Master Sourcing 49ers Backpacks: Strategies for B2B Buyers

Guide to 49Ers Backpack

- Introduction: Navigating the Global Market for 49ers backpack

- Understanding 49ers backpack Types and Variations

- Key Industrial Applications of 49ers backpack

- Strategic Material Selection Guide for 49ers backpack

- In-depth Look: Manufacturing Processes and Quality Assurance for 49ers backpack

- Comprehensive Cost and Pricing Analysis for 49ers backpack Sourcing

- Spotlight on Potential 49ers backpack Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for 49ers backpack

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the 49ers backpack Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of 49ers backpack

- Strategic Sourcing Conclusion and Outlook for 49ers backpack

Introduction: Navigating the Global Market for 49ers backpack

In today’s competitive landscape, the 49ers backpack has emerged as a vital product for retailers and wholesalers aiming to capture the attention of sports enthusiasts and casual consumers alike. As an international B2B buyer, understanding the nuances of sourcing this iconic merchandise can significantly enhance your product offerings and bolster your brand reputation. This guide is designed to equip you with comprehensive insights into various aspects of the 49ers backpack, from the types available and material choices to manufacturing processes, quality control measures, and supplier evaluations.

Navigating the global market requires a keen understanding of local preferences and trends, particularly for buyers in regions such as Africa, South America, the Middle East, and Europe. Each market presents unique challenges and opportunities, and this guide will delve into the specifics that matter most to you.

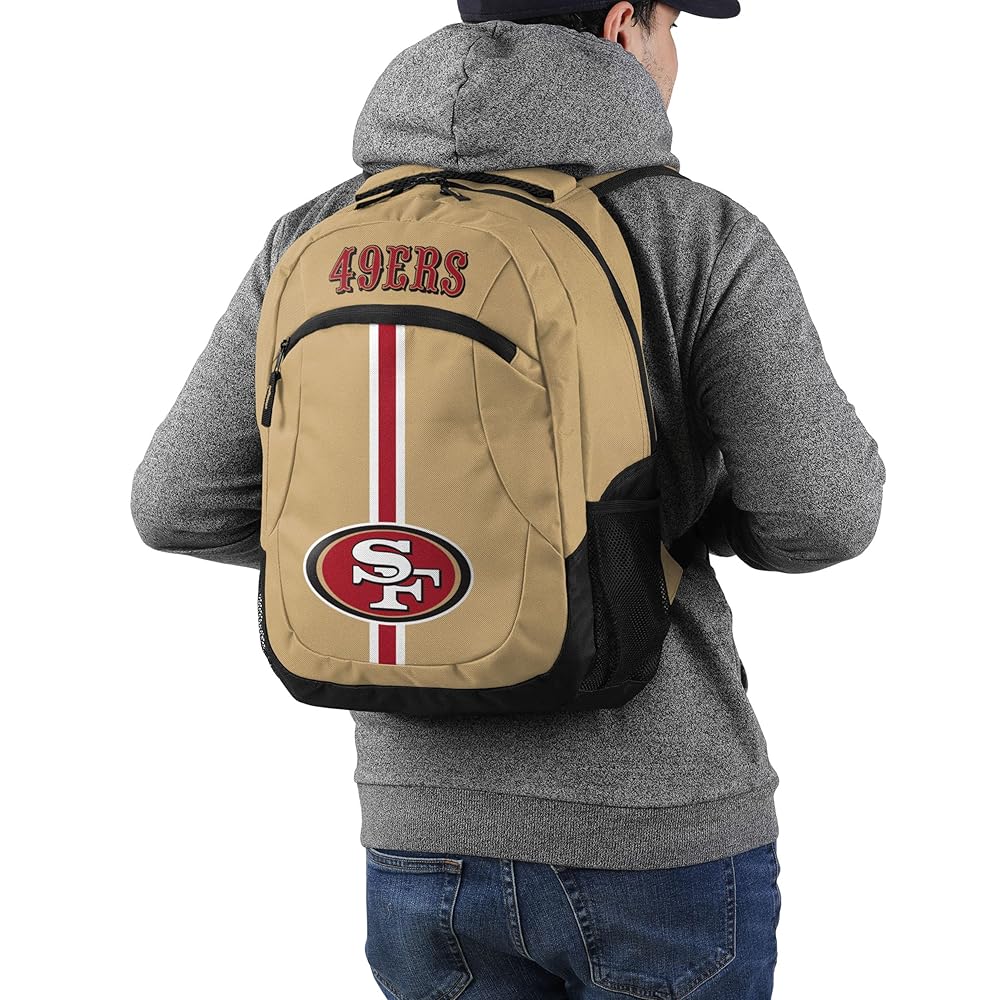

Illustrative Image (Source: Google Search)

Key topics covered include:

- Types of 49ers backpacks: Explore the diverse range of styles tailored to different demographics.

- Materials and durability: Learn about the best materials that ensure longevity and customer satisfaction.

- Manufacturing and quality control: Gain insights into best practices that can help avoid common pitfalls in sourcing.

- Supplier sourcing: Discover how to identify reliable suppliers that align with your quality standards.

- Cost considerations: Understand pricing structures to make informed purchasing decisions.

- Market insights: Analyze trends and consumer preferences in your target regions.

- FAQs: Address common concerns and queries related to sourcing.

By leveraging the actionable insights provided in this guide, B2B buyers can make informed decisions that lead to successful sourcing of 49ers backpacks, ensuring they meet the quality expectations of their customers while enhancing their market presence.

Understanding 49ers backpack Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Daypack | Lightweight, compact, with minimal storage capacity | Outdoor retailers, schools, e-commerce | Pros: Affordable, versatile; Cons: Limited storage space. |

| Hydration Pack | Integrated water reservoir, designed for active use | Sports retailers, outdoor adventures | Pros: Convenient hydration; Cons: Limited gear storage. |

| Tactical Backpack | Durable, multi-pocket design with military-grade materials | Military supply, outdoor gear retailers | Pros: High durability, functional; Cons: Heavier, bulkier. |

| Laptop Backpack | Padded compartments for electronics, stylish designs | Corporate suppliers, tech retailers | Pros: Protection for devices; Cons: Can be pricier. |

| Travel Backpack | Large capacity with organizational compartments | Travel agencies, outdoor adventure firms | Pros: Spacious and organized; Cons: Can be cumbersome. |

Daypack

Daypacks are ideal for everyday use, featuring a lightweight design and minimal storage capacity. They are typically used in outdoor retail settings, schools, and by e-commerce platforms targeting casual users. When purchasing daypacks, buyers should consider the quality of materials, as well as the comfort of straps and back support, to ensure user satisfaction.

Hydration Pack

Hydration packs come equipped with a water reservoir and a drinking tube, making them perfect for active individuals. These backpacks are commonly sold by sports retailers and are essential for outdoor adventures. B2B buyers should focus on the reservoir capacity and ease of cleaning, as well as the overall fit and comfort for various body types.

Tactical Backpack

Tactical backpacks are built for durability and functionality, featuring a multi-pocket design and military-grade materials. They are often sourced by military supply companies and outdoor gear retailers. Buyers should prioritize the strength of zippers and stitching, as well as the versatility of pockets for various gear, to ensure they meet the rigorous demands of their end users.

Laptop Backpack

Laptop backpacks provide padded compartments specifically designed to protect electronic devices, making them popular among corporate suppliers and tech retailers. When sourcing these backpacks, buyers should evaluate the padding quality, security features, and style to appeal to professionals who value both functionality and aesthetics.

Travel Backpack

Travel backpacks are designed for larger capacities and include organizational compartments for easy packing. They are primarily used by travel agencies and outdoor adventure firms. B2B buyers should consider the weight of the backpack, ease of access to compartments, and overall durability, especially for frequent travelers who require reliable gear.

Related Video: What Makes Large Language Models Expensive?

Key Industrial Applications of 49ers backpack

| Industry/Sector | Specific Application of 49ers backpack | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Education | Student backpacks for schools and universities | Enhanced student engagement and brand visibility | Durability, comfort, and ergonomic design for daily use |

| Outdoor Recreation | Hiking and camping gear for adventure tourism | Lightweight, durable design for outdoor activities | Weather resistance, material quality, and safety features |

| Corporate Gifts | Promotional items for businesses | Brand promotion and employee satisfaction | Customization options, quality assurance, and lead time |

| Logistics and Transport | Gear for delivery personnel | Functional design for carrying essential items | Load capacity, material strength, and accessibility |

| Retail and E-commerce | Stock for online and brick-and-mortar stores | Diverse offerings to attract various customer segments | Market trends, supply chain reliability, and pricing |

Education

In the education sector, 49ers backpacks serve as essential tools for students at schools and universities. These backpacks are designed to be durable and comfortable, making them ideal for daily use. They help enhance student engagement by providing a platform for schools to showcase their branding through custom designs. For international B2B buyers, particularly in regions like Africa and Europe, sourcing considerations include ensuring the backpacks meet safety standards and are made from high-quality materials to withstand wear and tear.

Outdoor Recreation

The outdoor recreation industry leverages 49ers backpacks for hiking and camping activities. These backpacks are lightweight and designed for durability, making them perfect for adventure tourism. They address the need for reliable storage solutions that can withstand various weather conditions. Buyers in South America and the Middle East should focus on sourcing options that include weather-resistant materials and features that enhance usability, such as hydration reservoirs and easy-access pockets.

Corporate Gifts

In the corporate sector, 49ers backpacks are increasingly used as promotional items. They serve as effective branding tools, helping businesses promote their logos while providing practical gifts to employees and clients. The value lies in their ability to enhance employee satisfaction and loyalty. When sourcing, businesses should consider customization options, ensuring the backpacks align with their brand identity, as well as quality assurance to prevent any negative impact on brand reputation.

Logistics and Transport

In logistics and transport, 49ers backpacks are utilized by delivery personnel for carrying essential items during their routes. These backpacks are designed for functionality, offering ample storage and easy accessibility. They solve the problem of transporting goods efficiently while maintaining a professional appearance. Buyers in the Middle East and Africa should prioritize load capacity and material strength to ensure the backpacks can handle heavy usage and various weather conditions.

Retail and E-commerce

For retail and e-commerce businesses, 49ers backpacks are a versatile product that can attract a wide range of customers. They can be marketed as fashion items, functional gear, or educational tools, depending on the target demographic. Sourcing considerations should include staying updated on market trends, ensuring supply chain reliability, and evaluating pricing strategies to maintain competitive advantage. Buyers in Europe, for instance, should focus on seasonal trends and customer preferences to optimize their inventory.

Related Video: LABORATORY APPARATUS AND THEIR USES

Strategic Material Selection Guide for 49ers backpack

When selecting materials for the 49ers backpack, it is essential to consider various factors that impact performance, durability, and overall user satisfaction. Below is an analysis of several common materials used in backpack manufacturing, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Nylon

Key Properties: Nylon is known for its high tensile strength, resistance to abrasion, and lightweight nature. It performs well under varying temperatures and is resistant to mildew and mold.

Pros & Cons: The durability of nylon makes it an excellent choice for outdoor and rugged use. It is relatively affordable, but the manufacturing process can be complex due to the need for specialized stitching techniques to prevent fraying. Additionally, while nylon is generally resistant to wear, it can degrade under prolonged exposure to UV light.

Impact on Application: Nylon is compatible with various media, including water-resistant coatings, making it suitable for backpacks intended for outdoor activities.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should be aware of the need for UV-resistant treatments in sunny climates. Compliance with ASTM standards for textile durability is also crucial.

2. Polyester

Key Properties: Polyester is known for its resistance to shrinking and stretching, as well as its quick-drying capabilities. It has good color retention and can be treated for water resistance.

Pros & Cons: Polyester is cost-effective and easy to dye, which allows for vibrant colors and patterns. However, it is generally less durable than nylon and may not withstand heavy use as well. The manufacturing process is simpler than nylon, making it easier to produce at scale.

Impact on Application: Polyester’s quick-drying properties make it ideal for backpacks used in humid or wet conditions, enhancing user comfort.

Considerations for International Buyers: Buyers in Europe may prefer recycled polyester options due to increasing sustainability standards. Compliance with European Union regulations on textile production is essential.

3. Cordura

Key Properties: Cordura is a brand of fabric known for its durability and resistance to abrasions, tears, and scuffs. It is often used in military and outdoor applications due to its strength.

Pros & Cons: The primary advantage of Cordura is its exceptional durability, making it suitable for heavy-duty backpacks. However, it is more expensive than standard nylon or polyester, which can impact overall product pricing. The complexity of manufacturing with Cordura may also require specialized equipment.

Impact on Application: Cordura is compatible with various waterproofing treatments, making it ideal for backpacks intended for extreme conditions.

Considerations for International Buyers: Buyers from South America and Africa should consider the higher upfront costs versus the long-term durability benefits. Ensuring that suppliers comply with international quality standards (like JIS and DIN) will be vital.

4. Leather

Key Properties: Leather offers natural durability and a premium aesthetic. It is resistant to wear and can be treated for water resistance.

Pros & Cons: Leather provides a high-end look and feel, appealing to luxury markets. However, it is significantly more expensive and requires more maintenance than synthetic materials. The manufacturing complexity is higher due to the need for specialized stitching and treatment processes.

Impact on Application: Leather is less suitable for extreme outdoor conditions but is excellent for urban and fashion-oriented backpacks.

Considerations for International Buyers: Buyers in Europe may face stricter regulations regarding the sourcing of leather, especially concerning animal welfare standards. Understanding compliance with local regulations is essential.

Summary Table

| Material | Typical Use Case for 49ers backpack | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | Outdoor and rugged use | High durability and lightweight | Degrades under UV exposure | Medium |

| Polyester | Casual and everyday use | Cost-effective and easy to dye | Less durable than nylon | Low |

| Cordura | Heavy-duty and extreme conditions | Exceptional durability | Higher cost and manufacturing complexity | High |

| Leather | Luxury and urban use | Premium aesthetic and natural durability | Expensive and requires maintenance | High |

This analysis provides a comprehensive overview of material options for the 49ers backpack, enabling B2B buyers to make informed decisions based on performance, cost, and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 49ers backpack

The manufacturing of a high-quality backpack, such as the 49ers backpack, involves a series of meticulous processes and stringent quality assurance protocols. Understanding these processes is crucial for B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, to ensure they source products that meet their market demands while maintaining brand integrity.

Manufacturing Processes

1. Material Preparation

The first step in the manufacturing process is the selection and preparation of materials. High-quality backpacks typically use durable fabrics such as nylon, polyester, or canvas, which are chosen based on the backpack’s intended use, whether for outdoor activities or everyday carry.

- Sourcing: Buyers should visit reputable fabric markets or work with established suppliers who can provide certified materials.

- Testing: Materials should undergo rigorous testing for properties such as tear strength, water resistance, and color fastness before use.

2. Forming

Once materials are selected, the next stage involves creating patterns and templates. This is crucial for ensuring that all components are cut accurately.

- Pattern Creation: Designers use CAD software to create detailed templates that guide the cutting process.

- Cutting Techniques: Precision cutting can be performed manually for small batches or using automated cutting machines for larger orders, reducing material wastage.

3. Assembly

The assembly stage is where the individual components come together to form the finished backpack.

- Sewing: Skilled workers utilize industrial sewing machines, often employing techniques such as double-stitching and bar tacking at stress points to enhance durability.

- Quality Checks: Inline inspections should occur during assembly to catch any issues early, ensuring consistent quality across the production run.

4. Finishing

The final stage involves adding any additional features and preparing the backpack for shipment.

- Final Inspections: After assembly, a thorough inspection is conducted to check for defects, alignment of zippers and straps, and overall aesthetics.

- Packaging: Proper packaging is essential to prevent damage during transport, and each backpack should be tagged with care instructions and brand information.

Quality Assurance

Quality assurance is vital for ensuring that the finished product meets international standards and customer expectations. For B2B buyers, understanding the relevant standards and quality checkpoints can greatly influence sourcing decisions.

International Standards

B2B buyers should be familiar with various international quality standards that pertain to manufacturing:

- ISO 9001: This standard focuses on quality management systems and ensures that manufacturers consistently meet customer and regulatory requirements.

- CE Marking: Particularly relevant for products sold in the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Specifications: While more common in industrial applications, these specifications can sometimes apply to durable goods like backpacks, especially for rugged outdoor models.

Quality Control Checkpoints

Implementing quality control checkpoints throughout the manufacturing process helps in identifying and resolving issues promptly.

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): Regular checks during the manufacturing process can help identify deviations from quality standards early on.

- Final Quality Control (FQC): A comprehensive inspection of the finished product ensures that all aspects of the backpack meet quality expectations before shipping.

Common Testing Methods

Various testing methods are employed to evaluate the quality and durability of backpacks:

- Abrasion Resistance Tests: Determine how well the fabric withstands wear and tear.

- Waterproof Tests: Assess the effectiveness of waterproof materials and coatings.

- Load Tests: Evaluate the strength and durability of straps and seams under weight.

Verification of Supplier Quality Control

For international B2B buyers, verifying a supplier’s quality control measures is essential to mitigate risks associated with sourcing.

- Supplier Audits: Conducting audits of potential suppliers can provide insight into their quality management systems and manufacturing processes. This can be done through in-person visits or third-party services.

- Quality Reports: Requesting documentation of quality testing results and certifications can help validate a supplier’s claims about their quality assurance practices.

- Third-Party Inspections: Engaging third-party inspection agencies to evaluate products before shipment can help ensure compliance with specified standards and reduce the risk of receiving defective items.

Quality Control Nuances for International Buyers

Buyers from Africa, South America, the Middle East, and Europe should be aware of specific nuances related to quality control:

- Cultural and Regulatory Differences: Familiarity with the regulatory landscape in the target market is crucial. For instance, EU regulations may differ significantly from those in other regions.

- Language Barriers: Communication can pose challenges; thus, working with suppliers who are fluent in the buyer’s language can help clarify quality expectations.

- Local Partnerships: Establishing relationships with local representatives or agencies can facilitate better understanding and adherence to quality standards.

By comprehensively understanding the manufacturing processes and quality assurance protocols, B2B buyers can make informed decisions that lead to successful sourcing of high-quality backpacks like the 49ers model. This diligence not only enhances customer satisfaction but also strengthens the buyer’s brand reputation in competitive markets.

Related Video: How a Backpack is Made : Every Step on the Production Line

Comprehensive Cost and Pricing Analysis for 49ers backpack Sourcing

Understanding the cost structure and pricing dynamics of sourcing 49ers backpacks is crucial for international B2B buyers. This analysis breaks down the key cost components and price influencers while offering actionable insights to ensure effective negotiation and procurement strategies.

Cost Components

-

Materials

The quality of materials significantly impacts the overall cost. Common materials for backpacks include durable fabrics like nylon or polyester, zippers, and hardware. The choice of materials not only affects durability but also influences consumer perception. High-quality materials may command a higher price, but they can lead to greater customer satisfaction and reduced return rates. -

Labor

Labor costs can vary widely depending on the manufacturing location. Countries with lower labor costs may offer cheaper backpacks, but this can sometimes come at the expense of quality. It’s essential to evaluate the skill level of workers and the labor practices of suppliers to ensure that you’re not compromising on quality for cost savings. -

Manufacturing Overhead

This includes utilities, rent, and administrative costs associated with running a manufacturing facility. Higher overhead can lead to increased prices, so it’s advisable to source from manufacturers with efficient operations to keep costs down. -

Tooling

Initial tooling costs for custom designs can be substantial, especially if unique molds or cutting templates are required. However, these costs can be amortized over larger production runs, making it essential to consider minimum order quantities (MOQs) when calculating total costs. -

Quality Control (QC)

Investing in robust quality control processes is vital to avoid defects that can lead to returns and brand damage. Ensure that the supplier has a clear QC process in place, which may include in-line inspections and final product checks. This can add to costs but will pay off in the long run through higher customer satisfaction. -

Logistics

Logistics costs encompass shipping, customs duties, and warehousing. These costs can vary significantly based on the shipping method (air vs. sea), destination, and Incoterms. It’s essential to factor in these costs early in the sourcing process to avoid unexpected expenses. -

Margin

Suppliers will typically build a profit margin into their pricing. This margin can vary based on market demand, competition, and the supplier’s positioning. Understanding the supplier’s pricing strategy can help you negotiate better terms.

Price Influencers

-

Volume/MOQ: Larger orders generally lead to lower per-unit costs. Suppliers are often more willing to negotiate prices for bulk orders, so consider consolidating orders to maximize savings.

-

Specifications/Customization: Custom designs and specifications can significantly impact costs. Be clear about your requirements to avoid unnecessary expenses and ensure that the supplier can meet your standards.

-

Material Quality/Certifications: The presence of certifications (e.g., ISO, OEKO-TEX) can influence pricing. Products that meet higher standards may cost more but can enhance your brand’s credibility and appeal.

-

Supplier Factors: Factors such as the supplier’s reputation, production capacity, and location can influence pricing. Established suppliers may charge more due to their reliability and quality assurance processes.

-

Incoterms: Understanding Incoterms is crucial as they define the responsibilities of buyers and sellers in shipping arrangements. Terms like FOB (Free on Board) can significantly affect the total landed cost.

Buyer Tips

-

Negotiate Effectively: Always approach negotiations with a clear understanding of your budget and the market rates. Establish relationships with suppliers and communicate your long-term purchasing intentions to secure better pricing.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the upfront price. Consider factors like durability, warranty, and potential returns when assessing overall value.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, import tariffs, and local taxes that can impact pricing. Engaging with local experts or consultants can provide valuable insights into these variables.

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and changes in material costs. It is advisable to conduct thorough research and obtain multiple quotes before finalizing any sourcing decisions.

Illustrative Image (Source: Google Search)

Spotlight on Potential 49ers backpack Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ’49ers backpack’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for 49ers backpack

When considering the procurement of 49ers backpacks, it is essential for B2B buyers to understand the key technical properties and trade terminology associated with these products. This knowledge not only aids in making informed purchasing decisions but also enhances negotiations with suppliers.

Critical Specifications for 49ers Backpacks

-

Material Grade

– Definition: The classification of materials based on their quality and durability, often indicated by specific standards (e.g., denier for fabrics).

– Importance: High-grade materials ensure that the backpack can withstand wear and tear, enhancing longevity and customer satisfaction. For example, a 1000D nylon fabric offers superior strength compared to a 600D variant, making it ideal for rugged use. -

Tensile Strength

– Definition: The maximum amount of tensile (pulling) stress that a material can withstand without breaking, usually measured in pounds or kilograms.

– Importance: This property is crucial for backpacks that will carry heavy loads. Understanding tensile strength helps buyers select products that can handle the expected weight without compromising safety or quality. -

Water Resistance Rating

– Definition: A measure of how well the materials used in the backpack can resist water penetration, typically rated in millimeters (e.g., 1000mm waterproof).

– Importance: For customers in regions with heavy rainfall or for outdoor enthusiasts, a high water resistance rating is critical. It ensures that contents remain dry during adverse weather conditions, leading to higher customer satisfaction. -

Zipper Quality

– Definition: Refers to the durability and reliability of zippers used in the backpack, which can vary by type (e.g., YKK zippers are often regarded as top-tier).

– Importance: Zipper failures can lead to product returns and dissatisfaction. Selecting backpacks with high-quality zippers mitigates this risk, ensuring the product’s functionality over time. -

Weight Capacity

– Definition: The maximum weight the backpack is designed to carry safely, often specified in kilograms or pounds.

– Importance: Knowing the weight capacity is essential for targeting the right market segment. For instance, backpacks aimed at students may have lower weight limits compared to those designed for hikers or travelers. -

Comfort Features

– Definition: Aspects such as padded shoulder straps, back support, and adjustable components that enhance user experience.

– Importance: Comfort features are pivotal for user satisfaction, especially for long-term wear. Backpacks that prioritize ergonomics can lead to repeat purchases and positive brand reputation.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships is vital for buyers looking for customized backpacks that may incorporate specific branding or features. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Knowing the MOQ helps buyers plan their inventory and budget effectively. Suppliers may have different MOQs based on the product’s complexity and manufacturing costs. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and other relevant information for a specific product or service.

– Relevance: Utilizing RFQs is essential for comparing prices and terms among different suppliers, helping buyers make cost-effective decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of international rules that define the responsibilities of buyers and sellers in shipping and freight.

– Relevance: Familiarity with Incoterms is crucial for B2B buyers to understand shipping costs, risks, and insurance, which can significantly impact the total landed cost of the backpacks. -

Lead Time

– Definition: The amount of time from placing an order to receiving the goods.

– Relevance: Knowing the lead time helps buyers manage inventory levels and sales forecasts, ensuring they can meet customer demand without delays.

By equipping themselves with knowledge of these technical properties and trade terms, B2B buyers can enhance their sourcing strategies, minimize risks, and ultimately improve their purchasing outcomes in the competitive backpack market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the 49ers backpack Sector

Market Overview & Key Trends

The global backpack market, particularly the segment focusing on the 49ers backpack, is witnessing significant growth driven by increasing consumer demand for functional and stylish bags. Factors such as urbanization, rising disposable incomes, and an active lifestyle are propelling this market. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for strategic sourcing.

Key trends include the integration of technology in manufacturing processes, such as automated cutting and sewing, which enhances efficiency and reduces lead times. Furthermore, the rise of e-commerce has shifted the way backpacks are marketed and sold, leading to a demand for direct-to-consumer models. Buyers should leverage platforms like Alibaba or specialized sourcing agents to navigate these changes effectively.

Sustainability is also becoming a pivotal aspect of sourcing strategies. As consumers increasingly prioritize eco-friendly products, B2B buyers must consider suppliers who utilize sustainable materials and practices. This trend is particularly relevant for buyers in regions like Europe, where regulatory frameworks are promoting sustainable manufacturing. Adapting to these trends not only aligns with consumer expectations but also enhances the competitiveness of brands in diverse markets.

Sustainability & Ethical Sourcing in B2B

The environmental impact of backpack production is substantial, making sustainability a critical consideration for B2B buyers. The use of synthetic materials, often derived from petroleum, contributes to pollution and waste. Buyers should prioritize suppliers who employ eco-friendly materials, such as recycled polyester or organic cotton, which significantly reduce the carbon footprint.

Ethical sourcing is equally important. Ensuring that suppliers adhere to fair labor practices and provide safe working conditions is not only a moral obligation but also a competitive advantage. Certifications such as Fair Trade, Global Organic Textile Standard (GOTS), and OEKO-TEX can serve as indicators of a supplier’s commitment to ethical practices.

Investing in sustainability also opens up opportunities for marketing products as environmentally friendly, appealing to a growing segment of consumers who value corporate social responsibility. As a B2B buyer, aligning with suppliers who prioritize sustainability can enhance brand loyalty and differentiate offerings in competitive markets.

Brief Evolution/History

The evolution of backpacks has transitioned from basic utilitarian designs to sophisticated and stylish products catering to diverse consumer needs. Initially designed for hikers and travelers, modern backpacks now incorporate advanced features such as ergonomic designs, smart technology, and sustainable materials. This shift reflects broader consumer trends towards multifunctionality and sustainability.

For B2B buyers, understanding the historical context of backpacks can provide valuable insights into market demands and consumer preferences. The rise of lifestyle brands, particularly among younger demographics, has influenced the design and marketing of backpacks, making it essential for international buyers to stay abreast of these developments to remain competitive in their offerings.

Related Video: What Is International Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of 49ers backpack

-

What should I consider when vetting suppliers for 49ers backpacks?

When vetting suppliers, prioritize their experience in backpack manufacturing and their reputation in the industry. Request references and check online reviews to understand their reliability. Additionally, assess their production capabilities, including quality control processes. It’s also crucial to verify their compliance with international safety and quality standards, such as ISO certifications. Conducting a factory visit, if feasible, can provide further insights into their operations and working conditions, ensuring they align with your business values. -

Can I customize the 49ers backpacks for my brand?

Yes, many manufacturers offer customization options for 49ers backpacks, including logo placement, color choices, and specific features tailored to your target market. Discuss your requirements early in the sourcing process to ensure the supplier can accommodate them. Be clear about your design specifications and any additional functionalities you wish to incorporate, such as extra pockets or specialized materials. Requesting prototypes can help evaluate the final product before placing a larger order. -

What are the typical minimum order quantities (MOQs) and lead times for sourcing?

Minimum order quantities for 49ers backpacks can vary widely depending on the manufacturer and the level of customization required. Generally, MOQs may range from 100 to 500 units. Lead times can also differ, often taking between 4 to 12 weeks for production after design approval. It’s essential to discuss these details upfront and negotiate terms that align with your business needs, especially if you require smaller quantities or have tight timelines. -

How can I ensure quality assurance and certification compliance for my order?

To ensure quality assurance, request documentation of the supplier’s quality control processes, including any certifications they hold, such as ISO 9001. Ask for samples before full production to evaluate material quality and craftsmanship. Additionally, consider implementing third-party inspections at various stages of the production process to catch any defects early. Establishing clear quality standards in your contract can help mitigate risks and ensure compliance with your specifications. -

What payment terms are common in international B2B transactions?

Payment terms can vary by supplier, but common practices include a deposit (typically 30-50%) before production and the balance upon completion or before shipment. Some suppliers may offer more flexible terms based on your relationship and order size. Using secure payment methods, such as letters of credit or escrow services, can provide additional protection against fraud. Always clarify payment terms in your contract to avoid misunderstandings and ensure a smooth transaction. -

What logistics considerations should I keep in mind when importing 49ers backpacks?

Logistics play a crucial role in international sourcing. Consider factors such as shipping methods (air vs. sea), customs duties, and import regulations in your country. Collaborate with a freight forwarder who understands the complexities of international shipping to streamline the process. Be aware of potential delays and ensure your supplier provides accurate shipping timelines. Additionally, factor in costs related to warehousing and distribution to maintain profitability. -

How should I handle disputes with suppliers during the sourcing process?

Disputes can arise in any business relationship, so having a clear contract is essential. Establish terms regarding quality standards, delivery timelines, and payment conditions to minimize potential conflicts. In the event of a dispute, maintain open communication with the supplier to address issues directly. If necessary, consider mediation or arbitration to resolve conflicts amicably. Document all interactions and agreements to provide a clear record of the discussion. -

What are some best practices for maintaining a long-term relationship with suppliers?

Building a strong, long-term relationship with suppliers involves regular communication and transparency. Provide feedback on product quality and delivery timelines, and express appreciation for their efforts. Consider visiting their facilities periodically to foster trust and collaboration. Engage in joint problem-solving when challenges arise, and discuss potential future projects to align business goals. A positive relationship can lead to better pricing, priority service, and improved product offerings in the long run.

Illustrative Image (Source: Google Search)

Strategic Sourcing Conclusion and Outlook for 49ers backpack

In conclusion, strategic sourcing is paramount for B2B buyers seeking to procure high-quality 49ers backpacks that will satisfy customer expectations and enhance brand reputation. By focusing on key quality control measures—such as rigorous material testing, thorough supplier assessments, and proactive quality checks—buyers can mitigate risks associated with defects and ensure product durability.

Key Takeaways:

- Prioritize Quality: Always request samples and testing reports to verify materials and craftsmanship.

- Supplier Relationships: Develop strong partnerships with reputable manufacturers who understand your quality requirements.

- Market Adaptability: Stay informed about regional preferences and trends in Africa, South America, the Middle East, and Europe to tailor your offerings effectively.

As the global market continues to evolve, the demand for reliable, stylish, and durable backpacks remains strong. Now is the time for international B2B buyers to leverage strategic sourcing practices to not only meet this demand but to also position themselves as leaders in their respective markets. Take action today—research potential suppliers, assess quality standards, and align your sourcing strategy with the needs of your target audience for long-term success.