Your Ultimate Guide to Sourcing Backpack Pattern’

Guide to Backpack Pattern’

- Introduction: Navigating the Global Market for backpack pattern’

- Understanding backpack pattern’ Types and Variations

- Key Industrial Applications of backpack pattern’

- Strategic Material Selection Guide for backpack pattern’

- In-depth Look: Manufacturing Processes and Quality Assurance for backpack pattern’

- Comprehensive Cost and Pricing Analysis for backpack pattern’ Sourcing

- Spotlight on Potential backpack pattern’ Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for backpack pattern’

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the backpack pattern’ Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of backpack pattern’

- Strategic Sourcing Conclusion and Outlook for backpack pattern’

Introduction: Navigating the Global Market for backpack pattern’

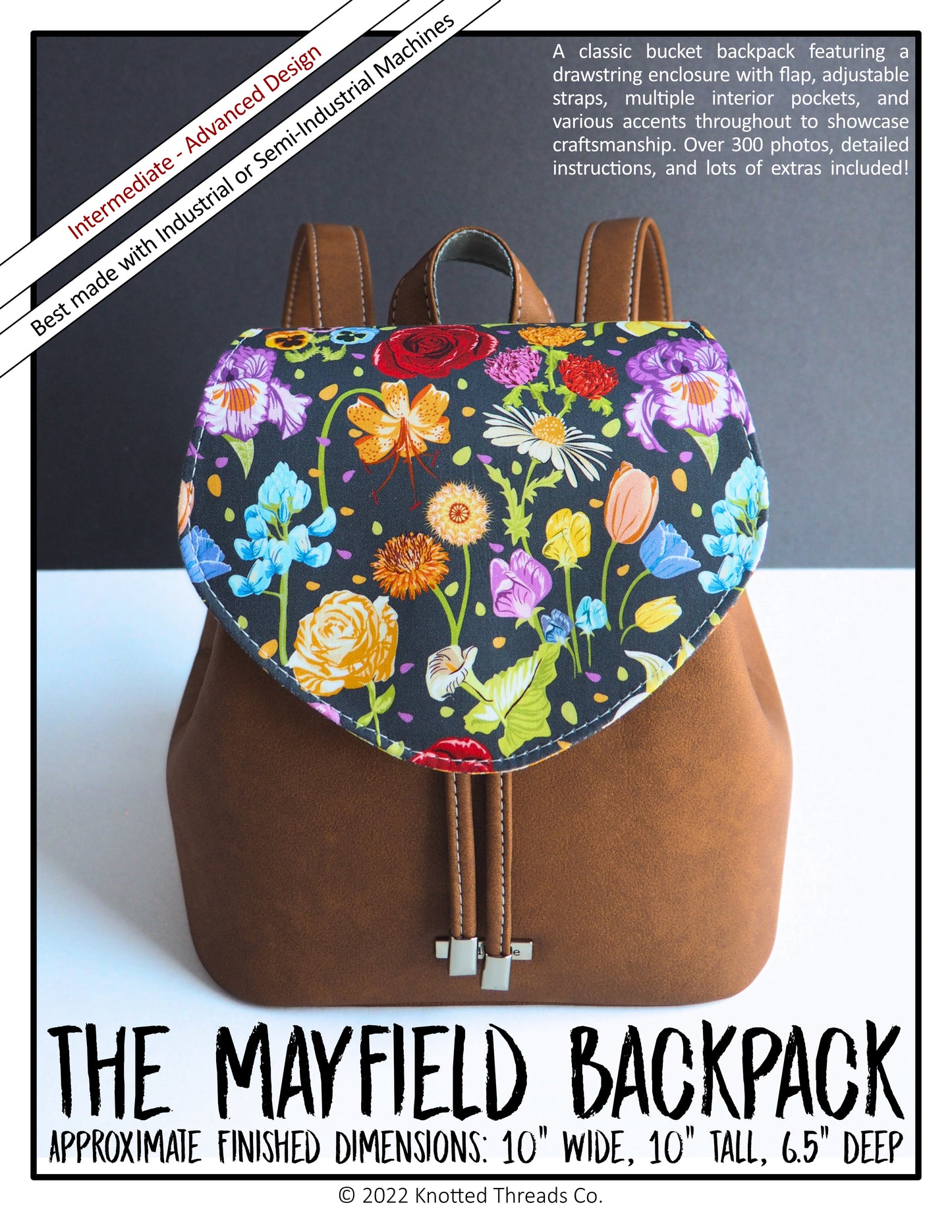

Navigating the global market for backpack patterns is essential for B2B buyers seeking to capitalize on the booming backpack industry. As consumer preferences shift towards unique, sustainable, and high-quality products, understanding the intricacies of backpack pattern development becomes crucial. The right pattern not only defines the aesthetics and functionality of a backpack but also plays a pivotal role in manufacturing efficiency, material selection, and ultimately, profitability.

This comprehensive guide will equip you with the knowledge needed to make informed sourcing decisions. We will delve into various types of backpack patterns, the best materials for different applications, and the critical manufacturing processes that ensure quality and durability. Additionally, we will explore supplier options, cost considerations, and current market trends, particularly relevant to buyers from Africa, South America, the Middle East, and Europe, including key markets like Brazil and Poland.

By leveraging the insights provided in this guide, B2B buyers can navigate potential pitfalls in sourcing, negotiate better deals, and align their products with consumer expectations. Whether you’re a startup looking to launch a custom line or an established brand seeking to enhance your offerings, understanding the nuances of backpack patterns will empower you to stand out in a competitive marketplace.

Understanding backpack pattern’ Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Daypack | Compact size, minimal features, designed for daily use | Education, urban commuting | Pros: Lightweight, easy to manufacture. Cons: Limited storage capacity. |

| Hiking Backpack | Enhanced durability, hydration reservoirs, and gear loops | Outdoor recreation, camping | Pros: High capacity, weather-resistant. Cons: Heavier and more complex design. |

| Laptop Backpack | Padded compartments for electronics, organizational pockets | Corporate, education | Pros: Protective, professional appearance. Cons: Can be bulky. |

| Travel Backpack | Versatile design, often with wheels and multiple compartments | Travel, tourism | Pros: Multi-functional, ample storage. Cons: More expensive due to features. |

| Eco-friendly Backpack | Made from sustainable materials, often with minimalistic design | Eco-conscious brands, outdoor activities | Pros: Appeals to eco-aware consumers. Cons: May have higher production costs. |

Daypack

Daypacks are characterized by their compact size and minimal features, making them ideal for daily use. They are often utilized in educational settings or for urban commuting. When considering purchasing daypacks, B2B buyers should focus on lightweight materials and manufacturing efficiency, as these factors contribute to lower costs and higher turnover rates. However, the limited storage capacity may not meet the needs of all users, particularly those requiring more extensive gear or supplies.

Hiking Backpack

Designed for outdoor enthusiasts, hiking backpacks are built with enhanced durability and often include features like hydration reservoirs and gear loops. Their primary applications include outdoor recreation and camping, where robust construction and high capacity are essential. B2B buyers should consider the weight and comfort of these backpacks, as they can significantly impact user experience during prolonged use. While hiking backpacks are generally more expensive due to their complex designs and materials, their longevity and functionality can justify the investment.

Laptop Backpack

Laptop backpacks feature padded compartments specifically designed to protect electronics, alongside various organizational pockets. These backpacks are primarily used in corporate and educational environments, where the protection of devices is paramount. Buyers should prioritize quality materials and ergonomic designs to ensure comfort for daily use. While they offer a professional appearance and protective features, their bulkiness can be a drawback for some consumers, potentially limiting their appeal in certain markets.

Travel Backpack

Travel backpacks are versatile, often equipped with wheels and multiple compartments for organization. They are ideal for the travel and tourism sectors, catering to the needs of frequent travelers. B2B buyers should evaluate the multifunctionality and storage capacity of these products, as they often need to accommodate a range of travel essentials. Although travel backpacks tend to be more expensive due to their features, their ability to serve multiple purposes can provide excellent value for businesses targeting the travel market.

Eco-friendly Backpack

Eco-friendly backpacks are constructed from sustainable materials and often feature minimalistic designs. They cater to eco-conscious brands and outdoor activities, appealing to consumers who prioritize environmental responsibility. When purchasing eco-friendly backpacks, B2B buyers should consider the sourcing of materials and production processes, as these can impact both costs and brand image. While the production costs may be higher, the growing demand for sustainable products can make these backpacks a lucrative investment for businesses looking to differentiate themselves in a competitive market.

Related Video: Large Language Models (LLMs) – Everything You NEED To Know

Key Industrial Applications of backpack pattern’

| Industry/Sector | Specific Application of backpack pattern | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Education | School backpacks for students | Enhanced brand visibility, customer loyalty | Material durability, safety certifications, design customization |

| Outdoor Recreation | Hiking and camping backpacks | Increased customer satisfaction, repeat purchases | Weather resistance, ergonomic design, weight considerations |

| Fashion & Retail | Fashion-forward backpacks | Differentiation in a competitive market | Trend alignment, material sourcing, branding options |

| Logistics & Distribution | Delivery and logistics backpacks | Improved efficiency in transportation of goods | Load capacity, compartmentalization, durability |

| Corporate & Promotional | Branded corporate backpacks | Enhanced brand recognition, employee satisfaction | Customization options, bulk order pricing, lead times |

Education

In the education sector, the backpack pattern is vital for creating school backpacks that are both functional and appealing to students. These bags often feature compartments for laptops, books, and personal items, addressing the need for organization and ease of access. International buyers must consider durability, safety certifications (like non-toxic materials), and design customization to cater to local preferences. In regions like Africa and South America, where school attendance is critical, investing in quality backpacks can significantly enhance brand loyalty among parents and students.

Outdoor Recreation

For the outdoor recreation industry, the backpack pattern is utilized in designing hiking and camping backpacks that withstand rugged use. These backpacks must be lightweight yet durable, with features like waterproofing and ergonomic straps to enhance user comfort during long treks. Buyers should prioritize sourcing materials that are both weather-resistant and eco-friendly, particularly as global consumers become more environmentally conscious. In Europe and the Middle East, where outdoor activities are popular, ensuring that products meet local outdoor standards can lead to increased customer satisfaction and brand loyalty.

Fashion & Retail

In the fashion industry, the backpack pattern is integral for creating stylish, trend-forward backpacks that appeal to fashion-conscious consumers. These products often feature unique designs and high-quality materials to stand out in a saturated market. For B2B buyers, aligning with current fashion trends and ensuring material sourcing reflects sustainability practices can enhance brand reputation. In regions like Brazil and Poland, where fashion trends rapidly evolve, manufacturers must be agile in their design and production processes to meet consumer demands.

Logistics & Distribution

The logistics and distribution sector leverages the backpack pattern for creating specialized backpacks designed for transporting goods efficiently. These backpacks often feature multiple compartments to organize tools or supplies, enhancing operational efficiency. Buyers in this sector should focus on durability and load capacity while sourcing, as well as the ability to customize designs to fit specific logistical needs. In markets across Africa and South America, where supply chain solutions are critical, investing in high-quality backpacks can streamline operations and improve service delivery.

Corporate & Promotional

In the corporate sector, the backpack pattern is used to create branded backpacks for employee use or promotional giveaways. These backpacks enhance brand recognition and can contribute to employee satisfaction by providing practical items that are used daily. International B2B buyers should consider customization options that allow for company logos and branding, as well as bulk order pricing to optimize costs. In Europe and the Middle East, where corporate gifting is prevalent, ensuring timely production and delivery can significantly impact brand perception and employee morale.

Related Video: Uses of Metals and Non Metals

Strategic Material Selection Guide for backpack pattern’

When selecting materials for backpack patterns, international B2B buyers must consider various factors, including performance properties, cost, and manufacturing complexity. Below is an analysis of four common materials used in backpack manufacturing, focusing on their characteristics and implications for buyers, particularly from Africa, South America, the Middle East, and Europe.

1. Nylon

Key Properties: Nylon is known for its exceptional strength-to-weight ratio, abrasion resistance, and water resistance. It performs well in a range of temperatures, making it suitable for various climates.

Pros & Cons: Nylon is highly durable and lightweight, which makes it ideal for outdoor and travel backpacks. However, it can be more expensive than other materials and may require specialized manufacturing processes to achieve desired finishes.

Impact on Application: Nylon is compatible with various media, including dyes and prints, allowing for vibrant designs. It is often used in high-performance backpacks designed for hiking or travel.

Considerations for International Buyers: Buyers should ensure compliance with local regulations regarding synthetic materials. Standards such as ASTM D5034 (for tearing strength) are relevant. In regions like Europe, eco-labels may also influence purchasing decisions.

2. Polyester

Key Properties: Polyester is resistant to shrinking and stretching, has good chemical resistance, and dries quickly. It can withstand moderate temperatures but may not perform as well as nylon in extreme conditions.

Pros & Cons: Polyester is generally more affordable than nylon and offers decent durability. However, it may not be as strong or lightweight, which can limit its application in high-performance backpacks.

Impact on Application: Polyester is suitable for everyday backpacks and school bags. It can be easily treated for water resistance, making it versatile for various uses.

Considerations for International Buyers: Compliance with standards like ISO 13934-1 (for tensile strength) is essential. Buyers should also be aware of regional preferences for recycled polyester, which is gaining traction in markets like Europe.

3. Canvas

Key Properties: Canvas is a heavy-duty fabric made from cotton or a blend of cotton and synthetic fibers. It provides good durability and is breathable, making it suitable for various applications.

Pros & Cons: Canvas is relatively inexpensive and offers a classic aesthetic. However, it can be heavier than nylon or polyester and may require additional treatments for water resistance.

Impact on Application: Canvas is often used in casual backpacks, tote bags, and school bags. Its compatibility with prints and embroidery makes it popular for branding.

Considerations for International Buyers: Buyers should consider the environmental impact of cotton production, especially in regions where sustainability is a priority. Compliance with standards like OEKO-TEX is important for ensuring the absence of harmful substances.

4. Leather

Key Properties: Leather is known for its durability, aesthetic appeal, and ability to withstand wear and tear. It offers good temperature resistance but can be sensitive to moisture.

Pros & Cons: Leather provides a premium look and feel, making it suitable for high-end backpacks. However, it is often more expensive and requires careful maintenance to prevent damage.

Impact on Application: Leather is commonly used in luxury backpacks and fashion-oriented designs. Its compatibility with various finishes allows for unique branding opportunities.

Considerations for International Buyers: Buyers must ensure compliance with animal welfare regulations and standards like ISO 17075 (for leather testing). The demand for sustainable leather alternatives is growing, particularly in Europe.

Summary Table

| Material | Typical Use Case for backpack pattern” | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | High-performance outdoor and travel backpacks | Exceptional strength-to-weight ratio | Higher cost, specialized manufacturing | High |

| Polyester | Everyday backpacks, school bags | Affordable, decent durability | Less strong and lightweight than nylon | Medium |

| Canvas | Casual backpacks, tote bags | Inexpensive, classic aesthetic | Heavier, requires water resistance treatment | Low |

| Leather | Luxury and fashion-oriented backpacks | Premium look and durability | Expensive, sensitive to moisture | High |

This strategic material selection guide provides international B2B buyers with a comprehensive understanding of the various materials available for backpack patterns. By considering the properties, pros and cons, and specific regional considerations, buyers can make informed decisions that align with their product goals and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for backpack pattern’

The manufacturing process of backpacks involves a series of well-defined stages, each critical to ensuring the final product meets quality standards and market demands. B2B buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe, must understand these processes to make informed purchasing decisions. This section will provide insights into the main stages of manufacturing, key techniques employed, and the quality assurance measures that are essential for a successful partnership with manufacturers.

Manufacturing Processes

1. Material Preparation

The first step in backpack manufacturing is the careful selection and preparation of materials. Key materials commonly used include:

- Fabrics: Options range from durable nylon and polyester to environmentally friendly materials like recycled polyester and organic cotton.

- Hardware: Zippers, buckles, and straps must be sourced based on their durability and suitability for the intended use of the backpack.

- Padding and Linings: These elements are crucial for comfort and protection of items carried in the backpack.

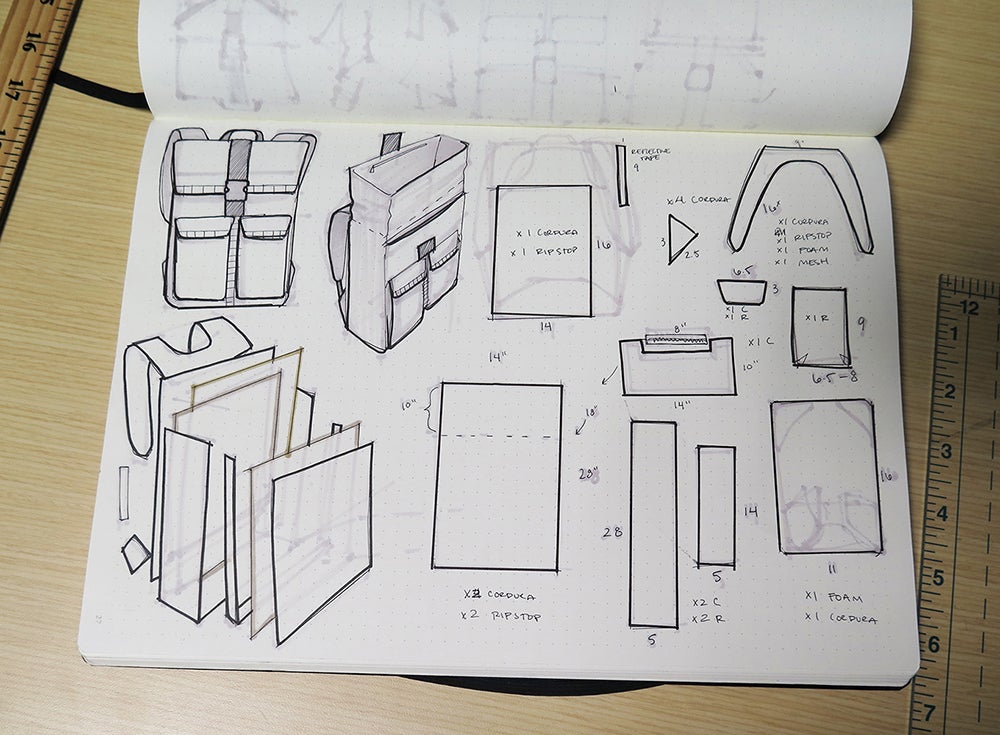

Key Techniques: Manufacturers often visit fabric markets or rely on trusted suppliers to ensure quality material selection. Utilizing CAD (Computer-Aided Design) software helps in creating precise specifications for the materials needed.

2. Forming

Once materials are prepared, the next phase involves creating patterns and cutting the fabric.

- Pattern Creation: Using CAD, designers develop detailed templates that dictate the shapes and dimensions of each component of the backpack.

- Cutting: The fabric is cut according to these patterns. Automated cutting machines are increasingly used for efficiency and accuracy, especially in large-scale production runs.

Key Techniques: Precision cutting is crucial to minimize waste and ensure all pieces fit together during assembly. Manufacturers may employ both manual and automated methods depending on their capacity and the complexity of the designs.

3. Assembly

The assembly stage is where the backpack begins to take shape.

- Sewing: Skilled operators use industrial sewing machines to stitch together various components. This includes attaching straps, adding pockets, and securing zippers.

- Quality Control During Assembly: At this stage, manufacturers often implement in-process quality control (IPQC) to ensure each assembly step meets quality standards.

Key Techniques: Techniques like sewing inside out can enhance durability and aesthetics by hiding seams. This stage often employs assembly line methods to streamline production and maintain efficiency.

4. Finishing

After assembly, the backpack undergoes several finishing processes.

- Inversion: The backpack is turned right-side out, revealing its final shape.

- Trimming and Tidying: Loose threads and excess materials are removed to ensure a clean, professional appearance.

- Final Quality Checks: Before packaging, a thorough inspection is conducted to ensure all aspects of the backpack are up to standard.

Key Techniques: Additional features such as branding (logos, tags) may be added during this stage through methods like screen printing or embroidery.

Quality Assurance

Quality assurance is critical in ensuring that the final product meets both international standards and customer expectations. B2B buyers should be familiar with the following aspects of quality control:

International Standards

- ISO 9001: This standard focuses on quality management systems and is applicable to organizations seeking to ensure consistent quality in products and services.

- CE Marking: For products sold in the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards.

Industry-Specific Standards

- API (American Petroleum Institute): Relevant for backpacks designed for specialized industrial applications, ensuring performance under extreme conditions.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Inspection of materials upon arrival at the manufacturing facility to ensure they meet specified criteria.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process to catch defects early.

- Final Quality Control (FQC): A comprehensive review of the finished product before it is packaged and shipped.

Common Testing Methods

B2B buyers should be aware of common testing methods used in quality assurance, such as:

– Tensile Strength Tests: Assessing the strength of seams and materials.

– Water Resistance Tests: Important for outdoor backpacks.

– Durability Tests: Evaluating wear and tear under various conditions.

Verifying Supplier Quality Control

For international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a manufacturer’s quality control processes is essential. Here are some strategies to ensure your supplier meets necessary quality standards:

Illustrative Image (Source: Google Search)

- Supplier Audits: Conduct regular audits of the manufacturing facility to evaluate compliance with quality standards.

- Quality Reports: Request detailed quality control reports that outline testing results and compliance with international standards.

- Third-Party Inspections: Engage independent inspection services to verify the quality of products before shipment, providing an unbiased assessment of the goods.

Quality Control and Certification Nuances

Understanding the nuances of quality control and certification can significantly impact the success of international B2B transactions. Buyers should consider:

- Regional Regulations: Different regions may have specific regulations regarding materials and manufacturing processes, which can affect compliance.

- Sustainability Certifications: As eco-consciousness grows, certifications such as Global Recycled Standard (GRS) or OEKO-TEX® can enhance the appeal of products to environmentally aware consumers.

- Cultural Considerations: Awareness of cultural differences in quality perceptions can aid in negotiations and expectations management.

By comprehensively understanding the manufacturing processes and quality assurance practices involved in backpack production, B2B buyers can make informed decisions that align with their brand values and market needs. This knowledge not only enhances product quality but also fosters stronger partnerships with manufacturers, ultimately leading to successful business outcomes.

Related Video: How a Backpack is Made : Every Step on the Production Line

Comprehensive Cost and Pricing Analysis for backpack pattern’ Sourcing

Understanding the cost structure and pricing landscape for sourcing backpack patterns is essential for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. The manufacturing process encompasses various cost components and pricing influencers that can significantly impact the overall expenditure.

Cost Components

-

Materials: The choice of materials is one of the most significant cost factors. High-quality fabrics such as nylon, canvas, or eco-friendly alternatives like recycled polyester can vary greatly in price. Additionally, sourcing materials from local markets versus international suppliers can also influence costs.

-

Labor: Labor costs differ widely by region. Countries with lower labor costs, such as Vietnam or Bangladesh, can provide significant savings compared to those in Europe or North America. However, consider the skill level required for specific tasks, as highly skilled labor may demand higher wages.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and maintenance. Overhead can fluctuate based on the manufacturing environment and the efficiency of production processes.

-

Tooling: Initial costs for tooling, such as patterns and molds, can be substantial but are often amortized over larger production runs. Custom designs will incur higher tooling costs compared to standard patterns.

-

Quality Control (QC): Implementing stringent quality control measures is crucial to ensure product durability and customer satisfaction. QC processes can add to costs but are essential for maintaining brand reputation.

-

Logistics: Shipping and handling costs are critical, especially for international buyers. Factors such as distance, shipping method, and customs duties can significantly affect overall costs.

-

Margin: Manufacturers typically apply a margin to cover their risks and ensure profitability. This margin can vary based on market competition and the perceived value of the product.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQ) play a crucial role in pricing. Larger orders often result in lower per-unit costs, making bulk purchasing an attractive option for buyers.

-

Specifications/Customization: Custom designs and specifications will lead to higher costs. Standard patterns are generally more economical due to established processes and efficiencies.

-

Materials Quality/Certifications: Products made from premium materials or those with certifications (e.g., eco-friendly certifications) will command higher prices. Buyers should evaluate the trade-off between material cost and product longevity.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established manufacturers with a proven track record may charge a premium but can offer better quality assurance and support.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital as they define the responsibilities of buyers and sellers during shipping. Different terms can affect overall costs, including insurance, customs, and delivery.

Buyer Tips

-

Negotiation: Always negotiate prices, especially when dealing with larger orders. Suppliers may offer discounts or flexible payment terms for significant commitments.

-

Cost-Efficiency: Assess the total cost of ownership (TCO), which includes not only the purchase price but also costs associated with storage, logistics, and potential returns. This comprehensive view can guide more informed decisions.

-

Pricing Nuances: For international buyers, be aware of currency fluctuations and regional economic conditions that might affect pricing. Additionally, consider the impact of tariffs and trade regulations when sourcing from different regions.

-

Due Diligence: Conduct thorough research on potential suppliers. Reviews, case studies, and direct communication can provide insights into their reliability and product quality.

Disclaimer

Prices can fluctuate based on market conditions, material availability, and supplier negotiations. It is advisable to obtain multiple quotes and conduct a detailed analysis before finalizing any sourcing decisions.

By understanding these components and influencers, B2B buyers can make informed choices that align with their operational needs and budget constraints while capitalizing on the opportunities within the global backpack manufacturing market.

Spotlight on Potential backpack pattern’ Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘backpack pattern” market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for backpack pattern’

Key Technical Properties of Backpack Patterns

Understanding the technical properties of backpack patterns is essential for B2B buyers to ensure quality, durability, and functionality in their products. Here are some critical specifications to consider:

-

Material Grade

The quality of materials used in backpack production directly impacts the product’s durability and performance. Common materials include nylon, polyester, and canvas, each with varying grades that determine strength, weight, and resistance to wear and tear. Buyers should prioritize high-grade materials that meet specific performance standards to ensure longevity. -

Tolerance Levels

Tolerance refers to the allowable variation in dimensions during the manufacturing process. For backpack patterns, maintaining tight tolerances is crucial to ensure that all components fit together seamlessly. This is particularly important for features like zippers and straps, where poor alignment can affect functionality and aesthetics. -

Water Resistance Rating

This specification indicates the level of water resistance a backpack can offer. Measured in millimeters (mm), a higher rating signifies better protection against moisture. B2B buyers targeting outdoor or urban markets should consider backpacks with a minimum water resistance rating to meet customer expectations for performance in various weather conditions. -

Weight Capacity

Each backpack pattern is designed to carry a specific weight load. Understanding the weight capacity is vital for ensuring that the backpack can handle the intended use, whether for daily commuting or outdoor adventures. Manufacturers often test their products to guarantee that they can withstand the specified load without compromising structural integrity. -

Durability Standards

Durability is assessed through various tests, including abrasion resistance and tear strength. These standards indicate how well the backpack can withstand everyday use and harsh conditions. Buyers should inquire about the durability certifications of materials and overall construction to ensure the product meets their market needs.

Common Trade Terminology in Backpack Manufacturing

Familiarity with industry jargon helps B2B buyers navigate the manufacturing landscape effectively. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the backpack industry, this often means partnering with a manufacturer that can create custom designs while leveraging their production capabilities. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers, especially startups, as it affects inventory management and cash flow. Negotiating lower MOQs can help businesses test market demand without excessive upfront investment.

-

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and details about specific products. For B2B buyers, issuing an RFQ allows for comparative pricing and clarifies the terms of service. It is a critical step in the procurement process that can lead to better deals and supplier relationships. -

Incoterms (International Commercial Terms)

Incoterms are standardized international shipping terms that define the responsibilities of buyers and sellers in a transaction. Understanding these terms helps buyers manage shipping costs and risks associated with international logistics, ensuring clarity in the delivery process. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. For backpack manufacturers, lead time can vary based on production schedules and material availability. Buyers should factor in lead times when planning their inventory to avoid stock shortages.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that align with their product requirements and market demands. This knowledge empowers them to establish stronger partnerships with manufacturers and achieve successful outcomes in their backpack production endeavors.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the backpack pattern’ Sector

The global backpack manufacturing industry is undergoing a significant transformation driven by various market dynamics and emerging trends. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, look to source backpacks, understanding these changes is crucial.

Market Overview & Key Trends

The backpack pattern sector is influenced by several global drivers, including increasing consumer demand for customization, sustainability, and technological advancements in manufacturing. Buyers are increasingly seeking custom backpack solutions that reflect unique designs tailored to specific customer preferences, which allows brands to stand out in a competitive marketplace. Additionally, there is a noticeable shift toward sustainable practices, with manufacturers adopting eco-friendly materials such as recycled polyester and organic cotton to meet the demands of environmentally conscious consumers.

Emerging B2B technologies are also reshaping the sourcing landscape. Automation in production processes, such as automated cutting and high-precision sewing, enhances efficiency and reduces lead times, making it easier for manufacturers to respond to market demands swiftly. Furthermore, the rise of digital platforms for sourcing, such as Alibaba and specialized garment sourcing websites, offers buyers an array of options but requires due diligence to avoid unpredictable pricing.

Geographically, Vietnam is gaining traction as a competitive alternative to traditional manufacturing powerhouses like China, primarily due to lower labor costs and favorable trade agreements. For B2B buyers, understanding these geographical dynamics and sourcing trends is essential for optimizing supply chains and ensuring quality production.

Sustainability & Ethical Sourcing in B2B

The environmental impact of the backpack manufacturing process cannot be overstated. As the industry faces increasing scrutiny over its carbon footprint, the importance of ethical supply chains is becoming paramount. B2B buyers should prioritize manufacturers who demonstrate a commitment to sustainable practices, which not only mitigate environmental harm but also enhance brand reputation.

Green certifications such as Global Recycled Standard (GRS) and OEKO-TEX® can serve as valuable indicators of a manufacturer’s commitment to sustainability. Utilizing materials like recycled nylon and natural fibers not only reduces waste but also appeals to a growing market segment that values eco-friendly products. Moreover, ethical sourcing practices ensure that labor conditions are fair and that the rights of workers are protected, which is increasingly important to consumers worldwide.

B2B buyers should actively seek partnerships with manufacturers who prioritize sustainability, as this alignment can lead to long-term benefits, including customer loyalty and enhanced market positioning.

Brief Evolution/History

The evolution of the backpack manufacturing sector reflects broader changes in consumer behavior and technological advancements. Initially, backpacks were primarily utilitarian, designed for functionality. However, over the years, they have transformed into fashion statements and lifestyle products. The advent of advanced materials and production techniques has enabled manufacturers to create backpacks that are not only durable and functional but also stylish and customizable. This evolution is significant for B2B buyers, as it highlights the importance of innovation and adaptability in meeting changing consumer preferences.

Understanding these market dynamics, sourcing trends, and sustainability imperatives is vital for international B2B buyers looking to navigate the complexities of the backpack manufacturing sector effectively. By aligning with manufacturers that prioritize quality, sustainability, and innovation, businesses can enhance their competitive advantage in a rapidly evolving market.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of backpack pattern’

-

What should I consider when vetting suppliers for backpack patterns?

When vetting suppliers, assess their experience in backpack manufacturing, especially in your target market. Look for suppliers with a proven track record and positive reviews. Request samples to evaluate quality and craftsmanship. Additionally, verify their certifications, such as ISO or OEKO-TEX, to ensure compliance with international quality standards. Conduct background checks and consider visiting their facility if feasible to observe operations and working conditions. -

Can I customize backpack patterns to suit my brand?

Yes, most manufacturers offer customization options for backpack patterns. You can tailor the design, materials, colors, and features to align with your brand identity. Provide clear specifications and engage in open communication with the supplier to ensure your vision is accurately translated into the final product. Some manufacturers may also offer design assistance, which can be beneficial for startups or those unfamiliar with the design process. -

What are the typical minimum order quantities (MOQs) and lead times for backpack production?

MOQs for backpack production vary by supplier and can range from 100 to 1,000 units. Smaller manufacturers may accommodate lower MOQs, which can be advantageous for startups testing market demand. Lead times typically range from 4 to 12 weeks, depending on order size, complexity, and supplier capacity. Always clarify these details upfront to avoid potential delays and plan your inventory accordingly.

Illustrative Image (Source: Google Search)

-

What payment methods are generally accepted by backpack manufacturers?

Most backpack manufacturers accept various payment methods, including bank transfers, PayPal, and letters of credit. It’s essential to discuss payment terms during negotiations. Many suppliers require a deposit (usually 30-50%) upfront, with the balance paid upon completion or before shipment. Ensure that the payment method offers adequate protection for international transactions, and consider using escrow services for added security. -

How can I ensure quality assurance (QA) for my backpack orders?

To ensure quality assurance, establish clear quality standards and communicate them with your supplier. Request pre-production samples to evaluate quality before full-scale manufacturing begins. Implement regular quality checks during production and before shipment. Consider hiring a third-party inspection service to conduct quality audits, which can be particularly useful for international transactions where you may not be able to oversee the process directly. -

What certifications should I look for in backpack manufacturers?

Key certifications to look for include ISO 9001 for quality management, ISO 14001 for environmental management, and OEKO-TEX Standard 100 for product safety. These certifications indicate that the manufacturer adheres to international quality standards and sustainable practices. Additionally, certifications related to ethical labor practices, such as Fair Trade or SA8000, can provide assurance that the supplier maintains responsible labor practices. -

What logistics considerations should I keep in mind when sourcing backpacks internationally?

When sourcing backpacks internationally, consider shipping methods (air vs. sea), costs, and transit times. Evaluate customs regulations and import duties in your country, as these can impact overall costs. Partnering with a reliable freight forwarder can streamline the logistics process and help navigate complex international shipping requirements. Ensure that all shipping documentation is accurate to avoid delays at customs. -

How should I handle disputes with suppliers?

To handle disputes with suppliers effectively, maintain clear communication and documentation of all agreements. Establish a formal process for addressing issues, which may include mediation or arbitration clauses in your contract. If a dispute arises, approach the supplier professionally and seek a mutually beneficial resolution. If necessary, consult legal counsel familiar with international trade laws to explore your options for resolving the dispute.

Strategic Sourcing Conclusion and Outlook for backpack pattern’

In navigating the complexities of backpack manufacturing, international B2B buyers must prioritize strategic sourcing to ensure quality, efficiency, and market competitiveness. Key takeaways include the importance of thorough research into material selection, understanding the production process, and identifying reliable manufacturers that align with your brand values, especially regarding sustainability.

Illustrative Image (Source: Google Search)

Establishing partnerships with manufacturers who offer flexibility in order quantities and customization can significantly enhance your ability to respond to market trends. The rise of eco-friendly materials and production practices reflects a growing consumer demand for sustainable products, making it essential for brands to adapt accordingly.

As the backpack manufacturing landscape evolves, the potential for innovation and differentiation is immense. Buyers from Africa, South America, the Middle East, and Europe should leverage these insights to forge strategic partnerships that drive growth and sustainability.

Take action today: Explore potential manufacturers, engage in consultations, and consider how you can position your brand to meet the needs of today’s eco-conscious consumers. By doing so, you will not only enhance your product offerings but also secure a competitive edge in the global marketplace.