Master Sourcing Tasmanian Tiger Backpacks for Unmatched

Guide to Tasmanian Tiger Backpack

- Introduction: Navigating the Global Market for tasmanian tiger backpack

- Understanding tasmanian tiger backpack Types and Variations

- Key Industrial Applications of tasmanian tiger backpack

- Strategic Material Selection Guide for tasmanian tiger backpack

- In-depth Look: Manufacturing Processes and Quality Assurance for tasmanian tiger backpack

- Comprehensive Cost and Pricing Analysis for tasmanian tiger backpack Sourcing

- Spotlight on Potential tasmanian tiger backpack Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for tasmanian tiger backpack

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the tasmanian tiger backpack Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of tasmanian tiger backpack

- Strategic Sourcing Conclusion and Outlook for tasmanian tiger backpack

Introduction: Navigating the Global Market for tasmanian tiger backpack

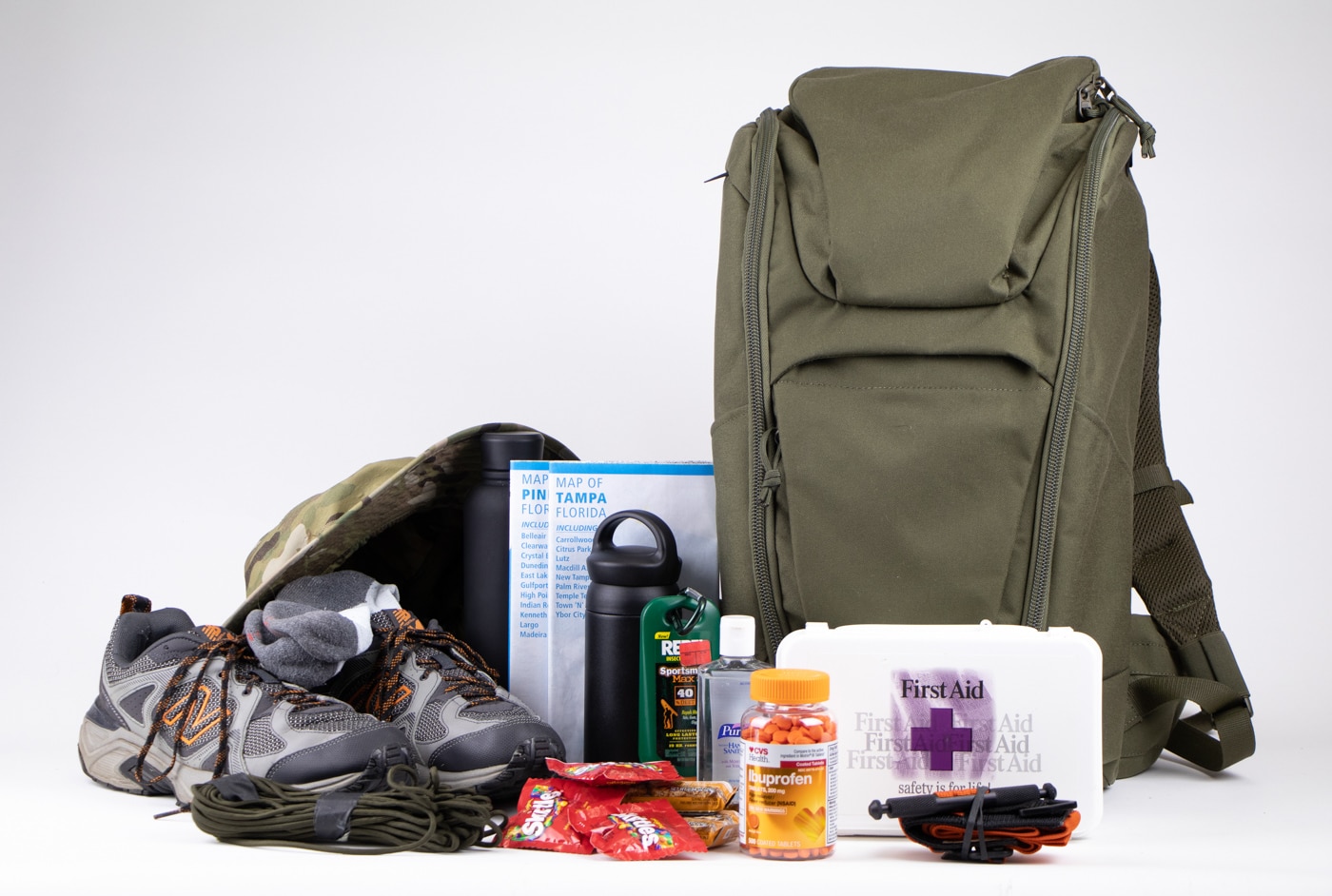

In the dynamic landscape of international procurement, Tasmanian Tiger backpacks stand out as a premium choice for organizations seeking high-performance gear. Whether outfitting military units in Kenya, supporting adventure tourism in South America, or equipping humanitarian missions in the Middle East, these backpacks are synonymous with reliability and adaptability. The importance of selecting the right backpack cannot be overstated; it directly influences operational efficiency, safety, and the overall reputation of your organization in challenging environments.

This comprehensive guide is designed specifically for B2B buyers across Africa, South America, the Middle East, and Europe, offering a deep dive into the Tasmanian Tiger backpack range. Buyers will discover a detailed overview of various backpack types—from long-range tactical models to specialized medical-response packs—along with insights into construction materials, durability, and compliance with international manufacturing standards. The guide also highlights reputable suppliers and distribution channels, ensuring you have access to the best products available.

Moreover, it addresses critical cost structures and global sourcing practices, along with FAQs tailored to regional contexts. With this information at hand, procurement decision-makers can confidently navigate the complexities of sourcing Tasmanian Tiger backpacks, ensuring that their investments directly contribute to mission success and organizational growth on the global stage.

Understanding tasmanian tiger backpack Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Long-Range Tactical Backpacks | High capacity (60–75L+), modular design, robust frame | Military, law enforcement, humanitarian expeditions | Exceptional durability and space; however, they are heavier and more expensive. |

| Short-Range / Daypacks | Compact size (15–30L), lightweight, efficient compartments | Patrols, ERT, field teams, corporate outdoor initiatives | Highly portable and cost-effective; limited carrying capacity may restrict use. |

| Medical-Response Backpacks | Specialized internal organizers, fast-access panels | Emergency services, NGOs, remote clinics | Ideal for targeted medical storage; less versatile for non-medical applications. |

| Waterproof / Anfibia Series | Fully waterproof construction, roll-top closure | Water rescue, disaster response, high-humidity operations | Superior weather protection; typically higher cost and less breathability. |

| Modular Assault Packs | MOLLE system, adaptable volume, expandable modules | Security contractors, special operations | Highly adaptable and modular; requires compatible accessories, increasing complexity. |

Long-Range Tactical Backpacks

Long-range tactical backpacks are designed for extended missions, offering a substantial carrying capacity of 60-75 liters. Their modular design allows for customized loadouts, making them ideal for military, law enforcement, and humanitarian expeditions. Buyers should focus on frame quality, attachment compatibility (MOLLE/PALS), and durability against harsh conditions. While they provide excellent durability and space, the higher cost and weight can be significant considerations for budget-conscious organizations.

Short-Range / Daypacks

Short-range or daypacks are compact, lightweight backpacks ranging from 15 to 30 liters, making them suitable for short-duration tasks. They are particularly useful for patrols, emergency response teams (ERT), and corporate outdoor initiatives. When purchasing, B2B buyers should prioritize ergonomic design and organizational features. While these packs are cost-effective and portable, their limited capacity may restrict their application in more demanding scenarios.

Medical-Response Backpacks

Medical-response backpacks focus on specialized compartmentalization and rapid-access features, crucial for emergency services and NGOs. Their design includes reinforced zips and fast-deploy panels, making them indispensable for field medics and remote clinics. Buyers should look for customizable inserts and color-coded compartments for efficient organization. However, while they excel in medical contexts, their specialization may limit versatility for non-medical uses.

Waterproof / Anfibia Series

The Waterproof or Anfibia series is engineered for extreme weather conditions, featuring fully waterproof construction and roll-top closures. These backpacks are essential for water rescue operations and agencies working in high-humidity environments. B2B buyers must consider IP ratings and reparability when sourcing these products. Although they provide superior weather protection, they often come at a higher price point and may not be suitable for hot, arid climates due to reduced breathability.

Modular Assault Packs

Modular assault packs incorporate a MOLLE system, allowing for adaptable volume and expandable modules. They are favored by security contractors and special operations teams that require flexibility in their gear. When considering these packs, buyers should evaluate the range of compatible accessories and the overall weight of the system. While their modularity offers significant advantages, it also introduces complexity, requiring careful planning in procurement to ensure all components work seamlessly together.

Related Video: Not Your Average Tactical Backpack – Tasmanian Tiger Pathfinder MK II Backpack Review

Key Industrial Applications of tasmanian tiger backpack

| Industry/Sector | Specific Application of Tasmanian Tiger Backpack | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Military & Defense | Tactical operations and field missions | Enhanced durability and modularity for varied missions | Compliance with military standards, weight considerations |

| Emergency Response & Medical | Rapid deployment for medical emergencies | Organized storage for medical supplies, quick access | Customization options, visibility, and hygiene features |

| Adventure Tourism | Guiding and trekking expeditions | Lightweight design for comfort during long treks | Ergonomic features, weather resistance, storage capacity |

| Law Enforcement | Patrol and surveillance operations | Reliable gear for everyday use in diverse environments | Durability, ease of access, and covert design elements |

| Humanitarian Aid | Logistics and transportation in disaster zones | Reliable performance in extreme conditions | Sourcing from certified suppliers, compliance with aid standards |

Military & Defense

In military and defense applications, Tasmanian Tiger backpacks are essential for tactical operations and field missions. Their robust construction and modular designs allow for customization based on mission requirements, ensuring soldiers can carry the necessary equipment efficiently. International buyers, particularly from regions with active military operations, must consider compliance with military standards and evaluate the weight of the packs for ease of transport. The ability to bulk purchase can also lead to cost savings while ensuring uniformity across units.

Emergency Response & Medical

For emergency response and medical applications, Tasmanian Tiger backpacks are invaluable in facilitating rapid deployment. These backpacks feature specialized compartments for medical supplies, enabling quick access during critical situations. Organizations such as NGOs and health agencies in Africa and the Middle East require backpacks that prioritize organization and visibility. Buyers should look for options with customizable inserts and hygiene-friendly materials to meet specific operational needs while ensuring compliance with health and safety regulations.

Adventure Tourism

In the adventure tourism sector, Tasmanian Tiger backpacks are favored for their lightweight design and ergonomic features, which enhance comfort during extended treks. Tour operators in South America and Europe often seek durable, weather-resistant packs that can withstand varying climates while providing ample storage for gear and supplies. Buyers should prioritize models that offer a balance between weight, durability, and storage capacity to ensure a positive experience for clients engaging in outdoor activities.

Law Enforcement

Law enforcement agencies utilize Tasmanian Tiger backpacks for patrol and surveillance operations, where reliable gear is crucial. These backpacks are designed for everyday use and can accommodate various equipment, ensuring officers are prepared for diverse situations. Buyers in this sector should focus on durability, ease of access, and covert design elements that allow for discreet carrying of necessary gear. Sourcing from reputable suppliers that ensure compliance with law enforcement standards is essential to maintain operational effectiveness.

Humanitarian Aid

In humanitarian aid contexts, Tasmanian Tiger backpacks play a vital role in logistics and transportation during disaster response efforts. Their ability to perform reliably in extreme conditions makes them suitable for use in challenging environments, often faced by aid organizations in Africa and the Middle East. Buyers should prioritize sourcing from certified suppliers who comply with international aid standards, ensuring that the backpacks meet the rigorous demands of humanitarian operations while also providing comfort and functionality for field workers.

Related Video: TT Medic Assault Pack MK II – First Aid Backpack | TASMANIAN TIGER – THE PROS’ EQUIPMENT

Strategic Material Selection Guide for tasmanian tiger backpack

When selecting materials for Tasmanian Tiger backpacks, international B2B buyers must consider various factors that influence performance, durability, and cost. Here, we analyze four common materials used in these backpacks, highlighting their properties, advantages, disadvantages, and implications for different markets, particularly in Africa, South America, the Middle East, and Europe.

1. Cordura Nylon

Key Properties:

Cordura nylon is known for its exceptional durability and resistance to abrasion, tears, and scuffs. It typically has a temperature rating of up to 100°C and offers good water resistance, making it suitable for various environments.

Pros & Cons:

Cordura is highly durable and lightweight, which enhances the overall performance of the backpack. However, its manufacturing process can be complex, leading to higher production costs. Additionally, while it provides excellent protection against wear and tear, it may not be as breathable as other materials.

Impact on Application:

Cordura nylon is ideal for tactical and outdoor applications where durability is critical. Its water-resistant properties make it suitable for use in humid or wet conditions, common in regions like the Middle East and parts of South America.

Considerations for International Buyers:

Buyers should ensure that the Cordura used meets international standards such as ASTM and DIN for durability and safety. In regions like Germany, compliance with environmental regulations regarding chemical treatments is also essential.

2. Polyester

Key Properties:

Polyester is a synthetic fabric known for its resistance to shrinking and stretching. It typically withstands temperatures up to 80°C and offers moderate water resistance.

Pros & Cons:

Polyester is generally more cost-effective than Cordura, making it a popular choice for budget-conscious buyers. However, it is less durable and can wear out faster under heavy use. Its lower weight can be an advantage for short-range backpacks but may compromise long-term performance.

Impact on Application:

Polyester is suitable for less demanding applications, such as daypacks or corporate outdoor gear. It performs well in moderate climates but may not hold up in extreme conditions found in some African or Middle Eastern environments.

Considerations for International Buyers:

Buyers should evaluate the quality of polyester used, as there are various grades available. Compliance with local regulations regarding synthetic materials is also crucial, especially in Europe, where sustainability is increasingly prioritized.

3. Ripstop Fabric

Key Properties:

Ripstop fabric is woven with a reinforcing technique that makes it resistant to tearing and ripping. It can handle temperatures up to 90°C and is often treated for water resistance.

Pros & Cons:

The main advantage of ripstop is its lightweight nature combined with high durability. However, it can be more expensive to produce due to the specialized weaving process. While it is versatile, it may not provide the same level of abrasion resistance as Cordura.

Impact on Application:

Ripstop is ideal for tactical operations and outdoor adventures where weight is a concern. Its tear-resistant properties make it suitable for rugged terrains, which are common in many African and South American regions.

Considerations for International Buyers:

Buyers should verify that ripstop fabrics meet relevant standards for strength and durability. In regions like Europe, certifications for environmental impact and chemical safety are increasingly important.

4. Waterproof Coatings (e.g., PU or TPU)

Key Properties:

Waterproof coatings such as polyurethane (PU) or thermoplastic polyurethane (TPU) provide excellent water resistance and can withstand various environmental conditions.

Pros & Cons:

These coatings enhance the backpack’s functionality in wet conditions, making them ideal for water rescue operations or humid climates. However, they can add to the overall cost and may require specific care to maintain their effectiveness.

Impact on Application:

Waterproof coatings are essential for backpacks used in disaster response or adventure tourism in regions prone to heavy rainfall, such as parts of South America and Africa.

Considerations for International Buyers:

Buyers should ensure that the coatings meet international waterproof standards. Additionally, understanding local preferences for waterproofing methods is critical, as some markets may favor eco-friendly options.

Summary Table

| Material | Typical Use Case for tasmanian tiger backpack | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cordura Nylon | Tactical and outdoor backpacks | Exceptional durability and abrasion resistance | Higher production costs, less breathable | High |

| Polyester | Daypacks and corporate gear | Cost-effective, lightweight | Less durable, can wear out faster | Low |

| Ripstop Fabric | Tactical operations, outdoor adventures | Lightweight and tear-resistant | More expensive, less abrasion resistance | Medium |

| Waterproof Coatings | Water rescue, disaster response | Excellent water resistance | Adds to overall cost, requires care | Medium |

This analysis provides a comprehensive overview of material considerations for Tasmanian Tiger backpacks, equipping B2B buyers with the insights needed to make informed procurement decisions tailored to their operational needs and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for tasmanian tiger backpack

Manufacturing Processes of Tasmanian Tiger Backpacks

The manufacturing of Tasmanian Tiger backpacks is a meticulous process that ensures high performance and durability, essential for various international applications. Below are the main stages involved in the manufacturing process, key techniques utilized, and how these processes align with B2B buyers’ expectations.

Main Stages of Manufacturing

-

Material Preparation

– Selection of Fabrics: The first step involves selecting high-quality materials such as Cordura® nylon, which is known for its strength and resistance to abrasion. Other materials may include water-resistant fabrics for specific models.

– Cutting: Once the materials are selected, they are cut into patterns using automated cutting machines. This precision helps minimize waste and ensures uniformity across products. -

Forming

– Shaping Components: The cut fabrics are then shaped into various components of the backpack, such as the main body, pockets, and straps. This may involve techniques like heat sealing and ultrasonic welding to create waterproof seams.

– Reinforcement: Areas subject to high stress, such as strap attachments and load-bearing sections, are reinforced with additional layers of material or stitching techniques to enhance durability. -

Assembly

– Sewing: The individual components are sewn together using industrial sewing machines. This stage often employs double stitching and bar tacks at critical points to ensure that seams can withstand heavy loads.

– Attachment of Hardware: Zippers, buckles, and MOLLE (Modular Lightweight Load-carrying Equipment) systems are attached during this phase, contributing to the pack’s functionality and versatility. -

Finishing

– Quality Checks: Each assembled backpack undergoes initial quality checks, where visual inspections for stitching, alignment, and overall aesthetics are performed.

– Final Treatments: Some backpacks receive additional treatments, such as water repellency or UV protection, before being packaged for distribution.

Key Manufacturing Techniques

- Ultrasonic Welding: This technique is used to join fabrics without the need for traditional stitching, creating stronger and more waterproof seams.

- Computer-Aided Design (CAD): CAD software helps in designing backpack patterns, ensuring precise dimensions and reducing production errors.

- Robotic Automation: Some stages of the manufacturing process, particularly cutting and sewing, are increasingly automated to enhance efficiency and consistency.

Quality Assurance Standards

Quality assurance is paramount in the production of Tasmanian Tiger backpacks, ensuring that products meet international standards. Here are the key aspects of their quality assurance processes:

Relevant International Standards

- ISO 9001: This standard outlines criteria for a quality management system (QMS). Manufacturers that adhere to ISO 9001 demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

- CE Marking: For products sold in the European Union, the CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: Particularly for tactical and military applications, adherence to American Petroleum Institute (API) standards may be relevant, especially in terms of materials used in backpacks designed for rugged environments.

Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– Raw materials and components are inspected upon arrival to ensure they meet specified quality standards before production begins. This includes checking for defects and verifying material certifications. -

In-Process Quality Control (IPQC)

– Throughout the manufacturing stages, random samples are taken to assess the quality of the assembly process. This includes checking stitch quality, seam integrity, and overall construction. -

Final Quality Control (FQC)

– Once production is complete, every backpack undergoes a final inspection. This includes functionality tests, such as zipper operation, load testing for straps, and overall aesthetic checks.

Illustrative Image (Source: Google Search)

Common Testing Methods

- Load Testing: Backpacks are subjected to weight tests to ensure that they can hold specified loads without failure.

- Water Resistance Tests: For waterproof models, tests are conducted to verify the integrity of seals and materials against water exposure.

- Abrasion Resistance Tests: Fabrics are tested for durability against wear and tear, simulating real-world usage conditions.

Verifying Supplier Quality Control

For B2B buyers, particularly those operating in diverse regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential. Here are actionable steps to ensure compliance and quality:

- Conduct Supplier Audits: Regular audits of manufacturing facilities can provide insights into their quality control practices, adherence to international standards, and overall operational efficiency.

- Request Quality Reports: Suppliers should provide documentation that outlines their quality control processes, testing methods, and results from their quality checks.

- Engage Third-Party Inspectors: Utilizing independent third-party inspection services can validate the quality of products before shipment, offering an unbiased assessment of compliance with specifications.

Regional Considerations for B2B Buyers

When sourcing Tasmanian Tiger backpacks, international buyers must consider regional regulatory requirements and market expectations:

- Africa: Buyers may need to navigate varying import regulations and standards, ensuring compliance with local laws related to safety and materials.

- South America: Understanding local preferences for outdoor gear can influence purchasing decisions, particularly in adventure tourism sectors.

- Middle East: The harsh environmental conditions may necessitate additional emphasis on waterproof and durable materials.

- Europe (e.g., Germany): Buyers must ensure that products meet stringent EU regulations and quality certifications, particularly in sectors like law enforcement and military.

By understanding the manufacturing processes and quality assurance standards of Tasmanian Tiger backpacks, B2B buyers can make informed decisions that align with their operational needs and compliance requirements. This not only enhances procurement effectiveness but also contributes to the overall success of their missions.

Related Video: How a Backpack is Made : Every Step on the Production Line

Comprehensive Cost and Pricing Analysis for tasmanian tiger backpack Sourcing

When sourcing Tasmanian Tiger backpacks, understanding the cost structure and pricing dynamics is essential for B2B buyers looking to optimize their procurement strategies. The cost components and price influencers play a critical role in determining the overall expenditure and can significantly impact the total cost of ownership.

Cost Components

-

Materials: The quality of materials used in Tasmanian Tiger backpacks is a significant cost driver. High-performance fabrics, waterproof coatings, and durable zippers contribute to the overall cost. Buyers should evaluate the types of materials used and their corresponding costs to ensure they align with their operational needs.

-

Labor: Labor costs vary depending on the manufacturing location. Tasmanian Tiger products, known for their German engineering, may have higher labor costs associated with stringent quality standards. Understanding labor dynamics in the manufacturing country can provide insights into pricing.

-

Manufacturing Overhead: This includes costs related to facility maintenance, equipment depreciation, and utilities. B2B buyers should inquire about the manufacturer’s overhead to better understand the price structure.

-

Tooling: Customization often requires specific tooling, which can add to the initial costs. Buyers interested in bespoke solutions should factor in these potential expenses when negotiating prices.

-

Quality Control (QC): Rigorous QC processes ensure product reliability and compliance with international standards. While this adds to the cost, it is crucial for buyers in sectors like military or humanitarian services where performance is non-negotiable.

-

Logistics: Shipping and handling costs can vary significantly based on the destination. For buyers from Africa, South America, the Middle East, and Europe, understanding shipping routes and associated fees is vital for total cost calculations.

-

Margin: The supplier’s profit margin will also influence the final pricing. Buyers should consider this while assessing supplier quotes to ensure they are receiving competitive pricing.

Price Influencers

-

Volume/MOQ: Bulk orders can lead to reduced per-unit costs. B2B buyers should negotiate minimum order quantities (MOQs) that align with their needs to leverage better pricing.

-

Specifications/Customization: Custom features or specifications can increase costs. Buyers should clearly define their requirements to avoid unexpected pricing increases.

-

Materials and Quality Certifications: The choice of materials and certifications (like ISO) can affect pricing. Higher quality or specialized certifications typically command higher prices, but they also ensure better performance.

Illustrative Image (Source: Google Search)

-

Supplier Factors: Reputation, reliability, and financial stability of the supplier can impact pricing. Established suppliers might charge more but offer better guarantees and service.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial. They define responsibilities for shipping costs, insurance, and risk during transit. Buyers should choose terms that minimize their liabilities.

Buyer Tips

-

Negotiation: Always negotiate pricing, especially for bulk purchases. Building a relationship with suppliers can lead to better terms and discounts.

-

Cost-Efficiency: Consider not just the purchase price but the total cost of ownership, including maintenance and potential replacement costs.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and import duties that can affect final costs. Engaging local legal and logistics experts can provide clarity on these issues.

-

Market Research: Conduct thorough market research to understand prevailing prices and competitor offerings. This knowledge can empower negotiation and decision-making.

Disclaimer

The prices for Tasmanian Tiger backpacks can vary widely based on the factors outlined above. It is advisable for buyers to conduct thorough due diligence and obtain multiple quotes to ensure a competitive pricing strategy.

Spotlight on Potential tasmanian tiger backpack Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘tasmanian tiger backpack’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for tasmanian tiger backpack

To effectively procure Tasmanian Tiger backpacks, understanding their essential technical properties and trade terminology is crucial for B2B buyers. This knowledge not only aids in making informed decisions but also ensures that the selected products meet operational requirements across various sectors.

Key Technical Properties

-

Material Grade

– Definition: The quality and type of fabric used in the backpack, such as Cordura® nylon or polyester.

– B2B Importance: Higher-grade materials provide better durability, abrasion resistance, and weatherproofing. This is essential for organizations operating in harsh environments, where equipment longevity directly impacts mission success. -

Load Capacity

– Definition: The maximum weight the backpack can safely carry, typically measured in liters (L).

– B2B Importance: Understanding load capacity helps buyers select the appropriate model for specific tasks, whether for military operations or humanitarian missions. Ensuring the right capacity prevents equipment failure and enhances user comfort. -

Water Resistance Rating (WRR)

– Definition: A measure of how well the backpack can resist water penetration, often denoted by IP ratings.

– B2B Importance: For buyers in regions prone to heavy rainfall or water-related activities, knowing the WRR ensures that the backpack will protect contents from moisture, thus maintaining operational integrity.

Illustrative Image (Source: Google Search)

-

Weight

– Definition: The total weight of the empty backpack, crucial for portability.

– B2B Importance: Lighter backpacks reduce fatigue for users on long missions or during rapid deployments. This factor is particularly vital for teams operating in remote areas where mobility is key. -

Ergonomic Design

– Definition: Features that enhance user comfort, such as padded straps, adjustable frames, and ventilation.

– B2B Importance: Ergonomically designed backpacks reduce the risk of injury and improve user efficiency, which is critical for organizations with personnel who spend extended periods in the field.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships is vital for buyers seeking quality assurance and the potential for customized products tailored to specific operational needs. -

MOQ (Minimum Order Quantity)

– Definition: The smallest amount of product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers plan budgets and inventory management. It can also affect sourcing decisions, particularly for organizations looking to purchase in bulk. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to suppliers requesting pricing and terms for specific products.

– Importance: An RFQ is a crucial step in the procurement process, allowing buyers to compare prices and terms from multiple suppliers, ultimately leading to more informed purchasing decisions. -

Incoterms

– Definition: International commercial terms that define the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms is essential for international B2B buyers to understand shipping responsibilities, risk management, and cost allocation during transportation. -

Lead Time

– Definition: The time taken from placing an order to receiving the product.

– Importance: Understanding lead times is critical for operational planning, especially for organizations that require timely delivery of gear for missions or events. -

Durability Standards

– Definition: Specifications that define the expected lifespan and performance of the product under various conditions.

– Importance: Knowledge of durability standards helps buyers ensure that the backpacks can withstand the rigors of their intended use, reducing the likelihood of premature failure and associated costs.

By grasping these technical properties and trade terminologies, B2B buyers can streamline the procurement process, ensuring they select the right Tasmanian Tiger backpacks for their specific needs. This knowledge not only enhances product performance but also contributes to overall operational success.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the tasmanian tiger backpack Sector

Market Overview & Key Trends

The global market for Tasmanian Tiger backpacks is currently driven by several key factors, including the increasing demand for durable and high-performance gear across diverse sectors such as military, law enforcement, humanitarian aid, and adventure tourism. As organizations in Africa, South America, the Middle East, and Europe expand their operations in challenging environments, the need for reliable equipment has intensified. Buyers are increasingly seeking products that not only meet rigorous performance standards but also adhere to local regulations and logistical considerations.

Emerging trends in B2B procurement include the adoption of technology solutions for supply chain management, enhancing visibility and efficiency. Platforms that facilitate real-time tracking of shipments and inventory are becoming essential for organizations operating in remote areas. Moreover, the shift towards online procurement channels is reshaping how buyers source Tasmanian Tiger backpacks, allowing for more streamlined comparisons of product offerings and pricing.

Additionally, buyers are prioritizing suppliers who can demonstrate agility in fulfilling orders, particularly in regions prone to supply chain disruptions. This includes the ability to customize orders based on specific operational needs, which is critical for agencies operating under unique conditions. Understanding these market dynamics allows B2B buyers to make informed decisions that align with their organizational goals and operational requirements.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a non-negotiable aspect of procurement strategy for international buyers. The environmental impact of manufacturing processes, including the sourcing of raw materials, is under increasing scrutiny. For Tasmanian Tiger backpacks, buyers should seek suppliers who prioritize ethical sourcing practices and demonstrate transparency in their supply chains. This not only mitigates risks associated with environmental degradation but also enhances the brand’s reputation among environmentally conscious consumers.

Buyers should look for products made from sustainable materials, such as recycled fabrics or organic cotton, which can significantly reduce the ecological footprint of their purchases. Certifications like GOTS (Global Organic Textile Standard) or OEKO-TEX® can serve as indicators of a product’s environmental credentials. Furthermore, engaging with suppliers who have implemented waste reduction initiatives and carbon offset programs can enhance the overall sustainability profile of procurement efforts.

By prioritizing sustainability, organizations can not only meet regulatory requirements but also appeal to a growing demographic of consumers and stakeholders who value corporate responsibility. This strategic approach to sourcing can lead to long-term cost savings and improved operational efficiencies.

Brief Evolution/History

Tasmanian Tiger has established itself as a leading brand in the tactical gear market, rooted in German engineering excellence. The brand’s evolution reflects a commitment to innovation and quality, adapting to the needs of various sectors from military to outdoor recreation. Over the years, Tasmanian Tiger has expanded its product range to include specialized backpacks designed for specific applications, such as medical response and waterproof operations. This diversification has positioned the brand as a trusted choice for international B2B buyers seeking reliable solutions for demanding environments. Understanding this historical context can help buyers appreciate the brand’s legacy of quality and innovation as they make procurement decisions.

Related Video: Tasmanian Tiger Modular Pack 30

Frequently Asked Questions (FAQs) for B2B Buyers of tasmanian tiger backpack

-

What should I consider when vetting suppliers for Tasmanian Tiger backpacks?

When vetting suppliers, prioritize their experience and reputation in the tactical equipment market. Request references from previous clients, particularly those in your region. Ensure the supplier is compliant with international standards and has the necessary certifications for quality and safety. Evaluate their supply chain reliability, including lead times and logistics capabilities, especially for shipments to Africa, South America, the Middle East, or Europe. Additionally, assess their customer service responsiveness and willingness to support post-purchase needs. -

Can Tasmanian Tiger backpacks be customized for my organization’s needs?

Yes, many Tasmanian Tiger backpacks offer customization options to meet specific operational requirements. Discuss your needs with the supplier, including branding, color preferences, and functional modifications such as additional pockets or specialized compartments. Ensure you clarify any associated costs and lead times for custom orders. Customization can enhance the utility of the backpacks for your team, making them more effective in the field.

-

What are the minimum order quantities (MOQ) and lead times for Tasmanian Tiger backpacks?

Minimum order quantities can vary significantly based on the supplier and the specific model of the backpack. Typically, MOQs may range from 10 to 100 units. Lead times also depend on the order size and customization requirements, generally ranging from 4 to 12 weeks. It’s advisable to communicate with the supplier about your timelines to ensure they can meet your delivery needs, especially if you have urgent procurement requirements. -

What payment options are available when sourcing Tasmanian Tiger backpacks?

Payment options may include wire transfers, letters of credit, or payment platforms like PayPal, depending on the supplier’s policies. Be sure to negotiate terms that protect your interests, such as partial payments upfront and the remainder upon delivery. Understand any currency exchange implications, especially when dealing with international suppliers, to avoid unexpected costs. Establishing a clear payment schedule can help maintain transparency and trust in the supplier relationship. -

How can I ensure quality assurance and compliance with certifications for the backpacks?

Request documentation of quality assurance processes and certifications from the supplier, such as ISO 9001 or specific compliance with military or environmental standards. Inquire about their testing methods for durability, weather resistance, and safety features. Conducting a factory audit, if feasible, can provide further insight into their manufacturing processes. Also, consider requesting samples to assess the quality firsthand before making a larger commitment. -

What logistics considerations should I keep in mind when importing Tasmanian Tiger backpacks?

Logistics can be complex, especially for international shipments. Confirm the supplier’s shipping methods and whether they handle customs clearance. Understand the import regulations specific to your country, including tariffs, taxes, and required documentation. It’s also beneficial to work with logistics partners experienced in international trade to ensure timely delivery and compliance with local laws. Discuss shipping insurance options to protect against potential losses during transit. -

How should I handle disputes with suppliers regarding Tasmanian Tiger backpack orders?

Begin by reviewing the terms of your purchase agreement to understand your rights and obligations. Communicate openly with the supplier to address any issues, documenting all correspondence for reference. If the dispute cannot be resolved amicably, consider mediation or arbitration as alternatives to legal action. Maintaining a professional demeanor throughout the process can help preserve the business relationship while seeking a resolution. Always have a contingency plan for sourcing alternatives if disputes escalate. -

What are the best practices for post-purchase support and warranty claims for Tasmanian Tiger backpacks?

After purchase, familiarize yourself with the warranty terms and conditions provided by the supplier. Maintain records of your purchase and any communications regarding product issues. For warranty claims, promptly report any defects or issues to the supplier, including detailed descriptions and photographs if possible. Establish a clear understanding of the process for returns or exchanges to ensure a smooth experience. Regularly evaluate the performance of the backpacks in the field to inform future purchasing decisions.

Strategic Sourcing Conclusion and Outlook for tasmanian tiger backpack

In summary, the strategic sourcing of Tasmanian Tiger backpacks offers invaluable advantages for B2B buyers operating in diverse global markets. Understanding the specific types of backpacks available, such as long-range tactical models or specialized medical-response packs, allows organizations to align their procurement with operational needs. Key considerations include assessing durability, compliance with international standards, and regional adaptability, which are critical for ensuring mission success in challenging environments.

Moreover, leveraging robust supplier networks and exploring bulk purchasing options can significantly reduce costs while enhancing supply chain efficiency. For international buyers from Africa, South America, the Middle East, and Europe, the importance of sourcing high-quality gear that meets logistical demands cannot be overstated.

As the market evolves, staying informed about product innovations and emerging trends will empower procurement teams to make strategic decisions that bolster their operational capabilities. Engage with trusted suppliers, explore diverse options, and prioritize quality to ensure that your investments yield substantial returns. The future of your missions depends on the gear you choose today—make it count.