Source High-Quality Hemp Rucksack Backpacks for Sustainable

Guide to Hemp Rucksack Backpack

- Introduction: Navigating the Global Market for hemp rucksack backpack

- Understanding hemp rucksack backpack Types and Variations

- Key Industrial Applications of hemp rucksack backpack

- Strategic Material Selection Guide for hemp rucksack backpack

- In-depth Look: Manufacturing Processes and Quality Assurance for hemp rucksack backpack

- Comprehensive Cost and Pricing Analysis for hemp rucksack backpack Sourcing

- Spotlight on Potential hemp rucksack backpack Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for hemp rucksack backpack

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the hemp rucksack backpack Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of hemp rucksack backpack

- Strategic Sourcing Conclusion and Outlook for hemp rucksack backpack

Introduction: Navigating the Global Market for hemp rucksack backpack

In an era where sustainability meets functionality, the hemp rucksack backpack emerges as a vital asset for environmentally conscious businesses. As global demand for eco-friendly products surges, these backpacks not only cater to the needs of discerning consumers but also align with corporate social responsibility goals. Hemp, known for its durability and minimal environmental impact, offers a unique blend of strength and style, making it an ideal material for rucksacks that can withstand the rigors of daily use while being gentle on the planet.

This comprehensive guide aims to equip international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe (including markets like Spain and Poland), with the insights necessary to make informed sourcing decisions. We will delve into the various types of hemp rucksack backpacks available, explore sustainable manufacturing and quality control practices, and highlight reputable suppliers. Additionally, buyers will gain an understanding of cost factors, market trends, and answers to frequently asked questions.

By navigating this guide, businesses can not only enhance their product offerings but also contribute to a more sustainable future. The hemp rucksack backpack stands as a testament to innovation in eco-friendly materials, empowering buyers to make choices that reflect both quality and ethical responsibility.

Understanding hemp rucksack backpack Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Hemp Rucksack | Traditional design with a single large compartment | Outdoor retailers, eco-friendly brands | Pros: Durable, eco-friendly; Cons: Limited organization options |

| Laptop-Compatible Hemp Bag | Padded compartment for laptops and tech gear | Corporate gifting, educational institutions | Pros: Versatile for work and travel; Cons: Heavier due to padding |

| Multi-Pocket Hemp Backpack | Multiple compartments for organization | Travel agencies, adventure tourism companies | Pros: Excellent organization; Cons: Can be bulkier and heavier |

| Foldable Hemp Backpack | Lightweight and collapsible for easy storage | E-commerce, casual outdoor markets | Pros: Space-saving; Cons: Less durable than structured designs |

| Eco-Friendly Fashion Bag | Stylish design using hemp blends and sustainable materials | Fashion retailers, eco-conscious brands | Pros: Appeals to fashion-forward consumers; Cons: May lack ruggedness for outdoor use |

Classic Hemp Rucksack

The Classic Hemp Rucksack features a straightforward design, typically with a single large compartment and minimal external pockets. This type is ideal for outdoor retailers looking to offer a sustainable option that appeals to environmentally conscious consumers. Buyers should consider the durability and eco-friendliness of hemp, which provides a strong alternative to synthetic materials. However, the lack of organization may deter some buyers seeking multi-functional solutions.

Laptop-Compatible Hemp Bag

Designed with a padded compartment, the Laptop-Compatible Hemp Bag caters to professionals who need to transport tech gear safely. This type is well-suited for corporate gifting and educational institutions where sustainability is a priority. Buyers should note its versatility for both work and travel, but the added padding can increase weight, potentially impacting portability.

Multi-Pocket Hemp Backpack

The Multi-Pocket Hemp Backpack stands out for its multiple compartments, allowing for better organization of items. This type is particularly beneficial for travel agencies and adventure tourism companies that require functional and practical solutions for their clients. While it offers excellent organization, buyers should be aware that the additional pockets can make the backpack bulkier, which may not appeal to all consumers.

Foldable Hemp Backpack

Lightweight and collapsible, the Foldable Hemp Backpack is perfect for B2B applications in e-commerce and casual outdoor markets. This design is attractive for buyers looking for space-saving solutions, making it easier to store and transport. However, potential buyers should consider that while it is convenient, it may not be as durable as more structured options, which could limit its lifespan.

Eco-Friendly Fashion Bag

The Eco-Friendly Fashion Bag combines hemp with stylish designs, targeting fashion retailers and eco-conscious brands. This type appeals to consumers who prioritize aesthetics alongside sustainability. Buyers will find this option attractive for its marketability, but should also consider that it may lack the ruggedness required for outdoor adventures, potentially limiting its use in more demanding environments.

Related Video: Large Language Models (LLMs) – Everything You NEED To Know

Key Industrial Applications of hemp rucksack backpack

| Industry/Sector | Specific Application of hemp rucksack backpack | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Outdoor & Adventure | Eco-friendly travel gear for expeditions | Appeals to eco-conscious consumers, enhancing brand image | Certification of hemp sourcing, durability testing |

| Education | Sustainable backpacks for students | Promotes sustainability in educational institutions | Compliance with educational standards, material safety |

| Retail | Fashionable hemp backpacks for retail sales | Attracts environmentally-aware customers | Design versatility, pricing strategies |

| Logistics & Supply Chain | Durable backpacks for transport and delivery | Reduces environmental footprint in logistics operations | Weight capacity, waterproofing options |

| Tourism | Sustainable luggage for eco-tourism | Aligns with the growing eco-tourism market | Cultural adaptability, local sourcing opportunities |

Outdoor & Adventure

In the outdoor and adventure industry, hemp rucksack backpacks serve as eco-friendly travel gear for expeditions. These backpacks are highly durable and resistant to wear and tear, making them ideal for rugged terrains. They solve the problem of excessive waste from traditional synthetic materials by offering a biodegradable alternative. International B2B buyers in this sector should prioritize suppliers that can provide certifications for sustainable hemp sourcing and conduct durability testing to ensure the product meets rigorous outdoor demands.

Education

Educational institutions are increasingly adopting hemp rucksack backpacks as part of their sustainability initiatives. These bags not only promote eco-friendliness among students but also serve as a practical solution for carrying books and supplies. The challenge lies in ensuring compliance with educational standards, particularly regarding safety and material quality. Buyers in this sector should seek suppliers that can guarantee material safety and durability while also being able to customize designs to reflect school branding or values.

Retail

In the retail sector, hemp backpacks are marketed as fashionable and sustainable options, appealing to environmentally-conscious consumers. Retailers can leverage this trend to enhance their brand image and attract a niche market focused on sustainability. The key considerations for B2B buyers include the versatility of designs and pricing strategies that align with market expectations. Suppliers should be able to offer a range of styles and materials while maintaining competitive pricing to ensure profitability.

Logistics & Supply Chain

Hemp rucksack backpacks are also gaining traction in logistics and supply chain applications, where they are used for transport and delivery purposes. These backpacks help reduce the environmental footprint associated with traditional packaging and transport solutions. Buyers should focus on sourcing options that provide adequate weight capacity and waterproofing features to ensure that the backpacks meet the functional needs of this sector. Additionally, suppliers should demonstrate a commitment to sustainability throughout their supply chain.

Tourism

The tourism industry is increasingly embracing hemp rucksack backpacks as part of the eco-tourism movement. These backpacks cater to travelers who prioritize sustainability and seek products that reflect their values. B2B buyers in this sector should consider cultural adaptability when sourcing, ensuring that the designs resonate with local markets. Furthermore, local sourcing opportunities can enhance the appeal of these products, allowing businesses to support local economies while meeting the demands of eco-conscious travelers.

Related Video: LABORATORY APPARATUS AND THEIR USES

Strategic Material Selection Guide for hemp rucksack backpack

When selecting materials for hemp rucksack backpacks, international B2B buyers must consider various factors that impact performance, sustainability, and marketability. Below is an analysis of several common materials used in the production of hemp rucksack backpacks, focusing on their properties, advantages and disadvantages, and specific considerations for buyers in diverse regions such as Africa, South America, the Middle East, and Europe.

Hemp Fabric

Key Properties: Hemp fabric is known for its high tensile strength, which is about three times that of cotton. It is naturally UV-resistant, breathable, and becomes softer with use while maintaining durability.

Pros & Cons: The primary advantage of hemp fabric is its sustainability; it grows quickly, requires minimal water, and is biodegradable. However, it can wrinkle easily and is not inherently waterproof, which may necessitate additional treatments for specific applications. The manufacturing complexity is moderate, as it requires specialized processes for weaving and finishing.

Impact on Application: Hemp fabric is ideal for outdoor and eco-friendly markets, appealing to consumers who prioritize sustainability. Its natural look and feel resonate well with adventure and nature travel enthusiasts.

Considerations for Buyers: Buyers should ensure compliance with local regulations regarding textile production and sustainability certifications. In regions like Europe, standards such as OEKO-TEX® may be relevant.

Organic Cotton

Key Properties: Organic cotton is cultivated without synthetic pesticides and fertilizers, making it a more environmentally friendly option. It is soft, breathable, and has good moisture-wicking properties.

Pros & Cons: The primary advantage is its comfort and softness, which enhance user experience. However, organic cotton can be more expensive than conventional cotton and may not offer the same durability as hemp. Its manufacturing process can be complex due to the need for organic certification.

Impact on Application: Organic cotton is suitable for the inner linings and straps of hemp rucksacks, providing comfort against the skin. It is compatible with various dyeing processes, allowing for vibrant colors.

Considerations for Buyers: Buyers in regions like South America and Europe should be aware of certifications such as GOTS (Global Organic Textile Standard) to ensure product authenticity and compliance with organic standards.

Recycled Polyester

Key Properties: Recycled polyester is derived from post-consumer plastic waste, making it a sustainable alternative to virgin polyester. It is lightweight, durable, and resistant to shrinking and stretching.

Pros & Cons: The key advantage is its lower environmental impact compared to traditional polyester. However, it can shed microplastics during washing, which is a concern for eco-conscious consumers. The manufacturing process is relatively straightforward but may involve additional costs for sourcing recycled materials.

Impact on Application: Recycled polyester can be used for zippers, pockets, and reinforcements in hemp rucksacks, enhancing functionality while promoting sustainability.

Considerations for Buyers: Buyers should check for compliance with environmental regulations and standards related to recycled materials, especially in Europe, where eco-labels are gaining importance.

Waxed Canvas

Key Properties: Waxed canvas is a durable cotton fabric treated with wax to make it water-resistant. It is robust and has a unique aesthetic that appeals to outdoor enthusiasts.

Pros & Cons: The main advantage is its water resistance and durability, making it suitable for various weather conditions. However, it can be heavier than other materials and may require re-waxing over time to maintain its properties.

Impact on Application: Waxed canvas is ideal for the exterior of hemp rucksacks, providing weather protection and a rugged look that appeals to adventure travelers.

Considerations for Buyers: Buyers should consider the re-waxing requirement and ensure that the wax used complies with local regulations, especially in regions with strict environmental policies.

Summary Table

| Material | Typical Use Case for hemp rucksack backpack | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Hemp Fabric | Main body fabric for rucksacks | Highly durable and sustainable | Can wrinkle and is not waterproof | Medium |

| Organic Cotton | Inner linings and straps | Soft and comfortable | More expensive than conventional | High |

| Recycled Polyester | Zippers and pockets | Lower environmental impact | Microplastic shedding | Medium |

| Waxed Canvas | Exterior fabric for weather protection | Water-resistant and durable | Heavier and requires maintenance | Medium |

This strategic material selection guide equips international B2B buyers with essential insights to make informed decisions when sourcing materials for hemp rucksack backpacks, ensuring they align with sustainability goals and market demands.

Illustrative Image (Source: Google Search)

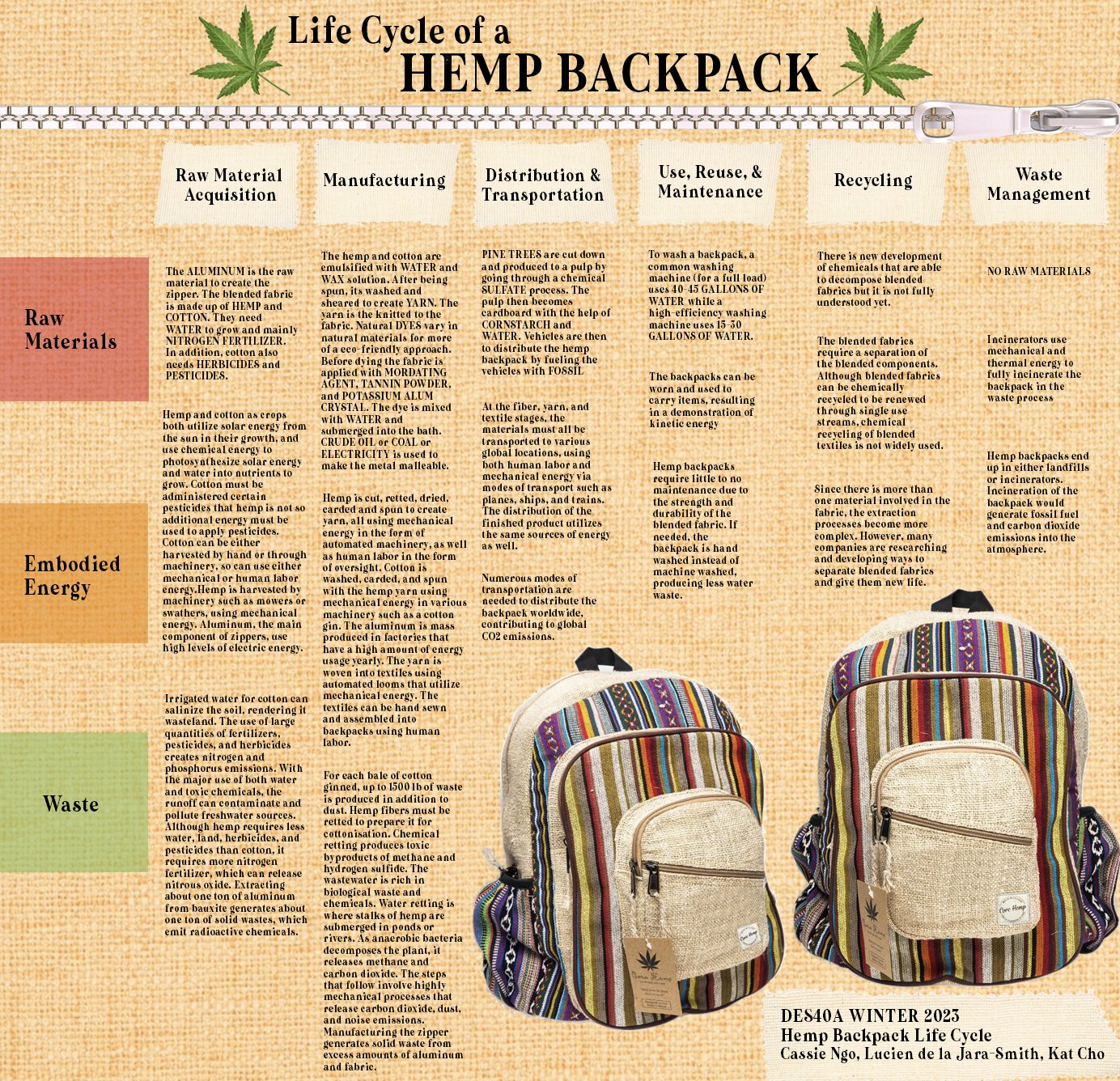

In-depth Look: Manufacturing Processes and Quality Assurance for hemp rucksack backpack

The manufacturing and quality assurance of hemp rucksack backpacks involve a series of meticulous processes and rigorous standards that ensure the final product meets the expectations of international B2B buyers. This section outlines the typical stages of manufacturing, key techniques used, and the quality control measures that guarantee the durability and sustainability of these eco-friendly products.

Manufacturing Process

1. Material Preparation

The journey of a hemp rucksack backpack begins with material preparation. Hemp fibers are sourced from sustainable farms that prioritize organic farming methods. The raw hemp undergoes several processes, including:

- Harvesting: Hemp plants are cut at the base and left to dry in the field, a method that enhances the fiber quality.

- Retting: This process involves soaking the harvested plants to separate the fibers from the stalks, which can be done using water, dew, or chemicals.

- Decortication: The retted hemp is mechanically processed to extract the fibers, which are then cleaned and sorted based on quality.

Once processed, the hemp fibers can be blended with organic cotton or recycled materials to enhance softness and durability.

2. Forming

The next stage is forming, where the prepared materials are shaped into the desired components of the backpack. Key techniques include:

- Weaving: Hemp fibers are woven into fabric using looms. Different weaving patterns can be employed to achieve varying textures and strengths.

- Dyeing: Eco-friendly dyes are used to color the hemp fabric, ensuring that the dyeing process does not compromise the material’s sustainability.

- Cutting: The dyed fabric is cut into panels that will form the backpack’s body, straps, and pockets.

3. Assembly

The assembly stage involves stitching the cut panels together to create the final product. This process typically includes:

- Sewing: Industrial sewing machines are used to join the fabric panels, ensuring strong seams that can withstand heavy loads.

- Attachment of Hardware: Zippers, buckles, and other hardware are securely attached during this stage, with particular attention paid to the quality and durability of these components.

- Quality Inspections: At various points during assembly, quality inspections are conducted to check for defects, alignment, and stitching integrity.

4. Finishing

In the finishing stage, the assembled backpack undergoes final touches to enhance its functionality and aesthetic appeal. This includes:

- Trimming: Excess threads and fabric are trimmed to give the backpack a polished look.

- Waterproofing: Some manufacturers apply eco-friendly waterproof treatments to the hemp fabric, ensuring the backpack can withstand various weather conditions.

- Final Quality Control: A thorough inspection is performed to ensure that the product meets the required specifications before packaging.

Quality Assurance

Quality assurance is critical in the production of hemp rucksack backpacks to ensure compliance with international standards and customer expectations.

International Standards

B2B buyers should be aware of several international quality standards that apply to hemp rucksack backpacks:

- ISO 9001: This standard focuses on quality management systems and is essential for manufacturers looking to demonstrate their commitment to quality.

- CE Marking: Required for products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- REACH Compliance: This regulation ensures that chemical substances used in the manufacturing process do not harm human health or the environment.

Quality Control Checkpoints

Quality control (QC) checkpoints are established throughout the manufacturing process to monitor and maintain product quality:

- Incoming Quality Control (IQC): Raw materials, including hemp and other components, are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During the assembly process, regular checks are conducted to identify defects or deviations from production standards.

- Final Quality Control (FQC): Once the backpacks are fully assembled, a comprehensive inspection is carried out to verify that each product adheres to quality specifications.

Common Testing Methods

Manufacturers employ various testing methods to ensure the durability and safety of hemp rucksack backpacks:

- Tensile Strength Testing: This test measures the strength of the fabric to ensure it can withstand heavy loads without tearing.

- Water Resistance Testing: This evaluates the effectiveness of waterproof treatments applied to the fabric.

- Chemical Testing: Ensures that no harmful substances are present in the final product, adhering to regulations like REACH.

Verifying Supplier Quality Control

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to ensure product reliability. Key strategies include:

- Supplier Audits: Conducting regular audits of suppliers can help assess their compliance with quality standards and production processes.

- Quality Reports: Requesting detailed quality reports that outline testing results and production metrics can provide insight into a manufacturer’s QC practices.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing process and final product quality.

Conclusion

The manufacturing processes and quality assurance measures for hemp rucksack backpacks play a pivotal role in delivering eco-friendly, durable products that meet the expectations of international B2B buyers. By understanding these processes and implementing rigorous QC practices, buyers can ensure they are sourcing high-quality backpacks that align with sustainability goals and industry standards. This knowledge is particularly beneficial for businesses operating across diverse markets, as it fosters trust and transparency in supply chain relationships.

Related Video: How a Backpack is Made : Every Step on the Production Line

Comprehensive Cost and Pricing Analysis for hemp rucksack backpack Sourcing

When sourcing hemp rucksack backpacks, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis will break down the key components that affect pricing and offer actionable insights for efficient procurement.

Cost Components

-

Materials: The primary material, hemp, is often more expensive than conventional materials like polyester or cotton due to its sustainable cultivation practices. Hemp’s durability and biodegradability add value but also contribute to higher initial costs. Additional materials, such as zippers, linings, and padding, can also impact overall costs.

-

Labor: Labor costs vary significantly based on the sourcing country. Countries with established textile industries may offer lower labor costs due to economies of scale, whereas artisanal producers may command higher wages for specialized craftsmanship, especially if they focus on ethical labor practices.

-

Manufacturing Overhead: This includes costs related to factory operations such as utilities, rent, and equipment maintenance. Sustainable manufacturers may have higher overhead costs associated with environmentally friendly practices.

-

Tooling: Initial tooling costs for creating molds and patterns can be significant, especially for custom designs. Buyers should consider whether they can use existing molds or require new ones, which can affect the initial investment.

-

Quality Control (QC): Ensuring that the product meets specific quality standards is crucial, especially for eco-friendly products that must adhere to sustainability certifications. Implementing strict QC processes can add to costs but can prevent costly returns and reputational damage.

-

Logistics: Shipping costs can vary widely depending on the distance, volume, and Incoterms agreed upon. Landlocked countries in Africa or South America may face higher shipping costs compared to European countries with better access to shipping routes.

-

Margin: Suppliers typically include a profit margin that varies based on the competitive landscape and perceived value of the product. Buyers should negotiate margins that reflect both quality and market demand.

Price Influencers

-

Volume/MOQ: Bulk orders typically reduce per-unit costs. Buyers should assess their capacity to purchase larger quantities to leverage better pricing.

-

Specifications/Customization: Custom designs or unique specifications can lead to higher costs. Buyers should balance the desire for customization with budget constraints.

-

Material Quality/Certifications: Eco-certifications (like GOTS for organic textiles) can add value but also increase costs. Buyers should consider the importance of these certifications in their target markets.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge a premium for their proven quality and service.

-

Incoterms: Understanding the implications of Incoterms on shipping and responsibilities can significantly affect total costs. For instance, “FOB” (Free on Board) pricing includes shipping to the port, while “CIF” (Cost, Insurance, and Freight) includes additional insurance and freight costs.

Buyer Tips

-

Negotiation: Always negotiate terms. Suppliers may have flexibility on pricing, especially if you can guarantee repeat business or larger orders.

-

Cost-Efficiency: Evaluate the total cost of ownership, which includes initial costs, shipping, and potential returns due to quality issues. A slightly higher upfront cost may lead to lower long-term costs if the product is more durable.

-

Pricing Nuances: International buyers should be aware of currency fluctuations, import tariffs, and local taxes that may affect overall pricing. Understanding the local market dynamics in Africa, South America, the Middle East, and Europe can provide leverage in negotiations.

Disclaimer

Prices and cost estimates are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. It is advisable to conduct thorough market research and obtain multiple quotes before making procurement decisions.

Spotlight on Potential hemp rucksack backpack Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘hemp rucksack backpack’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for hemp rucksack backpack

When sourcing hemp rucksack backpacks for international markets, it’s crucial to understand both the technical properties of the products and the trade terminology that governs transactions. This knowledge will empower buyers to make informed decisions and foster successful supplier relationships.

Key Technical Properties

-

Material Composition

– Definition: Hemp fabric is derived from the stalk of the hemp plant, known for its durability and eco-friendliness. It can be blended with other materials, such as organic cotton, to enhance comfort and usability.

– Importance: For B2B buyers, knowing the material composition is vital for assessing the product’s sustainability, durability, and market appeal. Hemp is naturally resistant to mold and UV light, making it suitable for outdoor use. -

Weight Capacity

– Definition: This refers to the maximum weight the backpack can carry without compromising its structure or comfort. Typically measured in kilograms or pounds.

– Importance: Understanding weight capacity is essential for buyers targeting specific markets, such as hikers or travelers, who may require different load-bearing capabilities depending on their activities. -

Water Resistance

– Definition: The ability of the backpack to repel water, often achieved through special coatings or treatments.

– Importance: In regions with varying climates, especially in Africa and South America, the demand for water-resistant backpacks is high. Buyers should verify the water resistance level to ensure it meets customer expectations. -

Dimensions and Volume

– Definition: The physical size of the backpack, usually measured in liters to indicate capacity (e.g., 20L, 40L).

– Importance: This specification helps buyers match backpacks to specific needs, whether for daily commuting or extended travel. It also influences shipping costs and storage requirements. -

Sustainability Certifications

– Definition: Certifications such as Global Organic Textile Standard (GOTS) or OEKO-TEX indicate that the materials and production processes meet specific environmental and social standards.

– Importance: Certifications can significantly enhance marketability, particularly in European and North American markets where eco-conscious consumerism is prevalent.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships helps buyers identify potential partners for custom designs or private-label products. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Buyers need to be aware of MOQs to align their purchasing strategies with supplier requirements, ensuring they can meet demand without overcommitting resources. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers asking for a price quote based on specified requirements.

– Importance: Submitting an RFQ allows buyers to compare costs and terms from multiple suppliers, enabling better negotiation and selection processes. -

Incoterms (International Commercial Terms)

– Definition: A series of predefined commercial terms published by the International Chamber of Commerce (ICC) related to international commercial law.

– Importance: Familiarity with Incoterms is crucial for understanding the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. -

Lead Time

– Definition: The time it takes from placing an order to the delivery of the product.

– Importance: Knowing the lead time is essential for inventory management and ensuring timely delivery to end customers, especially in fast-paced markets.

By leveraging this knowledge of technical properties and trade terminology, international B2B buyers can make strategic decisions that align with their business goals and customer expectations. Understanding these elements will also aid in navigating the complexities of global sourcing, thereby enhancing competitive advantage in the marketplace.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the hemp rucksack backpack Sector

Market Overview & Key Trends

The hemp rucksack backpack sector is experiencing significant growth driven by a combination of sustainability demands, shifting consumer preferences, and technological advancements in manufacturing. Globally, the market is projected to reach $72 billion by 2028, with eco-friendly materials like hemp at the forefront. Buyers from Africa, South America, the Middle East, and Europe (including Spain and Poland) are increasingly prioritizing environmentally sustainable products. This shift is influenced by heightened awareness of climate change and the environmental impact of traditional materials.

Key trends include the use of innovative materials such as hemp, which boasts durability and biodegradability, making it a preferred choice for eco-conscious brands. Smart sourcing technologies, such as blockchain for supply chain transparency, are also emerging, allowing buyers to verify the sustainability of their products. Furthermore, direct-to-consumer models are gaining traction, enabling brands to reduce costs and improve customer engagement. For international buyers, understanding these trends is crucial for aligning with consumer expectations and enhancing competitive advantage in the market.

Sustainability & Ethical Sourcing in B2B

Sustainability plays a pivotal role in the hemp rucksack backpack sector, not just as a marketing point but as a fundamental business practice. The environmental impact of conventional backpack materials is significant, often contributing to pollution and landfill waste. Hemp, in contrast, is a rapidly renewable resource that requires less water and no pesticides, resulting in a lower carbon footprint.

Moreover, ethical supply chains are becoming non-negotiable for B2B buyers. Brands that embrace ethical sourcing practices not only reduce their environmental impact but also cater to a growing consumer base that values corporate responsibility. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX are vital for verifying the sustainability of materials used in hemp backpacks. These certifications assure buyers of the product’s eco-friendliness and ethical production processes, enhancing brand trust and customer loyalty.

Brief Evolution/History

The use of hemp as a material dates back thousands of years, originally utilized for textiles, ropes, and sails due to its strength and durability. In recent decades, there has been a resurgence in the popularity of hemp, driven by the global shift towards sustainability and eco-friendly products. The modern hemp rucksack backpack has evolved to incorporate innovative designs and features, appealing to both outdoor enthusiasts and urban dwellers. This evolution reflects broader market dynamics, where functionality and sustainability converge, making hemp backpacks a desirable choice for environmentally conscious consumers and B2B buyers alike.

In conclusion, the hemp rucksack backpack market represents a unique opportunity for international B2B buyers to invest in sustainable, ethically sourced products that resonate with the values of today’s consumers. Understanding market dynamics, prioritizing sustainability, and recognizing the historical significance of hemp will guide businesses in making informed sourcing decisions.

Related Video: How Shipping Containers Control Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of hemp rucksack backpack

-

What key factors should I consider when vetting suppliers for hemp rucksack backpacks?

When vetting suppliers, focus on their experience in producing hemp products, including their certifications for eco-friendliness. Assess their production capacity and lead times to ensure they can meet your demands. Request samples to evaluate the quality of materials and craftsmanship. Additionally, check customer reviews and ask for references from other B2B clients to gauge reliability and service quality. Building a relationship with suppliers who are transparent about their processes can lead to a more sustainable partnership. -

Can I customize the design of hemp rucksack backpacks?

Yes, many manufacturers offer customization options for hemp rucksack backpacks. You can typically choose colors, sizes, logo placements, and additional features like compartments or straps. It’s crucial to communicate your requirements clearly and confirm the supplier’s ability to meet those specifications. Be aware that extensive customization may affect the minimum order quantity (MOQ) and lead times, so plan accordingly to align with your marketing strategy. -

What are the typical minimum order quantities (MOQs) and lead times for hemp rucksack backpacks?

MOQs for hemp rucksack backpacks can vary significantly depending on the supplier and customization options. Generally, you may find MOQs ranging from 100 to 500 units. Lead times can also differ based on production schedules and shipping logistics, often ranging from 4 to 12 weeks. It’s advisable to negotiate these terms upfront and consider placing larger orders to reduce per-unit costs and ensure timely delivery. -

What payment terms are common when sourcing hemp rucksack backpacks internationally?

Payment terms can vary widely among suppliers, but common practices include a 30% deposit upon order confirmation and 70% before shipment. Some suppliers may offer letter of credit (LC) options, which provide additional security. Always clarify payment methods accepted (e.g., bank transfer, PayPal) and ensure you understand any currency exchange implications. Establishing clear payment terms can prevent misunderstandings and build trust in your supplier relationship. -

How can I ensure quality assurance and certification for hemp rucksack backpacks?

To ensure quality, request certifications that verify the hemp used is organic and sustainably sourced, such as GOTS (Global Organic Textile Standard). Ask suppliers about their quality control processes, including inspections during production and before shipment. You can also consider hiring third-party inspection services to evaluate the products before they leave the factory. Regular communication with the supplier about quality expectations will help mitigate risks. -

What logistics considerations should I be aware of when importing hemp rucksack backpacks?

When importing hemp rucksack backpacks, consider shipping methods (air vs. sea) based on cost and urgency. Understand the customs regulations in your country regarding hemp products, as these may vary by region. Ensure your supplier provides all necessary documentation, such as invoices and packing lists, to facilitate smooth customs clearance. Additionally, partnering with a reliable freight forwarder can streamline logistics and help navigate potential challenges during transit.

Illustrative Image (Source: Google Search)

- How should I handle disputes with suppliers regarding hemp rucksack backpacks?

In the event of a dispute, maintain clear and professional communication with your supplier. Document all interactions and agreements to refer back to if necessary. Attempt to resolve issues amicably through dialogue, and if that fails, refer to your contract for dispute resolution mechanisms. Consider mediation or arbitration as alternatives to legal action, which can be costly and time-consuming. Establishing a good rapport with suppliers can often prevent disputes from escalating.

Illustrative Image (Source: Google Search)

- What are the environmental benefits of sourcing hemp rucksack backpacks?

Sourcing hemp rucksack backpacks supports sustainable practices as hemp is a highly renewable resource that requires less water and no pesticides for growth. The production of hemp fabric has a lower carbon footprint compared to conventional materials. By choosing hemp products, you align your business with eco-conscious values, appealing to a growing market segment that prioritizes sustainability. Highlighting these benefits can enhance your brand’s reputation and attract environmentally aware consumers.

Strategic Sourcing Conclusion and Outlook for hemp rucksack backpack

In conclusion, the strategic sourcing of hemp rucksack backpacks presents a valuable opportunity for international B2B buyers seeking sustainable and durable options. Key takeaways include the importance of eco-friendly materials that not only appeal to environmentally conscious consumers but also enhance brand reputation and loyalty. Buyers should prioritize suppliers that utilize certified hemp and demonstrate ethical production practices, ensuring compliance with sustainability standards.

Moreover, the versatility of hemp as a fabric—known for its durability, UV resistance, and biodegradability—positions it as a leading choice in the growing market for sustainable travel gear. Emphasizing innovation in design and functionality will further attract a diverse customer base, from eco-adventurers in Africa to urban commuters in Europe.

Looking ahead, international B2B buyers are encouraged to explore partnerships with manufacturers who prioritize sustainable practices. By investing in hemp rucksack backpacks, companies can not only meet the rising demand for eco-friendly products but also contribute to a more sustainable future. Embrace this opportunity to lead in the green revolution within the travel gear industry and capitalize on the increasing consumer preference for responsible sourcing.