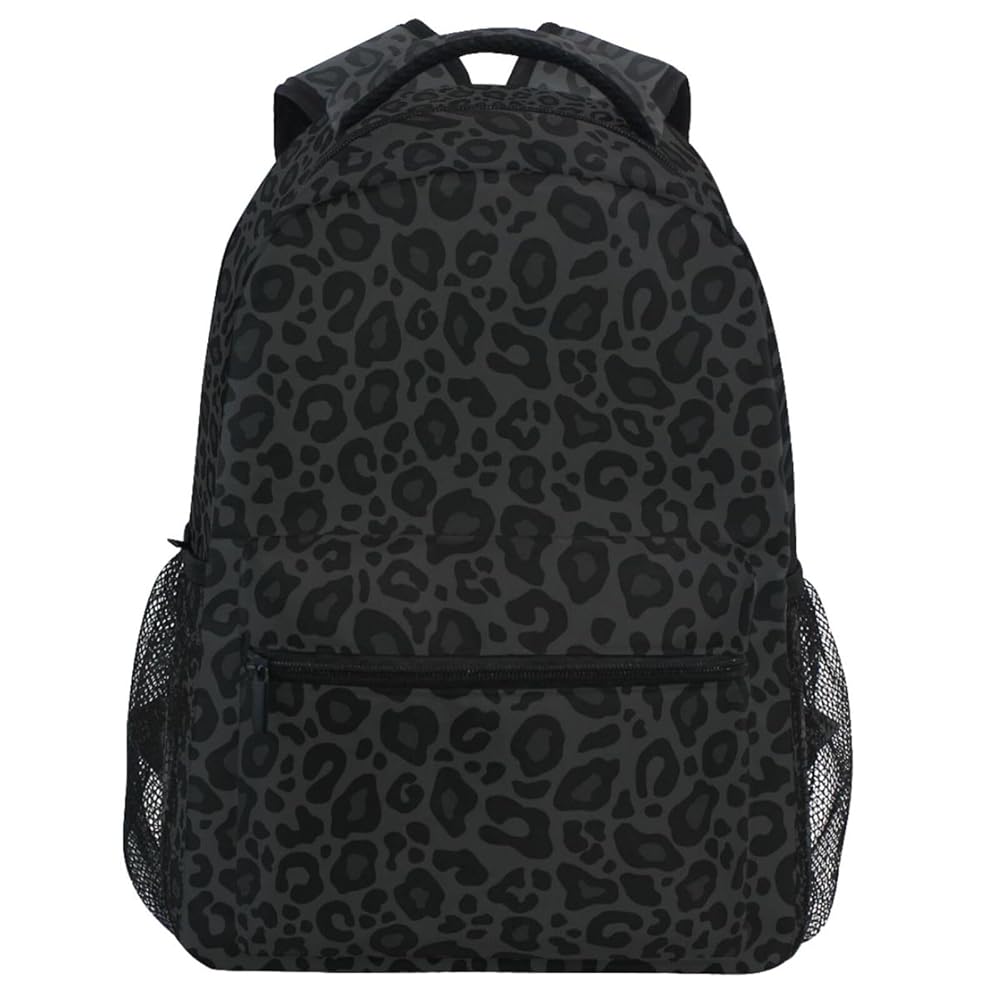

Master Sourcing High-Quality Leopard Backpacks for Your

Guide to Leopard Backpack

- Introduction: Navigating the Global Market for leopard backpack

- Understanding leopard backpack Types and Variations

- Key Industrial Applications of leopard backpack

- Strategic Material Selection Guide for leopard backpack

- In-depth Look: Manufacturing Processes and Quality Assurance for leopard backpack

- Comprehensive Cost and Pricing Analysis for leopard backpack Sourcing

- Spotlight on Potential leopard backpack Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for leopard backpack

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the leopard backpack Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leopard backpack

- Strategic Sourcing Conclusion and Outlook for leopard backpack

Introduction: Navigating the Global Market for leopard backpack

In today’s global marketplace, the leopard backpack has emerged as a distinctive product that resonates with consumers seeking both style and functionality. This unique design not only appeals to fashion-conscious individuals but also offers opportunities for businesses looking to differentiate their product offerings. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe explore sourcing options, understanding the intricacies of leopard backpack production becomes paramount.

This comprehensive guide is designed to equip buyers with critical insights into every aspect of leopard backpack manufacturing. It covers a wide array of topics, including types of backpacks, materials used, manufacturing processes, and quality control measures. Additionally, it provides an overview of reliable suppliers, cost considerations, market trends, and answers to frequently asked questions.

By delving into these areas, this guide empowers B2B buyers to make informed sourcing decisions that align with their business goals. Whether you are a startup in South Africa looking to launch a unique product line or an established brand in Spain aiming to expand your catalog, understanding the dynamics of the leopard backpack market will enhance your strategic planning and operational efficiency. With the right knowledge, you can navigate the complexities of global sourcing and capitalize on the growing demand for fashionable, durable backpacks.

Understanding leopard backpack Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Casual Leopard Backpack | Trendy designs with various compartments | Fashion retailers, youth brands | Pros: Appeals to younger demographics; stylish. Cons: May lack durability for heavy use. |

| Tactical Leopard Backpack | Rugged construction with military-style features | Outdoor retailers, military surplus stores | Pros: High durability; functional for outdoor activities. Cons: Heavier and bulkier than casual options. |

| Eco-Friendly Leopard Backpack | Made from sustainable materials like recycled fabrics | Eco-conscious brands, specialty retailers | Pros: Appeals to eco-conscious consumers; supports sustainability. Cons: Higher production costs may affect pricing. |

| Laptop Leopard Backpack | Padded compartments for electronics | Tech retailers, corporate gifting | Pros: Protects valuable electronics; versatile usage. Cons: May not cater to all outdoor needs. |

| Customizable Leopard Backpack | Options for personalized designs and branding | Promotional products, corporate branding | Pros: Unique branding opportunities; tailored to specific markets. Cons: Higher MOQs may apply. |

Casual Leopard Backpack

Casual leopard backpacks are characterized by trendy designs and multiple compartments, making them ideal for everyday use. They are particularly suitable for fashion retailers targeting younger demographics who seek both functionality and style. When purchasing, buyers should consider the balance between aesthetics and durability, as these backpacks may not withstand heavy usage like other types.

Tactical Leopard Backpack

Designed for rugged use, tactical leopard backpacks feature military-style elements and durable construction. They are ideal for outdoor retailers and military surplus stores, catering to consumers who prioritize functionality and resilience. B2B buyers should evaluate the materials used and the overall weight of the backpack, as tactical models can be bulkier but offer superior durability for demanding environments.

Eco-Friendly Leopard Backpack

Eco-friendly leopard backpacks are crafted from sustainable materials, such as recycled fabrics, appealing to brands focused on environmental responsibility. These backpacks are increasingly popular among eco-conscious consumers and specialty retailers. Buyers should be aware that while these options support sustainability, they may come with higher production costs, which can influence retail pricing.

Laptop Leopard Backpack

Laptop leopard backpacks come with padded compartments specifically designed to protect electronic devices. They are well-suited for tech retailers and corporate gifting, where functionality meets style. When sourcing these backpacks, B2B buyers should assess the protective features and overall design, ensuring they meet the needs of professionals who often carry laptops or tablets.

Customizable Leopard Backpack

Customizable leopard backpacks offer options for personalized designs and branding, making them perfect for promotional products and corporate branding. These backpacks allow businesses to create unique offerings tailored to specific markets. Buyers should consider minimum order quantities (MOQs) and the potential for increased costs associated with customization, but the branding opportunities can significantly enhance market presence.

Related Video: What are Diffusion Models?

Key Industrial Applications of leopard backpack

| Industry/Sector | Specific Application of Leopard Backpack | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Education | Student backpacks for schools and universities | Enhanced brand visibility, durable and functional design | Material durability, customization options, compliance with safety standards |

| Outdoor Recreation | Gear for hiking and camping activities | Lightweight, weather-resistant, and ergonomic design | Material selection (e.g., waterproof fabrics), weight specifications, and comfort features |

| Logistics & Transport | Cargo backpacks for delivery personnel | Increased efficiency in transporting goods | Load capacity, durability under pressure, and ease of access for quick retrieval |

| Fashion Retail | Trendy backpacks for urban consumers | Appeal to fashion-conscious consumers, brand differentiation | Aesthetic design, eco-friendly materials, and alignment with current fashion trends |

| Military & Defense | Tactical backpacks for military personnel | Enhanced functionality, ruggedness, and reliability | Compliance with military specifications, durability under extreme conditions, and modular features |

Education

In the education sector, leopard backpacks are utilized as student backpacks for schools and universities. These bags provide enhanced brand visibility for educational institutions and serve as practical, durable solutions for students. International buyers in this sector should focus on sourcing materials that meet safety standards and offer customization options, such as school logos or colors, to create a unique product that resonates with students.

Outdoor Recreation

Leopard backpacks are ideal for outdoor recreation, specifically for hiking and camping activities. Their lightweight, weather-resistant design caters to adventurers who require reliable gear. Buyers from regions with diverse climates, such as Africa and South America, should prioritize sourcing backpacks made from durable, waterproof materials that ensure comfort and functionality during prolonged outdoor use. Ergonomic designs that support the back and shoulders are also essential to enhance user experience.

Logistics & Transport

In the logistics and transport industry, leopard backpacks are used as cargo backpacks for delivery personnel. These backpacks increase efficiency by allowing workers to transport goods easily and securely. B2B buyers must consider the load capacity and durability of the backpacks, as they need to withstand daily wear and tear. Additionally, ease of access for quick retrieval of items is crucial for maintaining operational efficiency in fast-paced environments.

Fashion Retail

Leopard backpacks have found their way into the fashion retail sector, appealing to urban consumers looking for trendy and stylish accessories. These backpacks help brands differentiate themselves in a crowded market by offering unique designs that resonate with fashion-conscious buyers. International fashion retailers should focus on sourcing aesthetically pleasing backpacks made from eco-friendly materials to align with the growing trend of sustainability in fashion.

Military & Defense

In military and defense applications, leopard backpacks serve as tactical backpacks for personnel. These bags are designed for ruggedness and reliability, essential for military operations in diverse environments. Buyers in this sector must ensure that the backpacks comply with military specifications, including durability under extreme conditions and modular features for carrying additional gear. Sourcing from manufacturers with experience in military-grade products is crucial to meet these stringent requirements.

Related Video: Introduction to Uses and Gratifications Theory

Strategic Material Selection Guide for leopard backpack

When selecting materials for a leopard backpack, international B2B buyers must consider several factors, including performance properties, manufacturing complexities, and market preferences. Below is an analysis of four common materials used in backpack manufacturing, focusing on their key properties, advantages, disadvantages, and specific considerations for international buyers.

1. Nylon

Key Properties: Nylon is known for its high tensile strength and resistance to abrasion. It performs well under varying temperatures and is resistant to mold and mildew, making it suitable for outdoor applications.

Pros & Cons: The durability of nylon is a significant advantage, as it can withstand heavy use and harsh conditions. However, it can be more expensive than other materials like polyester. Manufacturing complexity is moderate, as nylon requires specific handling during cutting and sewing to avoid fraying.

Impact on Application: Nylon is compatible with various media, including water-resistant coatings, which enhances its suitability for outdoor backpacks.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM for textile performance. In regions like Africa and South America, where outdoor activities are prevalent, the demand for durable nylon backpacks is high.

2. Polyester

Key Properties: Polyester is lightweight, quick-drying, and resistant to shrinking and stretching. It also has decent UV resistance, making it suitable for sunny environments.

Pros & Cons: The primary advantage of polyester is its cost-effectiveness compared to nylon, making it a popular choice for budget-conscious brands. However, it may not be as durable as nylon, especially in high-abrasion scenarios. The manufacturing process is straightforward, allowing for efficient production.

Impact on Application: Polyester’s compatibility with water-repellent finishes makes it a good choice for backpacks intended for casual use or light outdoor activities.

Considerations for International Buyers: Compliance with environmental standards is crucial, especially in Europe, where eco-friendly materials are increasingly demanded. Buyers should also consider local preferences for lightweight materials in tropical climates.

3. Canvas

Key Properties: Canvas is a heavy-duty fabric made from cotton or a blend of cotton and synthetic fibers. It offers excellent durability and breathability, making it suitable for various applications.

Pros & Cons: The robust nature of canvas makes it ideal for rugged use, and it can be treated for water resistance. However, it is heavier than nylon and polyester, which may not appeal to all consumers. The manufacturing complexity is moderate, as canvas requires specific sewing techniques to maintain its integrity.

Impact on Application: Canvas backpacks are well-suited for urban use and casual outings, appealing to buyers looking for style as well as function.

Considerations for International Buyers: In regions like the Middle East, where fashion trends influence purchasing decisions, canvas backpacks can be marketed as stylish and durable. Compliance with local textile regulations is essential.

4. Leather

Key Properties: Leather is known for its luxurious feel and aesthetic appeal. It offers good durability and resistance to wear, but its performance can vary based on the type of leather used.

Pros & Cons: The primary advantage of leather is its premium look and feel, which can justify a higher price point. However, it requires more maintenance and can be susceptible to water damage if not treated properly. The manufacturing process is more complex, often requiring specialized skills.

Impact on Application: Leather is often used in high-end backpacks, appealing to consumers looking for luxury and style.

Considerations for International Buyers: Buyers should be aware of ethical sourcing practices, especially in Europe where sustainability is a significant concern. Compliance with animal welfare standards is also critical.

Summary Table

| Material | Typical Use Case for leopard backpack | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | Outdoor and rugged backpacks | High durability and abrasion resistance | Higher cost than polyester | High |

| Polyester | Casual and light outdoor use | Cost-effective and lightweight | Less durable than nylon | Medium |

| Canvas | Urban and casual backpacks | Stylish and robust | Heavier than synthetic options | Medium |

| Leather | High-end fashion backpacks | Premium look and feel | Requires maintenance and care | High |

This strategic material selection guide provides a comprehensive overview for international B2B buyers considering the production of leopard backpacks. By understanding the properties and implications of each material, buyers can make informed decisions that align with market demands and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for leopard backpack

The manufacturing process of leopard backpacks involves several key stages, each critical to ensuring the final product meets both quality and design specifications. Understanding these processes can empower B2B buyers to make informed decisions when sourcing backpacks for their markets, particularly in regions like Africa, South America, the Middle East, and Europe.

Manufacturing Process

1. Material Preparation

The first step in manufacturing a leopard backpack is the selection and preparation of materials. High-quality fabrics, such as durable nylon or eco-friendly materials like recycled polyester, are commonly used. The choice of fabric affects not only the backpack’s durability but also its weight and environmental impact.

- Sourcing Materials: Buyers should prioritize suppliers that offer a variety of fabric options and have a reputation for quality. International textile markets, such as those in Guangzhou or Istanbul, can be excellent sources for diverse materials.

- Pre-treatment: Fabrics may undergo treatments for water resistance or UV protection, enhancing the backpack’s functionality.

2. Forming

This stage involves creating patterns and templates that dictate how the materials will be cut and assembled.

- Pattern Creation: CAD (Computer-Aided Design) software is often used to design the backpack layout. This technology allows for precise measurements and modifications, ensuring that the final product aligns with design specifications.

- Cutting the Fabric: Using automated cutting machines or manual methods, the fabric is cut according to the created patterns. Precision in this stage is crucial to minimize waste and ensure component fit.

3. Assembly

Once the materials are cut, the assembly process begins. This involves stitching and combining various components to create the finished backpack.

- Sewing Techniques: Industrial sewing machines are utilized to join fabric pieces, attach zippers, and secure straps. Techniques such as double stitching are often employed for added strength, especially in high-stress areas.

- Quality Control During Assembly: Regular checks during the assembly process (In-Process Quality Control, or IPQC) help identify defects early, reducing the risk of producing faulty products.

4. Finishing

The final stage focuses on detailing and ensuring the backpack is ready for the market.

- Trimming and Tidying: Loose threads are trimmed, and any additional finishing touches, such as branding tags or logos, are added.

- Final Inspection: A thorough inspection (Final Quality Control, or FQC) is conducted to ensure that the backpack meets all quality standards and design specifications before packaging.

Quality Assurance

Quality assurance is an essential aspect of backpack manufacturing, especially for B2B buyers who need to ensure that their products meet international standards.

Relevant International Standards

- ISO 9001: This standard outlines the criteria for a quality management system, ensuring that organizations consistently provide products that meet customer and regulatory requirements.

- CE Marking: For products sold in Europe, CE marking indicates compliance with safety, health, and environmental protection standards.

Illustrative Image (Source: Google Search)

Quality Control Checkpoints

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet required specifications.

- In-Process Quality Control (IPQC): Ongoing checks throughout the manufacturing process help catch defects early and reduce rework costs.

- Final Quality Control (FQC): The final inspection assesses the completed backpacks to ensure they meet all quality criteria before shipment.

Illustrative Image (Source: Google Search)

Common Testing Methods

- Tensile Strength Testing: This method assesses how much force the fabric can withstand before breaking, crucial for durability.

- Water Resistance Testing: Ensures that the materials can repel water, an essential feature for outdoor backpacks.

- Zipper Durability Testing: Evaluates how well zippers function under stress, particularly important for backpacks designed for heavy use.

Verifying Supplier Quality Control

B2B buyers must implement strategies to verify the quality control practices of their suppliers:

- Audits: Conducting regular audits of manufacturing facilities can provide insights into the quality management systems in place and adherence to international standards.

- Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand the processes and results of quality checks.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing process and final products. This is particularly important for buyers in Africa and South America, where establishing trust in local suppliers may be challenging.

QC and Certification Nuances for International Buyers

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality certification is crucial:

- Cultural and Regulatory Differences: Be aware that quality expectations and regulatory requirements can vary significantly across regions. For instance, while CE marking is essential in Europe, other regions may have different safety standards.

- Sustainability Certifications: Increasingly, buyers are looking for suppliers that adhere to sustainability practices. Certifications such as GOTS (Global Organic Textile Standard) or OEKO-TEX can indicate a commitment to environmentally friendly manufacturing.

By comprehensively understanding the manufacturing processes and quality assurance measures involved in producing leopard backpacks, B2B buyers can make informed sourcing decisions that align with their business objectives and market demands.

Related Video: How a Backpack is Made : Every Step on the Production Line

Comprehensive Cost and Pricing Analysis for leopard backpack Sourcing

When sourcing leopard backpacks, understanding the cost structure and pricing dynamics is essential for B2B buyers to make informed decisions. This analysis will break down the primary cost components involved in manufacturing, highlight key price influencers, and provide actionable tips for buyers, particularly those from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The choice of fabric, such as durable nylon or eco-friendly options like recycled polyester, significantly impacts the overall cost. Specialty materials for specific functionalities, such as waterproofing or lightweight designs, can also elevate expenses.

-

Labor: Labor costs vary by region. For instance, manufacturing in countries like Vietnam may offer lower wages compared to China or Europe. Understanding local labor market conditions can help in negotiating better rates.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Overhead can vary based on the manufacturer’s location and operational efficiency.

-

Tooling: Initial tooling costs, such as molds and cutting dies, can be substantial, particularly for custom designs. These costs should be amortized over the production run to understand the per-unit impact.

-

Quality Control (QC): Rigorous QC processes ensure product reliability but come with additional costs. Investing in quality checks can prevent costly returns and damage to brand reputation.

-

Logistics: Shipping costs, including freight, customs duties, and insurance, must be factored into the total cost. The choice of Incoterms (e.g., FOB, CIF) can influence these expenses significantly.

-

Margin: Manufacturers typically add a profit margin, which can vary widely based on competition, market demand, and perceived value of the product.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQ) can affect pricing. Larger orders generally lead to lower per-unit costs due to economies of scale. Buyers should assess their capacity to meet MOQs to optimize pricing.

-

Specifications/Customization: Custom designs and specifications can lead to higher costs due to additional labor and material requirements. Buyers should balance the need for unique designs with budget constraints.

-

Materials: The choice of materials not only affects cost but also the perceived value of the product. High-quality, sustainable materials may command higher prices but can attract eco-conscious consumers.

-

Quality/Certifications: Products that meet specific quality standards or certifications (e.g., ISO, SGS) may incur higher costs but can enhance marketability and consumer trust.

-

Supplier Factors: The supplier’s reputation, experience, and location can influence pricing. Established suppliers may charge a premium for their reliability and quality assurance.

-

Incoterms: Understanding the implications of different Incoterms is crucial for budgeting logistics costs accurately. For example, CIF (Cost, Insurance, and Freight) includes shipping and insurance, which can affect overall pricing.

Buyer Tips

-

Negotiation: Effective negotiation can lead to better pricing. Consider discussing volume discounts, flexible payment terms, or bundled services to enhance value.

-

Cost-Efficiency: Conduct a thorough analysis of the Total Cost of Ownership (TCO), including all associated costs from production to delivery. This holistic view can uncover hidden expenses and inform better purchasing decisions.

-

Pricing Nuances for International Buyers: Buyers from diverse regions should be aware of currency fluctuations, import duties, and local market conditions that may affect pricing. Establishing relationships with local agents can facilitate smoother transactions.

-

Disclaimer for Indicative Prices: Prices can fluctuate based on market conditions and specific requirements. Always seek updated quotes and be prepared for negotiations to secure the best possible deal.

By carefully analyzing these components and influencers, B2B buyers can make more strategic sourcing decisions when purchasing leopard backpacks, ensuring they achieve both quality and cost-effectiveness in their procurement processes.

Spotlight on Potential leopard backpack Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘leopard backpack’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for leopard backpack

Understanding the essential technical properties and trade terminology associated with leopard backpacks is crucial for B2B buyers looking to make informed purchasing decisions. Below are key specifications and industry terms that will enhance your understanding and aid in effective negotiations with manufacturers.

Critical Specifications

-

Material Grade

– Definition: The quality and type of fabric used in the backpack, such as nylon, polyester, or canvas, which dictates durability, weight, and water resistance.

– B2B Importance: Selecting the right material grade ensures the product meets performance expectations and market demands. For instance, waterproof materials are essential for outdoor backpacks, while lightweight fabrics are preferred for travel. -

Weight Capacity

– Definition: The maximum load the backpack can safely carry, usually measured in kilograms or pounds.

– B2B Importance: Knowing the weight capacity helps buyers assess whether the backpack meets the needs of specific target markets, such as hikers or students, ensuring customer satisfaction and reducing returns. -

Tolerances

– Definition: The allowable variations in dimensions and specifications of the backpack components (e.g., seams, zippers).

– B2B Importance: Tighter tolerances often indicate better craftsmanship and quality control. Understanding tolerances helps buyers evaluate potential manufacturers and their ability to produce consistent products. -

Zipper Quality

– Definition: The type and durability of zippers used, which can range from plastic to metal, impacting the longevity of the backpack.

– B2B Importance: High-quality zippers reduce failure rates and improve user experience. As a B2B buyer, insisting on durable zippers can prevent product complaints and enhance brand reputation. -

Water Resistance Rating

– Definition: A measurement indicating how well the backpack can repel water, usually specified in millimeters (e.g., 1000mm waterproof).

– B2B Importance: This rating is vital for outdoor or travel backpacks. A higher water resistance rating can significantly influence purchasing decisions, especially in regions with wet climates. -

Sustainability Certifications

– Definition: Recognitions that indicate the use of environmentally friendly materials and manufacturing processes, such as Global Recycled Standard (GRS).

– B2B Importance: Eco-conscious consumers are increasingly demanding sustainable products. Certifications can enhance marketability and meet regulatory requirements in various regions.

Common Trade Terms

- OEM (Original Equipment Manufacturer)

– Definition: A manufacturer that produces products based on the designs and specifications provided by another company, which then sells them under its brand.

– Importance: Understanding OEM relationships helps buyers identify potential partners for custom designs and private label opportunities.

Illustrative Image (Source: Google Search)

-

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps businesses manage inventory costs and assess whether a supplier aligns with their production scale, especially important for startups. -

RFQ (Request for Quotation)

– Definition: A formal document issued by a buyer to suppliers to solicit pricing information for specific products or services.

– Importance: An RFQ allows buyers to compare pricing, terms, and capabilities of multiple suppliers, enabling informed decision-making. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers.

– Importance: Familiarity with Incoterms is essential for understanding shipping costs, insurance, and liability, which can significantly impact total landed costs. -

Lead Time

– Definition: The amount of time from the placement of an order to the delivery of the product.

– Importance: Understanding lead times is critical for inventory planning and meeting market demand, especially for seasonal products. -

Quality Assurance (QA)

– Definition: A systematic process of ensuring that products meet specified quality standards before they reach the market.

– Importance: QA processes are essential for maintaining product integrity and customer satisfaction, reducing the risk of returns and damage to brand reputation.

By familiarizing yourself with these specifications and trade terms, you can enhance your procurement strategy, ensuring that you select the right products and partners for your business needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the leopard backpack Sector

Market Overview & Key Trends

The leopard backpack sector is witnessing significant transformation, driven by global consumer preferences and technological advancements. One of the primary drivers is the rising demand for unique, custom-designed products, particularly in regions like Africa and South America, where local brands are gaining traction. International B2B buyers are increasingly looking for manufacturers that offer custom solutions, allowing them to stand out in a competitive market. In Europe, particularly in Spain, there is a notable shift towards eco-friendly products, pushing brands to adopt sustainable practices in their offerings.

Emerging technologies such as 3D modeling and automated cutting are enhancing the backpack manufacturing process, improving efficiency and reducing lead times. For B2B buyers, understanding these technological trends is crucial for making informed sourcing decisions. Additionally, the use of e-commerce platforms, like Alibaba, is prevalent; however, buyers must exercise caution, ensuring they engage with reputable suppliers to avoid unpredictable pricing and quality issues.

Moreover, geopolitical factors and supply chain disruptions have prompted companies to consider alternative sourcing locations. Vietnam, for instance, is becoming an attractive option due to its competitive labor costs and robust production capabilities, allowing B2B buyers to diversify their supply chains and mitigate risks associated with over-reliance on a single country.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a non-negotiable aspect of the backpack manufacturing industry, with increasing consumer awareness regarding environmental impacts. For B2B buyers of leopard backpacks, prioritizing ethical sourcing is essential. This includes selecting manufacturers that adhere to fair labor practices and maintain transparency in their supply chains. Ethical production not only enhances brand reputation but also aligns with the values of a growing segment of eco-conscious consumers.

Incorporating sustainable materials, such as recycled polyester or organic cotton, is a critical trend. B2B buyers should look for suppliers who possess certifications like Global Recycled Standard (GRS) or OEKO-TEX, which indicate compliance with environmental and safety standards. These certifications assure buyers that the materials used in the production of leopard backpacks are sourced responsibly and have a lower environmental footprint.

Furthermore, establishing partnerships with manufacturers committed to sustainable practices can enhance a brand’s market position. By showcasing a commitment to sustainability, brands can appeal to discerning consumers and differentiate themselves in a saturated market.

Brief Evolution/History

The leopard backpack, like many fashion accessories, has evolved significantly over the decades. Initially seen as purely functional, backpacks have transformed into style statements, particularly with the rise of streetwear culture. This shift has created opportunities for B2B buyers to tap into niche markets focused on unique designs and cultural representations.

In the late 20th century, the backpack industry began to embrace innovative materials and designs, paving the way for the modern leopard backpack. Today, with advancements in manufacturing technologies and a growing emphasis on sustainability, the sector is poised for further growth. B2B buyers must recognize the historical context of these trends to effectively navigate the market landscape and align their sourcing strategies with consumer expectations.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of leopard backpack

-

How can I effectively vet suppliers for leopard backpacks?

When sourcing leopard backpacks, start by conducting thorough background checks on potential suppliers. Look for manufacturers with a proven track record in the backpack industry, positive reviews, and certifications that meet international quality standards. Utilize platforms like Alibaba or trade shows to gather information. Request samples to assess the quality of materials and craftsmanship. Additionally, consider visiting the factory, if feasible, to observe production processes and working conditions firsthand. -

What customization options are typically available for leopard backpacks?

Most manufacturers offer a range of customization options, including material selection, size, color, and design features such as pockets and straps. Some suppliers also allow for unique branding, including logos and personalized embroidery. When discussing customization, clearly outline your specifications and ensure the manufacturer can meet your design needs. Establishing a collaborative relationship can lead to innovative solutions that enhance the final product. -

What are the common minimum order quantities (MOQs) for leopard backpacks?

MOQs can vary significantly based on the manufacturer and the complexity of the design. Generally, for custom leopard backpacks, MOQs may range from 100 to 1,000 units. Smaller manufacturers may offer lower MOQs, which is beneficial for startups or brands testing the market. Always confirm MOQs upfront and discuss any flexibility the supplier may have, especially if you are willing to pay a higher price for smaller batches. -

What should I know about lead times for sourcing leopard backpacks?

Lead times are influenced by the complexity of the design, the supplier’s production capacity, and the time taken for quality assurance. Typically, the production process for custom backpacks can take between 4 to 12 weeks. Ensure you discuss timelines early in the negotiation process and factor in additional time for shipping and customs clearance. Having a clear understanding of lead times helps in planning inventory and meeting market demands. -

How can I ensure quality assurance and certifications for leopard backpacks?

To ensure quality, request that suppliers provide certifications such as ISO 9001 or relevant safety standards specific to your market. Establish a quality control process that includes inspections at various production stages. It may be beneficial to hire third-party inspection services to verify quality before shipment. Discuss your quality expectations with the supplier upfront to prevent discrepancies later in the process. -

What payment terms are commonly used in international B2B transactions for backpacks?

Payment terms can vary, but common practices include a deposit (usually 30-50%) upfront, followed by the balance upon completion or before shipment. Consider using secure payment methods like letters of credit or escrow services to minimize risks. Always clarify payment terms in the contract and be wary of suppliers that demand full payment upfront, as this may indicate a lack of trustworthiness. -

How should I approach logistics and shipping for my leopard backpacks?

Logistics can be complex when dealing with international suppliers. Assess shipping options, including air freight for speed or sea freight for cost efficiency. Work with a freight forwarder experienced in handling goods from your supplier’s location to your target market. Ensure you understand customs regulations in your country, including duties and taxes. Planning logistics early can help avoid delays and additional costs.

- What steps can I take if disputes arise with my supplier?

To mitigate disputes, establish clear contracts that outline responsibilities, payment terms, and quality expectations. In the event of a disagreement, maintain open communication with the supplier to resolve issues amicably. If necessary, consider mediation or arbitration as a means to settle disputes without resorting to litigation. Keeping detailed records of all communications and agreements can provide crucial support should legal action become necessary.

Strategic Sourcing Conclusion and Outlook for leopard backpack

In conclusion, strategic sourcing is essential for international B2B buyers looking to navigate the complexities of the leopard backpack market. Understanding the intricacies of manufacturing—from material selection to quality control—allows buyers to make informed decisions that can significantly impact their bottom line. Leveraging local suppliers, embracing sustainable practices, and staying attuned to market trends are critical strategies for success.

Key Takeaways:

- Research and Relationships: Establishing strong relationships with manufacturers ensures better pricing and quality control.

- Sustainable Sourcing: The demand for eco-friendly products is rising, making it crucial to consider sustainable materials in your sourcing strategy.

- Market Awareness: Being aware of regional manufacturing differences, such as those between China and Vietnam, can lead to more effective sourcing decisions.

As you look to the future, consider the evolving landscape of backpack manufacturing and how it can align with your business goals. Engage with industry experts and explore innovative manufacturing solutions that cater to your specific needs. The journey towards effective sourcing starts now—connect with reliable partners to elevate your leopard backpack offerings in your respective markets.