Your Ultimate Guide to Sourcing Cow Print Backpack

Guide to Cow Print Backpack

- Introduction: Navigating the Global Market for cow print backpack

- Understanding cow print backpack Types and Variations

- Key Industrial Applications of cow print backpack

- Strategic Material Selection Guide for cow print backpack

- In-depth Look: Manufacturing Processes and Quality Assurance for cow print backpack

- Comprehensive Cost and Pricing Analysis for cow print backpack Sourcing

- Spotlight on Potential cow print backpack Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for cow print backpack

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the cow print backpack Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of cow print backpack

- Strategic Sourcing Conclusion and Outlook for cow print backpack

Introduction: Navigating the Global Market for cow print backpack

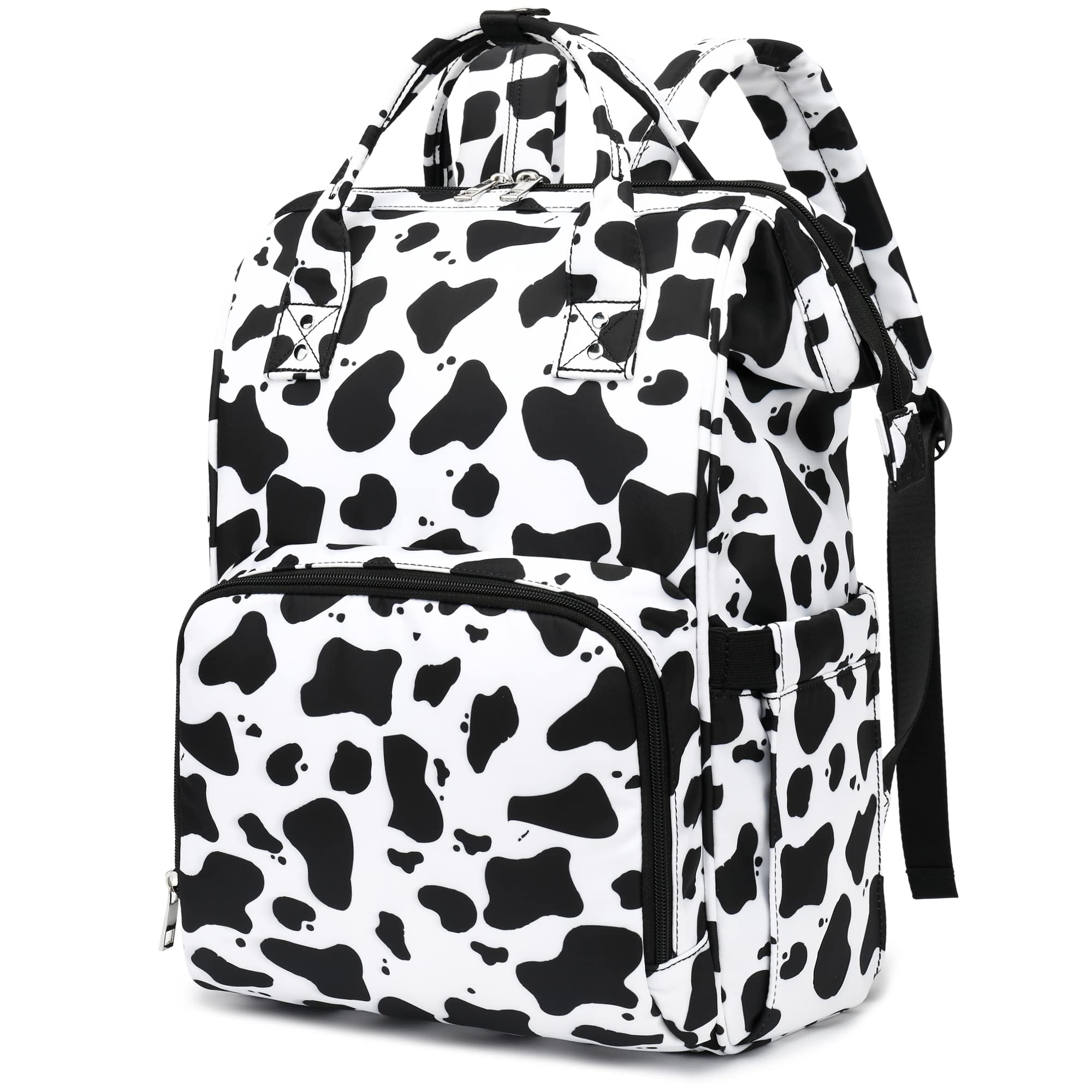

In today’s competitive landscape, the cow print backpack has emerged as a vibrant trend that captures the attention of consumers and brands alike. This unique design not only appeals to niche markets but also embodies a playful yet sophisticated aesthetic that can enhance brand identity. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek to diversify their product offerings, understanding the dynamics of the cow print backpack market becomes essential.

Illustrative Image (Source: Google Search)

This comprehensive guide is designed to empower you with actionable insights into the types, materials, and manufacturing processes associated with cow print backpacks. We will delve into quality control measures and highlight reliable suppliers to help you navigate sourcing effectively. Furthermore, we will provide a detailed overview of cost structures and market trends, ensuring you have the necessary information to make informed purchasing decisions.

By exploring frequently asked questions and addressing common challenges, this guide aims to equip you with the knowledge needed to capitalize on the growing demand for distinctive, stylish backpacks. Whether you’re looking to introduce a new product line or enhance your existing offerings, understanding the cow print backpack market will enable you to meet consumer preferences while maximizing profitability. Engage with this guide to unlock the potential of a unique market opportunity that resonates with diverse global audiences.

Understanding cow print backpack Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Cow Print Backpack | Traditional cow print pattern, varied sizes | Retail, promotional giveaways | Pros: Timeless design, versatile. Cons: May lack uniqueness in a competitive market. |

| Eco-Friendly Cow Print Bag | Made from sustainable materials | Eco-conscious brands, gifts | Pros: Appeals to eco-aware consumers. Cons: Higher production costs. |

| Customizable Cow Print Pack | Options for custom designs and logos | Branding, corporate gifts | Pros: Unique branding opportunities. Cons: Longer lead times for production. |

| Fashion-Forward Cow Print | Trendy designs, often paired with modern features | Fashion retail, niche markets | Pros: Attracts fashion-conscious buyers. Cons: May have limited appeal in conservative markets. |

| Functional Cow Print Backpack | Features like hydration packs or tech pockets | Outdoor activities, schools | Pros: Practical for active users. Cons: Can be heavier due to additional features. |

Classic Cow Print Backpack

The classic cow print backpack is characterized by its traditional design, featuring a recognizable black and white pattern. This type is often available in various sizes, making it suitable for both children and adults. B2B buyers in retail and promotional sectors appreciate its timeless appeal, although the design may not stand out in a saturated market. When considering this option, brands should evaluate their target audience’s preferences to ensure alignment.

Eco-Friendly Cow Print Bag

This variant emphasizes sustainability, utilizing materials like recycled polyester or organic cotton. It caters to businesses aiming to appeal to eco-conscious consumers and can be effectively used for corporate gifts or promotional items. While the eco-friendly aspect enhances brand reputation, buyers should note that production costs may be higher, which could affect pricing strategies.

Customizable Cow Print Pack

Customizable cow print backpacks allow businesses to incorporate their logos and unique designs, making them ideal for branding purposes. This type is particularly beneficial for companies looking to create a memorable promotional item or corporate gift. However, buyers should be aware of the longer lead times associated with custom orders, which can impact inventory management and marketing timelines.

Fashion-Forward Cow Print

Targeting the fashion-conscious consumer, this type features trendy designs and modern functionalities. It often appeals to niche markets within the fashion retail sector. While it can attract a specific demographic, its appeal may be limited in more conservative markets. B2B buyers should conduct market research to assess the viability of this option in their target regions.

Functional Cow Print Backpack

Designed for practicality, the functional cow print backpack includes features such as hydration compartments or tech pockets, making it suitable for outdoor activities or school use. This type appeals to active users and can be marketed effectively in sectors focused on adventure and education. However, the added features may increase the weight, which is a consideration for buyers looking to balance functionality with portability.

Related Video: Large Language Models (LLMs) – Everything You NEED To Know

Key Industrial Applications of cow print backpack

| Industry/Sector | Specific Application of cow print backpack | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail and Fashion | Trendy fashion accessory for boutiques | Differentiation in a competitive market | Quality of materials, design customization options |

| Tourism and Hospitality | Promotional item for travel agencies | Brand visibility and customer engagement | Custom branding options, durability for travel use |

| Education | Unique student backpacks for schools | Appeal to younger demographics | Safety standards, eco-friendly materials |

| Outdoor and Adventure | Specialty backpacks for camping and hiking | Attracting niche markets with unique designs | Weather-resistant materials, functionality features |

| Event Marketing | Giveaways for festivals and events | Enhancing brand recognition and customer loyalty | Cost-effectiveness, bulk production capabilities |

Retail and Fashion

In the retail and fashion industry, cow print backpacks serve as trendy fashion accessories that appeal to diverse consumer demographics. Retailers can leverage the unique aesthetic of these backpacks to stand out in a crowded marketplace, especially in boutiques and specialty shops. Buyers in this sector should focus on sourcing high-quality materials that ensure durability while also allowing for design customization to meet current fashion trends.

Tourism and Hospitality

Tourism and hospitality businesses, such as travel agencies and hotels, can utilize cow print backpacks as promotional items to enhance brand visibility. These backpacks can be offered as part of a welcome package or sold in gift shops, attracting customers with their distinctive design. For international B2B buyers, it’s essential to consider options for custom branding and the durability of the backpacks to withstand travel conditions, thereby ensuring they provide long-lasting value to customers.

Education

In the education sector, cow print backpacks can be marketed as unique student backpacks that appeal to younger demographics. Schools and educational institutions can incorporate these backpacks into their branding strategies, offering them as merchandise or rewards for student achievements. Buyers need to ensure that these backpacks meet safety standards and consider eco-friendly materials, which are increasingly in demand among environmentally conscious consumers.

Outdoor and Adventure

The outdoor and adventure industry can leverage cow print backpacks as specialty gear for camping and hiking enthusiasts. Their unique design can attract niche markets looking for functional yet stylish outdoor equipment. Buyers should prioritize sourcing weather-resistant materials and functionality features, such as ample storage and comfort, to meet the specific needs of outdoor adventurers.

Event Marketing

For event marketing, cow print backpacks can serve as effective giveaways at festivals and promotional events. They enhance brand recognition and foster customer loyalty by providing attendees with a memorable item that showcases the brand. B2B buyers in this sector should consider cost-effectiveness and the manufacturer’s ability to handle bulk production, ensuring timely delivery for large-scale events.

Related Video: Farm tools and their uses

Strategic Material Selection Guide for cow print backpack

When selecting materials for cow print backpacks, international B2B buyers must consider a range of factors including durability, cost, manufacturing complexity, and compliance with regional standards. Here, we analyze four common materials used in the production of cow print backpacks: polyester, canvas, nylon, and leather. Each material has unique properties and implications for the end product, making it essential for buyers to understand their characteristics.

Polyester

Key Properties: Polyester is known for its excellent durability and resistance to stretching, shrinking, and wrinkles. It also has a good resistance to UV rays, making it suitable for outdoor use.

Pros & Cons: The main advantages of polyester include its low cost, lightweight nature, and ease of dyeing, which is beneficial for achieving vibrant cow print designs. However, polyester can be less breathable than natural fibers, which may affect comfort during prolonged use.

Impact on Application: Polyester is compatible with various printing methods, including sublimation, which allows for high-quality cow print patterns.

Considerations for International Buyers: Polyester complies with various international standards such as ASTM and ISO. Buyers from regions like Africa and South America should ensure that the polyester sourced is of high quality to avoid issues with fading and wear.

Canvas

Key Properties: Canvas is a heavy-duty fabric made from cotton or a cotton-polyester blend. It is known for its robustness and ability to withstand wear and tear.

Pros & Cons: The key advantages of canvas include its durability and natural feel, which appeals to eco-conscious consumers. However, canvas can be heavier than other materials and may require special care to maintain its appearance.

Impact on Application: Canvas is suitable for screen printing and embroidery, making it ideal for custom designs. Its thickness can provide excellent structural integrity for backpacks.

Considerations for International Buyers: Compliance with environmental standards is crucial, especially in Europe, where regulations on cotton sourcing and pesticide use are stringent. Buyers should seek suppliers who can provide certifications.

Nylon

Key Properties: Nylon is a synthetic fabric known for its high tensile strength and abrasion resistance. It is lightweight and has excellent elasticity.

Pros & Cons: Nylon’s primary advantage is its durability and water resistance, making it suitable for outdoor backpacks. However, it can be more expensive than polyester and may require specific care to avoid damage from UV exposure.

Impact on Application: Nylon is highly compatible with various manufacturing techniques, including heat sealing, which enhances waterproof capabilities. Its strength allows for the incorporation of heavy-duty zippers and hardware.

Considerations for International Buyers: Buyers from the Middle East and Europe should consider the environmental impact of nylon production. Compliance with standards such as REACH in Europe is essential for ensuring that the material is free from harmful chemicals.

Leather

Key Properties: Leather is a natural material known for its luxurious feel and durability. It offers excellent resistance to wear and tear and can develop a unique patina over time.

Pros & Cons: The main advantage of leather is its premium aesthetic and longevity. However, it is significantly more expensive than synthetic materials and requires regular maintenance to preserve its quality.

Impact on Application: Leather is best suited for high-end cow print backpacks, where branding and aesthetics are prioritized. It can be embossed or printed to create unique designs.

Considerations for International Buyers: Buyers must be aware of regulations regarding animal products, especially in Europe where there are strict guidelines on sourcing and processing. Certifications such as Leather Working Group (LWG) can assure buyers of sustainable practices.

Summary Table

| Material | Typical Use Case for cow print backpack | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | General use, vibrant designs | Lightweight, cost-effective | Less breathable | Low |

| Canvas | Durable backpacks, eco-friendly options | Robust, natural feel | Heavier, requires care | Medium |

| Nylon | Outdoor and heavy-duty backpacks | High strength, water-resistant | More expensive, UV damage risk | Medium |

| Leather | Premium backpacks, luxury markets | Luxurious feel, durable | High cost, maintenance required | High |

This strategic material selection guide provides essential insights for B2B buyers in various international markets, ensuring informed decisions that align with their product goals and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for cow print backpack

The manufacturing of cow print backpacks involves a series of carefully coordinated processes and stringent quality assurance measures. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these processes is crucial for ensuring product quality, compliance, and overall business success.

Manufacturing Process

The production of cow print backpacks can be broken down into four main stages: material preparation, forming, assembly, and finishing. Each stage incorporates specific techniques and considerations that impact the final product’s quality and functionality.

Material Preparation

-

Sourcing Materials: The first step involves selecting high-quality textiles that meet design requirements. For cow print backpacks, the choice of fabric might include durable polyester, cotton blends, or even eco-friendly materials such as recycled polyester. International buyers should prioritize suppliers that provide certifications for sustainability.

-

Pattern and Template Creation: Using CAD software, manufacturers create detailed patterns that reflect the unique cow print design. This step is crucial for ensuring accurate cuts and minimal fabric waste.

-

Fabric Cutting: The cutting process can be done manually or through automated machines, depending on the batch size. Precision cutting is essential to maintain the integrity of the cow print pattern, which can be challenging due to the repetitive design.

Forming

-

Printing Techniques: The cow print design is typically applied using methods like digital printing or screen printing. Each technique has its advantages—digital printing allows for intricate designs and quick changes, while screen printing is cost-effective for larger runs.

-

Embroidery: For added branding or embellishments, embroidery may be applied. This requires specialized machines and skilled operators to ensure high-quality finishes.

Assembly

-

Sewing: This stage involves stitching together various components of the backpack, including the body, straps, and pockets. Industrial sewing machines are employed to enhance efficiency and maintain consistent quality.

-

Integration of Hardware: Zippers, buckles, and other accessories are attached during the assembly process. Buyers should ensure that the hardware meets durability standards to withstand regular use.

Finishing

-

Quality Checks: After assembly, the backpacks undergo a series of quality checks to identify any defects. This may involve visual inspections as well as functional tests to ensure zippers operate smoothly and seams are secure.

-

Final Touches: This includes adding brand tags, final cleaning, and packing for shipment. Effective organization at this stage can significantly enhance efficiency.

Quality Assurance

Quality assurance is paramount in the backpack manufacturing process, especially for international B2B buyers. Understanding relevant standards and implementing rigorous quality control measures will help ensure that the final product meets expectations.

Relevant International Standards

- ISO 9001: This certification indicates that a manufacturer adheres to quality management principles, ensuring consistent quality in production processes.

- CE Marking: For products sold within the European market, CE marking signifies compliance with health, safety, and environmental protection standards.

- API Standards: Although more common in the oil and gas sector, some manufacturers may also adhere to API standards for materials used in durable goods.

Quality Control Checkpoints

-

Incoming Quality Control (IQC): Before production begins, raw materials are inspected for quality and conformity to specifications. This is crucial for preventing defects in the final product.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular checks are conducted to ensure that each stage meets quality standards. This includes monitoring sewing precision and verifying print accuracy.

-

Final Quality Control (FQC): Once production is complete, a thorough inspection is conducted to assess the overall quality of the finished backpacks. This may involve random sampling and testing for durability.

Illustrative Image (Source: Google Search)

Common Testing Methods

- Tensile Strength Testing: Evaluates the strength of the fabric and seams to ensure they can withstand stress during use.

- Color Fastness Testing: Assesses how well the cow print holds up against washing and exposure to sunlight.

- Water Resistance Testing: Determines the backpack’s ability to repel water, an essential feature for outdoor use.

Verifying Supplier Quality Control

B2B buyers must take proactive steps to verify the quality control processes of their suppliers. Here are several strategies:

-

Supplier Audits: Conducting on-site audits can provide valuable insights into a manufacturer’s operations, including their adherence to quality standards and production capabilities.

-

Quality Reports: Request detailed quality control reports, including data from IQC, IPQC, and FQC. These documents should outline any defects found and corrective actions taken.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing process and product quality, ensuring compliance with international standards.

Nuances for International Buyers

For buyers from diverse regions such as Africa, South America, the Middle East, and Europe, understanding local market dynamics and regulations is essential. Here are a few considerations:

-

Cultural Preferences: Tailoring the cow print design to suit regional tastes can enhance marketability. For example, using vibrant colors may appeal more to South American consumers, while muted tones might be preferred in Europe.

-

Logistics and Shipping: Consider the logistics of shipping finished products to your region. Understanding import regulations and tariffs can help in cost calculations.

-

Sustainability Expectations: With growing consumer awareness of environmental issues, emphasizing eco-friendly manufacturing practices can be a significant selling point.

In conclusion, the manufacturing process for cow print backpacks is intricate and requires careful consideration at every stage, from material selection to quality assurance. By understanding these processes and implementing robust quality control measures, international B2B buyers can ensure that they source high-quality products that meet their market’s demands.

Related Video: How a Backpack is Made : Every Step on the Production Line

Comprehensive Cost and Pricing Analysis for cow print backpack Sourcing

Understanding the cost structure and pricing dynamics of sourcing cow print backpacks is essential for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. Below is a comprehensive analysis that outlines the key cost components, price influencers, and strategic buyer tips to navigate the complexities of sourcing.

Cost Components

-

Materials:

The choice of materials significantly impacts the overall cost. For cow print backpacks, options may include synthetic fabrics like polyester, eco-friendly materials such as recycled PET, or premium options like canvas or leather. The price per yard can vary greatly based on the quality and source of the material, so it is critical to evaluate suppliers thoroughly. -

Labor:

Labor costs can fluctuate widely depending on the manufacturing location. Countries like Vietnam and Bangladesh may offer lower labor costs compared to European nations. However, it’s essential to balance cost with quality, as skilled labor can lead to better craftsmanship and durability. -

Manufacturing Overhead:

This includes expenses related to factory operations, utilities, and administrative costs. A factory that employs advanced technology and efficient processes may have higher overheads but can offset this with lower production costs in the long run. -

Tooling:

Initial tooling costs for creating custom patterns and molds can be significant, especially for unique designs like cow prints. Buyers should consider these costs when calculating the total investment needed for custom orders. -

Quality Control (QC):

Quality assurance is crucial in the backpack industry, where durability and aesthetics are paramount. Incorporating QC checks throughout the manufacturing process may add to costs but can prevent expensive returns and reputational damage later. -

Logistics:

Shipping costs can vary based on distance, shipping method, and freight terms. Buyers should consider both inland transportation to the port and international shipping costs. Additionally, the choice of Incoterms (e.g., FOB, CIF) will affect the total logistics cost. -

Margin:

Manufacturers typically apply a markup on production costs to ensure profitability. Understanding the standard margins in the industry can help buyers gauge whether they are getting a fair price.

Price Influencers

-

Volume/MOQ:

Minimum Order Quantities (MOQs) can significantly influence pricing. Larger orders often lead to lower per-unit costs, making it crucial for buyers to assess their market demand accurately. -

Specifications/Customization:

Custom designs and specifications can increase costs. Buyers should clearly define their requirements to avoid unexpected charges. -

Materials:

The choice of material directly correlates with the price. Sustainable materials may carry a premium but can appeal to eco-conscious consumers. -

Quality/Certifications:

Certifications such as ISO or compliance with international safety standards can add to costs but may be necessary for market entry in certain regions. -

Supplier Factors:

The reputation and reliability of suppliers can impact pricing. Established manufacturers with a strong track record may charge higher prices due to their reliability and quality assurance. -

Incoterms:

Choosing the right Incoterms can significantly affect total costs. Buyers should weigh the pros and cons of different terms to determine the most cost-effective option.

Buyer Tips

-

Negotiation:

Effective negotiation is key to securing favorable pricing. Building a strong relationship with suppliers can lead to better terms and discounts. -

Cost-Efficiency:

Evaluate the Total Cost of Ownership (TCO), which includes not only the purchase price but also shipping, handling, and potential after-sales service costs. -

Pricing Nuances:

International buyers must be aware of local tariffs, taxes, and currency fluctuations that can affect final costs. Engage local experts or consultants to navigate these complexities. -

Research and Due Diligence:

Conduct thorough market research and supplier vetting to avoid common pitfalls. Utilize platforms like Alibaba cautiously, and consider consulting services for unbiased assessments. -

Flexibility:

Be open to adjusting order sizes or specifications to take advantage of better pricing structures from suppliers.

By understanding these cost components and pricing dynamics, B2B buyers can make informed decisions that align with their business goals and market strategies. It’s advisable to approach sourcing with a comprehensive view of both immediate costs and long-term implications.

Spotlight on Potential cow print backpack Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘cow print backpack’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for cow print backpack

Key Technical Properties of Cow Print Backpacks

When sourcing cow print backpacks, international B2B buyers should be aware of several essential technical properties that influence product quality, durability, and marketability. Here are the critical specifications:

-

Material Grade

– Definition: This refers to the quality of the fabric used in the backpack, such as nylon, polyester, or canvas. For cow print backpacks, the material should not only have the desired aesthetic but also provide durability and resistance to wear and tear.

– B2B Importance: Selecting a high-grade material ensures longevity and customer satisfaction. Lower-quality materials can lead to increased returns and negatively impact brand reputation. -

Water Resistance Rating (WR)

– Definition: This rating indicates how well the backpack can resist water penetration. Common ratings include 500 mm (light rain) to 10,000 mm (heavy rain).

– B2B Importance: For buyers in regions with diverse climates, understanding WR is critical for meeting consumer expectations. It enhances the product’s versatility and broadens its appeal. -

Weight Capacity

– Definition: This specification indicates the maximum weight the backpack can safely carry. It is typically expressed in kilograms or pounds.

– B2B Importance: Knowing the weight capacity is crucial for end-users who may use the backpack for various purposes, from school to outdoor activities. This property aids in marketing the backpack to specific demographics. -

Tolerance Levels

– Definition: Tolerance refers to the permissible limit of variation in dimensions and manufacturing processes, ensuring each backpack meets design specifications.

– B2B Importance: Understanding tolerance levels helps buyers ensure that the backpacks maintain consistent quality across production batches, which is essential for brand reliability. -

Stitching Quality

– Definition: This refers to the number of stitches per inch (SPI) and the type of stitching used (e.g., straight stitch, reinforced stitch).

– B2B Importance: Higher SPI and reinforced stitching contribute to the overall durability of the backpack. Buyers should prioritize manufacturers who adhere to strict quality control measures in stitching. -

Colorfastness

– Definition: This property measures how well the colors of the fabric resist fading due to washing, sunlight, or wear.

– B2B Importance: Cow print patterns are often vibrant; thus, high colorfastness ensures that the design remains appealing over time, reducing returns and enhancing customer satisfaction.

Illustrative Image (Source: Google Search)

Common Trade Terminology

Understanding industry jargon is vital for effective communication and negotiation in the backpack manufacturing sector. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer. In the backpack industry, OEMs create products based on the buyer’s specifications.

– Usage: Buyers often work with OEMs to develop unique cow print designs tailored to their brand. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell. For backpacks, this can vary significantly between manufacturers.

– Usage: Understanding MOQ is crucial for managing inventory costs and ensuring that production runs are financially viable. -

RFQ (Request for Quotation)

– Definition: A document that a buyer sends to suppliers to request pricing information for specific products.

– Usage: An RFQ is essential for comparing costs and establishing relationships with potential manufacturers. -

Incoterms (International Commercial Terms)

– Definition: A set of rules that define the responsibilities of sellers and buyers regarding the delivery of goods under sales contracts.

– Usage: Familiarity with Incoterms helps buyers understand shipping responsibilities, costs, and risk management, which is particularly important for international transactions. -

Lead Time

– Definition: The amount of time from the initiation of a process to its completion, often referring to the time it takes for a manufacturer to fulfill an order.

– Usage: Knowing the lead time is critical for planning inventory and ensuring timely product launches. -

Sustainability Certification

– Definition: A certification that indicates the product meets certain environmental standards, often related to materials and manufacturing processes.

– Usage: Increasingly, buyers seek sustainably produced backpacks to appeal to eco-conscious consumers, making this certification a valuable asset in marketing.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their business objectives and consumer expectations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the cow print backpack Sector

Market Overview & Key Trends

The cow print backpack market is witnessing a surge in demand, driven by unique fashion trends and a growing interest in personalization among consumers. This trend is particularly pronounced in regions such as Africa, South America, the Middle East, and Europe, where cultural influences and local preferences play a pivotal role in shaping consumer choices. B2B buyers are increasingly seeking manufacturers who can offer customized designs that resonate with local aesthetics and lifestyles.

Emerging technologies are transforming sourcing practices, with platforms like Alibaba and specialized garment sourcing consultancies offering streamlined access to manufacturers. However, buyers must exercise caution, as unverified suppliers can lead to unpredictable pricing and quality issues. Engaging with manufacturers that emphasize transparency and quality control can help mitigate these risks.

In addition to customization and technology, sustainability is becoming a key consideration. Many B2B buyers are prioritizing suppliers who utilize eco-friendly materials and sustainable production methods. This shift is not only driven by regulatory pressures in various regions but also by the growing consumer demand for responsible products. Brands that adopt sustainable practices can leverage this trend to differentiate themselves in a competitive market.

Sustainability & Ethical Sourcing in B2B

As environmental concerns take center stage, the importance of sustainability in the cow print backpack sector cannot be overstated. The production of backpacks often involves materials and processes that can negatively impact the environment, from resource-intensive fabric production to waste generation during manufacturing. B2B buyers must consider the environmental footprint of their sourcing decisions, prioritizing manufacturers that utilize sustainable practices.

Ethical sourcing is equally critical. Buyers should seek suppliers with transparent supply chains that adhere to fair labor practices. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® can help identify manufacturers committed to environmental and social responsibility. Utilizing materials like recycled polyester, organic cotton, or biodegradable alternatives not only reduces environmental impact but also appeals to eco-conscious consumers.

By emphasizing sustainability and ethical sourcing, B2B buyers can enhance their brand reputation and build stronger connections with their target markets. This approach not only fosters customer loyalty but also aligns with the growing regulatory and societal expectations for responsible business practices.

Brief Evolution/History

The cow print backpack’s evolution can be traced back to the broader trends in fashion and accessories, where unique patterns and designs began to gain traction in the late 20th century. Initially popularized by the rise of animal prints in fashion, cow print emerged as a playful and bold choice among younger consumers seeking to express individuality.

In recent years, the backpack market has seen a revival in retro and quirky designs, leading to a resurgence of cow print as a trendy option. This shift has been supported by social media influencers and fashion-forward brands, making cow print backpacks a staple in various markets. For B2B buyers, understanding this historical context can inform sourcing strategies and product development, ensuring alignment with current consumer preferences.

Related Video: Crude Oil Prices & Global Trade Market Seen Stabilising After Trump Announced Iran Israel Ceasefire

Frequently Asked Questions (FAQs) for B2B Buyers of cow print backpack

-

What should I consider when vetting suppliers for cow print backpacks?

When vetting suppliers, focus on their manufacturing capabilities, experience in producing similar products, and reputation in the industry. Request samples to assess quality and confirm their ability to meet design specifications. Check for certifications such as ISO or compliance with international labor standards. Additionally, gather references from other clients, especially those in your region, to understand their reliability and service quality. -

Can I customize cow print backpacks to fit my brand’s identity?

Yes, many manufacturers offer customization options. You can tailor the design, materials, colors, and branding elements like logos. Ensure that the supplier has experience with custom orders and can provide design assistance if needed. Discuss your specific requirements early in the process to ensure they align with the manufacturer’s capabilities and production timelines. -

What are the typical minimum order quantities (MOQs) and lead times for cow print backpacks?

MOQs vary by manufacturer, but they can range from 100 to 1,000 units for custom designs. Lower MOQs may be available with certain suppliers, particularly for startups. Lead times typically span from 4 to 12 weeks, depending on the complexity of the design and the supplier’s production capacity. Always confirm these details upfront to plan your inventory and marketing strategies accordingly. -

What payment options and terms should I expect when sourcing backpacks internationally?

Payment terms can vary, but common practices include a deposit (usually 30-50%) upfront, with the balance paid before shipment. Secure payment methods like letters of credit, PayPal, or escrow services are advisable to protect your investment. Always clarify payment terms and any additional fees, such as taxes or tariffs, to avoid unexpected costs. -

How can I ensure quality assurance (QA) and certifications for my cow print backpacks?

Request information on the manufacturer’s quality control processes, including inspections during production and final checks. Certifications such as ISO 9001 (quality management) and OEKO-TEX (safety of textiles) can provide assurance of product quality and compliance with international standards. Consider scheduling a factory visit or hiring a third-party inspection service to evaluate quality before shipment. -

What logistics considerations should I keep in mind when importing cow print backpacks?

Factor in shipping methods (air vs. sea), costs, and delivery times when planning logistics. Understand the customs regulations of your country to ensure compliance and avoid delays. Collaborating with a freight forwarder can streamline the process, as they can handle documentation and provide guidance on duties and tariffs. Always track shipments to address any issues promptly. -

How can I handle disputes or issues with my supplier effectively?

Clear communication is key to resolving disputes. Document all agreements and communications to establish a record. If issues arise, address them promptly with the supplier, and be specific about your concerns. If necessary, refer to the contract terms regarding dispute resolution. Consider mediation or arbitration as alternatives to legal action to save time and costs.

- What trends should I be aware of when sourcing cow print backpacks?

Sustainability is a growing trend; many buyers prefer eco-friendly materials and ethical manufacturing practices. Additionally, customization and unique designs are increasingly in demand as brands seek to differentiate themselves. Staying informed about market trends can help you align your product offerings with consumer preferences and enhance your competitive edge in the market.

Strategic Sourcing Conclusion and Outlook for cow print backpack

In conclusion, strategic sourcing for cow print backpacks presents a wealth of opportunities for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. Understanding the latest trends in the backpack manufacturing industry—such as customization and sustainability—can significantly enhance your competitive edge. By prioritizing eco-friendly materials and innovative design techniques, businesses can not only meet consumer demands but also align with global sustainability goals.

Key Takeaways:

– Emphasize Customization: Tailoring products to meet specific market needs can differentiate your brand in a crowded marketplace.

– Adopt Sustainable Practices: Eco-conscious consumers are increasingly influencing purchasing decisions, making sustainable sourcing a priority.

– Evaluate Manufacturing Locations: Consider factors like cost, quality, and lead times when selecting manufacturing partners, particularly in emerging markets like Vietnam.

As the demand for unique and environmentally friendly products continues to rise, now is the time to engage with reliable manufacturers and explore innovative designs. By doing so, you can position your business to thrive in a dynamic market landscape. Reach out today to discover how you can leverage strategic sourcing to elevate your product offerings and drive growth in your region.