruptions. Buyers should assess these factors to ensure long-term satisfaction and reliability.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring they select the right backpack weed eater to meet their operational needs while optimizing costs and efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the backpack weed eater Sector

Market Overview & Key Trends

The backpack weed eater market is experiencing significant growth, driven by various global factors. As landscaping and agricultural sectors expand, there is an increasing demand for efficient and user-friendly outdoor power equipment. Notably, the rise of urban gardening and landscaping in regions like Europe and the Middle East has led to a heightened interest in versatile tools that can handle diverse vegetation types.

Emerging B2B tech trends, such as electrification and the integration of smart technologies, are reshaping the landscape for backpack weed eaters. Manufacturers are focusing on developing battery-powered models that deliver comparable performance to their gasoline counterparts while minimizing emissions and noise pollution. This shift is particularly relevant for international buyers seeking eco-friendly solutions, as regulations around emissions are becoming stricter globally.

Moreover, the adoption of IoT technology in outdoor power equipment is gaining traction. Buyers are now looking for models equipped with features like GPS tracking and mobile app connectivity, which enhance operational efficiency and ease of use. This demand for innovation is compelling manufacturers to invest in research and development, ensuring they remain competitive in a rapidly evolving market.

International B2B buyers from regions such as Africa and South America are also increasingly interested in sourcing products that meet local agricultural needs while adhering to global standards. The ability to customize equipment for specific regional uses—like adapting to different terrains and vegetation—can provide a significant competitive edge.

Sustainability & Ethical Sourcing in B2B

In today’s market, sustainability is not just a trend; it is a fundamental expectation. The environmental impact of landscaping equipment, including backpack weed eaters, is under scrutiny as consumers and businesses alike become more environmentally conscious. B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices.

Ethical supply chains are critical in this context. Buyers should seek manufacturers who source materials responsibly and adhere to labor standards that protect workers’ rights. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a company’s commitment to sustainability and ethical practices.

Using eco-friendly materials in the production of backpack weed eaters is also essential. Buyers should look for products made from recyclable or biodegradable components, as well as those that utilize green manufacturing processes. This not only helps reduce environmental impact but also aligns with the values of consumers who prefer to support brands that prioritize sustainability.

Brief Evolution/History

The evolution of backpack weed eaters can be traced back to the increasing need for efficient landscaping tools in the mid-20th century. Originally designed for agricultural use, these devices have transformed significantly, with advances in technology leading to lighter, more powerful, and user-friendly designs.

Over the years, the introduction of battery-powered models has marked a pivotal shift in the industry. These innovations cater to growing environmental concerns and meet the demands of both professional landscapers and homeowners. As the market continues to evolve, the focus on sustainability and smart technology integration is likely to shape the future of backpack weed eaters, making them essential tools for modern landscaping and agricultural practices.

In summary, international B2B buyers should be aware of these market dynamics and trends to make informed purchasing decisions that align with their business objectives and sustainability goals.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of backpack weed eater

-

What should I consider when vetting suppliers for backpack weed eaters?

When vetting suppliers, focus on their reputation, experience, and compliance with international standards. Check for certifications such as ISO 9001 for quality management and ISO 14001 for environmental management. Request references from previous clients and assess their production capacity to ensure they can meet your demands. Additionally, evaluate their communication and responsiveness, as this is crucial for maintaining a smooth business relationship. -

Can I customize the backpack weed eater according to my needs?

Yes, many suppliers offer customization options for backpack weed eaters, including adjustments in design, color, and features tailored to specific markets. Discuss your requirements upfront and inquire about the supplier’s ability to accommodate these changes. Be aware that customization may impact lead times and minimum order quantities (MOQs), so ensure you understand any implications for your order. -

What are the typical lead times and minimum order quantities (MOQs) for backpack weed eaters?

Lead times for backpack weed eaters can vary based on the supplier and order size, typically ranging from 4 to 12 weeks. Smaller orders may be subject to higher unit prices due to MOQs, which can range from 50 to 100 units, depending on the manufacturer. It’s essential to negotiate these terms during initial discussions and consider your inventory needs to avoid stockouts or overstock situations. -

What payment terms are usually offered by suppliers?

Payment terms can vary widely, but common options include upfront payments, partial payments upon order confirmation, or payment on delivery. Many suppliers prefer letters of credit or escrow services for larger orders, providing security for both parties. Always clarify the payment terms before finalizing the deal, and ensure that you understand the implications of the chosen method on your cash flow.

Illustrative Image (Source: Google Search)

-

How do I ensure quality assurance and certifications for backpack weed eaters?

Request detailed information on the supplier’s quality assurance processes, including any relevant certifications such as CE marking for compliance with EU standards or other local regulations. Conduct factory audits if possible, or rely on third-party inspection services to verify product quality. Additionally, ask for samples before placing a large order to evaluate the product’s performance and durability firsthand. -

What logistics considerations should I keep in mind when importing backpack weed eaters?

Consider the shipping method (air freight vs. sea freight) based on your budget and urgency. Evaluate the supplier’s ability to manage logistics and whether they offer assistance with customs clearance and documentation. Be aware of import duties and taxes in your country, as these can significantly impact the total cost. Establishing a reliable logistics partner can streamline the process and mitigate potential delays.

Illustrative Image (Source: Google Search)

-

How can I handle disputes or issues with suppliers?

Establish clear terms and conditions in your contract to address potential disputes, including a defined process for conflict resolution. Maintain open communication with your supplier to resolve issues promptly. If disputes arise, consider mediation or arbitration as a cost-effective alternative to litigation. Document all correspondence and agreements to support your position if formal action becomes necessary. -

What are the key factors influencing the price of backpack weed eaters?

The price of backpack weed eaters is influenced by several factors, including material quality, technology used (e.g., battery-powered vs. gas), customization options, and production scale. Global market trends, such as demand for eco-friendly products and currency fluctuations, can also impact pricing. Stay informed about industry developments and compare prices from multiple suppliers to ensure you receive a competitive offer.

Strategic Sourcing Conclusion and Outlook for backpack weed eater

In the rapidly evolving market for backpack weed eaters, strategic sourcing has emerged as a crucial component for international B2B buyers aiming to enhance operational efficiency and sustainability. The integration of battery-powered technologies and smart features not only aligns with global environmental standards but also meets the growing demand for low-emission equipment across diverse markets, including Africa, South America, the Middle East, and Europe.

Buyers should prioritize supplier reliability, after-sales support, and product customization to cater to specific regional needs. Understanding local regulations and preferences will facilitate better product selection and ensure compliance, ultimately leading to improved customer satisfaction and loyalty.

As we look to the future, embracing innovations in outdoor power equipment will be key to maintaining a competitive edge. By investing in sustainable solutions and leveraging technology, B2B buyers can significantly enhance their service offerings while reducing their environmental footprint.

Illustrative Image (Source: Google Search)

Now is the time to act. Assess your sourcing strategies, explore partnerships with innovative manufacturers, and position your business at the forefront of this dynamic industry. Together, we can cultivate a greener future in landscape management.