Master Sourcing Space Junk Backpacks: Key Insights for B2B

Guide to Space Junk Backpack

- Introduction: Navigating the Global Market for space junk backpack

- Understanding space junk backpack Types and Variations

- Key Industrial Applications of space junk backpack

- Strategic Material Selection Guide for space junk backpack

- In-depth Look: Manufacturing Processes and Quality Assurance for space junk backpack

- Comprehensive Cost and Pricing Analysis for space junk backpack Sourcing

- Spotlight on Potential space junk backpack Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for space junk backpack

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the space junk backpack Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of space junk backpack

- Strategic Sourcing Conclusion and Outlook for space junk backpack

Introduction: Navigating the Global Market for space junk backpack

The emergence of the space junk backpack represents a pivotal innovation in the world of packaging and logistics, addressing the escalating concerns surrounding orbital debris. As the global space economy expands, so does the necessity for effective solutions that mitigate the risks posed by space debris. This guide provides international B2B buyers with crucial insights into the evolving landscape of space junk backpacks, detailing their significance in both environmental stewardship and operational efficiency.

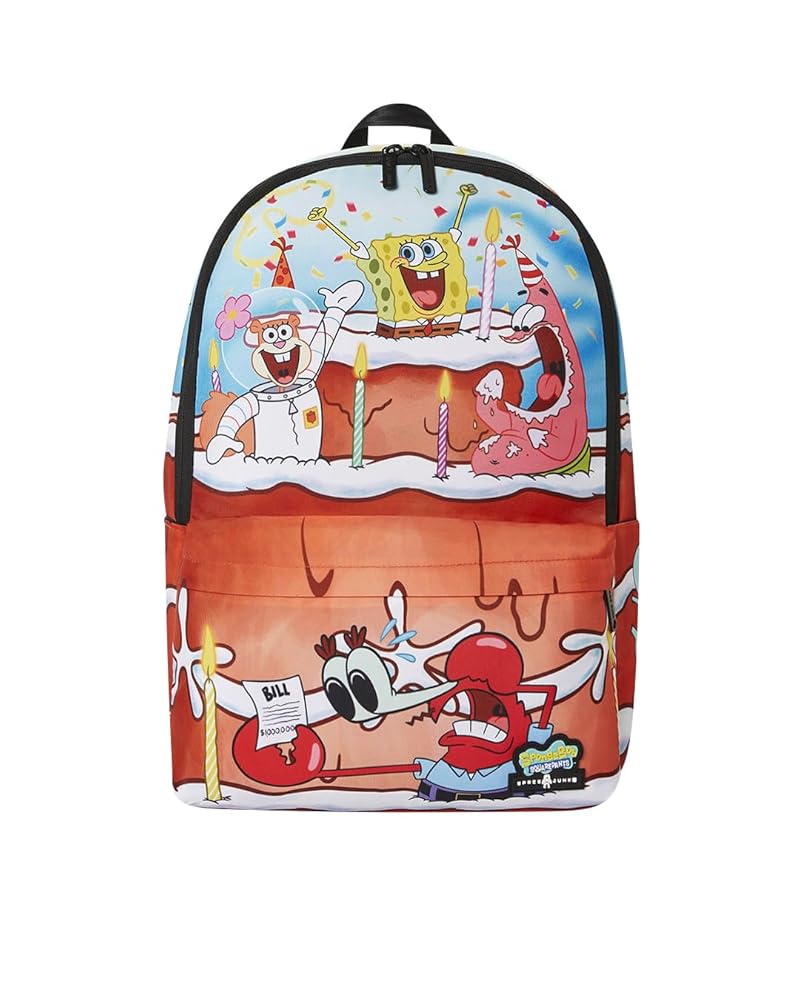

Illustrative Image (Source: Google Search)

Understanding the diverse types of space junk backpacks, the materials employed, and the manufacturing processes is vital for making informed sourcing decisions. This comprehensive resource delves into quality control standards, supplier evaluations, cost considerations, and market dynamics specific to regions such as Africa, South America, the Middle East, and Europe, including key players in countries like France and Brazil.

By equipping buyers with actionable insights, this guide empowers them to navigate the complexities of sourcing space junk backpacks effectively. It addresses frequently asked questions and highlights best practices in supplier engagement, ensuring that businesses can align their procurement strategies with sustainability goals and market demands. As global stakeholders prioritize eco-friendly solutions, the space junk backpack stands out as a critical investment for organizations aiming to enhance their operational resilience and environmental responsibility in the space sector.

Understanding space junk backpack Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Space Junk Backpack | Basic design, typically made from durable materials like nylon or polyester | General use in space missions and debris collection | Pros: Cost-effective, widely available. Cons: Limited specialized features. |

| Technical Space Junk Backpack | Enhanced features like reinforced seams and specialized compartments for tools | Use by engineers and technicians during missions | Pros: High durability, tailored for specific tasks. Cons: Higher price point. |

| Eco-Friendly Space Junk Backpack | Made from sustainable materials, often biodegradable or recycled | Companies focused on sustainability and environmental impact | Pros: Aligns with corporate social responsibility goals. Cons: May be more expensive than standard options. |

| High-Capacity Space Junk Backpack | Larger storage capacity, designed for prolonged missions | Extended missions where storage is critical | Pros: Ample space for equipment and debris. Cons: Bulkier, may be less portable. |

| Modular Space Junk Backpack | Customizable compartments and attachments for various tools and equipment | Organizations requiring flexibility in mission planning | Pros: Versatile design, adaptable to different missions. Cons: Complexity may lead to higher maintenance needs. |

Standard Space Junk Backpack

The standard space junk backpack is the most basic option available, typically constructed from durable materials such as nylon or polyester. These backpacks are primarily used for general purposes in space missions and debris collection. Buyers will appreciate their cost-effectiveness and availability, but they may find that the limited specialized features restrict their functionality in more demanding environments.

Technical Space Junk Backpack

Designed for engineers and technicians, the technical space junk backpack boasts enhanced features like reinforced seams and specialized compartments for tools. Its primary application lies in space missions where precision and durability are paramount. While these backpacks offer high durability and are tailored for specific tasks, their higher price point may deter budget-conscious buyers.

Eco-Friendly Space Junk Backpack

Eco-friendly space junk backpacks are crafted from sustainable materials, such as biodegradable or recycled fabrics. They cater to companies focused on sustainability and environmental impact, making them an attractive option for businesses aiming to align with corporate social responsibility goals. However, buyers should be aware that these backpacks may come at a premium compared to standard options.

High-Capacity Space Junk Backpack

High-capacity space junk backpacks are designed for prolonged missions, providing ample storage for equipment and debris. Their primary application is in scenarios where storage is critical, such as long-duration missions. While they offer significant space advantages, their bulkier design may compromise portability, which is a crucial consideration for some buyers.

Modular Space Junk Backpack

The modular space junk backpack features customizable compartments and attachments, allowing for flexibility in mission planning. This type is ideal for organizations that require adaptability in their operations. While the versatile design offers numerous benefits, the complexity of the system may lead to higher maintenance needs, which buyers must factor into their purchasing decisions.

Key Industrial Applications of space junk backpack

| Industry/Sector | Specific Application of Space Junk Backpack | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Debris management systems | Enhanced safety and operational efficiency | Compliance with aerospace standards, lightweight materials |

| Environmental Services | Pollution control in space | Improved sustainability and reduced environmental impact | Material durability, resistance to harsh conditions |

| Research & Development | Prototyping for space exploration technology | Innovation in space technology applications | Access to advanced materials, scalability of production |

| Education | Teaching tools for space science | Engaging learning experiences for students | Customization options, educational partnerships |

| Defense | Space situational awareness systems | Enhanced national security through debris tracking | Compliance with military specifications, high reliability |

Aerospace

In the aerospace sector, space junk backpacks can be integrated into debris management systems, which are critical for maintaining the safety of operational spacecraft. These backpacks can be designed to capture and neutralize small pieces of debris that pose a risk to satellites and space stations. For international buyers, especially those from Europe and the Middle East, compliance with rigorous aerospace standards and the use of lightweight yet durable materials are paramount to ensure performance and safety in space.

Environmental Services

For environmental services, space junk backpacks serve as innovative tools for pollution control in orbit. They can actively collect debris and pollutants, contributing to efforts aimed at reducing the environmental impact of space activities. This application not only enhances sustainability but also aligns with global environmental regulations, making it particularly relevant for buyers in Africa and South America who are increasingly focused on sustainable practices. Key considerations include the durability of materials and their ability to withstand extreme conditions.

Research & Development

In research and development, space junk backpacks can be utilized for prototyping new technologies aimed at space exploration. These backpacks provide a platform for testing various systems designed to capture or repurpose space debris, fostering innovation in the sector. For international buyers, particularly those in Europe, access to advanced materials and the capability to scale production are vital for ensuring successful prototype development and eventual commercialization.

Education

The education sector can leverage space junk backpacks as teaching tools for space science and technology. By providing hands-on learning experiences, these backpacks can engage students in understanding space debris and its implications. For educational institutions in regions like Brazil and South Africa, customization options and potential partnerships with technology providers can enhance the educational value and practical applications of these tools.

Defense

In defense applications, space junk backpacks can be part of space situational awareness systems, aiding in tracking and managing space debris that could threaten national security. These systems are essential for military operations that require precise knowledge of the space environment. Buyers from the Middle East and Europe must consider compliance with military specifications and the reliability of materials used in these backpacks to ensure they meet stringent operational demands.

Related Video: Everyday Applications of Magnets

Strategic Material Selection Guide for space junk backpack

When selecting materials for a space junk backpack, it is essential to consider their performance characteristics, manufacturing complexities, and compliance with international standards. Here, we analyze four common materials that are suitable for this application: Nylon, Polyester, Carbon Fiber, and Aluminum. Each material has unique properties that impact the overall functionality and marketability of the backpack.

Nylon

Key Properties: Nylon is known for its high tensile strength, flexibility, and resistance to abrasion. It can withstand a wide range of temperatures and is often treated to enhance its UV resistance, making it suitable for outdoor applications.

Pros & Cons:

– Pros: Durable, lightweight, and resistant to mildew and mold. It also has good elasticity, which allows for some stretching without losing shape.

– Cons: Nylon can absorb moisture, which may lead to issues in humid environments. Additionally, it can be more expensive than other synthetic materials.

Impact on Application: Nylon’s durability and flexibility make it ideal for backpacks that need to withstand harsh conditions, especially in space-related applications where weight is a critical factor.

Considerations for International Buyers: Buyers should ensure that the nylon used meets ASTM and ISO standards for strength and durability. Compliance with environmental regulations regarding synthetic materials is also crucial, especially in Europe.

Polyester

Key Properties: Polyester is another synthetic fabric known for its resistance to shrinking and stretching. It has a good strength-to-weight ratio and is often treated for water resistance.

Pros & Cons:

– Pros: Generally more cost-effective than nylon, polyester is also resistant to UV light and mildew, making it suitable for various climates.

– Cons: It is less durable than nylon and can be prone to fading over time, particularly when exposed to sunlight.

Impact on Application: Polyester’s water resistance and cost-effectiveness make it a popular choice for backpacks intended for outdoor use, although it may not perform as well under extreme conditions as nylon.

Considerations for International Buyers: Buyers should check for compliance with common standards such as ASTM D5034 for tearing strength. The environmental impact of polyester production is also a growing concern, particularly in Europe and South America.

Carbon Fiber

Key Properties: Carbon fiber is renowned for its exceptional strength-to-weight ratio and rigidity. It can withstand extreme temperatures and is resistant to corrosion.

Pros & Cons:

– Pros: Extremely lightweight and strong, making it ideal for high-performance applications. It also offers excellent thermal stability.

– Cons: The cost of carbon fiber is significantly higher than that of synthetic fabrics, and its manufacturing process can be complex.

Impact on Application: Carbon fiber is suitable for specialized backpacks designed for extreme conditions or high-tech applications, such as those used in aerospace or military settings.

Considerations for International Buyers: Buyers should verify that carbon fiber products comply with relevant aerospace standards, such as those set by ASTM and ISO. The higher cost may limit its appeal for mass-market products.

Aluminum

Key Properties: Aluminum is a lightweight metal known for its strength and resistance to corrosion. It is often used in the structural components of backpacks.

Pros & Cons:

– Pros: Durable and lightweight, aluminum can provide structural integrity without adding significant weight to the backpack.

– Cons: It can be prone to dents and scratches, and its manufacturing process may require more energy compared to synthetic materials.

Impact on Application: Aluminum is often used in frames or support structures within backpacks, providing a balance between weight and durability.

Considerations for International Buyers: Buyers should ensure that aluminum components meet international standards for quality and safety. Compliance with environmental regulations regarding metal production is also important, especially in Europe.

Summary Table

| Material | Typical Use Case for space junk backpack | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | High-performance outdoor backpacks | Durable and lightweight | Absorbs moisture, higher cost | Medium |

| Polyester | Cost-effective outdoor backpacks | Water-resistant and UV resistant | Less durable, prone to fading | Low |

| Carbon Fiber | Specialized high-tech backpacks | Exceptional strength-to-weight ratio | High cost, complex manufacturing | High |

| Aluminum | Structural components in backpacks | Lightweight and corrosion-resistant | Prone to dents, higher energy manufacturing | Medium |

This guide provides a comprehensive overview of material options for space junk backpacks, enabling international B2B buyers to make informed decisions based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for space junk backpack

Manufacturing Processes for Space Junk Backpacks

The manufacturing of space junk backpacks involves several critical processes, ensuring that the final product meets both functional and safety standards. Below is a detailed breakdown of the main stages of manufacturing, key techniques employed, and quality assurance measures that international B2B buyers should consider.

Main Stages of Manufacturing

-

Material Preparation

– Selection of Materials: High-performance materials like ballistic nylon, ripstop polyester, or other lightweight composites are selected for their durability and resistance to wear. Additionally, materials must be chosen based on their ability to withstand extreme conditions, including temperature fluctuations and exposure to UV radiation.

– Pre-Treatment: Materials may undergo pre-treatment processes to enhance their properties, such as water-repellent coatings or anti-static treatments, which are crucial for preventing the accumulation of space debris. -

Forming

– Cutting: Advanced cutting techniques, including laser cutting or die-cutting, are used to ensure precision in the shapes and sizes of backpack components. This step is essential for maintaining consistent quality across batches.

– Shaping: Components are shaped using techniques such as heat molding or stitching, allowing the manufacturer to create ergonomic designs that enhance user comfort and functionality. -

Assembly

– Sewing and Bonding: The assembly of the backpack involves sewing together various components using heavy-duty threads and reinforced stitching techniques. In some cases, adhesive bonding methods may be employed for specific materials to enhance durability.

– Integration of Features: Additional features such as compartments for tools, pockets for gadgets, and straps for securing items are integrated during this stage. This customization is critical for meeting the diverse needs of end-users. -

Finishing

– Quality Checks: Post-assembly, each backpack undergoes thorough inspections to ensure compliance with design specifications. This includes checking for structural integrity, stitching quality, and overall aesthetics.

– Final Treatments: The final stage may involve applying protective finishes, such as anti-abrasive coatings or UV protection treatments, to further enhance the product’s lifespan.

Quality Assurance Standards

Quality assurance is vital in the manufacturing process of space junk backpacks, ensuring that products not only meet customer expectations but also adhere to international standards.

Relevant International Standards

- ISO 9001: This standard outlines the criteria for a quality management system, focusing on meeting customer needs and enhancing satisfaction. Compliance with ISO 9001 is essential for suppliers aiming to establish credibility in international markets.

- CE Marking: For products marketed in Europe, CE marking indicates conformity with health, safety, and environmental protection standards. This is particularly crucial for products that may come into contact with sensitive equipment.

- API Standards: For backpacks that may be used in conjunction with aerospace applications, compliance with specific American Petroleum Institute (API) standards ensures that materials and processes are suitable for high-stress environments.

Quality Control Checkpoints

-

Incoming Quality Control (IQC):

– Materials are inspected upon arrival at the manufacturing facility. This includes verifying the specifications, certifications, and any compliance documentation from suppliers. -

In-Process Quality Control (IPQC):

– Throughout the manufacturing process, regular inspections are conducted to monitor adherence to quality standards. This includes checking stitching patterns, material integrity, and assembly accuracy. -

Final Quality Control (FQC):

– Once production is complete, a final inspection is performed. This includes functionality tests (e.g., load-bearing tests), visual inspections for defects, and compliance checks against customer specifications.

Common Testing Methods

To ensure that space junk backpacks can withstand the rigors of use, several testing methods are employed:

- Load Testing: Assessing the backpack’s ability to carry specified weights without compromising structural integrity.

- Durability Testing: Subjecting the backpack to wear and tear simulations to evaluate the longevity of materials and stitching.

- Environmental Testing: Exposing the backpack to extreme temperatures, humidity, and UV light to ensure it can withstand diverse environmental conditions.

- Water Resistance Testing: Checking the effectiveness of water-repellent treatments and the overall waterproofing of the backpack.

Verifying Supplier Quality Control

B2B buyers must take proactive measures to ensure that their suppliers maintain high-quality standards. Here are some actionable steps:

-

Supplier Audits:

– Conduct regular audits of potential suppliers to evaluate their manufacturing processes, quality control measures, and compliance with international standards. This can help identify any gaps in their quality management systems. -

Quality Reports:

– Request detailed quality reports that outline testing results, compliance certifications, and any corrective actions taken in response to past quality issues. This transparency fosters trust and reliability in the supplier relationship. -

Third-Party Inspections:

– Engage third-party inspection services to provide unbiased assessments of the manufacturing facility and the products. This can include pre-shipment inspections to ensure that the final products meet agreed specifications before shipment.

QC and Certification Nuances for International Buyers

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of certain nuances in quality control and certification:

- Cultural and Regulatory Differences: Different regions may have varying standards for quality assurance. It is essential for buyers to be familiar with local regulations and industry expectations to avoid compliance issues.

- Language Barriers: Ensure that all documentation and communication are clear and comprehensible. Consider using translation services if necessary to facilitate effective collaboration with suppliers.

- Sustainability Standards: As sustainability becomes a focal point in global markets, buyers should prioritize suppliers who adhere to eco-friendly practices and materials, which can enhance brand reputation and marketability.

By understanding the manufacturing processes and quality assurance standards, international B2B buyers can make informed decisions when sourcing space junk backpacks. This knowledge not only facilitates better supplier relationships but also enhances product reliability and customer satisfaction in a competitive marketplace.

Related Video: Amazing factories and processes| Manufacturing method and top 5 processes| Mass production process

Comprehensive Cost and Pricing Analysis for space junk backpack Sourcing

When sourcing space junk backpacks, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers. This analysis breaks down the various cost components and pricing influencers to help you make informed decisions.

Cost Components

-

Materials:

– The choice of materials significantly impacts the overall cost. High-performance fabrics, eco-friendly materials, and advanced composites can increase material costs but may be necessary for durability and sustainability.

– Prices can vary based on sourcing locations; for example, materials sourced from Europe may carry higher costs compared to those from Asia due to transportation and import duties. -

Labor:

– Labor costs differ across regions. Countries like Vietnam and Bangladesh offer competitive labor rates, whereas European manufacturers may charge a premium for skilled craftsmanship.

– Consider the skill level required for production; complex designs or specialized materials may necessitate higher labor costs. -

Manufacturing Overhead:

– This includes factory operational costs such as utilities, equipment depreciation, and administrative expenses. Factories with higher automation levels may have lower overhead but might require higher initial investments in machinery. -

Tooling:

– Tooling costs can be substantial, especially for custom designs. These are one-time expenses associated with creating molds or specific production setups. The amortization of these costs over larger production runs can lead to more cost-effective pricing per unit.

Illustrative Image (Source: Google Search)

-

Quality Control (QC):

– Implementing stringent QC processes is crucial for ensuring product quality, especially for items exposed to extreme conditions in space. QC costs can vary based on the complexity of the checks required and the certifications needed. -

Logistics:

– Shipping and handling costs should not be overlooked. These vary widely depending on the shipping method, distance, and Incoterms chosen. Air freight is faster but more expensive than sea freight, which can significantly influence the total cost. -

Margin:

– Supplier margins typically range from 15% to 30%, depending on the complexity of the product and market competition. Understanding supplier pricing strategies can help in negotiations.

Price Influencers

- Volume/MOQ:

-

Minimum Order Quantities (MOQs) can greatly affect unit pricing. Suppliers often offer better pricing for larger orders, making it essential to assess your purchasing needs against MOQ requirements.

-

Specifications/Customization:

-

Custom features or specifications increase costs. Simple designs may yield lower prices, while highly customized products will require more investment in both time and materials.

-

Quality/Certifications:

-

Products that meet specific international standards or certifications (like ISO) may carry higher costs but can enhance marketability and buyer trust.

-

Supplier Factors:

-

The reputation and reliability of suppliers can impact pricing. Established suppliers may charge a premium but often provide better quality assurance and reliability.

-

Incoterms:

- Understanding Incoterms is crucial for determining who bears the shipping costs and risks. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect overall pricing and negotiation strategies.

Buyer Tips

- Negotiation:

-

Engage suppliers in discussions about pricing and terms. Building long-term relationships can lead to more favorable pricing structures.

-

Cost-Efficiency:

-

Evaluate the Total Cost of Ownership (TCO) rather than just unit prices. Consider factors like durability, replacement costs, and warranty services in your assessments.

-

Pricing Nuances:

- Be aware of regional pricing differences. For instance, buyers in Europe may face different tariff structures compared to those in Africa or South America, affecting overall costs.

Disclaimer

Prices mentioned are indicative and can vary significantly based on market conditions, specific supplier terms, and negotiations. Always conduct thorough market research and supplier assessments to obtain the most accurate pricing information for your specific sourcing needs.

Spotlight on Potential space junk backpack Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘space junk backpack’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for space junk backpack

To effectively engage in the international market for space junk backpacks, understanding key technical properties and trade terminology is essential. This section outlines critical specifications and common jargon that B2B buyers should be familiar with.

Key Technical Properties

-

Material Grade

– Definition: The classification of materials based on their physical and chemical properties. In the context of space junk backpacks, materials such as ballistic nylon, Cordura, or aerospace-grade composites are often used.

– Importance: High-grade materials ensure durability and resistance to extreme conditions, which is crucial for products designed for space applications. Buyers should prioritize suppliers who adhere to strict material standards to ensure product longevity. -

Tolerance Levels

– Definition: Tolerance refers to the allowable deviation in dimensions or specifications of the backpack components. Tighter tolerances indicate higher precision in manufacturing.

– Importance: For space applications, where even minor discrepancies can lead to significant issues, understanding tolerance levels is vital. Buyers should ensure that manufacturers can consistently meet specified tolerances to maintain quality.

-

Load Capacity

– Definition: The maximum weight that the backpack can safely carry without compromising its structural integrity.

– Importance: Knowing the load capacity is essential for buyers to ensure that the backpack can handle the intended payload, especially in space missions where equipment can be heavy and cumbersome. -

Weight-to-Strength Ratio

– Definition: This property measures the strength of the material relative to its weight, often expressed as a ratio.

– Importance: A favorable weight-to-strength ratio is crucial for space applications, where minimizing weight while maximizing strength can enhance performance and efficiency. Buyers should evaluate products based on this ratio to ensure optimal performance in space environments. -

Thermal Resistance

– Definition: The ability of the backpack material to withstand extreme temperature fluctuations without degrading.

– Importance: Space environments can expose materials to extreme temperatures. Thermal resistance ensures that the backpack remains functional and intact, making it a key specification for buyers. -

Water Resistance Rating

– Definition: A measure of how well the backpack can resist water penetration, usually indicated by IP (Ingress Protection) ratings.

– Importance: Given the potential for exposure to moisture and other environmental factors, a high water resistance rating is critical for maintaining the integrity of the backpack and its contents.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships is crucial for buyers looking for custom or specialized backpacks, as it influences pricing, quality, and supply chain dynamics. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Buyers must consider MOQs to align their purchasing strategies with their demand forecasts. This can impact cash flow and inventory management. -

RFQ (Request for Quotation)

– Definition: A document that solicits quotes from suppliers for specific products or services.

– Relevance: Utilizing RFQs can streamline the procurement process, helping buyers compare pricing and terms from multiple suppliers efficiently. -

Incoterms (International Commercial Terms)

– Definition: A set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions.

– Relevance: Familiarity with Incoterms is essential for navigating shipping, insurance, and risk management, especially when sourcing from diverse regions. -

Lead Time

– Definition: The total time it takes from placing an order to receiving the product.

– Relevance: Understanding lead times is critical for planning and ensuring timely delivery, particularly for projects with strict deadlines. -

Quality Assurance (QA)

– Definition: A systematic process to ensure that products meet specified quality standards.

– Relevance: A strong QA process is essential for maintaining product consistency and reliability, especially in high-stakes environments like space missions.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring that their procurement strategies align with both quality standards and operational needs in the space sector.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the space junk backpack Sector

Market Overview & Key Trends

The global market for space junk backpacks is driven by several factors, including increasing consumer interest in space exploration, environmental awareness, and the rise of technological innovations in materials and manufacturing processes. As the space industry expands, so does the need for effective solutions to mitigate space debris, leading to a burgeoning demand for specialized backpacks designed to protect sensitive equipment from orbital debris.

Emerging B2B tech trends include the integration of advanced materials such as lightweight composites and high-strength fabrics that can withstand the rigors of space travel while being environmentally sustainable. Notably, sourcing strategies are evolving, with companies adopting a “China Plus One” approach, diversifying their supply chains to include manufacturers from Southeast Asia and South America. This strategy enhances resilience and reduces risks associated with geopolitical tensions or supply chain disruptions.

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding local market dynamics is crucial. Countries like Brazil and France are investing in space programs, creating a fertile ground for partnerships with manufacturers of space-related gear. Buyers should also consider logistics and lead times, as well as the total cost of ownership, which encompasses production, shipping, and compliance with international standards.

Sustainability & Ethical Sourcing in B2B

Sustainability is a pivotal concern in the space junk backpack sector, as the environmental impact of production and disposal practices comes under increasing scrutiny. Ethical sourcing practices are becoming essential, with buyers encouraged to seek suppliers who prioritize sustainability in their manufacturing processes. This includes the use of recycled materials, responsible sourcing of raw materials, and adherence to fair labor practices.

Certification for “green” materials, such as those recognized by organizations like the Global Organic Textile Standard (GOTS) or the OEKO-TEX certification for textiles, can significantly enhance a brand’s reputation and marketability. B2B buyers should actively seek suppliers who can demonstrate compliance with these standards, ensuring that their products not only meet performance expectations but also align with global sustainability goals.

Furthermore, manufacturers are exploring innovative solutions, such as biodegradable materials and eco-friendly production methods, which can reduce waste and lower carbon footprints. As consumers and businesses alike become more environmentally conscious, aligning product offerings with sustainability objectives will be key to capturing market share in this evolving sector.

Brief Evolution/History

The concept of space junk backpacks has evolved alongside advancements in space exploration and environmental awareness. Initially, backpacks were designed primarily for utility and durability; however, with the increasing recognition of space debris as a significant issue, manufacturers began to innovate. The integration of specialized materials capable of protecting equipment from potential damage caused by space debris has transformed these products into essential tools for astronauts and space enthusiasts alike.

Today, the focus has shifted not only to functionality but also to sustainability. As the market matures, buyers are increasingly looking for products that reflect their values, particularly in terms of environmental stewardship and ethical sourcing. This evolution reflects broader trends in consumer behavior, where sustainability is now a core consideration in purchasing decisions. As a result, the space junk backpack sector continues to adapt, combining cutting-edge technology with responsible practices to meet the demands of a more conscientious marketplace.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of space junk backpack

-

What should I consider when vetting suppliers for space junk backpacks?

When vetting suppliers, prioritize their experience in producing specialized backpacks, particularly those designed for space applications. Assess their manufacturing capabilities, certifications (such as ISO 9001), and previous client references. It’s also crucial to evaluate their ability to meet international standards for quality and safety. For buyers from Africa, South America, the Middle East, and Europe, consider suppliers who have experience shipping to your region and understand local regulations. -

Can I customize space junk backpacks to meet specific needs?

Yes, many manufacturers offer customization options, which may include specific materials, sizes, colors, and branding. When discussing customization, ensure you communicate your requirements clearly and ask for samples to evaluate quality before placing a larger order. Consider the manufacturer’s flexibility in production; some may have minimum order quantities (MOQs) for custom designs, which can vary widely between suppliers. -

What are the typical MOQs and lead times for space junk backpacks?

Minimum order quantities (MOQs) for space junk backpacks can range from 500 to 5,000 units, depending on the supplier and the complexity of the design. Lead times generally vary from 4 to 12 weeks, influenced by factors such as the supplier’s production capacity and your location. For international buyers, it’s advisable to discuss these details upfront to align your procurement timelines with your market needs. -

What payment methods are commonly accepted by suppliers?

Most suppliers accept various payment methods, including bank transfers, letters of credit, and payment platforms like PayPal. For larger orders, letters of credit can offer protection for both parties. Always confirm payment terms upfront, as some suppliers may require a deposit before production begins, especially for customized orders. Understanding these terms can help mitigate risks associated with international trade. -

How do I ensure quality assurance and certification of the products?

To ensure quality assurance, request documentation of the supplier’s quality control processes and any relevant certifications (e.g., CE marking for European markets). Consider conducting factory audits if possible or hiring third-party inspection services to verify quality before shipment. Establishing a clear agreement on quality expectations in your purchase contract can also help avoid disputes later. -

What logistics considerations should I keep in mind when sourcing internationally?

When sourcing space junk backpacks, understand the logistics involved in international shipping, including customs regulations, duties, and tariffs specific to your region. Collaborate with logistics providers experienced in handling international freight, as they can navigate complexities such as documentation and tracking. Additionally, consider the supplier’s location relative to shipping ports to optimize shipping times and costs.

Illustrative Image (Source: Google Search)

-

How should disputes with suppliers be handled?

Disputes can arise from various issues such as quality discrepancies or delivery delays. To manage disputes effectively, establish clear communication channels and document all agreements and expectations in your contracts. If a dispute occurs, engage in direct discussions with the supplier to seek an amicable resolution. If necessary, consider mediation or arbitration as alternative dispute resolution methods to avoid lengthy litigation. -

What are the environmental considerations when sourcing space junk backpacks?

Sustainability is increasingly important in product sourcing. Inquire about the materials used in the production of space junk backpacks, ensuring they comply with environmental standards and regulations. Suppliers that utilize eco-friendly materials or sustainable manufacturing processes can enhance your brand’s reputation and appeal in markets that prioritize sustainability. Additionally, understanding the end-of-life options for the backpacks can further align your procurement strategy with environmental goals.

Strategic Sourcing Conclusion and Outlook for space junk backpack

In conclusion, the strategic sourcing of space junk backpacks represents a unique opportunity for international B2B buyers. As the global market for bags and luggage continues to expand, the demand for innovative solutions that address space debris is increasing. Companies must prioritize quality, supplier reliability, and sustainable practices when selecting manufacturing partners. This not only ensures compliance with evolving environmental standards but also enhances brand reputation in a competitive marketplace.

Buyers from Africa, South America, the Middle East, and Europe should consider diversifying their sourcing strategies to leverage the strengths of various manufacturing hubs. Countries like Vietnam and India offer competitive pricing and craftsmanship, while China remains a powerhouse for large-scale production. By adopting a “China Plus One” approach, businesses can mitigate risks associated with supply chain disruptions.

Looking ahead, as the importance of sustainability and responsible manufacturing grows, investing in space junk backpacks can position your business as a leader in innovation. Engage with suppliers who share your vision for a cleaner, more sustainable future in space exploration. Now is the time to act—embrace strategic sourcing to stay ahead in this emerging market.