Your Ultimate Guide to Sourcing Astronaut Backpack

Guide to Astronaut Backpack

- Introduction: Navigating the Global Market for astronaut backpack

- Understanding astronaut backpack Types and Variations

- Key Industrial Applications of astronaut backpack

- Strategic Material Selection Guide for astronaut backpack

- In-depth Look: Manufacturing Processes and Quality Assurance for astronaut backpack

- Comprehensive Cost and Pricing Analysis for astronaut backpack Sourcing

- Spotlight on Potential astronaut backpack Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for astronaut backpack

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the astronaut backpack Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of astronaut backpack

- Strategic Sourcing Conclusion and Outlook for astronaut backpack

Introduction: Navigating the Global Market for astronaut backpack

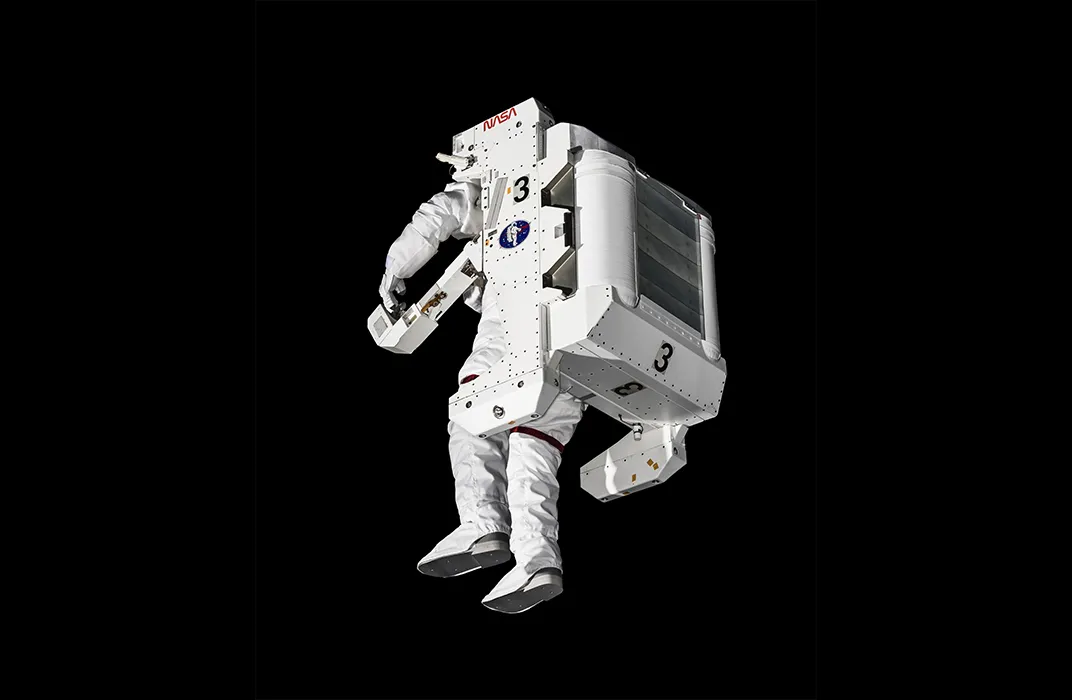

As the global marketplace expands, the demand for specialized products like astronaut backpacks is on the rise. These high-performance bags are not just fashion statements; they embody innovation and functionality, serving a diverse range of applications from outdoor adventures to professional use in various sectors. For B2B buyers in Africa, South America, the Middle East, and Europe, understanding the intricacies of sourcing astronaut backpacks is crucial to maintaining competitive advantage.

This comprehensive guide will equip you with the essential insights needed to navigate the complexities of the astronaut backpack market. You’ll learn about the different types of backpacks available, the materials that ensure durability and comfort, and the best practices for manufacturing and quality control. We’ll also delve into supplier selection, cost considerations, and market trends, providing you with a holistic view of the landscape.

By empowering you with actionable strategies and in-depth knowledge, this guide enables you to make informed sourcing decisions. Whether you are looking to enhance your retail offerings or fulfill specific business needs, understanding the astronaut backpack market will help you align your procurement strategies with customer expectations and industry standards. Prepare to explore the potential of astronaut backpacks, ensuring your business remains at the forefront of innovation and quality.

Understanding astronaut backpack Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Life Support Backpack | Integrated life support systems for oxygen and CO2 removal | Space missions, astronaut training | Pros: Essential for survival; Cons: High maintenance cost and complexity. |

| Utility Backpack | Modular design with customizable compartments | Research missions, equipment transport | Pros: Versatile; Cons: May require training for optimal use. |

| Cargo Backpack | High-capacity for transporting tools and supplies | Construction, logistics in space | Pros: Maximizes payload; Cons: Bulkiness can limit mobility. |

| Tactical Backpack | Enhanced durability with military-grade materials | Emergency response, tactical operations | Pros: Robust and reliable; Cons: Heavier than standard options. |

| Communication Backpack | Integrated tech for communication and navigation | Space exploration, scientific missions | Pros: Facilitates real-time data sharing; Cons: Dependence on tech reliability. |

Life Support Backpack

The Life Support Backpack is designed for astronauts’ survival in space, featuring integrated systems for oxygen supply and carbon dioxide removal. This type is crucial for space missions and astronaut training programs, ensuring that users can operate safely in hostile environments. When purchasing, buyers should consider the complexity of maintenance and the need for specialized training to operate the life support systems effectively.

Utility Backpack

Utility Backpacks are characterized by their modular design, allowing users to customize compartments based on mission requirements. These backpacks are widely used in research missions and for transporting equipment, making them a versatile choice for various applications. B2B buyers should evaluate the adaptability of the design and the potential need for user training to maximize functionality.

Cargo Backpack

Cargo Backpacks are built for high-capacity transport, ideal for carrying tools and supplies in space missions. They are particularly useful in construction or logistics within extraterrestrial environments. While these backpacks maximize payload efficiency, buyers must consider the trade-off in terms of bulkiness and how it may affect mobility during operations.

Tactical Backpack

Tactical Backpacks are constructed with military-grade materials, offering enhanced durability and reliability for emergency response and tactical operations. These backpacks are designed to withstand harsh conditions, making them suitable for critical missions. Buyers should weigh the benefits of robustness against the increased weight, which may impact user endurance during extended missions.

Communication Backpack

Communication Backpacks integrate advanced technology for navigation and real-time communication, essential for space exploration and scientific missions. They facilitate data sharing among team members, enhancing operational efficiency. However, B2B buyers need to consider the reliability of the technology and the potential need for technical support, as any failure could hinder mission success.

Key Industrial Applications of astronaut backpack

| Industry/Sector | Specific Application of astronaut backpack | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Astronaut training and simulation | Enhanced training experience, improved safety protocols | Compliance with aerospace standards, durability testing |

| Outdoor Adventure | Extreme weather expeditions | Reliable performance in harsh conditions, increased safety | Material performance in extreme conditions, ergonomic design |

| Emergency Services | Disaster response and rescue operations | Quick access to essential gear, improved mobility | Lightweight materials, rapid deployment features |

| Military and Defense | Tactical operations | Versatile gear transport, operational efficiency | Camouflage options, durability against wear and tear |

| Research and Exploration | Scientific fieldwork in remote areas | Protection for equipment, adaptability to various terrains | Waterproofing, rugged design for diverse environments |

Aerospace Applications

In the aerospace industry, astronaut backpacks are critical during training and simulations. They are designed to closely mimic the conditions astronauts face in space, ensuring that trainees can effectively learn how to handle equipment and emergencies. For international B2B buyers, sourcing these backpacks means ensuring compliance with stringent aerospace standards, including durability testing and safety certifications. Buyers should prioritize suppliers that can provide detailed documentation of material specifications and testing results to avoid quality issues.

Outdoor Adventure Applications

Astronaut backpacks are increasingly being utilized in extreme weather expeditions, where reliability and safety are paramount. These backpacks are engineered to withstand harsh environmental conditions, providing adventurers with essential gear protection. B2B buyers in the outdoor industry must focus on sourcing high-quality materials that ensure performance in extreme conditions, such as waterproof fabrics and reinforced stitching. Ergonomic design features are also crucial, as they enhance user comfort during long treks.

Emergency Services Applications

In emergency services, astronaut backpacks serve as essential gear for disaster response and rescue operations. They facilitate quick access to vital equipment, ensuring responders can act swiftly and efficiently. For buyers in this sector, sourcing considerations should include lightweight materials that do not compromise on durability, as well as features that enable rapid deployment of gear. Collaboration with manufacturers who specialize in emergency preparedness gear can provide added assurance of quality and functionality.

Military and Defense Applications

Military operations often require versatile and durable gear, making astronaut backpacks a valuable asset for tactical operations. These backpacks are designed to transport essential equipment efficiently while maintaining operational readiness. B2B buyers in the defense sector should look for suppliers that offer customization options, such as camouflage designs and reinforced materials that withstand heavy use. Ensuring that the backpacks meet military specifications for durability and functionality is essential for maintaining operational effectiveness.

Research and Exploration Applications

In the field of scientific research and exploration, astronaut backpacks are used to protect sensitive equipment in remote and challenging environments. They provide adaptability and protection, ensuring that researchers can transport their tools safely. International buyers should prioritize sourcing backpacks with waterproofing features and rugged designs that can endure diverse terrains. Collaborating with manufacturers that have experience in producing specialized backpacks for scientific applications can enhance the quality and reliability of the products sourced.

Related Video: LABORATORY APPARATUS AND THEIR USES

Strategic Material Selection Guide for astronaut backpack

When selecting materials for astronaut backpacks, it is crucial to consider the unique demands of space travel, including extreme temperatures, pressure variations, and potential exposure to corrosive substances. Below, we analyze several common materials used in the production of astronaut backpacks, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Nylon (e.g., Cordura)

Key Properties: Nylon is known for its high tensile strength, abrasion resistance, and lightweight characteristics. It can withstand a wide range of temperatures and is resistant to mold and mildew.

Pros & Cons:

– Advantages: Durable, lightweight, and resistant to wear and tear. It is also relatively easy to dye, allowing for various color options.

– Disadvantages: Can be susceptible to UV degradation over time, which might be a concern for prolonged exposure to sunlight in space environments. Additionally, it is less resistant to extreme temperatures compared to other materials.

Impact on Application: Nylon is suitable for general use in astronaut backpacks, providing a good balance of strength and weight. However, its UV sensitivity may necessitate additional treatments for long-term exposure.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM for fabric testing. It is also advisable to source from suppliers who can provide certifications regarding UV resistance.

2. Kevlar

Key Properties: Kevlar is a high-strength synthetic fiber known for its exceptional durability and resistance to cuts, abrasion, and heat. It has a high tensile strength-to-weight ratio.

Pros & Cons:

– Advantages: Extremely durable and resistant to impacts, making it ideal for high-stress areas of the backpack. It also offers thermal resistance, which is beneficial in extreme temperature conditions.

– Disadvantages: Higher cost compared to conventional materials like nylon. The manufacturing process can be complex, requiring specialized techniques.

Impact on Application: Kevlar is particularly suitable for areas of the backpack that may experience significant wear and tear, such as straps and base panels. Its heat resistance also makes it ideal for environments with fluctuating temperatures.

Considerations for International Buyers: Buyers should verify that Kevlar products meet relevant safety standards (e.g., ISO) and ensure that suppliers can provide detailed material specifications.

3. Gore-Tex

Key Properties: Gore-Tex is a waterproof, breathable fabric that provides excellent protection against moisture while allowing vapor to escape. It is highly resistant to various environmental factors.

Pros & Cons:

– Advantages: Provides excellent weather resistance, making it ideal for use in space where moisture control is critical. Its breathability enhances comfort for the wearer.

– Disadvantages: Generally more expensive than other materials and may require specific care to maintain its properties over time.

Impact on Application: Gore-Tex is particularly effective for astronaut backpacks designed for missions where moisture management is critical, such as during extravehicular activities (EVAs).

Considerations for International Buyers: Ensure that Gore-Tex products are certified to meet performance standards (e.g., ASTM, JIS). Buyers should also consider the environmental impact of the manufacturing process and seek suppliers with sustainable practices.

4. Aluminum Alloys

Key Properties: Aluminum alloys are lightweight, corrosion-resistant, and have excellent strength-to-weight ratios. They are often used in frames and structural components of backpacks.

Pros & Cons:

– Advantages: Lightweight and strong, providing structural integrity without adding excessive weight. Corrosion resistance makes them suitable for various environments.

– Disadvantages: Can be more expensive than traditional materials and may require specialized manufacturing techniques for forming and welding.

Impact on Application: Aluminum alloys are ideal for the internal frame of astronaut backpacks, providing support while keeping the overall weight low.

Considerations for International Buyers: Buyers should ensure that aluminum products comply with relevant metallurgical standards (e.g., ASTM, DIN). It is also important to assess the supplier’s capabilities in terms of custom fabrication and finishing processes.

Summary Table

| Material | Typical Use Case for astronaut backpack | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon (e.g., Cordura) | General fabric for outer shell and compartments | Durable, lightweight, resistant to wear | UV degradation over time | Medium |

| Kevlar | High-stress areas like straps and base panels | Extremely durable, cut-resistant | Higher cost, complex manufacturing | High |

| Gore-Tex | Moisture management in outer layers | Waterproof and breathable | More expensive, requires specific care | High |

| Aluminum Alloys | Structural components and frames | Lightweight, corrosion-resistant | More expensive, specialized manufacturing | Medium |

This strategic material selection guide aims to equip international B2B buyers with the necessary insights to make informed decisions when sourcing materials for astronaut backpacks. Understanding the properties and implications of each material will help ensure that the final products meet the rigorous demands of space travel while aligning with market expectations.

In-depth Look: Manufacturing Processes and Quality Assurance for astronaut backpack

When sourcing astronaut backpacks, understanding the manufacturing processes and quality assurance standards is paramount for international B2B buyers. This section outlines the typical manufacturing stages, key techniques, and quality control measures that can help ensure you procure high-quality products that meet your specific needs.

Manufacturing Processes for Astronaut Backpacks

The production of astronaut backpacks involves several critical stages, each essential for creating a durable and functional product. The main stages include:

1. Material Preparation

Material selection is the foundation of quality in backpack manufacturing. For astronaut backpacks, materials must be lightweight, durable, and resistant to extreme conditions. Common materials include high-strength fabrics like Cordura, nylon, and specialized insulation materials.

Key Techniques:

– Material Testing: Suppliers should provide evidence of material performance through testing for abrasion resistance, tensile strength, and weather resistance.

– Supplier Selection: Choose suppliers with a proven track record of sourcing high-quality materials that meet international standards.

2. Forming

This stage involves cutting the selected materials into the required shapes and sizes for different components of the backpack. Precision is crucial here to ensure all parts fit together seamlessly.

Key Techniques:

– Automated Cutting: Utilizing CNC machines can enhance accuracy in cutting fabric, which is critical for ensuring uniformity across production batches.

– Patterning: Create detailed patterns to guide the cutting process and ensure consistency in design.

3. Assembly

Assembly is where the various components come together to form the final product. This stage requires skilled labor to ensure that all parts are joined correctly and that quality is maintained throughout the process.

Key Techniques:

– Stitching: Employ high-quality stitching methods, such as double-stitching and bar-tacking at stress points, to enhance durability.

– Attachment of Components: Zippers, buckles, and straps must be aligned properly to ensure functionality and aesthetic appeal.

4. Finishing

The final stage involves adding any necessary finishes or treatments to enhance the backpack’s performance and appearance. This may include waterproofing treatments, applying logos, or final inspections.

Key Techniques:

– Quality Finishing Treatments: Use advanced finishes to improve water resistance and durability.

– Visual Inspection: Conduct thorough visual inspections to ensure that all components meet design specifications and quality standards.

Quality Assurance in Manufacturing

Quality assurance (QA) is critical in ensuring that the astronaut backpacks meet international standards and customer expectations. Key elements of QA include:

Relevant International Standards

- ISO 9001: This standard ensures that manufacturers have a quality management system in place, which is crucial for consistent product quality.

- CE Marking: This certification indicates that the product meets European safety standards, particularly important for markets in Europe.

- API Standards: For specialized applications, such as those used in space, adherence to API standards may be necessary.

Quality Control Checkpoints

Quality control (QC) checkpoints throughout the manufacturing process help ensure that defects are caught early. Common checkpoints include:

- Incoming Quality Control (IQC): Inspect materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Monitor production processes to identify and rectify any issues as they occur.

- Final Quality Control (FQC): Conduct a thorough inspection of the finished product to ensure it meets all quality standards before shipping.

Common Testing Methods

B2B buyers should be familiar with various testing methods that can ensure the quality and durability of astronaut backpacks:

- Abrasion Resistance Testing: Evaluates how well the material withstands wear and tear.

- Water Resistance Testing: Ensures the backpack can protect its contents in wet conditions.

- Load Testing: Tests the strength of straps and seams under weight to ensure they can handle expected loads.

Verifying Supplier Quality Control

To mitigate risks associated with sourcing, B2B buyers can take several steps to verify the quality control practices of their suppliers:

- Supplier Audits: Conduct regular audits of suppliers to ensure compliance with quality standards and practices.

- Request QC Reports: Ask suppliers for detailed quality control reports that outline testing results and procedures.

- Third-party Inspections: Engage third-party inspection services to conduct independent assessments of product quality and compliance with specifications.

Quality Control Nuances for International Buyers

B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

- Cultural Differences: Understanding cultural attitudes towards quality and manufacturing can help in establishing better communication with suppliers.

- Regulatory Compliance: Ensure that products comply with both local and international regulations, which can vary significantly between regions.

- Logistics and Shipping: Consider the impact of logistics on quality. Factors such as temperature, humidity, and handling during shipping can affect product integrity.

Conclusion

Sourcing astronaut backpacks requires a comprehensive understanding of the manufacturing processes and quality assurance practices involved. By focusing on material quality, employing rigorous testing, and establishing clear QC protocols, B2B buyers can ensure they procure high-quality backpacks that meet their needs. Engaging with suppliers who prioritize quality at every stage of production will not only enhance product reliability but also strengthen your brand reputation in the competitive B2B landscape.

Related Video: How a Backpack is Made : Every Step on the Production Line

Comprehensive Cost and Pricing Analysis for astronaut backpack Sourcing

When sourcing astronaut backpacks, understanding the comprehensive cost structure and pricing dynamics is essential for effective procurement. Below, we break down the critical cost components and price influencers, providing actionable insights for B2B buyers, especially from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials

– The quality and type of materials used significantly impact the overall cost. Premium materials, such as high-strength nylon, waterproof fabrics, and specialized insulation, can increase costs but enhance durability and performance. Always request samples to assess material quality before making a decision. -

Labor

– Labor costs vary widely depending on the production location. Countries with lower labor costs may offer more competitive pricing, but they can also introduce risks related to quality control. Assessing the skill level of workers and their training in specialized backpack manufacturing is crucial. -

Manufacturing Overhead

– This includes costs associated with running the factory, such as utilities, equipment maintenance, and administrative expenses. Understanding the overhead can help you gauge the supplier’s pricing structure. Suppliers with efficient operations may pass savings onto buyers.

Illustrative Image (Source: Google Search)

-

Tooling

– Custom tooling for unique designs or features can add to the initial cost. However, investing in the right tooling can lead to better quality and lower per-unit costs in the long run. Discuss tooling costs upfront to avoid surprises later. -

Quality Control (QC)

– Implementing thorough QC measures is essential to ensure the backpacks meet specified standards. This may include pre-production inspections, inline checks, and final audits. Suppliers that prioritize QC may charge more, but this investment can prevent costly returns and brand damage.

Illustrative Image (Source: Google Search)

-

Logistics

– Shipping costs can fluctuate based on the distance, shipping method, and volume of the order. Consider the Incoterms that define who is responsible for shipping and associated costs. Effective logistics management can significantly influence your total expenses. -

Margin

– Suppliers typically add a margin to cover their costs and profit. Understanding typical margins in the backpack industry can help in negotiating better prices. Aim for transparency in pricing to assess if margins are reasonable.

Price Influencers

-

Volume/MOQ: Bulk orders often lead to reduced per-unit costs. Establish clear Minimum Order Quantities (MOQs) that align with your sales forecasts to optimize pricing.

-

Specifications/Customization: Custom designs or features can drive up costs. Clearly define your specifications to avoid unnecessary expenses.

-

Materials Quality/Certifications: Higher-quality materials often come with certifications (e.g., ISO, CE), which can enhance the product’s marketability. However, they may also increase costs. Balance quality and budget.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms: Selecting the right Incoterms can mitigate risks and clarify responsibilities, impacting overall costs. Familiarize yourself with terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) to make informed decisions.

Buyer Tips

-

Negotiation: Build strong relationships with suppliers to facilitate negotiations. Leverage your purchasing power for better pricing and terms.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes not just the purchase price but also logistics, storage, and potential returns.

-

International Pricing Nuances: Be aware of currency fluctuations, tariffs, and import duties that can impact overall costs when sourcing from different regions.

-

Quality Assurance: Prioritize suppliers that demonstrate commitment to quality, as this can save costs related to returns and customer dissatisfaction.

Disclaimer

Prices and costs mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific project requirements. Always conduct thorough market research and supplier assessments to get accurate pricing for your sourcing needs.

Spotlight on Potential astronaut backpack Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘astronaut backpack’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for astronaut backpack

Key Technical Properties for Astronaut Backpacks

When sourcing astronaut backpacks, understanding specific technical properties is crucial for ensuring product quality and suitability for demanding environments. Here are several critical specifications to consider:

-

Material Grade

The material used in astronaut backpacks must be of high-grade, typically aerospace-grade fabrics such as Kevlar or high-denier nylon. These materials offer exceptional strength, durability, and resistance to extreme temperatures, which are essential for space missions. B2B buyers should prioritize suppliers who can provide material certifications and testing reports to ensure compliance with aerospace standards. -

Weight Capacity

Astronaut backpacks need to support significant weight while remaining lightweight for ease of mobility. Manufacturers often specify a maximum load capacity, usually measured in kilograms or pounds. Understanding this specification helps buyers select a backpack that can withstand the rigors of space travel without compromising on comfort or functionality. -

Tensile Strength

This specification measures the backpack’s resistance to being pulled apart. It is crucial for ensuring the integrity of seams and straps under load. Buyers should request tensile strength testing results to confirm that the backpack can handle the stress of use in space, which can involve dynamic movements and potential impacts. -

Thermal Resistance

Astronaut backpacks must provide thermal protection against extreme temperatures in space. This property refers to the material’s ability to insulate against heat and cold. B2B buyers should inquire about thermal testing data to ensure the backpack can maintain functionality across varying temperature ranges encountered in space. -

Water Resistance

Although primarily designed for space environments, astronaut backpacks should also be water-resistant to protect equipment in case of leaks or condensation. This property is measured by the Hydrostatic Head rating, indicating the pressure a fabric can withstand before water penetrates. Buyers should ensure that the backpack meets industry standards for water resistance.

Illustrative Image (Source: Google Search)

Common Trade Terminology

Familiarity with industry jargon is vital for effective communication and negotiation in the B2B environment. Here are essential terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of astronaut backpacks, buyers often work with OEMs to create custom designs or specifications tailored to their needs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory planning, especially for B2B buyers looking to enter new markets or test products. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price proposals from suppliers for specific products or services. For B2B buyers, issuing an RFQ allows them to compare pricing and terms from multiple manufacturers to make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce that delineate the responsibilities of buyers and sellers in international transactions. Understanding these terms helps buyers clarify shipping responsibilities, risk, and costs, which is particularly important for cross-border transactions involving astronaut backpacks. -

Lead Time

This term refers to the amount of time it takes from placing an order until the product is delivered. For B2B buyers, knowing the lead time is essential for planning inventory and ensuring timely availability of astronaut backpacks for their operations.

By grasping these technical properties and trade terminologies, B2B buyers can navigate the complexities of sourcing astronaut backpacks more effectively, ensuring they select products that meet their high standards and operational requirements.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the astronaut backpack Sector

Market Overview & Key Trends

The astronaut backpack market is experiencing a surge in demand, driven by the increasing popularity of adventure travel, outdoor activities, and technological advancements in materials and designs. B2B buyers from regions such as Africa, South America, the Middle East, and Europe are capitalizing on this trend, recognizing the potential for high-quality, durable backpacks that cater to both functional and aesthetic needs. Current market dynamics highlight a shift towards smart backpacks, equipped with features like solar panels for charging devices and integrated GPS tracking, appealing to tech-savvy consumers.

Emerging sourcing trends include a growing emphasis on direct manufacturer relationships to reduce costs and enhance supply chain transparency. As international trade barriers fluctuate, buyers are encouraged to evaluate suppliers based on their ability to meet stringent quality standards and deliver on time. Additionally, the integration of advanced manufacturing technologies, such as automation and 3D printing, is reshaping production capabilities, allowing for rapid prototyping and customization. For buyers in regions like Colombia and Australia, leveraging these trends can facilitate competitive pricing and product differentiation in the marketplace.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration for B2B buyers in the astronaut backpack sector. The environmental impact of manufacturing processes and the materials used in production are under increasing scrutiny. Buyers are encouraged to prioritize suppliers that demonstrate a commitment to sustainable practices, such as using recycled materials or reducing water consumption during production.

Ethical sourcing is equally important, as consumers increasingly demand transparency in supply chains. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX can guide buyers in selecting materials that are not only environmentally friendly but also safe for consumers. By opting for backpacks made from organic cotton, recycled polyester, or biodegradable materials, B2B buyers can align their purchasing decisions with their corporate social responsibility goals. This approach not only enhances brand reputation but also meets the expectations of an increasingly eco-conscious consumer base.

Brief Evolution/History

The astronaut backpack has evolved significantly from its early designs, which primarily focused on functionality and durability for extreme conditions. Initially developed for space missions, these backpacks have transitioned into mainstream markets, blending advanced materials with ergonomic designs suitable for everyday use. Over the years, innovations such as lightweight fabrics, modular storage solutions, and climate-responsive technologies have emerged, making astronaut backpacks versatile enough for various applications—from urban commuting to rugged outdoor adventures. This evolution reflects broader trends in consumer preferences towards multi-functional and stylish products, presenting ample opportunities for B2B buyers to explore diverse offerings in the market.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of astronaut backpack

-

What should I consider when vetting suppliers for astronaut backpacks?

When vetting suppliers, focus on their manufacturing capabilities, quality control processes, and past client reviews. Request certifications related to safety and quality standards, such as ISO or CE certifications, to ensure compliance with international norms. Additionally, visit their production facilities if possible or utilize third-party inspection services to verify their operations. Establish clear communication channels and gauge their responsiveness to ensure they can meet your specific needs efficiently. -

Can I customize astronaut backpacks for my brand?

Yes, many manufacturers offer customization options for astronaut backpacks, including design modifications, color choices, and branding elements like logos. Discuss your specific requirements during the initial negotiations. Ensure that the supplier has the capability to produce samples of your customized designs before committing to a bulk order. This step is crucial to ensure the final product aligns with your brand identity and customer expectations. -

What are the typical minimum order quantities (MOQs) and lead times for astronaut backpacks?

MOQs can vary significantly depending on the supplier and the complexity of the design. Generally, you might encounter MOQs ranging from 100 to 1,000 units. Lead times typically depend on the production schedule and can range from 4 to 12 weeks. Always confirm these details upfront and consider negotiating for smaller initial orders to test the market response before scaling production. -

How should I handle payment terms with international suppliers?

When dealing with international suppliers, it’s important to negotiate favorable payment terms. Common practices include a deposit (usually 30% to 50%) upfront, with the balance due upon completion or prior to shipping. Consider using secure payment methods such as letters of credit or escrow services to protect your investment. Always clarify the currency of payment and any potential transaction fees involved. -

What quality assurance measures should I expect from suppliers?

A reputable supplier should have robust quality assurance (QA) processes in place, including material inspections, in-process checks, and final product testing. Request documentation of their QA procedures and any relevant certifications. Establish specific quality criteria in your contract and consider conducting pre-shipment inspections to ensure that the backpacks meet your specifications before they are dispatched. -

What certifications should astronaut backpacks have for international trade?

Certifications can vary by market, but important ones include safety certifications (like EN or ISO standards) and environmental compliance certifications (like REACH or RoHS). These certifications ensure that the products meet the necessary safety and environmental regulations in your target markets. Always verify that the supplier can provide these certifications to avoid potential legal issues and enhance your product’s credibility. -

How can I ensure smooth logistics when importing astronaut backpacks?

To ensure smooth logistics, collaborate closely with your supplier to understand their shipping methods and lead times. Choose a reliable freight forwarder experienced in international shipping, particularly in handling backpacks. Consider customs clearance processes and ensure that all necessary documentation, including bills of lading and commercial invoices, are prepared in advance. Additionally, keep track of shipping schedules to manage inventory effectively. -

What steps should I take if disputes arise with my supplier?

In case of disputes, first attempt to resolve the issue directly through open communication with your supplier. Document all correspondence and agreements. If resolution fails, refer to the dispute resolution mechanisms outlined in your contract, which may include mediation or arbitration. It’s advisable to seek legal counsel familiar with international trade laws to navigate complex situations effectively and protect your business interests.

Strategic Sourcing Conclusion and Outlook for astronaut backpack

In conclusion, strategic sourcing of astronaut backpacks is essential for B2B buyers aiming to meet the growing demands of various markets across Africa, South America, the Middle East, and Europe. As highlighted, key considerations include ensuring material quality, rigorous testing, and effective supplier evaluation. By prioritizing these factors, businesses can mitigate common issues such as durability concerns and design flaws, ultimately enhancing customer satisfaction and brand reputation.

Investing in a robust sourcing strategy not only streamlines procurement processes but also opens avenues for innovation and competitive advantage. As global demand for high-quality astronaut backpacks continues to rise, forward-thinking buyers must remain vigilant in selecting suppliers who align with their quality standards and ethical practices.

As you navigate this dynamic landscape, consider leveraging technology and established networks to streamline your sourcing efforts. Collaborating with reliable manufacturing partners can significantly reduce lead times and production costs. Embrace the opportunities that lie ahead, and position your business to thrive in the evolving backpack market. The future is bright for those who act decisively and strategically in their sourcing endeavors.