Master Sourcing High-Quality EMS Backpacks: A Complete B2B

Guide to Ems Backpack

- Introduction: Navigating the Global Market for ems backpack

- Understanding ems backpack Types and Variations

- Key Industrial Applications of ems backpack

- Strategic Material Selection Guide for ems backpack

- In-depth Look: Manufacturing Processes and Quality Assurance for ems backpack

- Comprehensive Cost and Pricing Analysis for ems backpack Sourcing

- Spotlight on Potential ems backpack Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for ems backpack

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ems backpack Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of ems backpack

- Strategic Sourcing Conclusion and Outlook for ems backpack

Introduction: Navigating the Global Market for ems backpack

In the ever-evolving landscape of global commerce, the demand for specialized equipment like EMS backpacks has surged, particularly in sectors such as emergency services, outdoor recreation, and travel. These backpacks are not just carriers; they are vital tools designed to meet the rigorous demands of first responders and adventurers alike. Understanding the nuances of EMS backpacks—including their types, materials, and manufacturing processes—is crucial for international B2B buyers aiming to make informed sourcing decisions.

This guide offers a comprehensive exploration of the EMS backpack market, covering essential aspects such as material selection, manufacturing and quality control processes, and supplier options. We will delve into the various types of EMS backpacks available, highlighting features that cater to specific needs, from lightweight designs to durable, heavy-duty options. Additionally, we will provide insights into cost considerations and market trends, empowering buyers from regions such as Africa, South America, the Middle East, and Europe to navigate the complexities of procurement effectively.

By leveraging the insights presented in this guide, B2B buyers can enhance their sourcing strategies, ensuring they select products that not only meet quality standards but also resonate with the growing demand for functionality and sustainability in today’s marketplace. Whether you are a startup looking to establish a foothold or an established brand seeking innovative solutions, this guide will equip you with the knowledge needed to thrive in the competitive EMS backpack sector.

Understanding ems backpack Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard EMS Backpack | Basic design with essential compartments | General emergency services, first responders | Affordable and versatile but may lack specialized features. |

| Tactical EMS Backpack | Heavy-duty materials, modular design, MOLLE system | Military, tactical units, outdoor rescue | High durability and customization options but heavier weight. |

| Hydration Pack EMS Backpack | Integrated water reservoir, lightweight construction | Wilderness rescue, outdoor events | Excellent for hydration on the go, limited storage space. |

| Pediatric EMS Backpack | Smaller size, bright colors, child-friendly design | Pediatric emergency services, schools | Engaging for children but may lack adult-focused features. |

| Eco-Friendly EMS Backpack | Made from sustainable materials, recyclable options | Green organizations, eco-conscious services | Environmentally friendly but potentially higher cost. |

Standard EMS Backpack

The Standard EMS Backpack is designed for basic emergency medical services, featuring essential compartments for medical supplies, tools, and equipment. Its straightforward design makes it versatile for various emergency situations. B2B buyers should consider this type for general use in emergency services, as it offers a cost-effective solution. However, while it serves basic needs well, it may not have specialized compartments for advanced equipment.

Tactical EMS Backpack

The Tactical EMS Backpack is built for durability and functionality, often constructed from heavy-duty materials and featuring a modular design with a MOLLE (Modular Lightweight Load-carrying Equipment) system. This type is ideal for military and tactical units, as it allows for customization based on mission requirements. Buyers should weigh the benefits of its robust construction against its heavier weight, which may impact mobility during operations.

Hydration Pack EMS Backpack

Designed for outdoor and wilderness rescue operations, the Hydration Pack EMS Backpack includes an integrated water reservoir, allowing first responders to stay hydrated without needing to stop. This lightweight option is perfect for events where mobility is crucial. However, its primary focus on hydration means it has limited storage space for other medical supplies, which buyers should consider when evaluating their needs.

Pediatric EMS Backpack

The Pediatric EMS Backpack is specifically designed for emergencies involving children, featuring a smaller size and bright, engaging colors. This design helps to ease the anxiety of young patients during medical emergencies. Ideal for pediatric emergency services and schools, this backpack is a great choice for organizations focused on child care. However, its specialized design may not accommodate adult-sized medical equipment, which buyers should keep in mind.

Eco-Friendly EMS Backpack

The Eco-Friendly EMS Backpack is constructed from sustainable materials and often includes recyclable options, catering to organizations focused on environmental responsibility. This type appeals to green organizations and eco-conscious services aiming to reduce their carbon footprint. While it offers an environmentally friendly choice, buyers should be prepared for potentially higher costs compared to traditional materials, which can affect budget considerations.

Related Video: Medical Backpack (TSSI M9) | Overview & Contents

Key Industrial Applications of ems backpack

| Industry/Sector | Specific Application of ems backpack | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Emergency Services | Medical emergency response | Quick access to medical supplies and tools | Durability, water-resistance, and weight specifications |

| Outdoor Recreation | Adventure and survival gear | Enhanced portability and organization of gear | Material strength, weather resistance, and comfort |

| Education | Student and educational programs | Facilitates easy transport of learning materials | Custom branding, ergonomic design, and storage capacity |

| Logistics & Transport | Cargo and delivery systems | Efficient handling and transport of goods | Load capacity, material durability, and closure systems |

| Military & Defense | Tactical operations | Reliable storage for essential gear and equipment | Military-grade materials, camouflage options, and modularity |

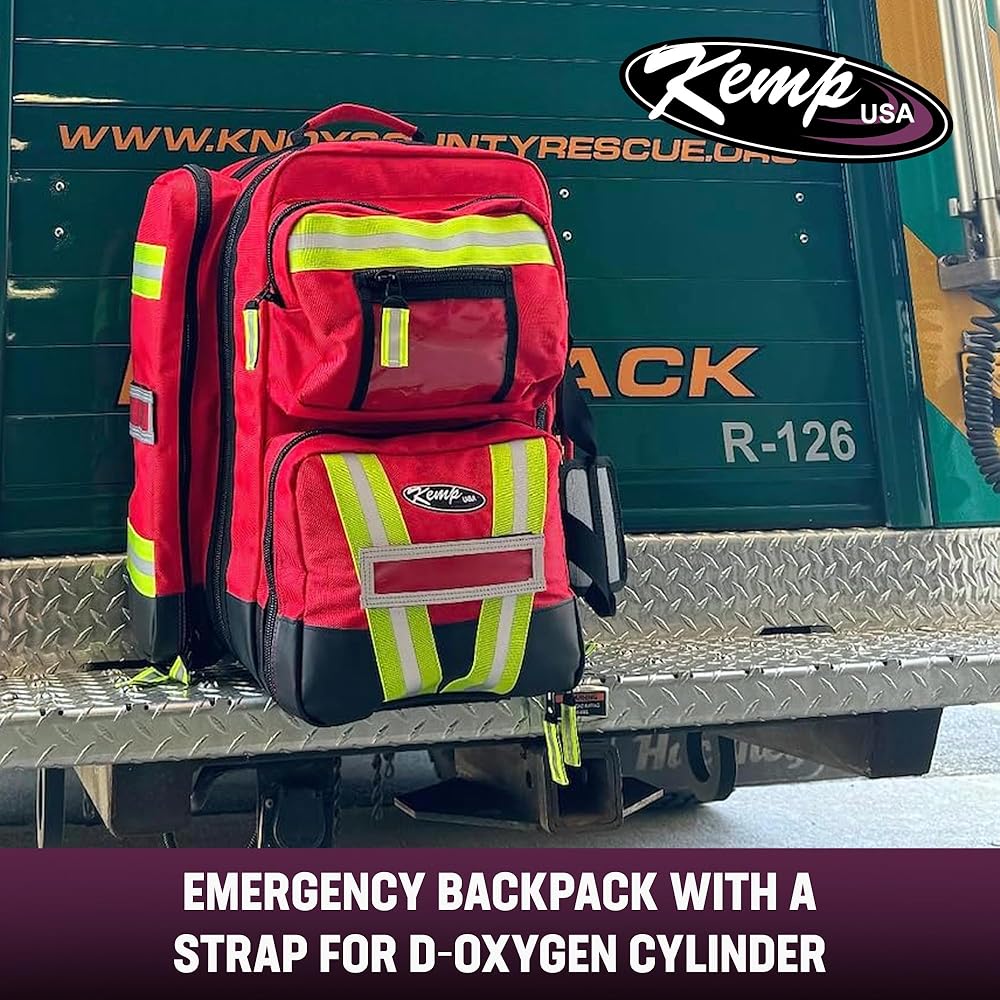

Emergency Services

In emergency response scenarios, the ems backpack is critical for providing immediate access to medical supplies and equipment. These backpacks are designed to be lightweight yet durable, allowing first responders to carry essential tools like first aid kits, oxygen tanks, and trauma supplies. For international buyers, particularly in regions like Africa and the Middle East, sourcing backpacks that meet stringent quality standards and are resistant to harsh environmental conditions is essential.

Outdoor Recreation

The ems backpack is widely used in outdoor recreation, serving as an essential gear-carrying solution for hikers, campers, and adventurers. These backpacks are designed to offer maximum comfort while distributing weight evenly, which is crucial for long treks. Buyers from South America and Europe should consider sourcing backpacks with specialized features like hydration reservoirs and weatherproof materials to meet the demands of diverse terrains and climates.

Education

In educational settings, ems backpacks are utilized by students to transport books, laptops, and other learning materials. The design often includes multiple compartments for organization, which enhances usability. For B2B buyers in Europe or Africa, focusing on custom branding options and ergonomic designs can create a unique selling proposition while ensuring comfort and functionality for students.

Logistics & Transport

Within logistics and transport sectors, ems backpacks are employed for the efficient handling and delivery of goods. Their design allows for easy access and organization of items, which is vital in fast-paced environments. Buyers in South America and the Middle East should prioritize sourcing backpacks that can withstand heavy loads and offer robust closure systems to secure items during transit.

Military & Defense

In military and defense applications, ems backpacks are integral for tactical operations, providing soldiers with reliable storage for essential gear. These backpacks are often made from military-grade materials that ensure durability and functionality in challenging conditions. International B2B buyers, particularly from regions with active military engagements, should focus on sourcing backpacks that offer modularity and camouflage options to meet operational needs.

Related Video: European Style Medical Bag ⎮PAX Emergency Backpack Review⎮

Strategic Material Selection Guide for ems backpack

Material Analysis for EMS Backpacks

When selecting materials for EMS backpacks, it is crucial to consider factors such as durability, weight, water resistance, and overall functionality. Below, we analyze four common materials used in the manufacturing of EMS backpacks, focusing on their properties, advantages and disadvantages, and implications for international buyers.

1. Nylon

Key Properties:

Nylon is known for its high tensile strength, flexibility, and resistance to abrasion. It typically has a temperature rating of up to 120°C and is resistant to most chemicals, making it suitable for various environments.

Pros & Cons:

Nylon is lightweight and durable, which makes it ideal for backpacks that need to withstand heavy use. However, it can be more expensive than other materials like polyester and may not be as environmentally friendly unless sourced from recycled options.

Impact on Application:

Nylon’s durability and resistance to wear make it suitable for EMS backpacks that may encounter rough handling and exposure to harsh conditions. It is compatible with a variety of media, including medical equipment and supplies.

Considerations for International Buyers:

Buyers from regions like Africa and the Middle East should consider sourcing nylon that complies with ASTM standards for textiles. Additionally, awareness of the environmental impact of nylon production is increasing, prompting a preference for recycled options.

2. Polyester

Key Properties:

Polyester is known for its excellent resistance to UV rays and moisture. It can withstand temperatures up to 130°C and is generally resistant to stretching and shrinking.

Pros & Cons:

Polyester is often more affordable than nylon and is easier to clean, making it a practical choice for EMS backpacks. However, it may not be as durable as nylon, particularly under extreme conditions.

Impact on Application:

Polyester’s moisture-wicking properties make it suitable for medical supplies that need to be kept dry. Its lightweight nature contributes to the overall portability of the backpack.

Considerations for International Buyers:

Buyers in Europe and South America should ensure that the polyester used meets relevant safety and environmental standards, such as those set by the European Union. Additionally, sourcing from manufacturers that utilize recycled polyester can align with sustainability goals.

3. Ripstop Fabric

Key Properties:

Ripstop fabric is made from nylon or polyester and features a crosshatch pattern that enhances its tear resistance. It typically has a temperature tolerance of around 100°C and is water-resistant.

Pros & Cons:

The key advantage of ripstop fabric is its durability, which makes it ideal for heavy-duty applications. However, it can be more expensive due to the specialized weaving process required for its production.

Impact on Application:

Ripstop fabric is particularly beneficial for EMS backpacks that are expected to endure rough conditions and heavy loads. Its tear-resistant properties ensure that the backpack maintains its integrity even under stress.

Considerations for International Buyers:

For buyers in regions like the UAE, it is essential to ensure that ripstop fabric complies with local regulations regarding textile safety and performance. Understanding the material’s sourcing and production processes can also be critical for compliance with sustainability initiatives.

4. Ballistic Nylon

Key Properties:

Ballistic nylon is a heavy-duty fabric designed to resist abrasions, tears, and impacts. It has a high temperature tolerance and is often used in military applications due to its strength.

Pros & Cons:

Ballistic nylon offers exceptional durability and is highly resistant to wear and tear. However, it is heavier and more expensive than other materials, which may affect the overall weight of the EMS backpack.

Impact on Application:

This material is ideal for EMS backpacks that require maximum protection for sensitive equipment and supplies. Its robust nature ensures that the backpack can handle challenging environments.

Considerations for International Buyers:

Buyers should verify that ballistic nylon meets international standards for safety and performance, such as those outlined by ISO. Additionally, understanding the supply chain and sourcing practices can help align with ethical procurement policies.

Summary Table

| Material | Typical Use Case for EMS Backpack | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | General EMS use, durable applications | Lightweight, high durability | Higher cost, environmental concerns | High |

| Polyester | Everyday EMS use, moisture-sensitive items | Affordable, easy to clean | Less durable under extreme conditions | Medium |

| Ripstop Fabric | Heavy-duty EMS backpacks for rough conditions | Tear-resistant, durable | Higher cost due to specialized production | High |

| Ballistic Nylon | Protective EMS backpacks for sensitive equipment | Exceptional durability | Heavier, more expensive | High |

This material selection guide provides valuable insights for international B2B buyers, enabling informed decisions when sourcing EMS backpacks tailored to specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for ems backpack

Manufacturing Processes for EMS Backpacks

The production of Emergency Medical Services (EMS) backpacks involves several critical stages designed to ensure functionality, durability, and safety. Understanding these processes is essential for international B2B buyers, especially those sourcing from diverse regions such as Africa, South America, the Middle East, and Europe.

1. Material Preparation

The first step in the manufacturing of EMS backpacks is selecting appropriate materials. These backpacks typically require high-performance fabrics that offer durability, water resistance, and lightweight properties. Common materials include:

- Nylon and Polyester: Known for their strength and resistance to wear and tear.

- Ballistic Nylon: Used for its exceptional durability, making it ideal for high-stress environments.

- Ripstop Fabrics: Prevents tearing and is useful in rugged conditions.

Sustainability is becoming increasingly important; thus, eco-friendly materials like recycled polyester are gaining traction. Buyers should inquire about material certifications to ensure compliance with environmental standards.

2. Forming

Once materials are selected, they undergo a forming process that involves cutting and shaping the fabric into specific components of the backpack. Key techniques include:

- Die Cutting: Utilized for precision cutting of fabric layers based on templates.

- Laser Cutting: Offers high accuracy, particularly for intricate designs and patterns, ensuring minimal waste.

This stage is crucial as it sets the foundation for the overall quality of the backpack. Precision in cutting affects the fit and function of the final product.

3. Assembly

The assembly stage combines all components into a finished product. This process typically includes:

- Sewing: Heavy-duty sewing machines are employed to stitch the components together, with reinforced seams in high-stress areas such as straps and zippers.

- Heat-Sealing: Applied in areas that require waterproofing, ensuring that seams are not only stitched but also sealed to prevent moisture ingress.

Attention to detail in this phase is paramount. Manufacturers often implement automated sewing solutions to enhance consistency and reduce human error.

4. Finishing

The finishing stage involves adding the final touches to the EMS backpack, which may include:

- Adding Accessories: Zippers, buckles, and reflective strips are attached for added functionality and safety.

- Branding: Logos or labels may be embroidered or printed, which is essential for brand identity.

Quality assurance begins at this stage, where manufacturers ensure that all components meet the specified design and functional requirements.

Quality Assurance (QA) in EMS Backpack Manufacturing

Quality assurance is critical in ensuring that EMS backpacks meet the necessary standards for safety and functionality. International B2B buyers should be familiar with the various quality control measures and standards that apply to this sector.

Relevant International Standards

- ISO 9001: This standard outlines a framework for quality management systems (QMS) and is crucial for ensuring consistent quality throughout the manufacturing process.

- CE Marking: Indicates that products comply with EU safety, health, and environmental requirements. For EMS backpacks, this is particularly important if they are to be sold in European markets.

- API Standards: Depending on the application, certain backpacks may need to comply with specific industry standards, especially if they are designed for use in medical or emergency services.

Quality Control Checkpoints

Quality control processes typically include several checkpoints:

- Incoming Quality Control (IQC): Inspects raw materials upon arrival to ensure they meet required specifications.

- In-Process Quality Control (IPQC): Conducted throughout the manufacturing process to monitor production quality. This includes checks after cutting, sewing, and assembly.

- Final Quality Control (FQC): A comprehensive inspection of the finished product, ensuring it meets all design and safety standards before shipping.

Common testing methods include:

- Tensile Strength Tests: To evaluate the durability of seams and straps.

- Waterproof Testing: Ensuring materials and seals perform well under wet conditions.

- Load Testing: Assessing the weight-bearing capacity of the backpack.

Verifying Supplier Quality Control

International B2B buyers can take several steps to verify the quality control processes of their suppliers:

- Conduct Audits: Regular audits of manufacturing facilities can help assess adherence to quality standards and operational practices.

- Request Quality Reports: Suppliers should provide documentation of quality checks, including any defects found and corrective actions taken.

- Third-Party Inspections: Engaging independent inspection services can provide an unbiased assessment of product quality.

QC and Certification Nuances for International Buyers

B2B buyers from regions like Africa, South America, the Middle East, and Europe should be aware of potential challenges in quality assurance:

- Cultural Differences: Variations in manufacturing practices and quality expectations may exist. Clear communication of quality standards is essential.

- Regulatory Compliance: Ensure that suppliers are aware of and comply with local regulations and standards in the buyer’s country.

- Sustainability Practices: With increasing demand for environmentally friendly products, verify that suppliers follow sustainable practices and can provide certifications for eco-friendly materials.

Conclusion

Understanding the manufacturing processes and quality assurance standards for EMS backpacks is crucial for international B2B buyers. By focusing on material selection, production techniques, and rigorous quality control measures, buyers can ensure they source high-quality products that meet their specific needs. Engaging in thorough supplier verification and maintaining open communication can further enhance the reliability of the procurement process, ultimately leading to successful partnerships and satisfied end-users.

Related Video: How a Backpack is Made : Every Step on the Production Line

Comprehensive Cost and Pricing Analysis for ems backpack Sourcing

Understanding the cost structure and pricing for sourcing EMS (Emergency Medical Services) backpacks is crucial for international B2B buyers. The costs associated with producing these specialized backpacks can be broken down into several key components, while various factors influence the final pricing.

Cost Components

-

Materials

The choice of materials is foundational to the cost structure. Common materials include:

– Nylon and Polyester: Lightweight and durable, these materials typically have a moderate cost.

– Specialty Fabrics: For higher durability and water resistance, fabrics like ballistic nylon or ripstop can increase costs significantly.

– Eco-Friendly Options: Sustainable materials may also be available at a premium. -

Labor

Labor costs vary by region and impact overall pricing. Countries with lower labor costs, such as Vietnam or Bangladesh, often provide cost advantages. However, higher labor costs in Europe may correlate with better craftsmanship and quality assurance. -

Manufacturing Overhead

This includes operational costs like utilities, rent, and equipment maintenance. Manufacturers with advanced technologies (e.g., automated cutting machines) may have higher overhead but can improve efficiency. -

Tooling

Initial tooling costs for creating molds or specialized equipment can be substantial, especially for custom designs. This expense is often amortized over larger production runs. -

Quality Control (QC)

Effective QC processes are essential to ensure product integrity. Costs here may include testing materials, inspecting finished products, and implementing corrective actions for defects. -

Logistics

Shipping and handling can significantly affect overall costs, especially for international buyers. Factors include:

– Transportation Mode: Air freight is faster but costlier than sea freight.

– Incoterms: Understanding Incoterms can help manage logistics costs and risks. -

Margin

Manufacturers typically apply a markup to cover their costs and ensure profitability. This margin can vary widely based on the manufacturer’s business model, market positioning, and competitive landscape.

Price Influencers

Several factors influence the pricing of EMS backpacks:

- Volume/MOQ (Minimum Order Quantity): Larger orders often lead to better pricing due to economies of scale.

- Specifications/Customization: Customized designs or specific features (e.g., reflective strips, additional compartments) can increase costs.

- Quality and Certifications: Higher quality standards or certifications (e.g., ISO, CE) may demand a premium.

- Supplier Factors: The reputation and reliability of the supplier can also influence pricing; established suppliers may charge more for their assurance of quality and service.

- Incoterms: Familiarity with terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help buyers negotiate better shipping arrangements.

Buyer Tips

-

Negotiation

Leverage volume orders and long-term contracts to negotiate better pricing. Establishing a good relationship with suppliers can lead to favorable terms. -

Cost-Efficiency

Consider total cost of ownership (TCO), which includes initial purchase price, shipping, and potential future costs (e.g., warranty claims). A higher upfront cost may result in lower maintenance and replacement costs. -

Pricing Nuances

International buyers should be aware of currency fluctuations and trade tariffs, which can affect the final cost. Understanding local market conditions in regions like Africa, South America, the Middle East, and Europe can provide insights into potential pricing strategies. -

Sourcing Strategy

Diversifying suppliers and exploring multiple regions can help mitigate risks associated with price volatility and supply chain disruptions.

Disclaimer

Pricing for EMS backpacks can vary widely based on the aforementioned factors. It is advisable for buyers to conduct thorough market research and consult multiple suppliers to obtain indicative quotes tailored to their specific needs.

Spotlight on Potential ems backpack Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ’ems backpack’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for ems backpack

Understanding the technical properties and trade terminology associated with EMS backpacks is essential for international B2B buyers. This knowledge enables informed decision-making, particularly when sourcing products from manufacturers across diverse regions like Africa, South America, the Middle East, and Europe. Below are key specifications and terms to consider.

Critical Technical Properties

-

Material Grade

– Definition: This refers to the specific type of fabric used in the backpack, which can include nylon, polyester, or canvas, each with varying levels of durability, water resistance, and weight.

– B2B Importance: Selecting the right material grade directly affects the backpack’s functionality and marketability. For instance, nylon is lightweight and water-resistant, making it ideal for outdoor EMS applications. -

Weight Capacity

– Definition: The maximum load the backpack can safely carry, typically measured in kilograms or pounds.

– B2B Importance: Knowing the weight capacity is crucial for ensuring that the backpack meets the operational needs of end-users, especially in emergency medical situations where carrying equipment is vital. -

Zipper Quality

– Definition: The strength and durability of zippers used in the backpack, which can be influenced by materials like YKK zippers known for their reliability.

– B2B Importance: High-quality zippers enhance the backpack’s longevity and ease of use, crucial for professionals who rely on quick access to medical supplies. -

Water Resistance Rating

– Definition: A measurement indicating how well the backpack can repel water, often given in millimeters (e.g., 1000mm water column).

– B2B Importance: For EMS backpacks, water resistance is essential to protect medical equipment from moisture, particularly in unpredictable weather conditions. -

Durability Standards

– Definition: This includes assessments such as abrasion resistance and tensile strength, often measured against industry standards like ISO or ASTM.

– B2B Importance: High durability standards ensure that the backpack can withstand the rigors of emergency use, thereby reducing replacement costs for buyers. -

Comfort Features

– Definition: Elements such as padded shoulder straps, adjustable back panels, and ergonomic designs that enhance user comfort.

– B2B Importance: Comfort is critical for professionals who may wear the backpack for extended periods, impacting their performance and efficiency in emergency scenarios.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships can help buyers identify reliable manufacturers who can produce custom EMS backpacks to specific requirements. -

MOQ (Minimum Order Quantity)

– Definition: The smallest number of units that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers gauge the feasibility of production runs and manage inventory effectively, especially for smaller businesses. -

RFQ (Request for Quotation)

– Definition: A document that solicits price quotes from suppliers for specific products or services.

– Importance: An RFQ is a vital tool for buyers to compare pricing and terms from different manufacturers, ensuring they secure the best deal. -

Incoterms (International Commercial Terms)

– Definition: A series of pre-defined commercial terms published by the International Chamber of Commerce that are widely used in international trade.

– Importance: Familiarity with Incoterms helps buyers understand their responsibilities regarding shipping, insurance, and risk management during transportation. -

Lead Time

– Definition: The time taken from placing an order to the delivery of the product.

– Importance: Knowing the lead time is essential for planning inventory and ensuring that products are available when needed, particularly in the fast-paced EMS environment. -

Certification Standards

– Definition: Standards that products must meet to ensure safety and quality, such as ISO certifications.

– Importance: Certifications provide assurance of quality and compliance, which is critical when sourcing products for medical applications.

By understanding these essential technical properties and trade terminology, B2B buyers can enhance their procurement strategies, ensuring they source high-quality EMS backpacks that meet the specific needs of their markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ems backpack Sector

Market Overview & Key Trends

The EMS backpack sector is experiencing robust growth driven by several global factors. The increasing demand for specialized backpacks, particularly in emergency services, outdoor activities, and adventure sports, is a key driver. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, seek to enhance their product offerings, understanding the dynamics of this market is crucial.

Current and Emerging Trends:

-

Customization: Brands are leaning towards custom backpack manufacturing to differentiate themselves. This trend is especially relevant for private label manufacturers, allowing them to offer tailored solutions that meet specific market needs.

-

Technological Advancements: The integration of advanced manufacturing technologies, such as automated cutting and 3D modeling, is streamlining production processes. This not only enhances precision but also reduces lead times, a critical factor for B2B buyers looking to respond swiftly to market demands.

-

Geographical Shifts: While China remains a dominant player in backpack manufacturing, countries like Vietnam and Bangladesh are emerging as viable alternatives due to lower labor costs and improved production capabilities. B2B buyers must evaluate these options based on quality, cost, and production timelines.

Illustrative Image (Source: Google Search)

- Sustainability: There is a marked shift towards eco-friendly materials and sustainable production practices. As consumers become more environmentally conscious, international B2B buyers should align their sourcing strategies with sustainability goals to attract a broader customer base.

Sustainability & Ethical Sourcing in B2B

The environmental impact of backpack manufacturing cannot be overlooked. The industry is associated with significant waste generation and resource consumption, necessitating a shift towards sustainable practices. For B2B buyers, prioritizing ethical sourcing and sustainability is not just a trend but a competitive advantage.

Illustrative Image (Source: Google Search)

Importance of Ethical Supply Chains:

-

Consumer Demand: Increasingly, consumers are favoring brands that demonstrate a commitment to sustainability. By sourcing from manufacturers that prioritize ethical practices, B2B buyers can enhance their brand reputation and customer loyalty.

-

Regulatory Compliance: Many regions, particularly in Europe, are implementing stricter regulations regarding environmental practices. Ensuring compliance through sustainable sourcing will mitigate legal risks and enhance market access.

Green Certifications and Materials:

B2B buyers should seek manufacturers that utilize eco-friendly materials such as recycled polyester and organic cotton. Certifications like Global Recycle Standard (GRS) and OEKO-TEX® ensure that the materials used are sustainably sourced and processed. These credentials not only validate a manufacturer’s commitment to sustainability but also provide assurance to buyers regarding the quality and safety of the products.

Illustrative Image (Source: Google Search)

Brief Evolution/History

The EMS backpack sector has evolved significantly over the past few decades. Initially designed for military and rescue operations, these backpacks have adapted to meet the demands of various industries, including outdoor recreation and everyday use. The introduction of lightweight, durable materials and innovative designs has expanded their functionality, making them popular among diverse consumer segments. Today, the focus is increasingly on integrating technology and sustainability into backpack design, reflecting broader societal trends towards environmental responsibility and customization.

By understanding these market dynamics and trends, international B2B buyers can make informed decisions that align with current demands and future growth opportunities in the EMS backpack sector.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of ems backpack

-

What should I look for when vetting suppliers for EMS backpacks?

When vetting suppliers, prioritize their experience in manufacturing EMS backpacks, including their knowledge of relevant certifications. Request samples to assess quality and durability. Additionally, evaluate their production capacity and reliability in meeting deadlines. Checking references and reviews from other B2B clients can provide insights into their operational integrity. Lastly, ensure they have clear communication protocols and customer support for ongoing collaboration. -

Can I customize my EMS backpack design?

Yes, most manufacturers offer customization options for EMS backpacks. This may include alterations in size, color, material, and additional features like pockets or straps. To facilitate this, provide detailed design specifications and prototypes if possible. Customization often enhances brand identity, so ensure that the manufacturer has the capability to meet your design requirements while maintaining quality standards. -

What are the typical minimum order quantities (MOQs) and lead times?

MOQs can vary significantly based on the manufacturer and the complexity of the design. Generally, expect MOQs ranging from 100 to 1,000 units for EMS backpacks. Lead times also depend on the order size and customization level, typically ranging from 4 to 12 weeks. Communicate clearly with your supplier about your needs and timelines to avoid misunderstandings and ensure timely delivery. -

What payment terms should I expect when sourcing EMS backpacks?

Payment terms can differ by supplier, but common practices include a 30-50% deposit upfront, with the balance due before shipment. Some manufacturers may offer credit terms for established relationships. Consider using secure payment methods, such as letters of credit or escrow services, to protect your investment. Clarifying payment terms early in negotiations helps to avoid disputes later in the process. -

How can I ensure quality assurance (QA) and certifications for my EMS backpacks?

Request documentation of the manufacturer’s quality assurance processes, including any relevant certifications like ISO 9001 or specific safety standards for EMS equipment. Implement a quality control plan that includes pre-production samples, in-line inspections, and final audits. Establish clear acceptance criteria and consider third-party quality inspectors if necessary, ensuring that the backpacks meet your standards before shipment. -

What logistics considerations should I keep in mind when importing EMS backpacks?

Logistics involves selecting reliable shipping methods and understanding customs regulations in your region. Choose between air freight for faster delivery or sea freight for cost-effectiveness, depending on your urgency and budget. Ensure your supplier provides appropriate export documentation to facilitate smooth customs clearance. Additionally, factor in shipping insurance to protect against potential losses during transit. -

How should I handle disputes with suppliers?

Disputes can arise over quality issues, delivery delays, or payment disagreements. Establish a clear communication channel to address concerns promptly. If a problem occurs, document all correspondence and evidence related to the issue. Consider negotiating a resolution directly with the supplier, and if necessary, refer to any contracts or agreements for guidance. For unresolved disputes, mediation or arbitration may be viable options. -

Are there any emerging trends in EMS backpack manufacturing I should be aware of?

Yes, recent trends include a growing demand for sustainable materials, such as recycled fabrics, which appeal to eco-conscious consumers. Customization is also on the rise, allowing brands to differentiate themselves in a competitive market. Additionally, advancements in manufacturing technology, like automated cutting and sewing, improve efficiency and product quality. Staying informed about these trends can help you make strategic sourcing decisions that align with market demands.

Strategic Sourcing Conclusion and Outlook for ems backpack

As the demand for high-quality EMS backpacks continues to rise globally, strategic sourcing emerges as a critical factor for international buyers. Understanding the intricacies of backpack manufacturing—from design and material selection to quality control—enables companies to make informed decisions that enhance product quality and reduce costs. The shift towards sustainable materials and custom designs not only meets consumer expectations but also strengthens brand identity in competitive markets.

B2B buyers, particularly in Africa, South America, the Middle East, and Europe, should prioritize partnerships with manufacturers that emphasize innovation and sustainability. Engaging with suppliers that offer flexibility in production, such as small batch options, can significantly mitigate risks associated with inventory and market fluctuations.

Looking ahead, the landscape of backpack manufacturing will likely evolve, driven by technological advancements and changing consumer preferences. By leveraging strategic sourcing practices, international buyers can position themselves advantageously in this dynamic market. We encourage you to explore partnerships with reputable manufacturers and stay ahead of industry trends to capitalize on emerging opportunities in the EMS backpack sector.