Master Sourcing High-Quality Ori Backpacks for Your

Guide to Ori Backpack

- Introduction: Navigating the Global Market for ori backpack

- Understanding ori backpack Types and Variations

- Key Industrial Applications of ori backpack

- Strategic Material Selection Guide for ori backpack

- In-depth Look: Manufacturing Processes and Quality Assurance for ori backpack

- Comprehensive Cost and Pricing Analysis for ori backpack Sourcing

- Spotlight on Potential ori backpack Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for ori backpack

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ori backpack Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of ori backpack

- Strategic Sourcing Conclusion and Outlook for ori backpack

Introduction: Navigating the Global Market for ori backpack

In today’s competitive global market, the demand for innovative and sustainable products is more crucial than ever, particularly in the realm of backpacks. The ori backpack stands out as a prime example of this trend, combining functionality with eco-friendly materials. For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, understanding the significance of the ori backpack can be a game changer for their inventory.

This comprehensive guide delves into various aspects of sourcing ori backpacks, providing invaluable insights that empower informed decision-making. It covers an array of topics, including the types of ori backpacks available, the materials that define their quality, and the manufacturing and quality control processes that ensure durability and performance. Furthermore, we will explore potential suppliers, cost considerations, and market trends, along with a FAQ section addressing common queries.

By leveraging this guide, buyers can confidently navigate the complexities of the global backpack market, ensuring they select products that not only meet their business needs but also resonate with environmentally conscious consumers. The ori backpack is not just a product; it’s a statement of quality and sustainability that can enhance your brand’s reputation and profitability.

Understanding ori backpack Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

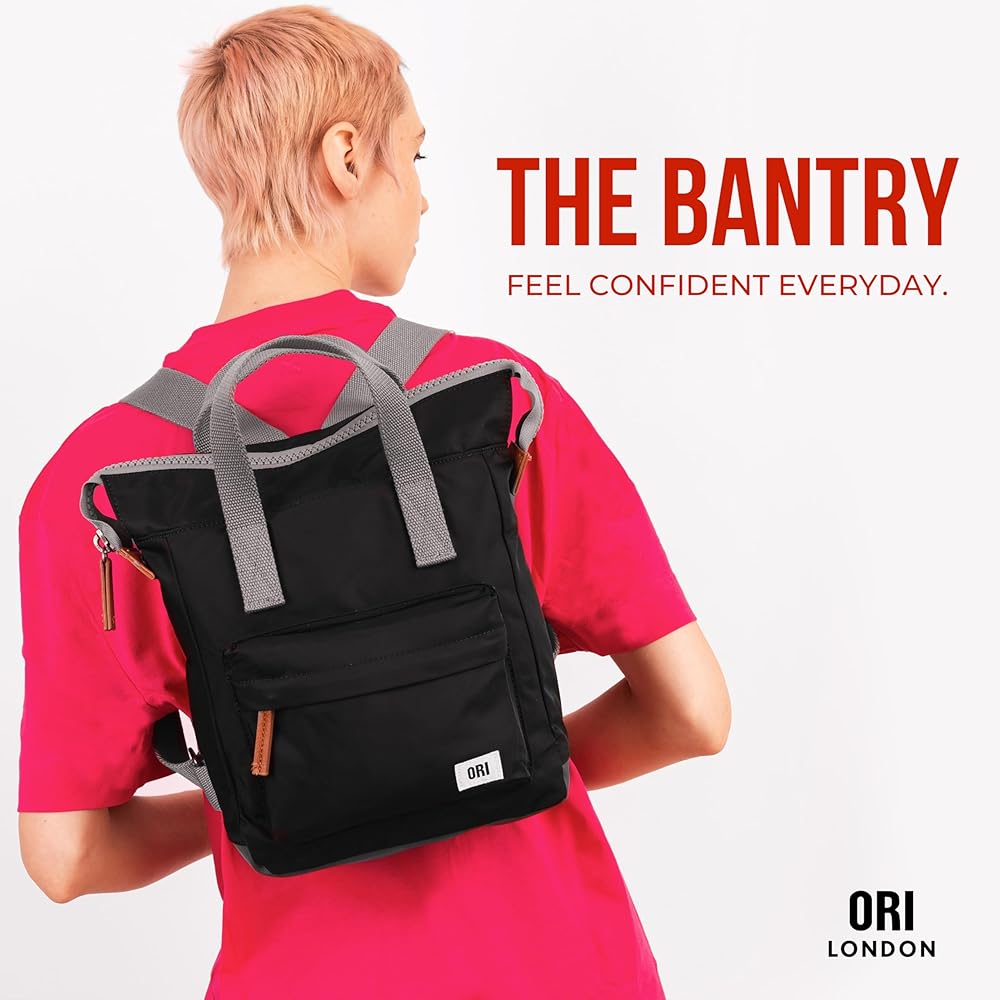

| Bantry Backpack | Original design, spacious main compartment | Retail, corporate gifts | Pros: Versatile and stylish; Cons: May not be suitable for heavy loads. |

| Canfield Roll Top Backpack | Adjustable roll-top closure, water-resistant fabric | Outdoor activities, travel | Pros: Offers flexibility in storage; Cons: Slightly heavier due to materials. |

| Finchley Minimalist Backpack | Sleek design, lightweight, minimal storage | Urban commuters, tech accessory | Pros: Ideal for daily use; Cons: Limited space for bulky items. |

| Richmond Adventurer’s Bag | Rugged design, multiple compartments | Adventure tourism, outdoor retailers | Pros: Durable and functional; Cons: Bulkier than standard backpacks. |

| Camden P Smart Storage Bag | Smart organizational features, modern aesthetics | E-commerce, corporate promotions | Pros: Great for tech and accessories; Cons: Higher price point. |

Bantry Backpack

The Bantry Backpack is characterized by its original design and spacious main compartment, making it an excellent choice for various retail applications and corporate gifting. Its versatility allows it to cater to different customer preferences, while its stylish appearance enhances brand visibility. Buyers should consider its suitability for lighter loads, as it may not perform well under heavy use, which could impact customer satisfaction.

Canfield Roll Top Backpack

The Canfield Roll Top Backpack features an adjustable roll-top closure and is made from water-resistant fabric, making it ideal for outdoor activities and travel. This design allows users to adjust the capacity based on their needs, which can be particularly appealing for adventure-oriented customers. However, buyers should note that the materials used may add weight, which could deter some users looking for lightweight options.

Finchley Minimalist Backpack

The Finchley Minimalist Backpack is known for its sleek design and lightweight nature, catering primarily to urban commuters and those looking for a tech accessory. Its minimal storage capacity is perfect for daily essentials, making it an attractive choice for modern consumers. Buyers should be aware that while it serves well for everyday items, it may not accommodate bulkier goods, limiting its versatility.

Richmond Adventurer’s Bag

The Richmond Adventurer’s Bag stands out with its rugged design and multiple compartments, making it well-suited for adventure tourism and outdoor retail applications. Its durability and functionality are key selling points, appealing to customers who require a reliable backpack for various terrains. However, its bulkier nature compared to standard backpacks may be a consideration for buyers focused on lightweight options.

Camden P Smart Storage Bag

The Camden P Smart Storage Bag offers innovative organizational features and modern aesthetics, making it an excellent choice for e-commerce and corporate promotional needs. Its design caters to tech-savvy consumers who appreciate practical storage solutions. While its higher price point may be a drawback for some buyers, the quality and functionality it provides can justify the investment for businesses targeting premium markets.

Related Video: Large Language Models (LLMs) – Everything You NEED To Know

Key Industrial Applications of ori backpack

| Industry/Sector | Specific Application of ori backpack | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Education | Student backpacks for schools and universities | Durable, stylish options for students; promotes brand visibility | Quality of materials, ergonomic design, and customization options |

| Travel & Tourism | Luggage for adventure tourism | Lightweight, functional design for travelers; enhances brand image | Durability testing, waterproof materials, and aesthetic appeal |

| Corporate & Events | Promotional backpacks for corporate events | Effective branding tool; practical giveaway for attendees | Customization capabilities, material quality, and supply timelines |

| Retail | Retail display for eco-friendly products | Aligns with sustainability initiatives; attracts eco-conscious consumers | Sourcing from sustainable materials, quality assurance processes |

| Logistics & Delivery | Employee backpacks for delivery personnel | Enhances employee mobility; functional storage solutions | Capacity and weight limits, material durability, and comfort features |

Education Sector

In the education sector, the ori backpack serves as an ideal solution for schools and universities, providing students with durable and stylish options. This not only meets the demand for practical and functional bags but also promotes brand visibility through customizable designs. Buyers in this sector should focus on the quality of materials to ensure longevity, ergonomic design for comfort, and the ability to customize for school branding.

Travel & Tourism

For the travel and tourism industry, ori backpacks are perfect for adventure tourism, where lightweight and functional designs are crucial. These backpacks cater to travelers who require reliable storage for their essentials while on the move. International B2B buyers should prioritize durability testing and waterproof materials to ensure the backpacks withstand various weather conditions, enhancing their brand image among tourists.

Corporate & Events

In the corporate sector, ori backpacks can be utilized as promotional items during events and conferences. They serve as practical giveaways that enhance brand recognition and provide utility to attendees. When sourcing for this application, businesses should consider customization capabilities, ensuring that the backpacks reflect their brand colors and logos. Additionally, material quality is essential to maintain a professional appearance.

Retail Sector

The retail industry can leverage ori backpacks as part of their eco-friendly product displays. These backpacks align with sustainability initiatives, appealing to a growing base of eco-conscious consumers. B2B buyers should focus on sourcing from sustainable materials and ensuring robust quality assurance processes to maintain brand integrity and attract customers.

Logistics & Delivery

In logistics and delivery operations, ori backpacks can be provided to employees for efficient mobility. These backpacks offer functional storage solutions, enabling delivery personnel to carry necessary items comfortably. Buyers in this sector should evaluate capacity and weight limits, ensuring that the backpacks are not only durable but also comfortable for extended use, enhancing employee satisfaction and productivity.

Related Video: Uses of Metals and Non Metals

Strategic Material Selection Guide for ori backpack

When selecting materials for the ori backpack, international B2B buyers must consider various factors that influence performance, durability, and overall cost. Below is an analysis of four common materials used in the production of backpacks, highlighting their key properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

1. Recycled Nylon

Key Properties:

Recycled nylon is known for its excellent strength-to-weight ratio, abrasion resistance, and water resistance. It can withstand a range of temperatures, making it suitable for various climates.

Pros & Cons:

The primary advantage of recycled nylon is its environmental sustainability, appealing to eco-conscious consumers. It is also lightweight and durable, which enhances the backpack’s usability. However, it can be more expensive than traditional nylon, and the manufacturing process may be complex, potentially leading to longer lead times.

Impact on Application:

Recycled nylon is compatible with various media, including water and moisture, making it ideal for outdoor and travel backpacks.

Considerations for International Buyers:

Buyers should ensure compliance with local environmental regulations and standards such as ISO 14001. The demand for sustainable products is increasing, especially in Europe and South America, where consumers are more environmentally aware.

2. Polyester

Key Properties:

Polyester is a synthetic fabric known for its durability, resistance to shrinking and stretching, and quick-drying capabilities. It generally performs well under varying temperatures and is resistant to mildew.

Pros & Cons:

Polyester is cost-effective and widely available, making it a popular choice for manufacturers. It offers good durability and is relatively easy to clean. However, it may not be as breathable as other materials, which can affect comfort during extended use.

Impact on Application:

This material is suitable for everyday use and travel backpacks, providing a good balance between performance and cost.

Considerations for International Buyers:

Buyers should look for compliance with ASTM and other relevant standards for fabric quality. In regions like Africa and the Middle East, polyester’s affordability can be a significant advantage for budget-conscious buyers.

3. Canvas

Key Properties:

Canvas is a heavy-duty fabric made from cotton or a blend of cotton and synthetic fibers. It is known for its excellent durability and resistance to wear and tear.

Pros & Cons:

The main advantage of canvas is its robustness, making it ideal for rugged use. It also has a classic aesthetic appeal. However, it can be heavier than synthetic materials and may require more care to maintain its appearance.

Impact on Application:

Canvas is particularly suitable for casual and lifestyle backpacks, appealing to consumers who prefer a vintage or rugged look.

Considerations for International Buyers:

Buyers should ensure that the canvas used meets local quality standards and is treated for water resistance if necessary. In Europe, there is a growing trend for sustainable and organic materials, which can affect canvas sourcing.

4. Cordura Fabric

Key Properties:

Cordura is a high-performance fabric known for its exceptional durability, tear resistance, and water repellency. It is often used in military and outdoor applications.

Pros & Cons:

The key advantage of Cordura is its superior strength and longevity, making it ideal for high-use backpacks. However, it tends to be more expensive than other fabrics and may require specialized manufacturing processes.

Impact on Application:

Cordura is well-suited for tactical and outdoor backpacks, where durability is paramount.

Considerations for International Buyers:

Buyers should verify the authenticity of Cordura and ensure it meets international standards for durability and performance. In markets like South Africa, where outdoor activities are popular, the demand for high-quality materials like Cordura is significant.

Summary Table

| Material | Typical Use Case for ori backpack | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Recycled Nylon | Eco-friendly outdoor backpacks | Environmentally sustainable | Higher cost, complex manufacturing | High |

| Polyester | Everyday use and travel backpacks | Cost-effective and durable | Less breathable | Med |

| Canvas | Casual and lifestyle backpacks | Robust and aesthetically appealing | Heavier, requires more care | Med |

| Cordura Fabric | Tactical and outdoor backpacks | Superior durability | Higher cost, specialized processes | High |

This material selection guide provides international B2B buyers with actionable insights to make informed decisions when sourcing materials for the ori backpack, ensuring product quality and market competitiveness.

In-depth Look: Manufacturing Processes and Quality Assurance for ori backpack

The manufacturing processes and quality assurance protocols for the Ori backpack are critical for ensuring that the products meet the expectations of international B2B buyers. This section delves into the stages of manufacturing, key techniques employed, quality control measures, and how B2B buyers can effectively verify supplier quality assurance.

Manufacturing Processes for Ori Backpacks

The manufacturing of Ori backpacks involves several key stages, each designed to uphold quality and sustainability. Understanding these processes can help B2B buyers make informed decisions.

1. Material Preparation

Material selection is foundational in backpack manufacturing. Ori focuses on using recycled materials, which not only reduces environmental impact but also caters to the growing consumer demand for sustainable products.

- Sourcing: High-quality recycled materials such as nylon and canvas are sourced from trusted suppliers. Buyers should inquire about the origin and certifications of these materials.

- Testing: Before production, materials undergo rigorous testing for durability, water resistance, and color fastness. This ensures that the backpacks will withstand daily use and various environmental conditions.

2. Forming

This stage involves cutting and shaping the materials into the components needed for the backpack.

- Cutting Techniques: Automated cutting machines are often used to ensure precision. This minimizes waste and ensures uniformity across production batches.

- Pattern Design: Custom patterns are developed for different backpack models, ensuring functionality and aesthetic appeal. Buyers should assess whether the manufacturer can accommodate custom designs.

3. Assembly

The assembly process is where the various components come together to form the final product.

- Stitching: Advanced stitching techniques, such as double-stitching and bar tacking, are employed at stress points to enhance durability. B2B buyers should verify that suppliers adhere to these practices.

- Attachment of Components: Zippers, buckles, and straps are attached with precision. Quality checks during this phase are crucial to avoid misalignment issues.

4. Finishing

The finishing stage ensures that the backpacks are ready for market.

- Quality Checks: Each backpack undergoes a thorough inspection to ensure that it meets design specifications and quality standards. This includes checking for stitching integrity, component alignment, and overall aesthetics.

- Final Touches: Branding elements, such as tags and logos, are added, and backpacks are packed for shipping. Buyers should confirm packaging practices to ensure that products arrive in pristine condition.

Quality Assurance Protocols

Effective quality assurance (QA) is essential for maintaining the integrity of the Ori brand and ensuring customer satisfaction. Here are the key aspects of QA relevant to international B2B buyers.

International Standards

B2B buyers should be aware of the various international standards that govern manufacturing processes:

- ISO 9001: This standard focuses on quality management systems and is essential for ensuring consistent product quality. Suppliers should provide certification documentation.

- CE Marking: For products sold within the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

Quality Control Checkpoints

Quality control is embedded at multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial check assesses the quality of materials upon arrival at the manufacturing facility. Buyers should request IQC reports to confirm compliance with specifications.

- In-Process Quality Control (IPQC): Inspections during the assembly process help catch defects early. Suppliers should maintain records of these inspections, which B2B buyers can review.

- Final Quality Control (FQC): Before shipping, a final inspection ensures that each backpack meets the established quality criteria. Buyers should request FQC reports as part of their due diligence.

Common Testing Methods

Various testing methods are employed to ensure product quality:

- Durability Testing: Tests such as abrasion resistance and tensile strength measure how well the materials hold up under stress. B2B buyers can request testing certifications to verify durability claims.

- Water Resistance Testing: This ensures that backpacks can withstand exposure to moisture, a key consideration for many consumers. Buyers should inquire about the specific water resistance tests conducted.

Verifying Supplier Quality Assurance

For international B2B buyers, verifying supplier quality assurance is crucial to mitigate risks associated with poor-quality products.

Audits and Inspections

- Supplier Audits: Conducting on-site audits can provide insight into the supplier’s manufacturing processes and quality control measures. This helps establish trust and transparency.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing process and product quality. Buyers should consider this option, especially for larger orders.

Documentation and Reports

- Quality Assurance Documentation: Suppliers should provide comprehensive documentation, including quality assurance plans, testing reports, and compliance certificates. Buyers should carefully review these documents to ensure they align with their expectations.

- Communication: Establishing clear lines of communication with suppliers is essential. Regular updates on production status and quality issues can help address concerns before they escalate.

Conclusion

Understanding the manufacturing processes and quality assurance protocols for Ori backpacks is vital for international B2B buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe. By focusing on the stages of manufacturing, international standards, quality checkpoints, and verification methods, buyers can ensure that they source high-quality products that meet their business needs. This proactive approach not only enhances customer satisfaction but also strengthens brand reputation in competitive markets.

Related Video: How a Backpack is Made : Every Step on the Production Line

Comprehensive Cost and Pricing Analysis for ori backpack Sourcing

When sourcing ori backpacks, understanding the comprehensive cost structure and pricing dynamics is crucial for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. This analysis will break down the key cost components and price influencers while offering actionable insights for international buyers.

Cost Components

-

Materials

– The choice of materials significantly impacts the overall cost. Ori backpacks utilize recycled fabrics, which may have a higher initial cost due to sustainable sourcing but can appeal to environmentally conscious consumers. Expect to pay more for high-quality, durable materials that withstand wear and tear. -

Labor

– Labor costs vary by region and influence pricing. Countries with lower labor costs may provide cheaper backpacks, but this can lead to quality concerns. Assessing the labor practices of suppliers ensures you maintain ethical standards while controlling costs. -

Manufacturing Overhead

– This encompasses the costs associated with running a production facility, including utilities, equipment maintenance, and administrative expenses. Efficient operations can help reduce these costs, which may be reflected in the final price. -

Tooling

– Initial tooling costs for molds and specific machinery can be significant, especially for customized designs. These costs are typically spread across the production volume, making higher Minimum Order Quantities (MOQs) more cost-effective per unit. -

Quality Control (QC)

– Rigorous QC processes are essential to avoid defects that could lead to returns and damaged reputation. While this adds to the upfront costs, investing in quality assurance can save money in the long run by reducing returns and increasing customer satisfaction. -

Logistics

– Transportation costs can vary widely based on the shipping method, distance, and Incoterms used. For international buyers, understanding these logistics costs, including customs duties and taxes, is vital to accurately assess total expenses. -

Margin

– Suppliers will add a profit margin to the base costs to ensure profitability. Understanding typical margins in the backpack industry can aid in negotiating better deals.

Price Influencers

-

Volume/MOQ: Higher order volumes can lead to significant cost savings per unit. Suppliers often offer better pricing for larger orders, making it beneficial for buyers to consolidate purchases.

-

Specifications/Customization: Custom designs or specific features can increase costs. Evaluate whether these enhancements align with your market needs and customer preferences.

-

Material Quality/Certifications: Opting for higher quality materials or certified sustainable products can drive up costs but may also justify higher retail prices and attract a premium customer base.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: The chosen Incoterms can significantly affect the overall cost structure. Understanding the implications of terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for budgeting.

Buyer Tips

-

Negotiation: Don’t hesitate to negotiate prices, especially when ordering large quantities. Suppliers may have flexibility, particularly if they are keen to secure a deal.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also logistics, potential returns, and quality issues. A slightly higher upfront cost may lead to lower TCO if it results in fewer customer complaints and returns.

-

International Pricing Nuances: Be mindful of currency fluctuations and regional market dynamics. Prices may vary based on local economic conditions and demand, especially in emerging markets.

Disclaimer

Prices for ori backpacks can fluctuate based on material availability, economic conditions, and supplier negotiations. This analysis provides indicative pricing structures but should be used as a guideline rather than an exact reference. Always conduct thorough supplier evaluations and market research before finalizing orders.

Spotlight on Potential ori backpack Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘ori backpack’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for ori backpack

Understanding the essential technical properties and trade terminology associated with the ori backpack is crucial for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. This section will outline the key specifications that define the quality and performance of the ori backpack, as well as the trade terms that are commonly used in the industry.

Key Technical Properties

-

Material Grade

– The material grade indicates the quality and durability of the fabrics used in the backpack. Common materials include recycled nylon and canvas, known for their environmental sustainability and robustness. High-grade materials enhance the backpack’s resistance to wear and tear, making them suitable for daily use in various environments.

– B2B Importance: Selecting high-grade materials reduces the likelihood of returns and enhances customer satisfaction, ultimately protecting your brand’s reputation. -

Weight Capacity

– This specification defines the maximum weight the backpack can safely carry without compromising structural integrity. For the ori backpack, this is particularly important for users who may carry heavy loads, such as students or professionals.

– B2B Importance: Knowing the weight capacity helps buyers ensure that the product meets the needs of their target market, thereby minimizing the risk of product failures. -

Water Resistance

– Water resistance is a critical property that indicates the backpack’s ability to repel water and protect contents from moisture. This is often achieved through specific coatings or fabric treatments.

– B2B Importance: In regions prone to rain, such as parts of South America and Africa, offering water-resistant backpacks can significantly enhance customer appeal. -

Stitching and Reinforcement

– The quality of stitching and reinforcement in high-stress areas (like straps and seams) is vital for durability. Techniques such as double-stitching and bar tacking are commonly used to enhance strength.

– B2B Importance: Ensuring robust stitching reduces the risk of product failure and increases the lifespan of the backpack, which is a key selling point for buyers. -

Dimensions and Capacity

– Dimensions refer to the physical size of the backpack, while capacity is typically measured in liters (L) to indicate how much can be stored. This includes compartments for laptops, books, and other items.

– B2B Importance: Providing accurate dimensions and capacity helps buyers select backpacks that fit their customers’ needs, particularly in educational or corporate sectors.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of backpacks, an OEM might produce a specific design for a brand.

– Significance: Understanding OEM relationships can help buyers negotiate better pricing and ensure product quality. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. For backpacks, this could affect inventory management and cash flow.

– Significance: Knowing the MOQ helps buyers plan their purchasing strategy and manage stock levels effectively. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting a price quote for specific products or services. This is a standard practice in B2B transactions.

– Significance: Using RFQs allows buyers to compare prices and terms from multiple suppliers, ensuring the best deal.

Illustrative Image (Source: Google Search)

-

Incoterms (International Commercial Terms)

– Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. Terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) clarify who is responsible for shipping and insurance.

– Significance: Familiarity with Incoterms helps buyers understand shipping costs and risks, facilitating smoother international transactions. -

Lead Time

– Lead time refers to the amount of time it takes from placing an order to receiving the goods. This can vary significantly based on the supplier’s location and production capacity.

– Significance: Understanding lead times is crucial for inventory planning and ensuring that products are available when needed.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing ori backpacks, aligning their purchases with market demands and operational capabilities.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ori backpack Sector

Market Overview & Key Trends

The global backpack market has seen a significant transformation driven by evolving consumer preferences, technological advancements, and sustainability demands. B2B buyers from regions like Africa, South America, the Middle East, and Europe are increasingly seeking products that not only meet functional requirements but also align with ethical and environmental standards.

One prominent trend is the rise of smart backpacks, integrating technology such as built-in USB ports for device charging and anti-theft features. This innovation appeals to tech-savvy consumers and enhances the value proposition for B2B buyers targeting the urban and student demographics. Furthermore, customization has become a vital selling point, allowing retailers to differentiate themselves in a crowded market by offering personalized designs and functionalities.

Additionally, online sourcing platforms have gained traction, enabling buyers to connect with suppliers globally and streamline procurement processes. For example, platforms that facilitate direct connections between manufacturers and retailers help reduce overhead costs and increase transparency in pricing.

In terms of market dynamics, the post-pandemic environment has led to a resurgence in outdoor activities, driving demand for durable, functional backpacks suitable for travel and adventure. International buyers should be aware of the regional preferences and cultural influences that may dictate design and functionality, particularly in diverse markets across Africa and South America.

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

Sustainability has transitioned from a niche concern to a core business strategy for many B2B buyers in the backpack sector. The environmental impact of traditional backpack production methods—often involving harmful chemicals and non-renewable materials—has prompted a shift towards more sustainable practices. Buyers are increasingly prioritizing suppliers who utilize recycled materials and eco-friendly manufacturing processes.

For the ori backpack sector, ethical sourcing is critical. Buyers should look for suppliers who adhere to green certifications, such as Global Recycled Standard (GRS) or OEKO-TEX, which ensure that materials are sourced responsibly and that labor practices are ethical. Emphasizing transparency in the supply chain can enhance brand reputation and customer loyalty, especially among environmentally conscious consumers.

Moreover, the integration of sustainable practices can lead to cost savings in the long run. By investing in durable, high-quality materials that reduce wear and tear, B2B buyers can minimize returns and increase customer satisfaction. Fostering partnerships with suppliers committed to sustainability not only aligns with consumer expectations but also positions businesses as leaders in ethical retailing.

Brief Evolution/History

The ori backpack sector has evolved significantly over the years, transitioning from basic functional designs to fashionable and multifunctional products. Initially, backpacks were primarily utilitarian, serving the needs of students and outdoor enthusiasts. However, with the rise of urban living and a focus on lifestyle branding, backpacks have transformed into essential fashion accessories.

This evolution has been marked by the introduction of innovative materials, such as recycled fabrics and weather-resistant coatings, which cater to both aesthetic and functional demands. The increasing awareness of environmental issues has also influenced the design philosophy, prompting brands to prioritize sustainability alongside style. As a result, modern backpacks now reflect a blend of practicality, ethical considerations, and individual expression, making them appealing to a broader audience.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of ori backpack

-

What should I consider when vetting suppliers for Ori backpacks?

When vetting suppliers, focus on their experience, reputation, and product quality. Request references from other B2B buyers and check online reviews. Ensure they have certifications for quality standards, such as ISO 9001 or compliance with environmental regulations. Conduct a factory visit if possible, or request a virtual tour to assess their production capabilities. Finally, ask for samples to evaluate the quality of the backpacks firsthand before committing to larger orders. -

Can I customize Ori backpacks for my brand?

Yes, Ori offers customization options for their backpacks, allowing you to tailor products to fit your brand identity. This can include custom colors, logos, and even specific design features. Discuss your requirements with the supplier early in the process to understand the possibilities and limitations. Keep in mind that customization may affect the minimum order quantities (MOQs) and lead times, so plan accordingly. -

What are the typical minimum order quantities (MOQs) and lead times for Ori backpacks?

MOQs can vary based on the style and customization of the backpacks. Generally, for standard models, you might expect MOQs to range from 100 to 500 units. Lead times typically range from 4 to 12 weeks depending on the order size and customization requirements. Always confirm these details upfront to avoid surprises and ensure your inventory aligns with your business needs. -

What payment methods are accepted for international orders?

Most suppliers, including Ori, typically accept various payment methods, including bank transfers, PayPal, and letters of credit. Discuss payment terms during negotiations to ensure they align with your cash flow needs. Additionally, consider using escrow services for larger transactions to safeguard your investment until the products are delivered and meet your quality expectations.

Illustrative Image (Source: Google Search)

-

How can I ensure quality assurance (QA) and certification for Ori backpacks?

To ensure quality assurance, request detailed information about the QA processes the supplier employs. This includes testing for materials, stitching, and overall durability. Ask for certifications such as OEKO-TEX or REACH compliance, which indicate adherence to safety and environmental standards. Regular inspections during production, as well as a final quality check before shipment, are also essential to ensure the backpacks meet your quality expectations. -

What logistics considerations should I keep in mind when sourcing from Ori?

When sourcing from Ori, consider shipping options, costs, and delivery timelines. Discuss whether the supplier offers direct shipping or if you will need to arrange logistics through a freight forwarder. Understand customs regulations in your country, as well as any import duties or tariffs that may apply. It’s also advisable to plan for potential delays, particularly if shipping internationally, to ensure your inventory arrives on time. -

How should disputes be handled with suppliers?

Establish clear communication channels and a dispute resolution process before entering into an agreement. It’s advisable to include terms in your contract regarding how disputes will be managed, whether through mediation, arbitration, or legal action. Maintain detailed records of all communications and agreements to support your position in case a dispute arises. Building a positive relationship with your supplier can also help mitigate potential conflicts. -

What are the common quality issues to look out for with Ori backpacks?

Common quality issues include material defects, stitching problems, and poor ergonomics. To mitigate these risks, request samples to assess material quality and stitching integrity. Look for features that enhance comfort, such as padded straps. Regular quality inspections during production can also help identify and rectify issues before the backpacks are shipped, ensuring that you receive a product that meets your standards and satisfies your customers.

Strategic Sourcing Conclusion and Outlook for ori backpack

As the demand for high-quality, sustainable backpacks continues to grow, strategic sourcing emerges as a vital component for B2B buyers. By prioritizing quality and functionality, particularly with products like the ori backpack, businesses can enhance their brand reputation and customer satisfaction. Key takeaways for buyers include the importance of thoroughly vetting suppliers, conducting rigorous material tests, and ensuring ergonomic designs that cater to diverse consumer needs.

Investing in high-quality backpacks not only reduces the risk of costly returns but also fosters customer loyalty. Buyers should leverage relationships with reputable suppliers who prioritize sustainable practices and quality assurance, especially in regions like Africa, South America, the Middle East, and Europe.

Looking ahead, the market for eco-friendly products is expected to expand, presenting significant opportunities for businesses that align with these trends. By embracing strategic sourcing now, international B2B buyers can position themselves at the forefront of this evolving industry. It is time to take action—evaluate your sourcing strategies and explore partnerships that emphasize quality and sustainability in the ori backpack range.