Your Ultimate Guide to Sourcing Rucksack Backpack Sewing

Guide to Rucksack Backpack Sewing Pattern

- Introduction: Navigating the Global Market for rucksack backpack sewing pattern

- Understanding rucksack backpack sewing pattern Types and Variations

- Key Industrial Applications of rucksack backpack sewing pattern

- Strategic Material Selection Guide for rucksack backpack sewing pattern

- In-depth Look: Manufacturing Processes and Quality Assurance for rucksack backpack sewing pattern

- Comprehensive Cost and Pricing Analysis for rucksack backpack sewing pattern Sourcing

- Spotlight on Potential rucksack backpack sewing pattern Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for rucksack backpack sewing pattern

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the rucksack backpack sewing pattern Sector

- Market Overview & Key Trends

- Sustainability & Ethical Sourcing in B2B

- Brief Evolution/History

- Frequently Asked Questions (FAQs) for B2B Buyers of rucksack backpack sewing pattern

- Strategic Sourcing Conclusion and Outlook for rucksack backpack sewing pattern

Introduction: Navigating the Global Market for rucksack backpack sewing pattern

In an increasingly interconnected world, the demand for rucksack backpacks has surged, driven by a blend of fashion, functionality, and sustainability. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of rucksack backpack sewing patterns is essential for making informed sourcing decisions. These patterns not only dictate the aesthetic appeal of the final product but also influence durability and usability—key factors in consumer satisfaction.

This comprehensive guide aims to equip buyers with critical insights into the diverse landscape of rucksack backpack sewing patterns. It covers essential topics such as various types of patterns, suitable materials, manufacturing processes, quality control measures, and market trends. Furthermore, we delve into the intricacies of sourcing suppliers and estimating costs, ensuring that you have a well-rounded understanding of the market dynamics.

By navigating through this guide, B2B buyers will gain actionable knowledge that empowers them to select the right patterns that align with their business needs. From understanding the latest design trends to evaluating supplier credibility, this resource serves as a strategic tool to enhance your sourcing strategy. Embrace the opportunity to innovate and differentiate your product offerings in the competitive backpack market, ensuring that your business stays ahead in this evolving industry.

Understanding rucksack backpack sewing pattern Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Rucksack | Traditional design with a drawstring closure | Outdoor gear, school bags | Pros: Timeless style, versatile. Cons: Limited organization features. |

| Technical Backpack | Specialized pockets for gear, hydration systems | Hiking, climbing, travel | Pros: Highly functional, durable materials. Cons: Higher cost, heavier. |

| Convertible Backpack | Transforms into a tote or messenger bag | Urban commuting, travel | Pros: Multi-functional, stylish. Cons: May compromise on space. |

| Minimalist Backpack | Streamlined design with fewer pockets | Everyday carry, tech bags | Pros: Lightweight, easy to carry. Cons: Limited storage capacity. |

| Eco-Friendly Backpack | Made from sustainable materials | Eco-conscious markets, schools | Pros: Appeals to green consumers, unique designs. Cons: Potentially higher price point. |

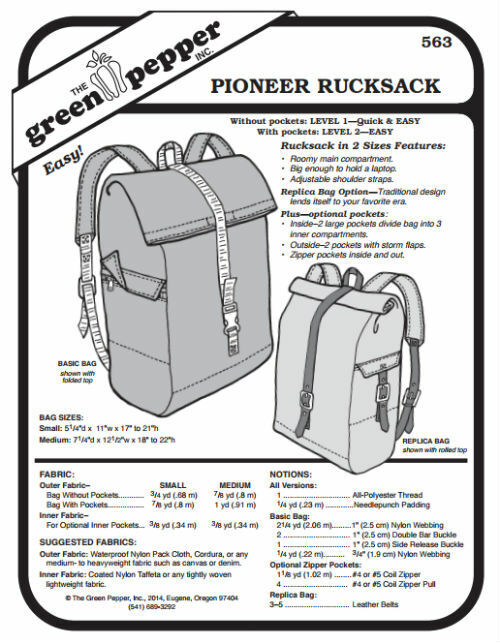

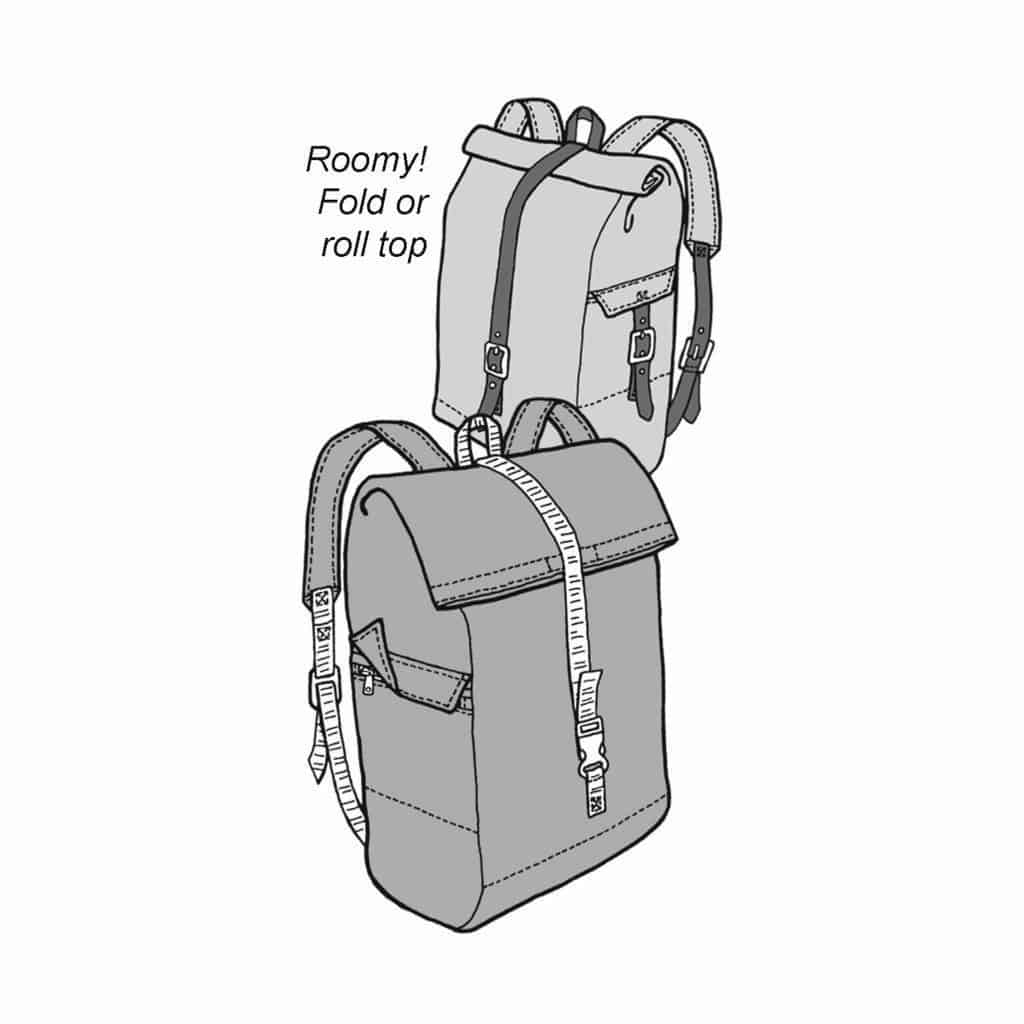

Classic Rucksack

The Classic Rucksack is characterized by its simple design, typically featuring a drawstring closure and a large main compartment. This design is ideal for B2B applications in outdoor gear and school bags, appealing to a broad audience due to its timeless style and versatility. Buyers should consider factors such as fabric durability and waterproofing, as these can significantly impact the rucksack’s performance in various environments.

Technical Backpack

Designed for specific outdoor activities, the Technical Backpack includes specialized pockets for gear, hydration systems, and often uses durable, weather-resistant materials. This type is particularly popular in hiking, climbing, and travel sectors, where functionality is paramount. B2B buyers should evaluate the weight-to-capacity ratio and the quality of zippers and seams, as these elements can influence the backpack’s longevity and usability in rugged conditions.

Convertible Backpack

The Convertible Backpack offers a unique advantage by transforming into a tote or messenger bag, catering to urban commuters and travelers. This versatility makes it a popular choice among fashion-forward consumers who value functionality. When purchasing, B2B buyers should assess the ease of conversion and the overall aesthetic appeal, ensuring the product aligns with market trends while maintaining practical features.

Minimalist Backpack

The Minimalist Backpack is designed with a streamlined approach, featuring fewer pockets and compartments. This type is particularly suitable for everyday carry and tech bags, appealing to consumers who prioritize lightweight designs. B2B buyers should consider the materials used, as well as the bag’s ergonomic design, which can enhance comfort during extended use. However, the limited storage capacity may not meet the needs of all consumers.

Eco-Friendly Backpack

Increasingly popular in today’s market, the Eco-Friendly Backpack is crafted from sustainable materials, appealing to eco-conscious consumers and businesses. This type is suitable for schools and eco-friendly markets, often featuring unique designs that emphasize environmental responsibility. Buyers should evaluate the sourcing of materials and the production processes involved, as these factors can significantly affect the brand’s reputation and marketability. While potentially more expensive, the long-term benefits of appealing to a growing demographic can outweigh the initial costs.

Related Video: DIY Sling Backpack Sewing from Cloth 🙌 Bag Making at Home

Key Industrial Applications of rucksack backpack sewing pattern

| Industry/Sector | Specific Application of rucksack backpack sewing pattern | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Outdoor & Adventure | Custom rucksacks for hiking and camping | Tailored designs enhance customer satisfaction | Durability of materials, weather resistance, and ergonomic design |

| Education | School backpacks with unique designs | Differentiation in a competitive market | Safety standards compliance, customization options, and pricing |

| Logistics & Transport | Durable backpacks for delivery personnel | Improved efficiency and branding opportunities | Load capacity, material strength, and comfort features |

| Fashion & Retail | Trendy rucksack styles for urban consumers | Increased market appeal and sales potential | Fabric quality, trend alignment, and production scalability |

| Military & Defense | Tactical backpacks for military use | Enhanced functionality and reliability | Material specifications, durability under extreme conditions, and compliance with military standards |

Outdoor & Adventure

In the outdoor and adventure sector, the rucksack backpack sewing pattern is instrumental in creating custom rucksacks tailored for hiking and camping. These backpacks often require specific features such as water-resistant materials and ergonomic designs to accommodate long treks. International buyers, particularly in regions like Africa and South America, seek durable options that can withstand diverse climates and terrains. Understanding local preferences and environmental factors is crucial for sourcing the right materials.

Education

For the education sector, rucksack backpack sewing patterns enable the production of unique school backpacks that cater to different age groups and preferences. Customization plays a significant role in this market, allowing businesses to differentiate their products. Buyers from Europe and the Middle East may prioritize safety standards compliance and the availability of eco-friendly materials. This attention to detail can enhance brand loyalty among parents and students alike.

Logistics & Transport

In logistics and transport, durable backpacks designed for delivery personnel are increasingly popular. These bags enhance efficiency by allowing workers to carry essential items while promoting the brand. Buyers must consider load capacity and material strength, ensuring that the backpacks can withstand daily wear and tear. Sourcing partnerships with manufacturers that understand ergonomic design can also provide a competitive edge in this sector.

Fashion & Retail

The fashion and retail industry leverages rucksack backpack sewing patterns to create trendy designs that appeal to urban consumers. This sector thrives on innovation and aesthetics, making it essential for businesses to stay aligned with current trends. Buyers should focus on fabric quality and the ability to scale production to meet demand. Additionally, understanding regional fashion preferences can significantly impact the success of new product lines in markets like Brazil and Poland.

Military & Defense

In the military and defense sector, tactical backpacks designed using rucksack sewing patterns are crucial for operational efficiency. These backpacks must meet stringent durability and functionality requirements, often needing to withstand extreme conditions. International buyers in this space prioritize compliance with military standards and specifications. Sourcing from manufacturers with expertise in tactical gear can ensure that the products are reliable and effective in the field.

Strategic Material Selection Guide for rucksack backpack sewing pattern

When selecting materials for rucksack backpack sewing patterns, international B2B buyers must consider various factors that influence performance, durability, and compliance with local standards. Below is an analysis of four common materials used in the production of rucksacks, highlighting their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

1. Nylon

Key Properties:

Nylon is a synthetic polymer known for its high tensile strength, elasticity, and resistance to abrasion. It typically performs well in a range of temperatures and is resistant to mildew and rot.

Pros & Cons:

Nylon is lightweight, durable, and water-resistant, making it an excellent choice for outdoor applications. However, it can be more expensive than other materials and may require specialized manufacturing techniques, which can increase production complexity.

Impact on Application:

Nylon’s compatibility with various coatings (like polyurethane) enhances its water resistance, making it suitable for outdoor and adventure rucksacks.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM and ISO for textile safety. Additionally, the availability of nylon may vary by region, impacting lead times and costs.

2. Polyester

Key Properties:

Polyester is another synthetic fiber known for its durability, resistance to shrinking and stretching, and quick-drying capabilities. It is less absorbent than natural fibers, which makes it suitable for moisture-wicking applications.

Pros & Cons:

Polyester is generally more affordable than nylon and offers good UV resistance, making it suitable for sun-exposed applications. However, it is less durable than nylon in high-abrasion situations and may not perform as well in extreme temperatures.

Impact on Application:

Polyester’s ability to retain color and resist fading makes it ideal for vibrant, printed designs on rucksacks. Its compatibility with various finishes allows for customization.

Considerations for International Buyers:

Buyers must consider local regulations on synthetic materials, especially in regions with strong environmental policies. Additionally, polyester’s production can be less sustainable, which may influence brand perception in eco-conscious markets.

3. Canvas

Key Properties:

Canvas is a heavy-duty fabric made from cotton or a blend of cotton and synthetic fibers. It is known for its sturdiness and breathability, making it a popular choice for casual and outdoor backpacks.

Pros & Cons:

Canvas is highly durable and can withstand rough handling, making it suitable for rugged use. However, it is heavier than synthetic options and may absorb moisture, leading to potential mildew issues if not treated.

Impact on Application:

Canvas is compatible with various treatments to enhance water resistance, making it versatile for different climates. Its natural texture provides a classic aesthetic appealing to specific consumer segments.

Considerations for International Buyers:

Buyers should be aware of compliance with organic certification if sourcing cotton canvas. Additionally, canvas may require more care in manufacturing and finishing processes, impacting costs.

4. Ripstop Fabric

Key Properties:

Ripstop fabric is woven with a special reinforcing technique that makes it resistant to tearing and ripping. It is commonly made from nylon or polyester and features a grid pattern.

Pros & Cons:

The primary advantage of ripstop fabric is its lightweight yet durable nature, making it ideal for high-performance rucksacks. However, it can be more expensive due to its specialized manufacturing process.

Impact on Application:

Ripstop fabric is particularly suitable for outdoor and military applications where durability is paramount. Its tear-resistant properties ensure longevity even in harsh conditions.

Considerations for International Buyers:

Buyers should consider the availability of ripstop fabric in their region, as it may not be as widely produced as standard nylon or polyester. Compliance with military specifications may also be necessary for certain applications.

| Material | Typical Use Case for rucksack backpack sewing pattern | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | High-performance outdoor rucksacks | Lightweight, durable | Higher cost, complex manufacturing | High |

| Polyester | Everyday and casual backpacks | Cost-effective, UV resistant | Less durable in high-abrasion situations | Medium |

| Canvas | Casual and rugged use backpacks | Highly durable, classic aesthetic | Heavier, moisture absorption | Medium |

| Ripstop Fabric | Outdoor and military rucksacks | Tear-resistant, lightweight | Higher cost, specialized manufacturing | High |

This guide provides international B2B buyers with actionable insights into material selection for rucksack backpack sewing patterns, ensuring informed decisions that align with performance requirements and market expectations.

In-depth Look: Manufacturing Processes and Quality Assurance for rucksack backpack sewing pattern

Manufacturing Processes for Rucksack Backpack Sewing Patterns

The manufacturing of rucksack backpack sewing patterns involves a series of well-defined stages, each crucial for ensuring that the final product meets the expectations of international B2B buyers. Understanding these processes can empower buyers to make informed decisions when selecting suppliers, especially in diverse markets such as Africa, South America, the Middle East, and Europe.

1. Material Preparation

The first stage in the manufacturing process is material preparation. This involves selecting high-quality fabrics, zippers, buckles, and other components. Common materials for rucksacks include nylon, polyester, and canvas, known for their durability and weather resistance.

- Sourcing: Buyers should focus on suppliers who source materials that comply with international standards for safety and environmental impact. For instance, materials should ideally meet OEKO-TEX® certification, which ensures that they are free from harmful substances.

- Pre-treatment: Fabrics may undergo pre-treatment processes such as dyeing and waterproofing. This stage is critical for enhancing the performance and longevity of the rucksacks.

2. Forming

After preparing the materials, the next step is forming. This involves cutting the fabric into specific shapes as per the sewing pattern.

- Cutting Techniques: Different cutting methods, such as laser cutting or die cutting, may be employed based on the complexity of the design and the type of fabric. Laser cutting offers precision and reduces fabric waste, which is beneficial for cost management.

- Pattern Marking: Accurate pattern marking is essential to ensure that all pieces align correctly during assembly. This can be done manually or with automated systems to enhance efficiency.

3. Assembly

The assembly stage is where the rucksack components come together. This is typically the most labor-intensive part of the manufacturing process.

- Sewing Techniques: Various sewing techniques, including straight stitching, zigzag stitching, and reinforced stitching, are used to ensure durability. Buyers should inquire about the type of stitching used, as this can significantly impact the product’s lifespan.

- Quality Checks During Assembly: It is vital to conduct inline quality checks (IPQC) during this stage to catch defects early. This can include checking stitch quality, seam alignment, and the functionality of zippers and buckles.

4. Finishing

Once assembled, the rucksacks undergo finishing processes which may include trimming excess threads, adding labels, and final inspections.

- Final Touches: This stage often includes applying protective coatings to enhance water resistance and aesthetics. Buyers should ask suppliers about the finishing techniques to ensure they align with customer expectations.

- Packing: Proper packing is crucial for international shipping. Rucksacks should be folded and packed in a way that prevents damage during transit.

Quality Assurance in Manufacturing

Quality assurance (QA) is an integral part of the manufacturing process for rucksack backpacks. It ensures that products meet specified requirements and international standards, which is especially important for B2B buyers.

International Standards

Understanding and complying with international standards is critical for maintaining product quality.

- ISO 9001: This is a widely recognized standard for quality management systems. Suppliers should be able to demonstrate their compliance with ISO 9001 through certification, which indicates a commitment to quality and continuous improvement.

- CE Marking: For products sold in Europe, CE marking is essential. It indicates that the product complies with EU safety, health, and environmental protection standards.

Quality Control Checkpoints

Quality control (QC) checkpoints should be integrated throughout the manufacturing process to ensure consistent quality.

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards. Buyers can request IQC reports to verify compliance.

- In-Process Quality Control (IPQC): Conducted during the manufacturing process, this includes regular inspections of sewing and assembly stages to catch defects early.

- Final Quality Control (FQC): This final inspection checks the completed products against quality standards before shipping. It should include functionality tests for zippers, seams, and other components.

Common Testing Methods

Different testing methods can be employed to assess the quality of rucksack backpacks:

- Durability Testing: This assesses the longevity of materials under stress, such as weight tests and abrasion tests.

- Water Resistance Testing: This ensures that the fabric can withstand exposure to water, which is crucial for outdoor rucksacks.

- Safety Testing: This checks for harmful substances in materials, ensuring compliance with safety standards.

Verifying Supplier Quality Control

B2B buyers must take proactive steps to verify the quality control measures of potential suppliers.

- Supplier Audits: Conducting audits can provide insight into the supplier’s quality management systems and processes. Buyers should consider both initial audits and periodic follow-ups.

- Quality Reports: Requesting detailed quality reports, including IQC, IPQC, and FQC results, can help buyers assess a supplier’s reliability.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes. This is particularly beneficial for international buyers who may not be able to visit production facilities.

Conclusion

A comprehensive understanding of the manufacturing processes and quality assurance measures for rucksack backpack sewing patterns is essential for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with stringent quality control measures, buyers can ensure they partner with reliable suppliers that meet their expectations. Implementing these insights will help buyers navigate the complexities of international sourcing, ensuring they receive high-quality products that align with their market requirements.

Related Video: Garments Full Production Process | Order receive to Ex-Factory | Episode 2

Comprehensive Cost and Pricing Analysis for rucksack backpack sewing pattern Sourcing

When sourcing rucksack backpack sewing patterns, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers. This analysis covers the primary cost components, price influencers, and offers actionable tips to help buyers navigate their sourcing decisions effectively.

Cost Components

-

Materials: The choice of fabric, zippers, straps, and other components significantly impacts the cost. High-quality, durable materials such as nylon or polyester may cost more upfront but can enhance the product’s longevity and appeal.

-

Labor: Labor costs vary by region and can be influenced by local wage standards. Countries with lower labor costs may offer more competitive pricing; however, this can also affect quality and craftsmanship.

-

Manufacturing Overhead: This includes factory costs such as utilities, equipment maintenance, and administrative expenses. Overhead can vary significantly depending on the production scale and location of the factory.

-

Tooling: Initial setup costs for sewing machines and molds, particularly for custom designs, can add to the overall cost. Investing in efficient tooling can reduce long-term manufacturing costs.

-

Quality Control (QC): Implementing rigorous quality control processes ensures that products meet specified standards. While this incurs additional costs, it helps mitigate returns and enhances brand reputation.

-

Logistics: Shipping costs, including freight and customs duties, must be factored into the total price. Incoterms, which define the responsibilities of buyers and sellers in international shipping, can significantly influence overall logistics costs.

-

Margin: Suppliers typically add a profit margin to cover their risks and operational costs. Understanding the margin expectations of different suppliers can help in negotiations.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to reduced per-unit costs. Buyers should evaluate their projected sales to negotiate favorable pricing based on order size.

-

Specifications/Customization: Custom designs or specifications can increase costs. Clear communication about requirements can help suppliers provide accurate pricing estimates.

-

Materials Quality and Certifications: The presence of certifications (e.g., ISO, OEKO-TEX) can add value and justify higher prices. Buyers should consider how certifications align with their brand values and customer expectations.

-

Supplier Factors: The supplier’s reputation, experience, and production capabilities can influence pricing. Building long-term relationships can lead to better pricing and service.

-

Incoterms: Understanding the implications of different Incoterms (like FOB, CIF, etc.) is crucial as they determine who bears costs and risks at various stages of the shipping process.

Buyer Tips

-

Negotiation: Always approach negotiations with a clear understanding of the cost structure. Being informed about market rates and competitor pricing can empower buyers during discussions.

-

Cost-Efficiency: Evaluate the total cost of ownership, which includes not just the purchase price but also shipping, tariffs, and potential return costs. This broader perspective can reveal the true value of a supplier.

-

Pricing Nuances: Be aware of regional pricing variations. For instance, suppliers in Africa may have different pricing structures compared to those in Europe or South America due to varying economic conditions.

-

Sample Orders: Before committing to large orders, request samples to assess quality and suitability. This can prevent costly mistakes and ensure satisfaction with the final product.

-

Market Trends: Stay updated on market trends that could affect pricing, such as fluctuations in raw material costs or shifts in consumer demand, which can lead to price adjustments.

Disclaimer

The prices and strategies mentioned herein are indicative and can vary based on specific circumstances and market conditions. Buyers should conduct their due diligence to obtain accurate quotes from multiple suppliers.

Spotlight on Potential rucksack backpack sewing pattern Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘rucksack backpack sewing pattern’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for rucksack backpack sewing pattern

When sourcing rucksack backpack sewing patterns, understanding key technical properties and industry terminology is essential for making informed purchasing decisions. This guide outlines critical specifications and common jargon that international B2B buyers, especially from Africa, South America, the Middle East, and Europe, should be familiar with.

Essential Technical Properties

-

Material Grade

– Definition: The classification of fabric based on its quality, durability, and performance characteristics.

– B2B Importance: Selecting the right material grade is crucial for ensuring the backpack meets specific functional requirements, such as weather resistance, weight capacity, and longevity. High-grade materials can enhance product appeal and customer satisfaction. -

Tolerance

– Definition: The allowable deviation from a specified dimension in the sewing pattern.

– B2B Importance: Tolerances are vital for ensuring that all components fit together correctly during production. Too tight a tolerance may lead to production delays, while too loose may compromise the product’s quality and functionality. -

Load Capacity

– Definition: The maximum weight that the rucksack can safely carry without compromising its integrity.

– B2B Importance: Understanding load capacity helps buyers determine the suitability of a backpack for specific activities, such as hiking or travel. It influences design decisions and impacts marketing strategies. -

Water Resistance

– Definition: The ability of the fabric and seams to prevent water from penetrating the backpack.

– B2B Importance: In regions prone to rain or humidity, water resistance is a critical feature that can differentiate products in the market. It can also justify a higher price point based on added value. -

Reinforcement Specifications

– Definition: Details regarding the additional stitching or materials used to strengthen areas of the backpack, such as straps and zippers.

– B2B Importance: Reinforcement is essential for durability, especially in high-stress areas. Buyers should look for patterns that specify reinforcement techniques to ensure long-lasting products. -

Sustainability Certifications

– Definition: Standards that indicate environmentally friendly practices in the sourcing and manufacturing processes.

– B2B Importance: Sustainability is increasingly becoming a purchasing criterion. Buyers should consider patterns that align with eco-friendly practices, as this can enhance brand reputation and marketability.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships can help buyers identify reliable manufacturers who can provide quality sewing patterns tailored to their specifications. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Knowing the MOQ is crucial for inventory management and cost control, especially for businesses looking to minimize risk while entering new markets. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to solicit pricing for specific products or services.

– Relevance: Utilizing RFQs can help buyers compare pricing and terms from various suppliers, leading to better negotiation outcomes. -

Incoterms (International Commercial Terms)

– Definition: A set of international rules that define the responsibilities of sellers and buyers in international transactions.

– Relevance: Familiarity with Incoterms is essential for understanding shipping responsibilities, risk transfer, and cost allocation, which can significantly impact total landed costs. -

Lead Time

– Definition: The time between the initiation of a process and its completion, often measured from the order date to the delivery date.

– Relevance: Knowing the lead time helps buyers plan their inventory and sales strategies, especially in fast-paced markets.

Illustrative Image (Source: Google Search)

- Quality Assurance (QA)

– Definition: A systematic process to ensure that products meet specified requirements and standards.

– Relevance: QA processes are vital for maintaining product consistency and reliability, which are crucial for building brand trust and customer loyalty.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can enhance their sourcing strategies for rucksack backpack sewing patterns, leading to more successful and profitable outcomes.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the rucksack backpack sewing pattern Sector

Market Overview & Key Trends

The global market for rucksack backpack sewing patterns is driven by several key factors, including the rise in outdoor activities, the growing popularity of customizable products, and the increasing demand for sustainable fashion. As consumers seek unique and personalized solutions, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe are witnessing a surge in demand for diverse and innovative sewing patterns.

Emerging technologies such as 3D printing and digital pattern making are reshaping the sourcing landscape, allowing manufacturers to produce intricate designs with greater efficiency. Buyers should consider partnerships with suppliers who leverage these technologies, as they can offer rapid prototyping and customized solutions that meet specific market needs. Furthermore, the integration of e-commerce platforms and social media marketing is facilitating direct interactions between pattern designers and consumers, enhancing brand visibility and customer engagement.

In Europe, particularly in countries like Poland, there is a notable trend toward local sourcing and production. This shift is driven by a desire for shorter supply chains, which can reduce lead times and enhance product quality. In contrast, buyers in regions such as Africa and South America may benefit from exploring partnerships with local artisans, who often bring unique cultural influences to their designs, creating a competitive edge in the marketplace.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical consideration in the rucksack backpack sewing pattern sector. The environmental impact of fabric production, waste generation, and resource depletion necessitates a shift towards more sustainable practices. B2B buyers should prioritize suppliers that demonstrate a commitment to sustainability through the use of eco-friendly materials, such as organic cotton, recycled polyester, and biodegradable fabrics.

Moreover, ethical sourcing is increasingly important, as consumers demand transparency in supply chains. Buyers should seek partnerships with manufacturers that adhere to fair labor practices and support local communities. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX can provide assurance regarding the environmental and social credentials of materials and processes.

Incorporating sustainable practices not only enhances brand reputation but also meets the growing consumer demand for environmentally responsible products. B2B buyers are encouraged to invest in suppliers who embrace sustainability as a core principle, creating a positive impact throughout the supply chain.

Brief Evolution/History

The evolution of rucksack backpack sewing patterns reflects broader trends in fashion and functionality. Initially designed for outdoor activities, these patterns have transformed to meet changing consumer preferences, incorporating advanced materials and innovative designs. Over the past two decades, the rise of DIY culture and the maker movement has further fueled interest in sewing patterns, allowing consumers to create personalized products that reflect their individual styles.

With the advent of digital technologies, the accessibility of sewing patterns has expanded significantly, enabling a global market for both buyers and creators. This evolution has led to an increasingly competitive landscape, where B2B buyers must stay informed about trends to maintain relevance and meet consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of rucksack backpack sewing pattern

-

What criteria should I use to vet suppliers of rucksack backpack sewing patterns?

When vetting suppliers, consider their experience in the industry, customer reviews, and product quality. Request samples to assess the craftsmanship and material quality. Verify certifications related to safety and environmental standards, which can be crucial for international trade. Additionally, check their production capacity to ensure they can meet your demands. Establishing direct communication with potential suppliers can also provide insights into their reliability and customer service responsiveness. -

Can I customize rucksack backpack sewing patterns according to my specifications?

Yes, many suppliers offer customization options. When discussing your requirements, be specific about materials, sizes, colors, and design modifications. Ensure to communicate any special features you need, such as compartments or closures. Customization can affect pricing and lead times, so confirm these details upfront. Additionally, inquire about the supplier’s previous custom projects to gauge their capability and creativity in fulfilling unique requests. -

What are the typical minimum order quantities (MOQs) and lead times for rucksack backpack sewing patterns?

MOQs can vary significantly among suppliers, typically ranging from 50 to 500 units depending on the complexity of the design and materials used. Lead times also fluctuate based on the supplier’s production capacity and your order size, generally ranging from 2 to 8 weeks. To avoid delays, plan your orders in advance and discuss potential bulk order discounts. Always confirm these details in your initial negotiations to set clear expectations.

Illustrative Image (Source: Google Search)

-

What payment methods are commonly accepted by suppliers?

Most international suppliers accept various payment methods, including bank transfers, PayPal, and letters of credit. Bank transfers are common for larger transactions, while PayPal may be used for smaller orders. Always confirm the payment terms, including deposit requirements and payment schedules. Be cautious of suppliers requiring full payment upfront, especially if you are working with them for the first time. Secure payment methods can provide additional protection against disputes. -

How can I ensure quality assurance (QA) for my orders?

Implementing a robust QA process is crucial. Request detailed product specifications and quality control measures from your supplier. Consider conducting third-party inspections during production and before shipment. Establish clear criteria for acceptable quality levels, and communicate these expectations to your supplier. Additionally, ensure that the supplier provides certificates of compliance with international quality standards, which can safeguard your business against subpar products. -

What certifications should I look for when sourcing rucksack backpack sewing patterns?

Look for certifications that demonstrate compliance with international standards, such as ISO 9001 for quality management and OEKO-TEX for textile safety. These certifications can reassure you of the supplier’s commitment to quality and safety. For products exported to specific regions, such as the EU or North America, additional certifications may be required. Always verify the authenticity of these certifications by requesting documentation from the supplier. -

What logistics considerations should I keep in mind when importing rucksack backpack sewing patterns?

Logistics are critical in international trade. Understand the shipping options available, such as air freight for quicker delivery or sea freight for cost-effectiveness. Discuss responsibilities for customs clearance and duties with your supplier. Ensure that the supplier has experience handling international shipments and can provide necessary shipping documentation. Consider working with a logistics partner familiar with your target market to streamline the process and mitigate risks. -

How should I handle disputes with suppliers?

To effectively manage disputes, maintain clear and open communication with your supplier. Establish a contract that outlines terms, conditions, and the dispute resolution process. If a disagreement arises, attempt to resolve it amicably through dialogue. If necessary, escalate the issue to a mediation process or arbitration, as specified in your contract. Document all communications and agreements related to the dispute, as this will help in resolving issues efficiently and protecting your interests.

Strategic Sourcing Conclusion and Outlook for rucksack backpack sewing pattern

In conclusion, strategic sourcing of rucksack backpack sewing patterns presents a significant opportunity for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. By leveraging local production capabilities and tapping into emerging markets, businesses can enhance their supply chains, reduce costs, and respond more swiftly to consumer demands.

Key takeaways include:

- Supplier Diversity: Engaging with suppliers from various regions can mitigate risks and foster innovation in product design.

- Cost Efficiency: Local sourcing can lower shipping costs and reduce lead times, making it an attractive option for businesses looking to optimize their operations.

- Sustainability: Increasingly, buyers are prioritizing eco-friendly materials and ethical manufacturing processes, which can enhance brand reputation and customer loyalty.

As the global market continues to evolve, embracing these sourcing strategies will be critical for staying competitive. Now is the time to explore new partnerships and invest in sustainable practices that not only meet current market demands but also anticipate future trends. By doing so, businesses can position themselves as leaders in the rucksack backpack sector, driving growth and innovation in the years to come.

Illustrative Image (Source: Google Search)