Master Sourcing Bucket Backpacks: Key Insights for B2B

Guide to Bucket Backpack

- Introduction: Navigating the Global Market for bucket backpack

- Understanding bucket backpack Types and Variations

- Key Industrial Applications of bucket backpack

- Strategic Material Selection Guide for bucket backpack

- In-depth Look: Manufacturing Processes and Quality Assurance for bucket backpack

- Comprehensive Cost and Pricing Analysis for bucket backpack Sourcing

- Spotlight on Potential bucket backpack Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for bucket backpack

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the bucket backpack Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of bucket backpack

- Strategic Sourcing Conclusion and Outlook for bucket backpack

Introduction: Navigating the Global Market for bucket backpack

In the ever-evolving landscape of global commerce, the bucket backpack has carved out a significant niche as a versatile and functional accessory, appealing to both outdoor enthusiasts and urban dwellers alike. This distinct style of backpack offers practicality, durability, and a unique aesthetic, making it a preferred choice among consumers in diverse markets, particularly in regions like Africa, South America, the Middle East, and Europe.

As B2B buyers, understanding the nuances of sourcing bucket backpacks is crucial for capitalizing on market opportunities. This comprehensive guide delves into the essential aspects of the bucket backpack market, including types, materials, manufacturing processes, quality control standards, supplier landscapes, and cost considerations. Additionally, it addresses common FAQs to equip buyers with the knowledge needed to make informed decisions.

By exploring this guide, international B2B buyers will gain valuable insights into the complexities of sourcing bucket backpacks, enabling them to navigate supply chains effectively and optimize their procurement strategies. Whether you are looking to enhance your product line or ensure compliance with quality standards, this guide empowers you to leverage the bucket backpack’s growing popularity to meet consumer demands while fostering sustainable and ethical sourcing practices.

Illustrative Image (Source: Google Search)

Understanding bucket backpack Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Bucket Backpack | Simple cylindrical design with drawstring closure | Outdoor activities, casual use | Pros: Lightweight, easy to pack; Cons: Limited organization options. |

| Technical Bucket Backpack | Enhanced durability with weather-resistant materials | Hiking, camping, outdoor sports | Pros: High durability, water-resistant; Cons: Heavier than classic versions. |

| Fashion Bucket Backpack | Trendy designs with various materials and colors | Fashion retail, youth markets | Pros: Attractive aesthetics, brand appeal; Cons: May sacrifice functionality for style. |

| Multi-Compartment Bucket Backpack | Multiple pockets for organization | School, travel, everyday use | Pros: Great for organization, versatile; Cons: Can be bulkier and heavier. |

| Eco-Friendly Bucket Backpack | Made from sustainable materials | Eco-conscious brands, promotions | Pros: Appeals to green consumers, unique marketing angle; Cons: Potentially higher costs. |

Classic Bucket Backpack

The Classic Bucket Backpack features a straightforward cylindrical design with a drawstring closure, making it a popular choice for casual outings. Its lightweight construction allows for easy packing and portability, making it ideal for day trips and casual use. However, this simplicity comes at the cost of limited organizational features, which may not meet the needs of buyers requiring more storage solutions.

Technical Bucket Backpack

Designed for rugged use, the Technical Bucket Backpack incorporates advanced materials that enhance durability and weather resistance. This type is particularly suited for outdoor enthusiasts engaged in hiking, camping, or other sports. While its robust construction provides excellent protection against the elements, it typically weighs more than classic models, which may be a consideration for buyers prioritizing lightweight gear.

Fashion Bucket Backpack

The Fashion Bucket Backpack merges style with functionality, offering trendy designs in various materials and colors. This variation is ideal for fashion retailers targeting youth markets and those seeking to make a style statement. Although it attracts consumers with its aesthetic appeal, the focus on design may compromise some practical features, such as storage capacity and durability.

Multi-Compartment Bucket Backpack

The Multi-Compartment Bucket Backpack is characterized by its multiple pockets and organizational features, making it suitable for a variety of applications such as school use, travel, and everyday activities. This versatility is a significant advantage for buyers looking for functionality. However, the added compartments can make the backpack bulkier and heavier, which may not appeal to all consumers.

Eco-Friendly Bucket Backpack

With a rising focus on sustainability, the Eco-Friendly Bucket Backpack is crafted from sustainable materials, targeting eco-conscious brands and consumers. This type can serve as a unique marketing angle for businesses aiming to appeal to environmentally aware customers. While these backpacks may come with a higher price tag due to their materials, the investment can enhance brand reputation and customer loyalty among green consumers.

Related Video: How Large Language Models Work

Key Industrial Applications of bucket backpack

| Industry/Sector | Specific Application of Bucket Backpack | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Outdoor Recreation | Hiking and Camping Gear | Enhanced portability and ease of access to essentials | Durability in various weather conditions, lightweight materials |

| Education | School Supplies and Student Kits | Cost-effective solution for bulk purchases | Compliance with educational standards, safety certifications |

| Event Management | Promotional and Marketing Events | Customizable branding options for visibility | Lead times for customization, cost-effectiveness for bulk orders |

| Emergency Services | First Response and Rescue Operations | Quick access to medical supplies and tools | Material durability and compliance with safety regulations |

| Logistics and Delivery | Transporting Goods in Warehouse Operations | Improved organization and efficiency in handling items | Load capacity, ease of handling, and material strength |

Outdoor Recreation

In the outdoor recreation sector, bucket backpacks are utilized for hiking and camping, providing a practical solution for carrying gear. These backpacks are designed to be lightweight yet durable, ensuring that adventurers can easily transport essentials like food, water, and safety equipment. International buyers should focus on sourcing materials that can withstand various weather conditions, ensuring longevity and reliability during outdoor activities.

Education

Bucket backpacks serve as an economical option for educational institutions looking to provide students with essential supplies. These backpacks can be customized to include school logos or colors, making them ideal for branding. For B2B buyers in this sector, it is crucial to ensure that the products comply with safety certifications and educational standards, particularly when sourcing for large quantities.

Event Management

In the realm of event management, bucket backpacks are increasingly used for promotional and marketing events. They offer customizable branding options, allowing businesses to enhance visibility while providing attendees with a practical item. Buyers should consider lead times for customization and the overall cost-effectiveness of bulk orders to maximize their marketing budgets.

Emergency Services

Bucket backpacks play a vital role in emergency services, particularly for first responders and rescue operations. These backpacks are designed for quick access to medical supplies and essential tools, which can be critical in life-or-death situations. International buyers should prioritize sourcing backpacks made from durable materials that comply with safety regulations to ensure they can withstand the rigors of emergency scenarios.

Logistics and Delivery

In logistics and delivery, bucket backpacks can significantly improve the organization and efficiency of transporting goods within warehouse operations. Their design allows for easy handling and access to items, which can streamline workflows. When sourcing these products, businesses should consider load capacity, ease of handling, and material strength to ensure they meet the demands of high-traffic environments.

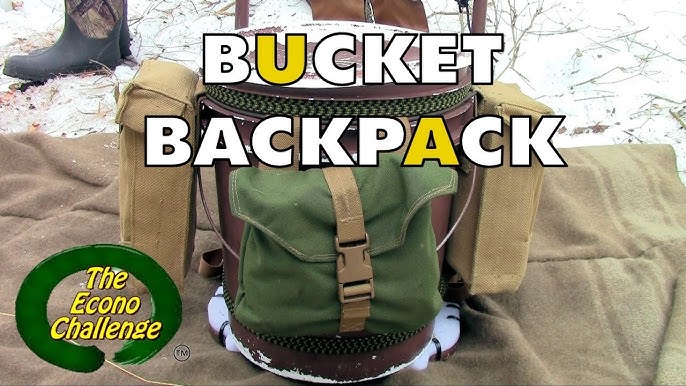

Related Video: The Bucket Backpack – Review – Econo Challenge

Strategic Material Selection Guide for bucket backpack

When selecting materials for bucket backpacks, international B2B buyers must consider various factors that impact product performance, cost, and market acceptance. Below is an analysis of four common materials used in bucket backpacks, focusing on their properties, advantages, disadvantages, and specific considerations for buyers in Africa, South America, the Middle East, and Europe.

1. Nylon

Key Properties: Nylon is known for its high tensile strength, abrasion resistance, and lightweight nature. It performs well in a range of temperatures and has good resistance to mildew and UV light.

Pros & Cons: Nylon is durable and water-resistant, making it suitable for outdoor use. However, it can be more expensive than other synthetic materials and may require specialized manufacturing processes. Additionally, while it is lightweight, it can be less breathable, which may affect comfort during extended wear.

Impact on Application: Nylon is compatible with various media, including water and moisture, making it ideal for outdoor and travel applications. Its durability ensures that it can withstand rough handling and harsh environments.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM for textile products. Additionally, sourcing from regions with established nylon manufacturing capabilities, like China or Vietnam, can help mitigate supply chain risks.

2. Polyester

Key Properties: Polyester offers good resistance to stretching, shrinking, and wrinkling. It is also resistant to mildew and most chemicals, making it a versatile choice for various applications.

Pros & Cons: Polyester is generally less expensive than nylon and is easier to dye, allowing for a wide range of colors and patterns. However, it is less durable than nylon and can degrade under prolonged exposure to UV light. Additionally, while it is water-resistant, it is not as effective as nylon in wet conditions.

Impact on Application: Polyester’s chemical resistance makes it suitable for applications where exposure to oils or solvents is likely. Its lightweight nature also contributes to the comfort of bucket backpacks.

Considerations for International Buyers: Buyers should be aware of the different grades of polyester and their respective certifications. Compliance with environmental regulations, especially in Europe, is crucial, as consumers increasingly demand sustainable materials.

3. Canvas

Key Properties: Canvas is a heavy-duty fabric, typically made from cotton or a cotton-polyester blend. It is known for its durability and resistance to wear and tear.

Pros & Cons: The primary advantage of canvas is its strength and ability to withstand heavy loads. It is also breathable, which enhances comfort. However, canvas can be heavier than synthetic materials and may require more complex manufacturing processes. Additionally, it is less water-resistant unless treated.

Impact on Application: Canvas is suitable for applications where durability is paramount, such as outdoor activities or heavy-duty use. Its natural fibers make it a preferred choice for eco-conscious consumers.

Considerations for International Buyers: Buyers should ensure that the canvas meets relevant environmental standards and certifications, particularly in Europe and North America. Sourcing from countries with a strong textile heritage, like India, can provide access to high-quality canvas products.

4. Leather

Key Properties: Leather is a natural material known for its durability, aesthetic appeal, and unique texture. It offers good resistance to wear and tear and can be treated for water resistance.

Pros & Cons: Leather provides a premium look and feel, making it suitable for high-end bucket backpacks. However, it is typically more expensive than synthetic options and requires careful maintenance. Leather can also be less flexible than other materials, impacting comfort.

Impact on Application: Leather is well-suited for applications where style and durability are essential, such as fashion-oriented backpacks. Its natural properties allow it to age gracefully, adding character over time.

Considerations for International Buyers: Buyers should consider sourcing leather from regions known for quality craftsmanship, like Italy or Brazil. Compliance with animal welfare standards and environmental regulations is increasingly important in the global market.

Summary Table

| Material | Typical Use Case for bucket backpack | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | Outdoor and travel backpacks | High durability and water resistance | Higher cost, less breathable | High |

| Polyester | Everyday use and casual backpacks | Cost-effective and easy to dye | Less durable, UV degradation | Medium |

| Canvas | Heavy-duty and eco-friendly backpacks | Strong and breathable | Heavier, requires treatment for water resistance | Medium |

| Leather | Premium and fashion-oriented backpacks | Aesthetic appeal and durability | Expensive, requires maintenance | High |

This guide provides a comprehensive overview of material options for bucket backpacks, assisting international B2B buyers in making informed decisions that align with their market needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for bucket backpack

Manufacturing Processes for Bucket Backpacks

The manufacturing of bucket backpacks involves a series of well-defined stages that ensure quality and functionality. Understanding these processes is crucial for international B2B buyers looking to source high-quality products.

1. Material Preparation

The first step in the manufacturing process is the selection and preparation of materials. Common materials for bucket backpacks include nylon, polyester, canvas, and leather. Each material is chosen based on durability, weight, and intended use.

- Material Sourcing: Suppliers should provide certifications for the materials used, ensuring they meet international standards for quality and safety.

- Cutting: Once the materials are sourced, they are cut into specific patterns using automated cutting machines for precision. This reduces waste and improves efficiency.

2. Forming

The forming stage involves shaping the cut materials into the desired structure of the bucket backpack.

- Stitching: High-strength threads are used to stitch the pieces together. Techniques such as double stitching and bar-tacking at stress points enhance durability.

- Molding and Shaping: If the design includes any structural elements (like frames or stiffeners), these are added during this stage. Thermoforming might be used for specific materials to ensure they hold their shape.

3. Assembly

After forming, the components are assembled into the final product.

- Zipper and Hardware Installation: Zippers, buckles, and other hardware are attached, ensuring they are functional and durable. Quality assurance checks should be in place to verify the functionality of these components.

- Lining and Padding: If the design includes internal linings or padding, these are added at this stage to enhance comfort and usability.

4. Finishing

The final stage of production is finishing, which includes various processes to ensure the backpack meets the desired aesthetic and functional standards.

- Quality Checks: Before the final inspection, backpacks undergo a series of quality checks to ensure that stitching is consistent, hardware is secure, and there are no defects.

- Packing: Once finished, the backpacks are packed according to international shipping standards, ensuring that they remain in good condition during transportation.

Quality Assurance (QA) in Bucket Backpack Manufacturing

Quality assurance is critical for ensuring that the final product meets both regulatory and customer standards. For B2B buyers, understanding the QA processes can provide confidence in their sourcing decisions.

Relevant International Standards

International standards play a significant role in the manufacturing and quality assurance of bucket backpacks:

- ISO 9001: This standard outlines requirements for a quality management system (QMS) that manufacturers must adhere to. It focuses on consistent quality and continuous improvement.

- CE Marking: For products sold in the European market, CE marking indicates compliance with EU safety, health, and environmental protection standards.

- API Standards: While not directly related to backpacks, understanding that suppliers adhere to rigorous testing and quality assurance frameworks (like those used in the oil and gas industry) can provide insights into their overall commitment to quality.

QC Checkpoints

Implementing a robust quality control system involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Regular checks during the manufacturing process help identify defects early, allowing for corrections before the final product assembly.

- Final Quality Control (FQC): This comprehensive inspection occurs before packing and shipping, ensuring that all specifications and quality standards have been met.

Common Testing Methods

Testing methods vary depending on material and design, but common practices include:

- Tensile Testing: Measures the strength of materials used.

- Water Resistance Tests: Assesses how well the backpack withstands water exposure.

- Durability Testing: Simulates wear and tear to ensure longevity.

Verifying Supplier Quality Control

B2B buyers should take proactive steps to verify the quality control practices of their suppliers:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, equipment, and quality control measures in place.

- Quality Reports: Requesting detailed quality reports can provide insights into past performance and any issues encountered during production.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of product quality before shipment.

QC and Certification Nuances for International Buyers

For international buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is crucial:

- Local Regulations: Each region may have specific regulations regarding product safety and quality. Buyers should familiarize themselves with these requirements to ensure compliance.

- Cultural Considerations: Different cultures may have varying perceptions of quality and craftsmanship. Engaging with local partners can provide insights into these differences.

- Environmental and Social Compliance: Increasingly, buyers are interested in the environmental impact of their products. Ensuring that suppliers adhere to sustainable practices can enhance brand reputation.

Conclusion

The manufacturing processes and quality assurance measures for bucket backpacks are intricate and essential for ensuring high-quality products. By understanding these processes, international B2B buyers can make informed sourcing decisions that align with their quality expectations and market standards. Careful consideration of supplier capabilities, adherence to international standards, and thorough quality verification practices will lead to successful partnerships and satisfied customers.

Related Video: How a Backpack is Made : Every Step on the Production Line

Comprehensive Cost and Pricing Analysis for bucket backpack Sourcing

When sourcing bucket backpacks, a thorough understanding of the cost structure and pricing dynamics is essential for international B2B buyers. The cost components involved in manufacturing bucket backpacks include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Cost Components Breakdown

-

Materials: The primary cost driver, materials for bucket backpacks typically include fabrics (nylon, polyester, canvas), zippers, buckles, and padding. The choice of materials directly impacts durability, aesthetics, and ultimately, the pricing. For instance, high-quality waterproof materials will elevate costs but may justify a higher retail price point.

-

Labor: Labor costs vary significantly by region. Countries like Vietnam and Bangladesh offer competitive labor rates, while European manufacturers may have higher costs due to stringent labor laws and wage standards. Understanding regional labor costs can help buyers determine the most cost-effective sourcing options.

-

Manufacturing Overhead: This includes costs related to factory operation, utilities, and administrative expenses. Buyers should assess suppliers’ overhead structures to understand how these costs affect the final pricing.

-

Tooling: Initial tooling costs for molds and production setups can be substantial, especially for customized or complex designs. Buyers should inquire about tooling costs and whether they will be amortized over the order volume.

-

Quality Control (QC): Investing in QC processes ensures product reliability and reduces returns. Quality inspections can add to costs but are essential for maintaining brand reputation.

-

Logistics: Shipping costs can be a significant part of the total cost. Factors like shipping distance, mode (air vs. sea), and Incoterms (e.g., FOB, CIF) can drastically influence logistics expenses.

-

Margin: Suppliers typically add a profit margin to cover risks and ensure sustainability. This margin can vary widely depending on the supplier’s market position and the complexity of the product.

Illustrative Image (Source: Google Search)

Price Influencers

Several key factors influence the pricing of bucket backpacks:

-

Volume/MOQ: Minimum order quantities (MOQs) can affect pricing significantly. Higher volumes often lead to reduced unit costs due to economies of scale.

-

Specifications/Customization: Custom designs or specialized materials will increase costs. Buyers should weigh the benefits of customization against the potential price increases.

-

Materials and Quality: The choice of materials and certifications (e.g., eco-friendly, safety standards) can raise costs. Buyers should assess the trade-offs between cost and quality.

-

Supplier Factors: Supplier reliability, communication efficiency, and past performance play a role in pricing. Established suppliers may charge a premium for their proven capabilities.

-

Incoterms: Understanding Incoterms is crucial for managing logistics costs. Terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) dictate who bears shipping costs and risks.

Buyer Tips

To navigate the complexities of bucket backpack sourcing, international B2B buyers should consider the following strategies:

-

Negotiation: Engage suppliers in discussions about pricing flexibility, especially for bulk orders. Building long-term relationships can yield better terms.

-

Cost-Efficiency: Focus on total cost of ownership rather than just unit price. This includes considering shipping, tariffs, and potential returns due to quality issues.

-

Pricing Nuances: Be aware of regional pricing differences, especially when sourcing from countries like China, Vietnam, or India. Each region has unique advantages that can impact overall costs.

-

Quality Assurance: Prioritize quality and craftsmanship to minimize returns and enhance customer satisfaction. Ensure that suppliers adhere to agreed-upon quality standards.

-

Market Research: Stay informed about market trends and competitor pricing to make data-driven decisions. Use market reports and forecasts to guide sourcing strategies.

Disclaimer

Prices and costs mentioned in this analysis are indicative and can vary based on specific supplier negotiations, market conditions, and individual buyer requirements. Always conduct thorough due diligence when sourcing to ensure the best outcomes.

Spotlight on Potential bucket backpack Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘bucket backpack’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for bucket backpack

Understanding the essential technical properties and terminology related to bucket backpacks is crucial for international B2B buyers. This section outlines key specifications and trade terms that will help streamline sourcing processes and enhance decision-making.

Critical Technical Properties

-

Material Grade

– Definition: Refers to the quality and type of fabric used in the backpack, such as nylon, polyester, or canvas.

– Importance: Material grade impacts durability, water resistance, and overall weight. High-quality materials can enhance product lifespan and customer satisfaction, which is vital for brand reputation. -

Capacity

– Definition: The volume that the bucket backpack can hold, typically measured in liters.

– Importance: Understanding capacity helps buyers select products that meet the needs of their target market, whether for casual use or specialized activities like hiking or travel. -

Weight Tolerance

– Definition: The maximum load the backpack can safely carry without compromising structural integrity, often specified in kilograms or pounds.

– Importance: Knowing the weight tolerance is essential for safety and usability, ensuring that the backpack performs well under expected conditions. -

Strap Construction

– Definition: The design and materials used for the backpack’s straps, including width, padding, and adjustability.

– Importance: Proper strap construction enhances comfort and usability. Buyers should consider ergonomics, especially for backpacks intended for long-term wear or heavy loads.

Illustrative Image (Source: Google Search)

-

Water Resistance Rating

– Definition: A measure of the backpack’s ability to repel water, often indicated by a rating system (e.g., IPX).

– Importance: This property is crucial for outdoor or travel backpacks, as it affects the protection of contents against environmental elements, thereby influencing buyer choice. -

Zipper Quality

– Definition: Refers to the type and durability of zippers used, such as YKK or other high-quality brands.

– Importance: The reliability of zippers impacts the overall functionality of the backpack. Strong, corrosion-resistant zippers enhance user experience and reduce return rates.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships can help buyers identify reliable suppliers who can produce customized bucket backpacks to meet specific market needs. -

MOQ (Minimum Order Quantity)

– Definition: The smallest number of units a supplier is willing to sell.

– Relevance: Knowing the MOQ is essential for budgeting and inventory planning. It influences sourcing decisions, especially for smaller businesses that may not need large quantities. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and terms for specific products.

– Relevance: Utilizing RFQs can streamline the procurement process, allowing buyers to compare prices and services efficiently across multiple suppliers. -

Incoterms

– Definition: International commercial terms that define the responsibilities of buyers and sellers in the shipping process.

– Relevance: Familiarity with Incoterms helps buyers understand shipping costs, risks, and delivery responsibilities, which can significantly affect overall pricing and logistics. -

Lead Time

– Definition: The time taken from placing an order to the delivery of the product.

– Relevance: Knowing lead times is crucial for planning and inventory management. It helps businesses align their supply chain with market demands. -

Certification Standards

– Definition: Compliance with specific industry standards (e.g., ISO, REACH) that ensure quality and safety.

– Relevance: Certifications can enhance a brand’s credibility and facilitate market access, particularly in regions with stringent regulatory requirements.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring that their sourcing strategies align with market demands and operational capabilities.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the bucket backpack Sector

Market Overview & Key Trends

The global bucket backpack market is experiencing a robust growth trajectory, driven by increasing demand for functional and stylish outdoor gear. Key factors fueling this expansion include the rising popularity of adventure tourism, outdoor recreational activities, and a growing urban lifestyle that favors versatile, multi-functional products. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of the emerging sourcing trends that focus on diversification beyond traditional manufacturing hubs.

China remains a dominant player, but brands are increasingly adopting “China Plus One” strategies, incorporating alternative suppliers in regions like Vietnam, India, and Bangladesh. These countries offer competitive pricing and quality, along with the added benefits of shorter lead times and reduced shipping costs due to their proximity to target markets. Emerging technologies, such as digital sourcing platforms and AI-driven supply chain management tools, are also revolutionizing procurement processes, enabling buyers to streamline operations and enhance efficiency.

For B2B buyers, understanding the local market dynamics is crucial. In Africa, for instance, a burgeoning middle class is driving demand for quality products, while in South America, eco-conscious consumers are influencing brands to adopt sustainable practices. Europe’s focus on quality and design also demands that suppliers adhere to high standards, making the selection of manufacturing partners a critical decision.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone of modern sourcing strategies in the bucket backpack sector. With increasing awareness of environmental impacts, international buyers must prioritize ethical supply chains. This involves selecting suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials, minimizing waste, and ensuring fair labor conditions.

Incorporating green certifications and materials is essential for brands looking to appeal to eco-conscious consumers. Certifications such as Global Organic Textile Standard (GOTS), Fair Trade, and OEKO-TEX can enhance brand credibility and marketability. Additionally, using eco-friendly materials like recycled polyester, organic cotton, and biodegradable plastics not only reduces the environmental footprint but also resonates with the values of modern consumers.

For B2B buyers, establishing partnerships with manufacturers who prioritize sustainability can lead to enhanced brand loyalty and customer satisfaction. This strategic focus not only mitigates risks associated with regulatory compliance but also positions companies favorably in markets increasingly driven by sustainability metrics.

Brief Evolution/History

The bucket backpack has evolved significantly since its inception, transitioning from a simple utility item to a stylish accessory that meets both functional and aesthetic demands. Initially designed for outdoor enthusiasts, its popularity surged in the 1990s as urban lifestyles began to embrace multifunctional designs.

Today, the bucket backpack is recognized for its versatility, catering to various demographics, including students, professionals, and travelers. This evolution reflects broader trends in consumer behavior, where style, sustainability, and functionality converge. For B2B buyers, understanding this evolution can inform product selection and branding strategies, ensuring alignment with current market demands.

In conclusion, navigating the bucket backpack sector requires a keen understanding of market dynamics, sourcing trends, and sustainability imperatives. By prioritizing ethical sourcing and leveraging emerging technologies, international B2B buyers can position themselves for success in a competitive landscape.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of bucket backpack

-

What should I consider when vetting suppliers for bucket backpacks?

When vetting suppliers, prioritize their experience and reputation in the backpack market. Request references from past clients and check online reviews. Assess their production capabilities, quality control processes, and compliance with international standards. It’s essential to evaluate their communication responsiveness and ability to meet your specific requirements. Additionally, verify if they have certifications relevant to your market, such as ISO or environmental certifications, to ensure they adhere to ethical and sustainable practices. -

Can I customize bucket backpacks to fit my brand’s needs?

Yes, many manufacturers offer customization options for bucket backpacks. This can include alterations in design, material, color, and branding elements such as logos or labels. When discussing customization, provide clear specifications and samples if possible. It’s also crucial to understand the implications of custom designs on pricing and lead times, as more complex modifications may increase costs and extend production schedules. -

What are typical minimum order quantities (MOQs) and lead times for bucket backpacks?

MOQs for bucket backpacks can vary significantly based on the supplier and customization level. Generally, you might encounter MOQs ranging from 500 to 5,000 units. Lead times typically span from 4 to 8 weeks, depending on the complexity of the order and the supplier’s capacity. Always clarify these details upfront to align your purchasing plans with your inventory needs, and consider negotiating smaller MOQs if you are a smaller business or testing new products. -

What payment terms should I expect when sourcing internationally?

Payment terms can vary widely among suppliers. Common practices include a deposit upfront (usually 30% of the total cost), with the balance paid before shipment. Some suppliers may offer letters of credit or payment via platforms like PayPal for added security. Discuss payment terms thoroughly before placing an order to avoid misunderstandings. Ensure you factor in currency exchange rates and potential bank fees when budgeting for your purchases. -

How can I ensure quality assurance and compliance with certifications?

To ensure quality assurance, request samples before placing a bulk order and conduct thorough inspections upon receipt. Ask suppliers about their quality control processes, and consider third-party inspections if necessary. Certifications such as ISO, CE, or specific textile standards can validate a supplier’s commitment to quality and safety. Ensure that any certifications are up to date and relevant to your target market, as this can impact your product’s acceptance in various regions. -

What logistics considerations should I keep in mind when importing bucket backpacks?

Logistics are crucial in international sourcing. Consider shipping methods (air vs. sea), as air freight is faster but more expensive, while sea freight is cost-effective for large shipments but slower. Assess customs regulations in your importing country, including duties and taxes that may apply. Establish a reliable shipping partner and ensure the supplier can provide necessary documentation (like bills of lading and commercial invoices) to facilitate smooth customs clearance. -

What steps should I take to resolve disputes with suppliers?

In the event of a dispute, maintain clear and professional communication with the supplier to address the issue directly. Document all correspondence and agreements to support your case. If initial discussions do not lead to a resolution, consider involving a neutral third-party mediator or an international trade organization. Having clear terms in your contract regarding dispute resolution processes can also help mitigate issues before they escalate. -

What are the potential risks of sourcing bucket backpacks internationally?

Sourcing internationally carries several risks, including supply chain disruptions, fluctuating currency exchange rates, and varying quality standards. Political instability in the supplier’s country can also impact production and shipping. To mitigate these risks, diversify your supplier base and maintain open lines of communication. Conduct thorough market research and stay informed about global trade policies that could affect your sourcing strategy. Establishing strong relationships with suppliers can also enhance reliability and reduce potential issues.

Strategic Sourcing Conclusion and Outlook for bucket backpack

In navigating the dynamic landscape of the bucket backpack market, international B2B buyers must prioritize strategic sourcing to leverage the best manufacturing capabilities globally. The insights gathered indicate that sourcing from countries like Vietnam and India can provide a balance of quality craftsmanship and competitive pricing, while Bangladesh offers unparalleled value for high-volume, price-sensitive products.

Understanding total cost of ownership, including shipping and compliance costs, is essential for making informed decisions. Additionally, adopting a multi-country sourcing strategy not only enhances resilience against supply chain disruptions but also allows buyers to capitalize on specific regional advantages, such as access to raw materials and labor expertise.

As the market evolves and consumer preferences shift towards sustainability and ethical manufacturing practices, B2B buyers must remain agile. Investing in relationships with reliable suppliers who share these values will be crucial.

Looking ahead, the potential for growth in the bucket backpack segment is significant, especially in emerging markets across Africa, South America, and the Middle East. By strategically aligning sourcing practices with market demands, buyers can position themselves for success. Embrace the opportunities that lie ahead and strengthen your supply chain today for a competitive edge tomorrow.