Your Ultimate Guide to Sourcing Backpack Patterns To Sew

Guide to Backpack Patterns To Sew Free

- Introduction: Navigating the Global Market for backpack patterns to sew free

- Understanding backpack patterns to sew free Types and Variations

- Key Industrial Applications of backpack patterns to sew free

- Strategic Material Selection Guide for backpack patterns to sew free

- In-depth Look: Manufacturing Processes and Quality Assurance for backpack patterns to sew free

- Comprehensive Cost and Pricing Analysis for backpack patterns to sew free Sourcing

- Spotlight on Potential backpack patterns to sew free Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for backpack patterns to sew free

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the backpack patterns to sew free Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of backpack patterns to sew free

- Strategic Sourcing Conclusion and Outlook for backpack patterns to sew free

Introduction: Navigating the Global Market for backpack patterns to sew free

Navigating the global market for backpack patterns to sew free offers a unique opportunity for B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. As the demand for customizable and sustainable products rises, understanding the nuances of backpack patterns becomes essential for competitive sourcing. These patterns not only cater to diverse consumer preferences but also allow for innovative design solutions that can differentiate your offerings in the marketplace.

This comprehensive guide delves into various types of backpack patterns, from simple canvas designs to multifunctional models suitable for diverse applications. It outlines essential materials, ensuring you are well-informed about quality and sustainability options. The guide also addresses manufacturing processes and quality control standards, which are critical for maintaining product integrity and meeting international regulations.

Additionally, we provide insights into supplier networks, cost considerations, and market trends that shape the global landscape for backpack patterns. By addressing frequently asked questions, this resource empowers buyers to make informed sourcing decisions, aligning with their strategic goals.

Whether you’re a small-scale manufacturer or a larger enterprise, understanding the dynamics of backpack patterns will enhance your ability to meet market demands effectively while promoting creativity and sustainability.

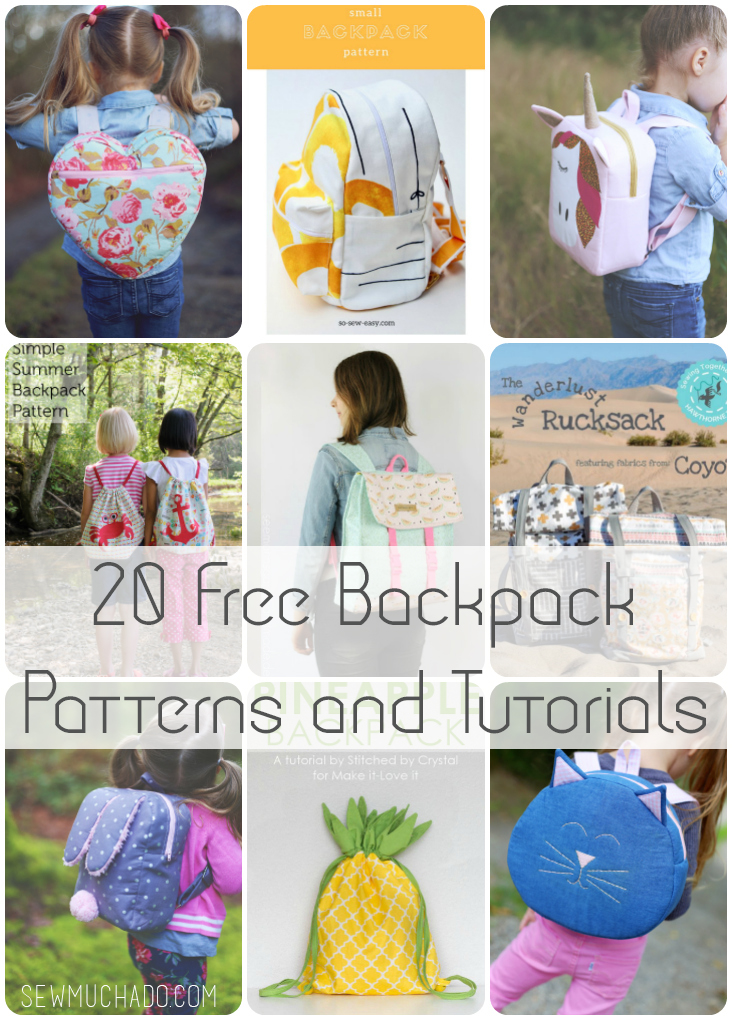

Understanding backpack patterns to sew free Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Simple Canvas Backpack | Made from durable cotton canvas, beginner-friendly design | Education, outdoor activities | Pros: Cost-effective, customizable; Cons: Limited waterproofing without additional treatment. |

| 2-in-1 Book Bag | Versatile design that converts between a backpack and tote | Retail, educational institutions | Pros: Multi-functional, appealing to diverse markets; Cons: May require more complex manufacturing. |

| Drawstring Backpack | Lightweight, easy to fold, and carry; simple closure system | Sports events, giveaways | Pros: Inexpensive, easy to produce; Cons: Less secure for valuable items. |

| Laptop Backpack | Padded compartments for electronics, ergonomic design | Corporate, educational sectors | Pros: High demand, tailored for tech users; Cons: Potentially higher production costs. |

| Hiking Backpack | Specialized compartments, rugged materials, and adjustable straps | Outdoor recreation, travel agencies | Pros: High durability, tailored for specific use; Cons: Higher complexity in design and production. |

Simple Canvas Backpack

The Simple Canvas Backpack is a staple for many businesses due to its durable construction and ease of customization. Typically made from 10oz cotton canvas, this backpack is ideal for educational institutions and outdoor activities. B2B buyers should consider the cost-effectiveness of this design, which allows for branding opportunities through screen printing or embroidery. However, it’s essential to note that while it is sturdy, it may require additional treatments for waterproofing, which could increase overall costs.

2-in-1 Book Bag

The 2-in-1 Book Bag is a versatile option that can transform from a backpack to a tote, catering to a wider audience, including students and retail customers. This adaptability makes it a valuable product for businesses focused on sustainability and multi-functionality. When considering this type, B2B buyers should evaluate the manufacturing complexity and potential pricing implications. The appeal of a dual-purpose bag can justify higher retail prices, making it an attractive option for educational institutions and retail shops.

Drawstring Backpack

Lightweight and easy to produce, the Drawstring Backpack is a popular choice for sporting events and promotional giveaways. Its simple design and minimal materials result in low production costs, making it an excellent option for bulk orders. However, B2B buyers should be mindful of its limitations, particularly regarding security for valuable items, as the drawstring closure does not provide the same level of protection as zippers or clasps. This factor is crucial for businesses targeting customers who prioritize security.

Laptop Backpack

The Laptop Backpack is tailored for modern professionals and students who carry electronic devices. With padded compartments and ergonomic designs, these backpacks are in high demand within corporate and educational sectors. B2B buyers should assess the market’s growing emphasis on tech-friendly products, as this can lead to higher sales volumes. However, the production costs may be higher due to the need for specialized materials and features, which should be factored into pricing strategies.

Hiking Backpack

Designed for outdoor enthusiasts, the Hiking Backpack features rugged materials and specialized compartments for gear. This type is ideal for businesses in the outdoor recreation industry and travel agencies. B2B buyers should consider the growing trend of eco-friendly materials and innovative designs that enhance user experience. While the complexity of design and production may increase costs, the potential for higher margins in niche markets makes it a worthwhile investment for companies focusing on outdoor activities.

Related Video: How to sew a handmade backpack easily!

Key Industrial Applications of backpack patterns to sew free

| Industry/Sector | Specific Application of backpack patterns to sew free | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Education | Customizable student backpacks | Increased student engagement and brand loyalty | Durability of materials, design adaptability, cost efficiency |

| Outdoor Recreation | Adventure and travel backpacks | Enhanced customer experience and brand differentiation | Weather resistance, ergonomic design, lightweight materials |

| Fashion & Retail | Trendy fashion backpacks | Ability to tap into emerging fashion trends | Fabric variety, trend alignment, production scalability |

| Non-profit Organizations | Backpacks for community programs | Support for local initiatives and brand visibility | Cost-effective materials, community impact, ethical sourcing |

| Corporate Gifts | Branded employee backpacks | Strengthening brand identity and employee morale | Customization options, quality assurance, lead time for production |

Education

In the educational sector, backpack patterns to sew free can be utilized to create customizable student backpacks. These backpacks can incorporate school colors, logos, and designs that resonate with students, thereby increasing engagement and loyalty. International B2B buyers in this sector must consider the durability of the materials used, as backpacks are subjected to daily wear and tear. Additionally, adaptability in design is crucial to accommodate various age groups and preferences, while cost efficiency remains a priority for budget-conscious institutions.

Outdoor Recreation

For outdoor recreation businesses, sewing free backpack patterns allows for the creation of specialized adventure and travel backpacks. These bags can be designed for specific activities, such as hiking or camping, providing features like weather resistance and ergonomic support. B2B buyers in this market should focus on lightweight materials that do not compromise durability, as well as ensuring that the design meets the functional needs of their target audience. The unique selling proposition lies in enhancing customer experiences through tailored solutions.

Fashion & Retail

In the fashion and retail industry, backpack patterns to sew free enable brands to produce trendy and stylish backpacks that cater to current fashion trends. This application allows businesses to quickly adapt to changing consumer preferences and create limited-edition items. Key considerations for B2B buyers include the variety of fabrics available, alignment with fashion trends, and the scalability of production to meet demand. By leveraging these patterns, businesses can enhance brand appeal and attract a broader customer base.

Non-profit Organizations

Non-profit organizations can utilize backpack patterns to sew free for community programs, such as providing backpacks to underprivileged children. This application not only supports local initiatives but also enhances brand visibility for the organization. Buyers in this sector should prioritize cost-effective materials while ensuring that the production process has a positive community impact. Ethical sourcing is essential, as it aligns with the values of many non-profit organizations and their stakeholders.

Corporate Gifts

In the corporate gifting sector, businesses can leverage backpack patterns to sew free to create branded employee backpacks. These gifts can serve as a practical tool for employees while reinforcing brand identity and boosting morale. B2B buyers should consider customization options to reflect the company’s branding, alongside quality assurance to ensure that the products are durable and appealing. Timely lead times for production are also critical to meet gifting schedules, especially during holidays or special events.

Related Video: DIY LOVELY BACKPACK TUTORIAL // Zipper Backpack with Pocket From Scratch Cut & Sew

Strategic Material Selection Guide for backpack patterns to sew free

When selecting materials for sewing backpack patterns, international B2B buyers should consider a range of factors including durability, cost, and suitability for specific applications. Here, we analyze four common materials used in backpack production: Cotton Canvas, Nylon, Polyester, and Leather. Each material has unique properties and implications for manufacturing and end-use.

Cotton Canvas

Key Properties: Cotton canvas is a robust, breathable fabric that offers good resistance to wear and tear. It typically has a temperature rating suitable for a wide range of climates, making it versatile for various regions.

Pros & Cons: This material is durable and can withstand heavy use, making it ideal for backpacks. However, it can be heavier than synthetic alternatives and may require additional treatments for water resistance. The manufacturing complexity is moderate, as it can be easily sewn and printed on.

Impact on Application: Cotton canvas is particularly compatible with eco-friendly branding, appealing to consumers in markets that prioritize sustainability. However, it may not perform well in extremely wet conditions unless treated.

Considerations for International Buyers: Buyers should ensure compliance with local textile standards, such as OEKO-TEX certification for harmful substances. In regions like Europe and parts of Africa, sustainable sourcing can influence purchasing decisions.

Nylon

Key Properties: Nylon is a synthetic fabric known for its high tensile strength and excellent abrasion resistance. It has a low moisture absorption rate, making it suitable for various environmental conditions.

Pros & Cons: The lightweight nature of nylon makes it a popular choice for outdoor and travel backpacks. However, it can be more expensive than cotton and may not be as breathable. Manufacturing nylon can be complex due to the need for specialized equipment.

Impact on Application: Nylon is particularly effective in applications requiring water resistance, such as hiking or travel backpacks. Its compatibility with various coatings enhances its performance in wet conditions.

Considerations for International Buyers: Buyers should be aware of the environmental impact of nylon production and look for suppliers who adhere to sustainability practices. Compliance with ASTM or ISO standards for textile performance may also be necessary.

Polyester

Key Properties: Polyester is another synthetic option that offers good strength and durability. It is resistant to shrinking and stretching, maintaining its shape over time.

Pros & Cons: Polyester is often more affordable than nylon and is easier to dye, allowing for vibrant colors and patterns. However, it can be less durable under heavy use compared to nylon and may not provide the same level of water resistance without additional treatments.

Impact on Application: Polyester is suitable for everyday backpacks and school bags, where aesthetics are important. It is also compatible with various printing techniques, enhancing branding opportunities.

Considerations for International Buyers: Polyester production can vary widely in quality, so buyers should verify the grade of polyester used. Compliance with local regulations regarding synthetic materials is crucial, especially in regions with strict environmental laws.

Leather

Key Properties: Leather is a natural material known for its durability and aesthetic appeal. It offers excellent abrasion resistance and can withstand significant wear.

Pros & Cons: While leather provides a premium look and feel, it can be heavy and requires regular maintenance to prevent drying and cracking. The manufacturing process is more complex and often involves higher costs.

Impact on Application: Leather is ideal for high-end backpacks aimed at fashion-conscious consumers. It is less suitable for rugged outdoor use unless treated for water resistance.

Considerations for International Buyers: Buyers should ensure that leather products comply with local animal welfare and environmental regulations. In markets like Europe, certifications such as Leather Working Group (LWG) can enhance product credibility.

| Material | Typical Use Case for backpack patterns to sew free | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cotton Canvas | Everyday carry, eco-friendly backpacks | Durable, customizable | Heavier, may require water treatment | Medium |

| Nylon | Outdoor, travel backpacks | Lightweight, abrasion-resistant | More expensive, complex manufacturing | High |

| Polyester | Everyday, school bags | Affordable, vibrant colors | Less durable than nylon, may need treatment | Low |

| Leather | High-end fashion backpacks | Premium look, durable | Heavy, requires maintenance | High |

This guide provides a comprehensive overview of materials suitable for sewing backpack patterns, helping international B2B buyers make informed decisions based on performance, cost, and market preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for backpack patterns to sew free

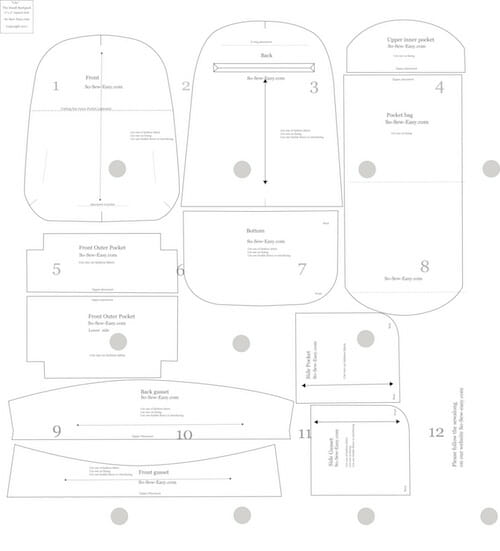

Manufacturing Processes for Backpack Patterns

When sourcing backpack patterns for sewing, understanding the manufacturing processes involved is crucial for B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe. This section outlines the key stages in the manufacturing of backpack patterns, alongside the quality assurance processes that ensure product reliability and safety.

Material Preparation

The first step in manufacturing backpack patterns involves selecting and preparing materials. Common materials include:

- Canvas Fabric: Often made from cotton or synthetic fibers, canvas is durable and suitable for various backpack styles.

- Webbing: Used for straps and handles, typically made from nylon or polyester for added strength.

- Zippers and Fasteners: Essential for functionality, these components must meet specific durability standards.

Buyers should verify the source and quality of these materials, ensuring they are compliant with international standards, such as those set by the OEKO-TEX® certification for textiles.

Forming

Once materials are prepared, the next step is forming. This involves:

- Cutting: Precision cutting of fabric according to the backpack pattern is crucial. Automated cutting machines can enhance accuracy and reduce waste.

- Printing Patterns: For custom designs, digital printing may be employed to apply patterns directly onto fabric.

B2B buyers should inquire about the technology used for cutting and printing, as these can significantly impact the final product’s quality.

Assembly

Assembly is where the backpack components come together. Key techniques include:

- Sewing: Various stitching methods are used, including straight, zigzag, and reinforced stitching, to ensure durability.

- Attaching Hardware: This step involves securely affixing zippers, straps, and other hardware to the main fabric.

Quality control during assembly is vital; manufacturers should have trained staff to handle machinery and ensure consistent stitching quality.

Finishing

The final stage of manufacturing is finishing, which involves:

- Trimming: Removing excess threads and ensuring the backpack has a polished look.

- Final Inspection: Conducting a thorough inspection of the finished product to check for defects, functionality, and overall appearance.

Buyers should request information about the finishing processes and any additional treatments, such as water resistance, which can enhance product longevity.

Quality Assurance Practices

Quality assurance (QA) is integral to ensuring that the final products meet the required standards. B2B buyers should be familiar with the following QA practices:

International Standards

- ISO 9001: This standard outlines the criteria for a quality management system (QMS). Manufacturers adhering to ISO 9001 demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

- CE Marking: Relevant for products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

Understanding these certifications can help buyers assess the reliability of their suppliers.

Quality Control Checkpoints

Quality control should encompass several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to catch defects early.

- Final Quality Control (FQC): A comprehensive examination of the finished product before shipment.

Each checkpoint plays a critical role in maintaining product quality, and buyers should request documentation of these inspections.

Common Testing Methods

Testing methods can vary, but typical approaches include:

- Tensile Strength Tests: Assessing the strength of seams and straps to ensure they can withstand expected loads.

- Water Resistance Tests: Evaluating the effectiveness of water-repellent treatments.

- Color Fastness Tests: Ensuring that colors do not fade or bleed under various conditions.

Buyers should inquire about the specific tests performed on their products and request certification of compliance.

Verifying Supplier Quality Control

To ensure that suppliers maintain rigorous quality control practices, B2B buyers should consider the following methods:

-

Supplier Audits: Regular audits can help verify that manufacturers adhere to quality standards. Buyers should schedule these audits periodically or request third-party audits for an objective assessment.

-

Quality Control Reports: Request detailed reports that outline the results of IQC, IPQC, and FQC. These documents can provide insight into the manufacturer’s quality processes.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide additional assurance of product quality before shipment, especially for international orders.

QC and Certification Nuances for International Buyers

For international buyers, particularly those from regions like Africa and South America, understanding the nuances of quality control and certification is critical:

- Import Regulations: Be aware of import regulations in your country regarding textile and consumer goods. Non-compliance can lead to delays and increased costs.

- Cultural Considerations: Different regions may have varying expectations regarding quality standards. Open communication with suppliers about these expectations can help bridge gaps.

- Local Certifications: Some regions may have specific local certifications. Understanding these can provide additional assurance of product quality.

Conclusion

Manufacturing backpack patterns involves several critical stages, from material preparation to finishing, with quality assurance playing a pivotal role throughout the process. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding these processes and implementing rigorous quality checks can ensure the procurement of high-quality products that meet market demands. By leveraging international standards, conducting thorough supplier evaluations, and maintaining open communication, buyers can effectively navigate the complexities of sourcing backpack patterns for sewing.

Comprehensive Cost and Pricing Analysis for backpack patterns to sew free Sourcing

When considering the sourcing of backpack patterns for sewing, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers. This analysis will break down the key cost components, price influencers, and provide actionable buyer tips tailored for markets in Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary cost driver is the selection of materials. For instance, high-quality cotton canvas can range from $5 to $15 per yard, depending on its weight and durability. Additional materials such as zippers, straps, and embellishments will add to this base cost.

-

Labor: Labor costs vary significantly by region. In countries with lower wage standards, such as parts of Africa or South America, the labor cost per hour can be considerably less than in Europe. It’s crucial to factor in the skill level required for sewing, as more complex designs will necessitate higher wages.

-

Manufacturing Overhead: This includes costs related to the facilities, utilities, and indirect labor. Depending on the production scale, overhead can significantly influence the total price. For larger volumes, overhead costs per unit typically decrease.

-

Tooling: If custom tooling is required for unique designs, this can represent a substantial upfront investment. The costs will depend on the complexity of the tooling required and can range from hundreds to thousands of dollars.

-

Quality Control (QC): Implementing quality control processes ensures that the final products meet specified standards. This may involve additional labor and material costs, particularly if samples need to be produced and tested.

Illustrative Image (Source: Google Search)

-

Logistics: Shipping costs, customs duties, and storage fees should be factored in. The choice of shipping method (air vs. sea) and the distance to the buyer’s location will greatly affect these costs.

-

Margin: Suppliers will typically include a profit margin of 10-30% on top of the total costs incurred, depending on market conditions and competition.

Price Influencers

-

Volume/MOQ: Larger order quantities often yield better pricing due to economies of scale. Minimum order quantities (MOQ) can vary by supplier, so negotiating these terms is vital.

-

Specifications/Customization: Custom designs or specifications can lead to higher costs due to the need for specialized materials or additional labor. Be clear about your design needs to avoid unexpected costs.

-

Materials Quality/Certifications: Premium materials and certifications (e.g., eco-friendly or fair trade) can increase costs but may also provide a competitive advantage in the market.

-

Supplier Factors: Supplier reputation, experience, and reliability can influence pricing. Established suppliers may charge higher prices but offer better quality assurance and service.

-

Incoterms: Understanding the terms of shipment is crucial. Different Incoterms (e.g., FOB, CIF) can impact the overall landed cost of goods.

Buyer Tips

-

Negotiation: Always negotiate terms and pricing. Building a relationship with suppliers can lead to better deals and more favorable terms.

-

Cost Efficiency: Analyze all cost components to identify areas for potential savings. Consider bulk purchasing to reduce material costs.

-

Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider long-term costs, including shipping, storage, and any potential rework due to quality issues.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and international tariffs that can affect pricing. Utilize contracts that account for these variables to mitigate risks.

In conclusion, understanding the intricate cost structure and pricing influences associated with sourcing backpack patterns is crucial for B2B buyers. By being informed and proactive in negotiations, buyers can optimize their purchasing strategies and achieve better financial outcomes. Always remember that indicative prices can vary based on market conditions and specific supplier offerings, so continuous market research is vital for staying competitive.

Spotlight on Potential backpack patterns to sew free Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘backpack patterns to sew free’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for backpack patterns to sew free

Key Technical Properties for Backpack Patterns

When sourcing backpack patterns, understanding the essential technical properties is critical for ensuring quality, durability, and functionality. Here are some of the most important specifications to consider:

-

Material Grade

The choice of fabric significantly impacts the backpack’s performance. Common materials include canvas, nylon, and polyester. Canvas offers durability and a classic aesthetic, while nylon is lightweight and water-resistant. It’s crucial to assess the material’s weight (measured in ounces per square yard) to ensure it meets the intended use, whether for everyday carry or specialized outdoor activities. -

Stitch Tolerance

This refers to the acceptable range of stitch length and density used in the construction of the backpack. A tighter stitch can provide greater strength, particularly in high-stress areas like seams and straps. For B2B buyers, understanding the stitch tolerance ensures that the product can withstand the wear and tear of regular use, ultimately reducing return rates and increasing customer satisfaction. -

Load Capacity

Knowing the maximum weight the backpack can carry is essential for meeting consumer needs. Specifications should include both the recommended load and the maximum load, which helps in determining the suitability for different activities (e.g., school, hiking, or travel). This information can also guide your marketing strategies by targeting specific customer segments. -

Water Resistance

This property indicates how well the materials resist moisture. Buyers should look for patterns that specify water-resistant or waterproof coatings, such as polyurethane or silicone treatments. This feature is particularly valuable in regions prone to rain, enhancing the product’s appeal in markets such as Europe and South America. -

Dimensions and Volume

Standard backpack dimensions are crucial for ensuring a good fit for various uses. Specifications typically include height, width, depth, and volume (in liters). Understanding these measurements allows buyers to match their product offerings with market demands, catering to different demographics, from children to adults. -

Durability Rating

A durability rating, often based on tests such as abrasion resistance or tensile strength, provides insight into the longevity of the backpack. This is vital for B2B buyers to communicate to end-users the expected lifespan of the product, aiding in trust and brand loyalty.

Common Trade Terminology in the Backpack Industry

Familiarity with industry jargon can streamline communication and negotiations. Here are some key terms to know:

-

OEM (Original Equipment Manufacturer)

Refers to companies that manufacture products based on specifications provided by another company. For B2B buyers, sourcing from OEMs can lead to customized products that align with brand requirements. -

MOQ (Minimum Order Quantity)

This is the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory management, especially for smaller businesses that may not need large quantities. -

RFQ (Request for Quotation)

An RFQ is a document issued to suppliers to request pricing and terms for specific products. B2B buyers should use RFQs to ensure competitive pricing and to gather detailed information about suppliers’ capabilities. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Knowing Incoterms is essential for understanding shipping costs and liability, particularly when importing from manufacturers in different regions. -

Lead Time

This term refers to the amount of time it takes from placing an order to receiving the products. Understanding lead times helps businesses plan their inventory and sales strategies effectively. -

Customization Options

Many manufacturers offer customization for patterns, materials, or features. Being aware of these options allows B2B buyers to cater to specific market needs, enhancing product appeal and differentiation.

Illustrative Image (Source: Google Search)

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions that align with their business objectives and consumer demands.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the backpack patterns to sew free Sector

Market Overview & Key Trends

The market for backpack patterns to sew free is experiencing dynamic shifts driven by several global factors. First, there is a growing demand for customizable and DIY products, which allows buyers to cater to specific consumer preferences. This trend is particularly strong in regions such as Africa and South America, where local artisans and small businesses are increasingly engaging in personalized product offerings. Moreover, the rise of online platforms has simplified access to patterns and materials, facilitating a more extensive global marketplace.

Another significant driver is the shift towards sustainable manufacturing practices. International buyers are now prioritizing sourcing patterns that utilize eco-friendly materials and processes. Technologies such as digital pattern printing and automated cutting are also gaining traction, enabling manufacturers to reduce waste and enhance production efficiency. In Europe, particularly in Spain, there is a strong emphasis on artisanal quality and heritage, which is influencing the types of patterns that are popular.

Emerging markets in the Middle East are also showing a keen interest in innovative designs that blend traditional craftsmanship with modern aesthetics. The need for flexibility in sourcing is paramount, as buyers seek to navigate fluctuating costs and supply chain challenges. Companies that can adapt quickly to these changes, while offering a diverse range of backpack patterns, will find themselves at a competitive advantage.

Sustainability & Ethical Sourcing in B2B

Sustainability is a critical concern for international B2B buyers in the backpack patterns sector. The environmental impact of materials and manufacturing processes is under scrutiny, leading to an increased demand for ethical sourcing practices. Buyers are encouraged to seek suppliers who prioritize green certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX, which ensure that materials are produced with minimal environmental impact and without harmful substances.

Incorporating sustainable materials, such as recycled fabrics or organic cotton, not only aligns with ethical practices but also appeals to a growing consumer base that values responsible purchasing decisions. Furthermore, transparency in the supply chain is becoming essential; buyers should engage with manufacturers who can provide clear insights into their sourcing and production methods. This not only enhances brand reputation but also fosters trust and loyalty among consumers increasingly concerned about sustainability.

Illustrative Image (Source: Google Search)

Additionally, incorporating circular economy principles—whereby materials are reused and recycled—can significantly reduce waste and promote longevity in product offerings. By prioritizing sustainable practices, businesses can not only comply with regulations but also tap into a market that increasingly favors eco-friendly products.

Brief Evolution/History

The evolution of backpack patterns has been significantly influenced by changes in consumer preferences and technological advancements. Initially, backpack designs were primarily utilitarian, aimed at functionality and durability. However, as outdoor activities and travel became more popular, so did the demand for stylish and versatile designs.

With the advent of home sewing and DIY culture, particularly in the late 20th century, patterns for making personalized backpacks became widely accessible. The rise of the internet further democratized this access, allowing designers to share their patterns globally and fostering a community of makers. Today, the focus has shifted towards customization, sustainability, and ethical sourcing, reshaping the landscape of backpack patterns to sew free. As buyers become more discerning, the industry continues to evolve, adapting to meet both aesthetic and ethical expectations.

Related Video: How to sew a small backpack easily – a detailed tutorial!

Frequently Asked Questions (FAQs) for B2B Buyers of backpack patterns to sew free

-

What should I consider when vetting suppliers for backpack patterns?

When vetting suppliers, assess their experience in producing backpack patterns and check their portfolio for quality and variety. Look for reviews or testimonials from previous clients to gauge reliability and responsiveness. Additionally, verify their compliance with international trade regulations and standards. For international buyers, consider suppliers with experience in exporting to your region, as they will understand logistics and customs processes better. -

Can I customize backpack patterns to suit my brand?

Yes, many suppliers offer customization options for backpack patterns, which can include alterations to size, design elements, and fabric choices. Ensure to communicate your specific requirements clearly to the supplier. Request samples or prototypes to evaluate the customization quality before placing a larger order. This is crucial for maintaining brand identity and meeting customer expectations. -

What are the typical minimum order quantities (MOQs) for backpack patterns?

MOQs can vary widely depending on the supplier and the complexity of the patterns. Generally, suppliers may set MOQs ranging from 50 to 500 units. Discuss your needs with potential suppliers to see if they can accommodate smaller orders, especially if you are a new business. Be prepared for higher per-unit costs with lower quantities due to setup and production efficiencies. -

What are the average lead times for orders of backpack patterns?

Lead times can depend on several factors, including the supplier’s production capacity, the complexity of the patterns, and the quantity ordered. Typically, lead times can range from 2 to 8 weeks. For urgent needs, inquire about expedited services, but be aware that this may incur additional costs. Always establish clear timelines in your agreement to avoid misunderstandings. -

What quality assurance processes should I expect from suppliers?

Reputable suppliers should have established quality assurance (QA) processes in place, including material inspections, pattern accuracy checks, and final product assessments. Ask suppliers for certifications that demonstrate their commitment to quality, such as ISO certifications or compliance with safety standards relevant to your market. Additionally, request regular updates during production to ensure adherence to quality expectations. -

How should I handle payment terms with international suppliers?

When dealing with international suppliers, negotiate payment terms that protect both parties. Common practices include a deposit upfront (usually 30-50%) and the balance upon delivery or before shipping. Consider using secure payment methods such as letters of credit or escrow services for larger transactions. Be aware of currency exchange rates and potential fees associated with international transactions. -

What logistical considerations should I keep in mind when sourcing patterns?

Logistics play a crucial role in the sourcing process. Discuss shipping options with your supplier, including air vs. sea freight, and understand the associated costs and delivery times. Ensure your supplier can provide necessary shipping documents and facilitate customs clearance. It’s also wise to work with a freight forwarder who can help navigate international shipping complexities and reduce potential delays. -

What steps can I take to resolve disputes with suppliers?

To mitigate disputes, establish clear contracts outlining expectations, responsibilities, and procedures for handling issues. If a dispute arises, initiate communication with the supplier to address concerns directly and seek a resolution amicably. If necessary, refer to the contract for guidance on dispute resolution mechanisms, such as mediation or arbitration. Maintaining a professional relationship can often lead to a more favorable outcome for both parties.

Strategic Sourcing Conclusion and Outlook for backpack patterns to sew free

In summary, the strategic sourcing of free backpack patterns presents a unique opportunity for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. By leveraging these accessible resources, businesses can reduce production costs while maintaining high-quality standards. The growing trend of DIY and customization in the backpack market allows companies to cater to diverse consumer preferences, enhancing brand loyalty.

Key Takeaways:

- Cost Efficiency: Free patterns significantly lower initial investment, enabling businesses to allocate resources elsewhere.

- Customization Potential: Sourcing patterns allows for unique designs that resonate with local markets and consumer trends.

- Sustainability: Emphasizing local materials and craftsmanship can strengthen brand positioning in environmentally conscious markets.

As the global market continues to evolve, staying ahead requires agility and innovation. B2B buyers are encouraged to explore partnerships with local artisans and manufacturers to bring these patterns to life, fostering community engagement and economic growth. Embrace this opportunity to enhance your product offerings and differentiate your brand in a competitive landscape. The future of backpack manufacturing is here—are you ready to seize it?