Master Backpack Mickey Sourcing: Key Insights for B2B Buyers

Guide to Backpack Mickey

- Introduction: Navigating the Global Market for backpack mickey

- Understanding backpack mickey Types and Variations

- Key Industrial Applications of backpack mickey

- Strategic Material Selection Guide for backpack mickey

- In-depth Look: Manufacturing Processes and Quality Assurance for backpack mickey

- Comprehensive Cost and Pricing Analysis for backpack mickey Sourcing

- Spotlight on Potential backpack mickey Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for backpack mickey

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the backpack mickey Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of backpack mickey

- Strategic Sourcing Conclusion and Outlook for backpack mickey

Introduction: Navigating the Global Market for backpack mickey

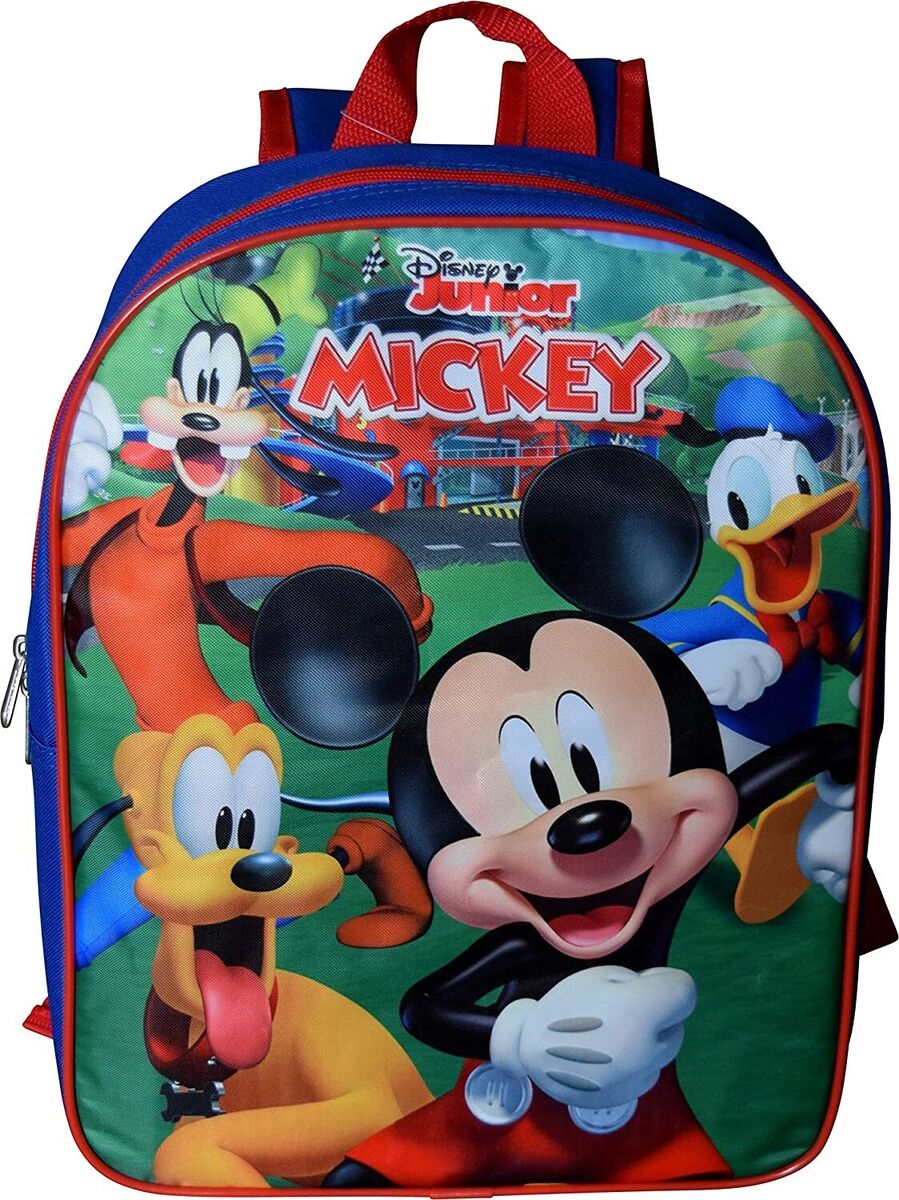

In today’s competitive landscape, the Backpack Mickey serves as a vital product for various markets, catering to diverse consumer needs across continents. As a symbol of functionality and style, this backpack not only appeals to children but also resonates with adults looking for nostalgic designs. For international B2B buyers—particularly those from Africa, South America, the Middle East, and Europe—understanding the intricacies of Backpack Mickey manufacturing is crucial for making informed sourcing decisions.

Illustrative Image (Source: Google Search)

This guide provides a comprehensive overview of the Backpack Mickey market, exploring key aspects such as various types and materials utilized in production, manufacturing processes, quality control measures, and supplier options. Additionally, it addresses cost considerations and market dynamics, empowering buyers to navigate their purchasing journeys effectively.

By delving into frequently asked questions, this resource aims to demystify the sourcing process, helping buyers identify the best practices for successful partnerships with manufacturers. As global demand for unique and sustainable products increases, understanding the nuances of Backpack Mickey can significantly enhance your competitive edge. This guide serves as a roadmap, equipping you with the insights needed to make strategic, cost-effective decisions that align with your business objectives in diverse international markets.

Understanding backpack mickey Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Backpack | Classic design with multiple compartments | Educational institutions, retail | Versatile use but may lack specialized features |

| Tactical Backpack | Rugged construction with MOLLE webbing | Military, outdoor activities, security | Highly durable and functional, but can be bulky |

| Eco-Friendly Backpack | Made from sustainable materials like recycled fabrics | Eco-conscious brands, outdoor retailers | Appeals to green consumers, but may have higher costs |

| Laptop Backpack | Padded compartments for electronics | Corporate, educational, tech companies | Provides protection for devices, but less space for other items |

| Customizable Backpack | Options for branding and specific features | Promotional events, corporate gifts | Unique branding opportunities, but longer lead times |

Standard Backpack

The standard backpack is characterized by its classic design featuring multiple compartments for organization. This type is widely used in educational institutions and retail environments, appealing to a broad audience. B2B buyers should consider the versatility of this backpack, as it meets various needs. However, its general design may lack the specialized features that some niche markets require.

Tactical Backpack

Tactical backpacks are designed for rugged use, often incorporating features like MOLLE (Modular Lightweight Load-carrying Equipment) webbing for attachment of additional gear. They are primarily utilized in military applications, outdoor activities, and security sectors. Buyers in these fields should appreciate the durability and functionality of tactical backpacks, although they can be bulkier than other options, which might be a consideration for storage and transport.

Eco-Friendly Backpack

With increasing consumer awareness about sustainability, eco-friendly backpacks made from recycled materials are gaining traction. These backpacks are ideal for brands targeting eco-conscious consumers, particularly in the outdoor retail space. While their appeal lies in sustainability, B2B buyers should factor in the potentially higher costs associated with sourcing eco-friendly materials, which can impact pricing strategies.

Laptop Backpack

Laptop backpacks feature padded compartments specifically designed to protect electronic devices. They are commonly used in corporate environments, educational settings, and by tech companies. B2B buyers should prioritize the protective features these backpacks offer, especially when transporting valuable equipment. However, the design may limit space for additional items, which could be a drawback for users needing more storage.

Customizable Backpack

Customizable backpacks allow brands to add unique features and branding elements, making them ideal for promotional events and corporate gifts. This type of backpack provides significant opportunities for differentiation in a competitive market. Buyers should be aware that while customization enhances brand visibility, it may also lead to longer lead times and increased production costs.

Related Video: All Machine Learning Models Explained in 5 Minutes | Types of ML Models Basics

Key Industrial Applications of backpack mickey

| Industry/Sector | Specific Application of Backpack Mickey | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Education | School backpacks | Durable, ergonomic design for daily student use | Material quality, customization options, safety standards |

| Outdoor Recreation | Hiking and camping gear | Lightweight and weather-resistant for outdoor activities | Sourcing sustainable materials, bulk order pricing |

| Logistics & Transport | Delivery and transport backpacks | Enhanced organization for efficient deliveries | Load capacity, ergonomic design, durability under stress |

| Retail | Branded promotional backpacks | Increased brand visibility and customer engagement | Customization capabilities, minimum order quantities |

| Corporate Gifting | Employee backpacks | Practical gifts that enhance employee satisfaction | Quality assurance, branding options, lead times |

Education

In the education sector, Backpack Mickey is widely utilized as a school backpack, providing students with a reliable and ergonomic solution for carrying their books and supplies. These backpacks are designed to endure daily wear and tear, ensuring longevity and comfort for students of all ages. For international buyers, especially in regions like Africa and South America, sourcing backpacks that meet local safety and quality standards is crucial. Additionally, customization options can cater to specific school branding needs, enhancing the appeal and identity of educational institutions.

Outdoor Recreation

For the outdoor recreation industry, Backpack Mickey serves as an essential component of hiking and camping gear. Its lightweight yet durable design allows outdoor enthusiasts to carry essential items while maintaining comfort during long treks. Buyers from Europe and the Middle East should prioritize sourcing backpacks made from weather-resistant materials to ensure performance in various climates. Sustainability is also a growing concern, making eco-friendly materials a significant consideration for brands aiming to attract environmentally conscious consumers.

Logistics & Transport

In logistics and transport, Backpack Mickey is used for delivery and transport backpacks, which facilitate the organization and efficient handling of packages. These backpacks are designed to accommodate various load capacities, ensuring that couriers can manage their deliveries effectively. For B2B buyers, especially in the logistics sector, key sourcing considerations include the ergonomic design for prolonged use, durability under heavy loads, and the ability to customize for branding purposes. Ensuring that backpacks meet industry standards for durability is essential for maintaining operational efficiency.

Retail

The retail industry leverages Backpack Mickey as a promotional tool, using branded backpacks to enhance customer engagement and visibility. These backpacks can be offered as giveaways or sold as part of a promotional campaign, creating an opportunity for increased brand recognition. International buyers should consider the customization capabilities of manufacturers, ensuring that backpacks can be tailored to fit specific branding needs. Additionally, understanding minimum order quantities and pricing structures is vital for effective inventory management.

Corporate Gifting

In the realm of corporate gifting, Backpack Mickey offers practical and stylish options for employee gifts. These backpacks not only serve a functional purpose but also enhance employee satisfaction and loyalty. Businesses looking to source these backpacks must focus on quality assurance and branding options, ensuring that the final product aligns with the company’s image. Lead times are also a crucial consideration, particularly for companies in fast-paced markets like Europe, where timely delivery is essential to maintain competitive advantage.

Related Video: LABORATORY APPARATUS AND THEIR USES

Strategic Material Selection Guide for backpack mickey

When selecting materials for manufacturing “backpack mickey,” it is essential to consider various factors that impact performance, durability, and cost. Below is an analysis of four common materials used in backpack manufacturing, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Nylon

Key Properties:

Nylon is a synthetic polymer known for its strength and elasticity. It exhibits excellent abrasion resistance and can withstand temperatures up to 120°C. Additionally, nylon is resistant to mildew and rot, making it suitable for outdoor applications.

Pros & Cons:

Nylon is highly durable, lightweight, and water-resistant, which makes it ideal for backpacks designed for hiking or travel. However, its production can be more complex due to the need for specialized weaving techniques, and it can be relatively expensive compared to other materials like polyester.

Impact on Application:

Nylon is compatible with various coatings, such as polyurethane (PU), enhancing its water resistance. This makes it suitable for outdoor backpacks that may encounter harsh weather conditions.

Considerations for International Buyers:

Buyers from regions like Africa and South America should ensure compliance with environmental regulations regarding synthetic materials. In Europe, adherence to standards such as REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) is crucial.

2. Polyester

Key Properties:

Polyester is another synthetic fabric known for its durability and resistance to shrinking and stretching. It can handle temperatures up to 100°C and is generally resistant to UV light.

Pros & Cons:

Polyester is less expensive than nylon and easier to manufacture, making it a popular choice for budget-friendly backpacks. However, it is less durable than nylon and can be prone to fading over time, especially when exposed to sunlight.

Impact on Application:

Polyester is often treated with water-repellent coatings, making it suitable for everyday backpacks. However, it may not perform as well in extreme weather conditions compared to nylon.

Considerations for International Buyers:

Buyers should consider the environmental impact of polyester production, particularly in regions with strict sustainability regulations. Compliance with ASTM standards for textile performance may also be necessary.

3. Canvas

Key Properties:

Canvas is a heavy-duty fabric made from cotton or a blend of cotton and synthetic fibers. It offers good tensile strength and can withstand considerable wear and tear.

Pros & Cons:

Canvas is highly durable and provides a classic aesthetic, making it popular for casual backpacks. However, it is heavier than nylon and polyester and may require more maintenance to keep it clean and free from mildew.

Impact on Application:

Canvas is suitable for urban and casual backpacks but may not be ideal for outdoor or extreme conditions unless treated for water resistance.

Considerations for International Buyers:

Buyers in Europe and the Middle East should ensure that the cotton used in canvas production meets organic standards if targeting eco-conscious consumers. Additionally, compliance with local textile regulations is essential.

4. Leather

Key Properties:

Leather is a natural material known for its durability and aesthetic appeal. It can withstand high temperatures and is resistant to wear and tear.

Pros & Cons:

Leather offers a premium look and feel, making it suitable for luxury backpacks. However, it is more expensive and requires careful maintenance to prevent damage from moisture and dirt.

Impact on Application:

Leather is often used in high-end fashion backpacks, appealing to consumers looking for style and longevity. However, it may not be suitable for outdoor use unless treated for water resistance.

Considerations for International Buyers:

B2B buyers should consider sourcing leather from suppliers that adhere to ethical practices, particularly in regions like Europe, where consumer awareness regarding animal welfare is high. Compliance with environmental regulations regarding tanning processes is also crucial.

Summary Table

| Material | Typical Use Case for backpack mickey | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | Outdoor and travel backpacks | Excellent durability and water resistance | Higher production complexity and cost | High |

| Polyester | Everyday and casual backpacks | Cost-effective and easy to manufacture | Less durable and prone to fading | Medium |

| Canvas | Urban and casual backpacks | Classic aesthetic and durability | Heavier and requires maintenance | Medium |

| Leather | Luxury and fashion backpacks | Premium look and longevity | High cost and maintenance requirements | High |

This material selection guide provides international B2B buyers with a comprehensive understanding of the key materials used in backpack manufacturing, aiding them in making informed decisions that align with their market needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for backpack mickey

The manufacturing process for ‘Backpack Mickey’ involves several critical stages, each designed to ensure that the final product meets quality standards while being efficient and cost-effective. For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding these processes can significantly influence procurement decisions.

Manufacturing Process

1. Material Preparation

The foundation of any backpack lies in its materials. For ‘Backpack Mickey’, manufacturers typically start by sourcing high-quality textiles, such as durable nylon or eco-friendly fabrics.

- Sourcing Locations: Buyers should consider reputable fabric markets, such as Guangzhou International Textile City, which offers a variety of textiles suitable for different backpack designs.

- Material Selection: The choice of materials impacts the backpack’s durability, weight, and appeal. Eco-friendly materials are increasingly popular due to growing consumer demand for sustainable products.

2. Forming

Once materials are selected, the next step involves creating patterns and templates.

- Pattern Creation: Designers utilize CAD software to develop precise templates that dictate the shapes and sizes of various components. This stage is crucial to ensure accuracy during cutting and assembly.

- Cutting Techniques: The cutting of fabric can be done manually or through automated machines. Automated cutting enhances precision and minimizes waste, which is particularly important in large-scale production.

3. Assembly

With the materials cut to size, the assembly process begins.

- Organizing Accessories: Before sewing, manufacturers gather all necessary hardware, such as zippers, buckles, and straps. This preparation helps streamline the assembly process.

- Sewing: Skilled workers or automated machines stitch the components together. Industrial sewing machines are commonly used, and the process typically involves sewing the bag inside out to hide seams, enhancing durability and aesthetics.

4. Finishing

The finishing stage focuses on refining the final product.

- Inversion and Detailing: After assembly, the backpack is inverted to reveal its final form. This is followed by adding any finishing touches, such as brand tags and final stitching.

- Quality Checks: A thorough inspection is conducted to ensure all components are correctly assembled and that the backpack meets specified quality standards.

Quality Assurance

Quality assurance (QA) is an essential part of the manufacturing process, ensuring that each ‘Backpack Mickey’ meets international standards and customer expectations.

Relevant International Standards

B2B buyers should look for compliance with various quality standards that ensure product safety and reliability:

- ISO 9001: This standard focuses on quality management systems and is crucial for manufacturers aiming to deliver consistent quality.

- CE Marking: Particularly relevant in Europe, CE marking indicates that products meet EU safety, health, and environmental requirements.

- API Standards: These may apply depending on the specific use of the backpack, especially in industries requiring high durability and performance.

QC Checkpoints

Quality control is typically divided into several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): At this stage, raw materials and components are inspected for quality before production begins. This step is critical to prevent defects from the outset.

- In-Process Quality Control (IPQC): Ongoing checks during the assembly process help identify and rectify issues in real time, maintaining production efficiency and quality.

- Final Quality Control (FQC): Once production is complete, the final product undergoes a comprehensive inspection to ensure it meets all specifications and quality standards.

Common Testing Methods

Manufacturers often employ various testing methods to evaluate the quality of backpacks, including:

- Durability Testing: Assessing the strength of seams, zippers, and overall wear resistance.

- Water Resistance Testing: Particularly important for outdoor backpacks, this test ensures that materials can withstand moisture.

- Safety Testing: Ensuring that all components are safe and free from harmful substances.

Verifying Supplier Quality Control

For international B2B buyers, particularly those from diverse regions, verifying a supplier’s quality control processes is essential:

- Supplier Audits: Conducting regular audits of potential suppliers can help assess their quality management systems and compliance with international standards.

- Quality Reports: Requesting detailed quality control reports can provide insights into a manufacturer’s QC processes and history.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of product quality before shipment.

QC and Certification Nuances for International Buyers

B2B buyers from different regions must navigate various certification and quality nuances:

- Regional Standards: Buyers in Europe may prioritize CE certification, while those in the Middle East might look for compliance with local standards.

- Cultural Considerations: Understanding cultural expectations regarding product quality can influence buyer-supplier relationships. For instance, buyers from Germany may have higher expectations for precision and durability compared to other regions.

- Sustainability Certifications: As eco-consciousness rises globally, certifications for sustainable materials can play a significant role in purchasing decisions, particularly in Europe and North America.

In conclusion, understanding the manufacturing processes and quality assurance practices for ‘Backpack Mickey’ is crucial for B2B buyers looking to make informed purchasing decisions. By focusing on material preparation, assembly techniques, and robust quality control measures, buyers can ensure they partner with manufacturers who deliver high-quality, reliable products that meet international standards.

Related Video: How a Backpack is Made : Every Step on the Production Line

Comprehensive Cost and Pricing Analysis for backpack mickey Sourcing

When sourcing “Backpack Mickey,” understanding the comprehensive cost structure and pricing dynamics is critical for international B2B buyers. This analysis will delve into the cost components involved in manufacturing, the factors influencing pricing, and essential tips for effective negotiations.

Cost Components

-

Materials

– The choice of materials significantly impacts the overall cost. High-quality fabrics such as nylon or eco-friendly options like recycled polyester can vary widely in price. Expect to spend between $5 to $20 per unit depending on the material specifications. -

Labor

– Labor costs are influenced by the manufacturing location. Countries in Southeast Asia, like Vietnam and Indonesia, may offer lower labor costs compared to China or Europe. Labor costs can range from $1 to $5 per unit, depending on skill level and local wage standards. -

Manufacturing Overhead

– This includes costs related to facility maintenance, utilities, and administrative expenses. A reasonable estimate for manufacturing overhead can be around 10-15% of the total production cost. -

Tooling

– Initial costs for tooling can be significant, especially for custom designs. Tooling costs may range from $500 to $5,000 depending on the complexity of the design and the number of molds required. -

Quality Control (QC)

– Implementing a thorough QC process ensures that the products meet quality standards, which can add approximately 5-10% to the manufacturing cost. This includes testing for durability, safety, and compliance with international standards. -

Logistics

– Shipping and handling costs vary based on the destination and chosen shipping method. For air freight, costs can be higher, ranging from $1 to $5 per unit, while sea freight is generally more economical but takes longer. -

Margin

– Manufacturers typically mark up their production costs by 20-50% to establish a profit margin, which can influence the final price offered to buyers.

Price Influencers

- Volume and Minimum Order Quantity (MOQ)

-

Larger orders usually attract better pricing, as manufacturers can spread fixed costs over more units. MOQs can range from 100 to 1,000 units depending on the supplier.

-

Specifications and Customization

-

Custom designs or specific features (like waterproofing or specialized pockets) can significantly increase costs. Customization may add 15-30% to the base price.

-

Materials Quality and Certifications

-

Higher quality materials and certifications (like OEKO-TEX or GRS for recycled materials) can raise production costs but may also justify higher retail prices.

-

Supplier Factors

-

Supplier reputation, reliability, and experience can influence pricing. Established manufacturers may charge a premium for their services.

-

Incoterms

- Understanding Incoterms is essential for determining who bears the cost of shipping, insurance, and tariffs, which can significantly affect the total landed cost.

Buyer Tips

- Negotiation

-

Always negotiate pricing and payment terms. Establishing a good relationship with suppliers can lead to better pricing and terms over time.

-

Cost Efficiency

-

Consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also shipping, handling, and potential import duties. This holistic view helps identify the most cost-effective suppliers.

-

Pricing Nuances for International Buyers

- Be aware of currency fluctuations and their impact on pricing. Local regulations, tariffs, and import duties can also affect the total costs, especially for buyers from Africa and South America.

Disclaimer

The prices mentioned are indicative and can vary significantly based on supplier negotiations, market conditions, and specific order requirements. It is advisable to conduct thorough research and obtain multiple quotes to ensure competitive pricing and quality standards.

Illustrative Image (Source: Google Search)

Spotlight on Potential backpack mickey Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘backpack mickey’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for backpack mickey

Key Technical Properties of Backpack Manufacturing

Understanding the essential technical properties of backpack manufacturing is crucial for B2B buyers to ensure product quality, durability, and market competitiveness. Here are some critical specifications that should be considered:

-

Material Grade

The material grade refers to the quality of the fabric used in manufacturing backpacks. Common materials include nylon, polyester, and canvas, each with varying degrees of durability, weight, and water resistance. Selecting high-grade materials is vital as it affects the longevity and functionality of the backpack, which can influence customer satisfaction and brand reputation. -

Tolerance

Tolerance in manufacturing defines the allowable deviation from a specified dimension. It is crucial in ensuring that components fit together correctly during assembly. For backpacks, maintaining tight tolerances in strap lengths, pocket sizes, and zipper placements can significantly enhance the product’s usability and aesthetic appeal. Poor tolerances can lead to operational failures and increased returns, impacting profitability. -

Load Capacity

Load capacity indicates the maximum weight a backpack can safely carry without compromising its structure. This specification is essential for positioning the product in the market, especially for outdoor or travel backpacks. Understanding load capacity helps buyers to target specific consumer needs, such as hiking or commuting, ensuring the product aligns with user expectations. -

Water Resistance Rating (WRR)

The Water Resistance Rating measures how well the backpack can repel water. This is particularly important for outdoor backpacks, where exposure to rain is common. A higher WRR signifies better protection against moisture, appealing to consumers who require durability in various weather conditions. Buyers should seek products with a clear WRR specification to meet customer demands effectively.

Illustrative Image (Source: Google Search)

- Sustainability Index

The Sustainability Index evaluates the environmental impact of the materials and manufacturing processes used. With a growing trend toward eco-friendly products, understanding this index allows buyers to align with consumer values and regulatory requirements. Brands that emphasize sustainability can differentiate themselves in a competitive market, attracting environmentally conscious customers.

Common Trade Terminology in Backpack Manufacturing

Familiarity with industry jargon is essential for effective communication and negotiation. Here are some key terms relevant to backpack manufacturing:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products based on the designs and specifications provided by another company. In backpack manufacturing, partnering with an OEM can allow brands to leverage specialized expertise and resources without investing heavily in production capabilities. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to produce. This is a critical factor for B2B buyers, especially startups, as it affects inventory management and cash flow. Understanding MOQs helps buyers negotiate better terms and assess the feasibility of product launches. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific quantities of products. It is an essential tool for obtaining competitive quotes and comparing potential suppliers. Crafting a detailed RFQ can lead to better pricing and service terms. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers to navigate shipping logistics, costs, and risks effectively, ensuring smooth importation of backpacks. -

Lead Time

Lead time refers to the total time it takes from placing an order to receiving the final product. It includes production time, shipping, and any additional processing. For B2B buyers, managing lead time is essential for planning inventory and meeting market demands, particularly during peak seasons.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions, enhance their negotiation strategies, and ultimately improve their product offerings in the competitive backpack market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the backpack mickey Sector

Market Overview & Key Trends

The backpack mickey sector is witnessing dynamic shifts, driven by global consumer preferences and technological advancements. International B2B buyers from regions like Africa, South America, the Middle East, and Europe are increasingly focusing on customized products that cater to local tastes and functional needs. The rise of e-commerce has facilitated direct sourcing from manufacturers, allowing buyers to bypass traditional distribution channels and negotiate better pricing and terms.

Key trends include the demand for customization and private label options, enabling brands to differentiate themselves in a crowded marketplace. Buyers are now looking for manufacturers that can provide unique designs tailored to specific demographics, enhancing brand loyalty. Additionally, the integration of technology in manufacturing processes, such as automated cutting and high-precision sewing, is elevating product quality while reducing lead times.

Sourcing trends are also shifting towards sustainable materials and eco-friendly production practices. Buyers are increasingly aware of the environmental impact of their purchases, leading them to prioritize suppliers who demonstrate a commitment to sustainability. Moreover, the geopolitical landscape is influencing sourcing decisions, with manufacturers in Vietnam gaining traction due to lower labor costs and fewer trade restrictions compared to traditional powerhouses like China. This geographical diversification allows buyers to mitigate risks and ensure consistent supply chains.

Sustainability & Ethical Sourcing in B2B

The environmental impact of backpack manufacturing is significant, necessitating a shift towards sustainable practices. For international B2B buyers, ethical sourcing is not just a trend but a crucial component of brand reputation and consumer trust. The use of recycled materials, such as PET from plastic bottles, and organic cotton is becoming increasingly prevalent in the production of backpack mickey products. These materials not only reduce waste but also appeal to environmentally conscious consumers.

Furthermore, buyers should consider suppliers that hold green certifications, such as GOTS (Global Organic Textile Standard) or OEKO-TEX, which ensure that products meet strict environmental and social standards. Ethical supply chains that prioritize fair labor practices are essential for maintaining brand integrity and consumer confidence. By partnering with manufacturers committed to sustainability, businesses can enhance their market positioning and attract a growing segment of eco-aware consumers.

Investing in sustainable practices can also lead to cost savings in the long run, as manufacturers increasingly optimize their processes to minimize waste and energy consumption. Buyers are encouraged to ask potential suppliers about their sustainability initiatives and verify their claims through third-party certifications.

Brief Evolution/History

The evolution of the backpack manufacturing industry has been marked by innovation and adaptability. Originally focused on utility, modern backpacks have transformed into fashion statements and lifestyle products. The introduction of advanced materials and production techniques has allowed manufacturers to enhance durability and functionality while responding to changing consumer preferences.

The rise of globalization has also played a crucial role, enabling brands to access a wider range of materials and manufacturing capabilities across different regions. Today, B2B buyers benefit from a competitive landscape where they can leverage technology, sustainability, and customization to meet the demands of a diverse market. Understanding this evolution is essential for making informed sourcing decisions that align with current trends and consumer expectations.

Related Video: Chapter 9: International Trade

Frequently Asked Questions (FAQs) for B2B Buyers of backpack mickey

-

What factors should I consider when vetting suppliers for ‘backpack mickey’?

When vetting suppliers, prioritize their experience in backpack manufacturing, particularly in your target market. Request references and check their track record for quality and delivery. Evaluate their production capabilities, certifications (like ISO or SGS), and compliance with international standards. Additionally, consider their responsiveness and communication style; a supplier that is easy to reach can significantly streamline your sourcing process. -

Can I customize ‘backpack mickey’ designs?

Yes, many manufacturers offer customization options for ‘backpack mickey’ designs. This can include alterations to size, color, material, and branding elements like logos or patterns. Before placing an order, discuss your specific requirements with potential suppliers to ensure they can accommodate your customization requests. Providing detailed sketches or prototypes can help clarify your vision and facilitate the design process. -

What are the typical minimum order quantities (MOQs) and lead times for ‘backpack mickey’?

MOQs for ‘backpack mickey’ can vary widely depending on the supplier and the complexity of the design. Generally, expect MOQs to range from 100 to 1,000 units for custom designs. Lead times can also differ; standard production may take 4-12 weeks, while custom designs might require additional time for prototyping. Always confirm these details upfront to ensure they align with your business timeline and budget. -

What payment terms are commonly used in international B2B transactions?

Payment terms in international B2B transactions often include options like a 30% deposit upfront and the remaining balance before shipment. Some suppliers may accept letters of credit or escrow services to secure transactions. It’s essential to negotiate terms that protect both parties, ensuring that you have recourse in case of disputes. Always document agreed-upon terms in a formal contract to avoid misunderstandings. -

How can I ensure quality assurance for ‘backpack mickey’?

To ensure quality, request samples before placing a bulk order. Establish clear quality control standards with your supplier, specifying acceptable tolerances and testing protocols. Consider conducting factory audits or hiring third-party inspection services to verify manufacturing practices. Additionally, ask for certifications related to materials (e.g., REACH compliance) to ensure they meet safety and environmental standards. -

What logistics considerations should I keep in mind when importing ‘backpack mickey’?

When importing ‘backpack mickey’, consider shipping methods (air vs. sea) based on your budget and urgency. Factor in customs clearance processes, tariffs, and potential delays due to paperwork or inspections. Working with a reliable freight forwarder can streamline logistics and provide guidance on compliance with import regulations in your country. Ensure all documentation, such as invoices and packing lists, is accurate to avoid complications. -

What steps should I take if I encounter a dispute with my supplier?

If a dispute arises, start by addressing the issue directly with your supplier through clear and constructive communication. Document all interactions and agreements to provide a record of the situation. If resolution is not achieved, consider mediation or arbitration as alternatives to legal action. Including dispute resolution clauses in your contracts can help outline the steps to take in case of conflicts, promoting a more amicable resolution process. -

What certifications should I look for in suppliers of ‘backpack mickey’?

Look for certifications that demonstrate compliance with international quality and safety standards. Key certifications include ISO 9001 (Quality Management), Oeko-Tex Standard 100 (Textile Safety), and WRAP (Worldwide Responsible Accredited Production). These certifications indicate that the manufacturer adheres to best practices in production and environmental responsibility. Ensure your supplier can provide documentation for these certifications to verify their claims.

Strategic Sourcing Conclusion and Outlook for backpack mickey

In conclusion, the strategic sourcing of Backpack Mickey offers a wealth of opportunities for international B2B buyers, especially those from Africa, South America, the Middle East, and Europe. By understanding the intricacies of the backpack manufacturing process—from material selection to quality control—buyers can make informed decisions that enhance their product offerings.

Key takeaways include:

- Thorough Research: Invest time in researching potential manufacturers to avoid unpredictable pricing and ensure quality.

- Sustainability Trends: Aligning with eco-friendly practices can resonate with a growing consumer base, especially in regions increasingly focused on sustainability.

- Custom Solutions: Consider partnering with manufacturers that offer bespoke services to differentiate your products in a competitive market.

The value of strategic sourcing cannot be overstated. It equips businesses with the knowledge and resources to navigate the complexities of production effectively. As we look ahead, it is essential for B2B buyers to embrace innovation and sustainability in their sourcing strategies. Take action now—connect with reliable manufacturers, explore new materials, and position your brand to thrive in the evolving marketplace. Your journey to creating exceptional backpacks starts today!