Your Ultimate Guide to Sourcing Rucksack Backpack Pattern

Guide to Rucksack Backpack Pattern

- Introduction: Navigating the Global Market for rucksack backpack pattern

- Understanding rucksack backpack pattern Types and Variations

- Key Industrial Applications of rucksack backpack pattern

- Strategic Material Selection Guide for rucksack backpack pattern

- In-depth Look: Manufacturing Processes and Quality Assurance for rucksack backpack pattern

- Comprehensive Cost and Pricing Analysis for rucksack backpack pattern Sourcing

- Spotlight on Potential rucksack backpack pattern Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for rucksack backpack pattern

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the rucksack backpack pattern Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of rucksack backpack pattern

- Strategic Sourcing Conclusion and Outlook for rucksack backpack pattern

Introduction: Navigating the Global Market for rucksack backpack pattern

In an increasingly interconnected global marketplace, the demand for high-quality rucksack backpack patterns is surging. These patterns are essential for manufacturers aiming to produce durable, functional, and stylish backpacks that meet the diverse needs of consumers across various regions. For international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, understanding the intricacies of rucksack backpack patterns is critical to making informed sourcing decisions.

This comprehensive guide delves into the multifaceted world of rucksack backpack patterns, covering essential topics such as types of patterns, material selections, manufacturing processes, and quality control measures. Buyers will also find valuable insights into supplier evaluations, cost considerations, and current market trends. The guide aims to empower businesses by providing actionable information that facilitates successful procurement strategies.

By leveraging the insights within this guide, international B2B buyers can enhance their product offerings, streamline supply chain processes, and ultimately drive profitability. Whether you are a retailer, a manufacturer, or a wholesaler, navigating the global market for rucksack backpack patterns is crucial for staying competitive and meeting the evolving demands of your customers. Get ready to unlock the potential of your business with informed sourcing decisions that cater to diverse markets and consumer preferences.

Understanding rucksack backpack pattern Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Rucksack | Classic design with top flap closure and drawstring | Outdoor gear, travel, education | Pros: Durable, versatile; Cons: Can be bulky for urban use |

| Hydration Pack | Integrated water reservoir and tube for easy access | Hiking, biking, sports | Pros: Lightweight, convenient hydration; Cons: Limited storage space |

| Tactical Backpack | Military-inspired features like MOLLE webbing | Law enforcement, military, outdoor | Pros: Highly customizable, durable; Cons: Heavier than standard backpacks |

| Laptop Rucksack | Dedicated padded compartment for laptops | Corporate, education, travel | Pros: Provides protection for devices; Cons: May lack extra storage for other gear |

| Eco-Friendly Rucksack | Made from sustainable materials like recycled fabrics | Green initiatives, eco-conscious buyers | Pros: Appeals to environmentally conscious consumers; Cons: May be pricier than conventional options |

Traditional Rucksack

The traditional rucksack is characterized by its classic design, often featuring a top flap closure and a drawstring for securing contents. It is widely used in outdoor gear, travel, and educational contexts. B2B buyers should consider the durability and versatility of this type, as it can accommodate various activities. However, its bulkiness may be a drawback for urban users who prefer a sleeker profile.

Hydration Pack

Hydration packs come with an integrated water reservoir and a drinking tube, making them ideal for hiking, biking, and sports. These packs are lightweight and designed for convenience, allowing users to stay hydrated on the go. For B2B buyers, the focus should be on the pack’s comfort and ease of use. However, the limited storage space may restrict its utility for longer trips or when carrying additional gear.

Tactical Backpack

Tactical backpacks are designed with military-inspired features, including MOLLE webbing for attaching additional gear. They are commonly used in law enforcement, military operations, and outdoor activities. Buyers in B2B markets should note the customization options and durability that these backpacks offer. However, they tend to be heavier than standard backpacks, which might be a consideration for users seeking lightweight alternatives.

Laptop Rucksack

The laptop rucksack includes a dedicated padded compartment for laptops, making it suitable for corporate, educational, and travel applications. This design provides essential protection for electronic devices, which is a significant consideration for B2B buyers in tech-driven industries. While these backpacks excel in device safety, they may lack additional storage for other items, which could limit their functionality for some users.

Eco-Friendly Rucksack

Eco-friendly rucksacks are crafted from sustainable materials, such as recycled fabrics, appealing to businesses focused on green initiatives. These backpacks resonate with eco-conscious buyers and can enhance a brand’s image. B2B purchasers should weigh the environmental benefits against potential higher costs compared to conventional options. While these backpacks can attract a specific customer segment, their price point may deter some buyers looking for budget-friendly solutions.

Related Video: Leather Rucksack? You’ll Be Surprised How Simple It Is! (FREE Pattern & Tutorial)

Key Industrial Applications of rucksack backpack pattern

| Industry/Sector | Specific Application of rucksack backpack pattern | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Outdoor Recreation | Custom hiking backpacks | Enhanced brand loyalty through customized products | Material durability, waterproofing options |

| Education | School backpacks for students | Increased student engagement and satisfaction | Safety standards, ergonomic design, and affordability |

| Military & Defense | Tactical gear for soldiers | Improved operational efficiency and soldier comfort | Compliance with military specifications and standards |

| Logistics & Shipping | Transport backpacks for delivery personnel | Streamlined operations and improved delivery speed | Weight capacity, material strength, and cost-effectiveness |

| Sports & Fitness | Gym bags and sports backpacks | Brand differentiation in a competitive market | Breathability, lightweight materials, and storage options |

Outdoor Recreation

In the outdoor recreation industry, the rucksack backpack pattern is utilized to create custom hiking backpacks that cater to specific user needs. These backpacks can be tailored with pockets for hydration systems, gear loops for climbing equipment, and adjustable straps for comfort. For international B2B buyers, particularly in regions like Africa and South America, sourcing durable and weather-resistant materials is crucial. Additionally, local manufacturing can help meet specific environmental conditions, enhancing the usability of the product.

Education

Educational institutions often adopt the rucksack backpack pattern to design school backpacks that are not only functional but also appealing to students. These backpacks can be customized with school logos, vibrant colors, and ergonomic features to support young learners. B2B buyers in Europe and the Middle East should prioritize safety standards, ensuring that materials used are non-toxic and comply with local regulations. Affordability is also key, as schools often operate under tight budgets.

Military & Defense

In the military and defense sector, the rucksack backpack pattern is critical for producing tactical gear that meets rigorous operational demands. These backpacks are designed for durability and functionality, featuring compartments for essential gear, hydration systems, and modular attachments. Buyers in this sector must ensure compliance with military specifications, focusing on materials that withstand harsh environments. Additionally, suppliers should be vetted for their ability to meet stringent delivery timelines and quality assurance processes.

Logistics & Shipping

For logistics and shipping companies, the rucksack backpack pattern is applied in creating transport backpacks for delivery personnel. These backpacks can be designed to hold packages securely while allowing for easy access and mobility. The key benefits include streamlined operations and improved delivery speed, which are essential in a competitive market. B2B buyers need to consider the weight capacity and material strength of the backpacks to ensure they can handle various package sizes while remaining cost-effective.

Sports & Fitness

In the sports and fitness industry, the rucksack backpack pattern is leveraged to develop gym bags and sports backpacks that resonate with active consumers. These bags can include features such as breathable materials, separate compartments for shoes and wet clothes, and lightweight designs. Buyers should focus on brand differentiation in a crowded market, ensuring that the bags are not only functional but also stylish. Key sourcing considerations include the use of moisture-wicking fabrics and innovative storage solutions to enhance user experience.

Related Video: DIY LOVELY BACKPACK TUTORIAL // Zipper Backpack with Pocket From Scratch Cut & Sew

Strategic Material Selection Guide for rucksack backpack pattern

When selecting materials for rucksack backpack patterns, international B2B buyers must consider various factors that affect performance, durability, and cost. Below is an analysis of four common materials used in the production of rucksacks, tailored to the needs of buyers from Africa, South America, the Middle East, and Europe.

1. Nylon

Key Properties:

Nylon is known for its exceptional strength-to-weight ratio, making it ideal for backpacks that require durability without adding excessive weight. It is resistant to abrasion and has a good degree of water resistance, especially when treated with coatings.

Pros & Cons:

Pros include high tensile strength and flexibility, which contribute to the longevity of the product. However, nylon can be more expensive than other materials and may require additional treatments to enhance water resistance.

Impact on Application:

Nylon’s compatibility with various weather conditions makes it suitable for outdoor applications. It performs well in both humid and dry environments, which is advantageous for diverse climates across continents.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM and ISO for textile products. Additionally, sourcing from suppliers who adhere to sustainable practices can enhance brand reputation in environmentally conscious markets.

2. Polyester

Key Properties:

Polyester is a synthetic fabric that offers good resistance to UV light, moisture, and mildew. It is less expensive than nylon and can be produced in various weights, making it versatile for different backpack designs.

Pros & Cons:

The primary advantage of polyester is its affordability and ease of maintenance. However, it is generally less durable than nylon and may not withstand heavy wear and tear as effectively.

Impact on Application:

Polyester is suitable for casual and urban backpacks, where exposure to harsh conditions is limited. Its lightweight nature makes it ideal for everyday use.

Considerations for International Buyers:

Buyers should verify the fabric’s compliance with local regulations regarding chemical treatments and dyeing processes, especially in regions with strict environmental laws.

3. Cordura Fabric

Key Properties:

Cordura is a brand of fabric known for its durability and resistance to abrasions, tears, and scuffs. It is often made from nylon but can also be blended with other fibers for enhanced performance.

Pros & Cons:

Cordura’s main advantage is its exceptional durability, making it suitable for heavy-duty applications. However, it tends to be more expensive than standard nylon or polyester, which may affect budget constraints.

Impact on Application:

This fabric is ideal for military and tactical backpacks that require high performance under extreme conditions. Its robustness makes it suitable for rugged outdoor activities.

Considerations for International Buyers:

Buyers should look for certifications that prove the fabric’s durability and performance, such as the Military Specification (MIL-SPEC) standards. Understanding the supply chain for Cordura can also help in managing costs and lead times.

4. Canvas

Key Properties:

Canvas is a heavy-duty fabric that is typically made from cotton or a cotton-polyester blend. It is known for its sturdiness and breathability, making it a classic choice for backpacks.

Pros & Cons:

Canvas is durable and can be treated for water resistance, but it is heavier than synthetic options. It may also be less resistant to mold and mildew if not properly treated.

Impact on Application:

Canvas backpacks are often favored for their aesthetic appeal and are commonly used in urban and casual settings. They can also be used for light outdoor activities.

Considerations for International Buyers:

Buyers should consider the environmental impact of cotton sourcing and manufacturing processes. Compliance with organic standards can be a selling point in markets that prioritize sustainability.

| Material | Typical Use Case for rucksack backpack pattern | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | Lightweight, durable backpacks for outdoor use | High strength-to-weight ratio | Higher cost compared to other options | High |

| Polyester | Casual and urban backpacks | Affordable and easy to maintain | Less durable than nylon | Low |

| Cordura Fabric | Heavy-duty, tactical backpacks | Exceptional durability | More expensive than standard fabrics | High |

| Canvas | Urban and casual backpacks | Sturdy and breathable | Heavier, less resistant to mold | Medium |

This strategic material selection guide provides insights that can help international B2B buyers make informed decisions when sourcing materials for rucksack backpack patterns. Understanding the properties, advantages, and limitations of each material will facilitate better alignment with market demands and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for rucksack backpack pattern

The manufacturing of rucksack backpacks involves several critical processes that ensure the final product meets quality standards and customer expectations. This section provides an in-depth look at the manufacturing stages, key techniques used, and the quality assurance measures that international B2B buyers should be aware of.

Manufacturing Processes

1. Material Preparation

Material preparation is the first and crucial step in the manufacturing process. Rucksack backpacks are typically made from various materials, including:

- Fabrics: Common choices include nylon, polyester, and cotton canvas, known for their durability and resistance to wear and tear.

- Hardware: Components such as zippers, buckles, and straps are sourced from reliable suppliers to ensure quality.

- Lining and Padding: Materials for lining (like mesh or nylon) and padding (like foam) are selected based on the intended use of the backpack.

The selection of materials must consider environmental factors, especially for buyers from regions like Africa and South America, where climate and terrain can affect the backpack’s performance.

2. Forming

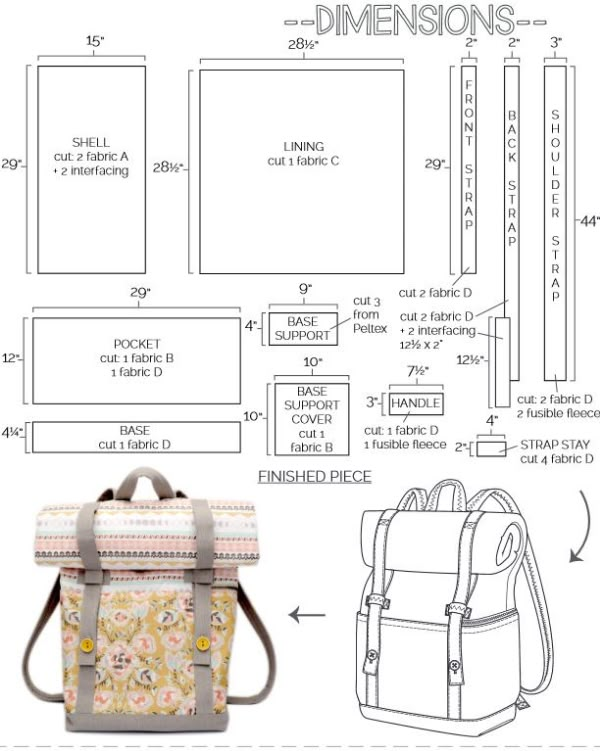

This stage involves cutting the prepared materials into specific shapes and sizes according to the rucksack backpack pattern. Key techniques include:

- Die Cutting: Automated machines are used to cut multiple layers of fabric simultaneously, increasing efficiency and precision.

- Laser Cutting: This method offers high accuracy, especially for intricate designs and patterns, ensuring that each piece fits perfectly during assembly.

Proper forming is essential to minimize waste and ensure uniformity across all produced backpacks.

3. Assembly

The assembly process is where the cut materials are stitched together to form the backpack. This involves several steps:

- Sewing: Industrial sewing machines are employed to join the fabric pieces. Techniques like double stitching or reinforced stitching are used to enhance durability.

- Attachment of Hardware: Zippers, straps, and other components are attached at this stage, ensuring they are secure and functional.

- Quality Checks: Inline quality checks (IPQC) are conducted during the assembly to catch defects early, reducing rework costs.

Efficient assembly lines can significantly impact production timelines, an important factor for B2B buyers needing timely deliveries.

4. Finishing

The finishing stage includes any final touches to ensure the backpack meets design specifications and quality standards. Key activities include:

- Trimming: Excess threads and fabric edges are trimmed for a clean look.

- Waterproofing and Coating: Many manufacturers apply a waterproof coating to enhance the backpack’s durability against the elements.

- Final Inspection: A thorough examination of the finished product ensures that it meets all quality requirements before packaging.

Quality Assurance

Quality assurance (QA) is critical in the manufacturing process, especially for international B2B transactions where standards may vary across regions. Key aspects of QA include:

Relevant International Standards

International standards such as ISO 9001 provide a framework for quality management systems. Adhering to these standards demonstrates a commitment to quality, which is particularly important for buyers from Europe and other regions with strict regulatory requirements.

Illustrative Image (Source: Google Search)

- CE Marking: In Europe, the CE mark indicates compliance with health, safety, and environmental protection standards.

- API Standards: For specialized backpacks (e.g., military or tactical), compliance with American Petroleum Institute (API) standards may be relevant.

QC Checkpoints

Quality control (QC) checkpoints are integral to maintaining product quality. Common checkpoints include:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process to detect and rectify issues promptly.

- Final Quality Control (FQC): A thorough review of the finished product, including functionality tests and visual inspections.

Common Testing Methods

Several testing methods are employed to ensure the quality and performance of rucksack backpacks:

- Tensile Strength Testing: Measures the force required to pull the fabric apart, ensuring it can withstand heavy loads.

- Water Resistance Testing: Evaluates how well the materials can repel water.

- Color Fastness Testing: Assesses the fabric’s resistance to fading when exposed to light or washing.

Verifying Supplier Quality Control

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are actionable strategies:

- Audits: Conduct regular audits of the manufacturing facilities to ensure compliance with quality standards and operational efficiency.

- Reports: Request detailed quality control reports from suppliers, including inspection results and compliance certifications.

- Third-Party Inspections: Utilize third-party inspection services to conduct unbiased assessments of the manufacturing process and final products.

QC/Cert Nuances for International B2B Buyers

Understanding the nuances of quality control and certification is vital for international buyers. Here are key considerations:

- Cultural Differences: Awareness of different cultural approaches to quality can affect negotiations and expectations. For example, buyers from Europe may prioritize stringent quality checks compared to those from other regions.

- Regulatory Compliance: Ensure that suppliers are aware of and comply with both local and international regulations concerning product safety and quality.

- Language Barriers: Clear communication is essential. Consider hiring translators or quality consultants who can bridge gaps and ensure that quality expectations are understood.

By focusing on these manufacturing processes and quality assurance measures, international B2B buyers can make informed decisions when sourcing rucksack backpacks, ensuring they receive high-quality products that meet their specific needs.

Related Video: How a Backpack is Made : Every Step on the Production Line

Comprehensive Cost and Pricing Analysis for rucksack backpack pattern Sourcing

The sourcing of rucksack backpack patterns involves a multifaceted cost structure that international B2B buyers must navigate to ensure profitability and efficiency. Understanding the various components of costs and the factors influencing pricing can provide valuable insights for making informed purchasing decisions.

Cost Components

-

Materials: The choice of fabric (e.g., ripstop nylon, canvas) significantly affects the overall cost. Premium materials can range from $5 to $20 per yard, depending on quality and specifications. Additional components, such as zippers and webbing, also contribute to material costs.

-

Labor: Labor costs vary by region and the complexity of the design. In countries with lower labor costs, like some in Africa and South America, the hourly wage might be as low as $2-$5, whereas in Europe, it can range from $15 to $30. The time taken to produce a pattern, which may require skilled labor, can add to this cost.

-

Manufacturing Overhead: This includes utilities, rent, and equipment depreciation. Typically, overhead can account for 10-20% of total production costs. Efficient manufacturing practices can help lower these expenses.

-

Tooling: Initial setup costs for creating patterns can be substantial, especially for custom designs. This cost can be amortized over larger production runs, making it essential to consider Minimum Order Quantities (MOQs).

-

Quality Control (QC): Implementing QC processes ensures the final product meets specifications, which can add 5-10% to production costs. Buyers should insist on quality certifications to avoid defects and returns.

-

Logistics: Shipping costs can vary significantly based on the distance from the supplier to the buyer, the chosen Incoterms, and the mode of transport. Air freight is faster but more expensive than sea freight, which is often preferred for bulk orders.

Illustrative Image (Source: Google Search)

- Margin: Suppliers typically add a margin of 15-30% on top of their costs. Understanding the supplier’s pricing strategy can help buyers negotiate better deals.

Price Influencers

-

Volume/MOQ: Larger orders typically yield lower per-unit costs. Suppliers may offer significant discounts for bulk purchases, making it economically beneficial for buyers to consolidate orders.

-

Specifications/Customization: Custom patterns and specific features (e.g., waterproofing, additional pockets) can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality/Certifications: Higher-quality materials and certifications (like ISO or environmental standards) can drive up costs but may lead to better performance and customer satisfaction.

-

Supplier Factors: The supplier’s location, reputation, and production capacity can influence pricing. It is crucial to assess the supplier’s reliability and track record.

-

Incoterms: The choice of Incoterms affects logistics costs and responsibilities. For example, DDP (Delivered Duty Paid) includes all costs until delivery, while FOB (Free on Board) places more responsibility on the buyer.

Buyer Tips

-

Negotiation: Always negotiate prices, especially for large orders. Highlighting long-term relationships can incentivize suppliers to offer better rates.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes all associated costs such as shipping, duties, and QC. A cheaper upfront price might lead to higher long-term costs.

-

Pricing Nuances: International buyers should be aware of currency fluctuations and potential tariffs that could affect the final price. It’s wise to lock in prices when favorable exchange rates occur.

Disclaimer

Prices mentioned above are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Buyers should conduct thorough market research and supplier assessments to obtain accurate pricing tailored to their needs.

Illustrative Image (Source: Google Search)

Spotlight on Potential rucksack backpack pattern Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘rucksack backpack pattern’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for rucksack backpack pattern

Critical Specifications for Rucksack Backpack Patterns

Understanding the essential technical properties of rucksack backpack patterns is crucial for international B2B buyers, especially when sourcing materials and components. Below are some key specifications:

-

Material Grade: The quality of fabric used in rucksack backpacks is paramount. Common materials include nylon, polyester, and canvas. For instance, ripstop nylon is known for its durability and resistance to tearing, making it ideal for rugged outdoor use. Selecting the right material grade ensures the backpack can withstand environmental stresses, which is critical for customer satisfaction and brand reputation.

-

Tolerance: This refers to the acceptable deviation in dimensions during manufacturing. For example, a rucksack pattern might specify a tolerance of ±0.5 cm for seams and zippers. Understanding tolerances is essential for ensuring that all components fit together correctly, reducing the risk of returns or customer dissatisfaction due to poor fit.

-

Water Resistance Rating: This specification indicates how well the material can repel water. Measured in millimeters, a higher rating (e.g., 1000mm) signifies better water resistance. For B2B buyers, knowing the water resistance can help in targeting specific markets, such as outdoor enthusiasts or urban commuters.

-

Weight Capacity: This indicates the maximum load the backpack can safely carry. Manufacturers often specify this in kilograms or pounds. Understanding weight capacity is crucial for buyers aiming to meet customer needs in various segments, from casual users to serious hikers.

-

Durability Standards: This encompasses various tests, such as abrasion resistance and tensile strength. For instance, a rucksack may be tested to withstand a certain number of rubs before showing wear. Knowledge of durability standards helps buyers assess product longevity, which is a key selling point in competitive markets.

Common Trade Terminology

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B landscape. Below are some common terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For rucksack backpacks, understanding OEM relationships can help buyers source high-quality components efficiently.

-

MOQ (Minimum Order Quantity): This is the smallest number of units that a supplier is willing to sell. Knowing the MOQ is critical for buyers to plan inventory and manage cash flow, especially in markets where demand fluctuates.

-

RFQ (Request for Quotation): An RFQ is a document issued by a buyer to request price proposals from suppliers. This process is vital for B2B buyers to gauge market rates and ensure they are getting competitive pricing for rucksack patterns.

-

Incoterms (International Commercial Terms): These are a series of pre-defined commercial terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs and risks, making it easier to negotiate terms with suppliers.

-

Lead Time: This refers to the time it takes from placing an order to receiving the goods. Understanding lead time is essential for B2B buyers to manage their supply chain effectively and ensure timely product availability in their markets.

By grasping these specifications and trade terms, international B2B buyers can make informed decisions when sourcing rucksack backpack patterns, ultimately leading to better product offerings and enhanced customer satisfaction.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the rucksack backpack pattern Sector

Market Overview & Key Trends

The rucksack backpack pattern sector is witnessing significant growth driven by increasing consumer demand for multifunctional and durable products. Key markets in Africa, South America, the Middle East, and Europe are seeing a surge in outdoor activities and urban commuting, which in turn fuels the need for high-quality backpacks. B2B buyers are increasingly focused on sourcing products that offer innovative designs and sustainable materials. Emerging trends include the integration of technology in backpacks, such as built-in charging ports and smart features, which cater to the tech-savvy consumer base.

Additionally, the rise of e-commerce platforms has transformed sourcing dynamics, enabling international buyers to access a broader range of suppliers and products. Buyers from regions like Brazil and Argentina are particularly interested in leveraging online marketplaces to find unique patterns and designs that resonate with local preferences. Supply chain diversification is another trend; buyers are seeking suppliers who can provide reliable, high-quality materials at competitive prices while ensuring ethical practices. As the market evolves, collaborations between manufacturers and designers are becoming more common, allowing for customization and the creation of exclusive product lines.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly becoming a cornerstone of purchasing decisions in the rucksack backpack pattern sector. Buyers are now prioritizing environmentally friendly materials and production processes, recognizing the importance of minimizing environmental impact. The use of recycled fabrics, organic cotton, and biodegradable materials is gaining traction, appealing to eco-conscious consumers and businesses alike.

Moreover, ethical sourcing is critical for building trust with customers and enhancing brand reputation. B2B buyers should seek suppliers who adhere to fair labor practices and possess certifications such as Global Organic Textile Standard (GOTS) or OEKO-TEX, which ensure sustainable and ethical production processes. These certifications not only validate the sustainability claims of products but also attract a growing segment of consumers who prefer to support environmentally responsible brands. By aligning purchasing strategies with sustainability goals, businesses can differentiate themselves in a competitive market and contribute positively to global environmental efforts.

Brief Evolution/History

The rucksack backpack has evolved significantly from its origins as a simple storage solution for hikers and outdoor enthusiasts. Initially crafted from durable canvas and leather, the design has transformed with advancements in materials and technology. The introduction of lightweight synthetic fabrics, such as nylon and polyester, has enhanced the functionality and durability of backpacks, making them suitable for a wider range of activities.

In recent years, the focus has shifted towards customization and unique patterns that cater to diverse consumer tastes. This evolution reflects broader trends in the fashion and outdoor industries, where personalization and sustainability are becoming paramount. As international B2B buyers navigate this dynamic landscape, understanding these historical shifts can inform better sourcing decisions and align product offerings with current market demands.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of rucksack backpack pattern

-

What should I consider when vetting suppliers for rucksack backpack patterns?

When vetting suppliers, evaluate their experience in the industry, production capabilities, and reputation. Request samples of their previous work to assess quality and craftsmanship. It’s also vital to check for certifications, such as ISO standards, which indicate adherence to quality management systems. Additionally, consider their financial stability and ability to meet your specific demands, including customization options and timelines. Establishing clear communication with potential suppliers is crucial to ensure alignment on expectations and requirements. -

Can I customize the rucksack backpack patterns to suit my brand?

Yes, most reputable suppliers offer customization options. This can include adjustments in design, color, fabric choice, and branding elements such as logos. Discuss your specific needs upfront and request a portfolio of past customization projects to gauge their capabilities. Keep in mind that extensive customization may affect the minimum order quantities (MOQs) and lead times, so clarify these details during negotiations to avoid surprises later. -

What are the typical minimum order quantities (MOQs) for rucksack backpack patterns?

MOQs can vary significantly based on the supplier and the complexity of the order. Generally, for customized patterns, MOQs may range from 100 to 500 units. However, some suppliers might offer lower MOQs for standard patterns. It’s essential to confirm MOQs during your initial discussions, as they can impact your budgeting and inventory management strategies. If you require a smaller quantity, inquire about potential options or additional costs for lower MOQs. -

What are the common lead times for receiving rucksack backpack patterns?

Lead times depend on several factors, including the supplier’s location, the complexity of the design, and current production capacity. Typically, lead times can range from 4 to 12 weeks. For customized orders, anticipate longer lead times due to design approval processes and production adjustments. Ensure you establish a clear timeline with the supplier at the outset, and consider building in buffer time for potential delays, especially when planning for seasonal demands. -

How can I ensure quality assurance and compliance with certifications?

To ensure quality, request detailed documentation of the supplier’s quality assurance processes. This might include inspection reports, testing results, and compliance with international standards such as ISO 9001. Additionally, consider conducting on-site visits or third-party audits to verify their manufacturing practices. Implementing a clear quality control checklist that aligns with your specifications can help maintain product integrity and mitigate risks associated with defects or non-compliance. -

What payment methods are typically accepted by suppliers, and what are the associated risks?

Common payment methods include wire transfers, letters of credit, and online payment platforms. Each method has its own risk profile; for instance, wire transfers may offer less buyer protection compared to letters of credit, which provide a safeguard against non-delivery. Clarify payment terms, including deposits and final payments, before confirming orders. It’s advisable to negotiate terms that provide you with adequate protection while also ensuring the supplier feels secure in the transaction. -

What logistics considerations should I keep in mind when sourcing from international suppliers?

Key logistics considerations include shipping methods, customs regulations, and potential tariffs. Assess the best shipping options based on cost, speed, and reliability. Familiarize yourself with the customs requirements in your country to avoid delays or additional fees. Collaborating with a logistics provider who understands the nuances of international shipping can streamline the process and ensure compliance with all regulations, reducing the risk of disputes or lost shipments. -

How should I handle disputes with suppliers during the sourcing process?

To effectively handle disputes, establish a clear communication channel with your supplier from the beginning. Document all agreements and correspondence to provide a reference in case of misunderstandings. If a dispute arises, approach it professionally and aim for resolution through discussion. If necessary, utilize a mediator or arbitrator to facilitate a resolution. Having a well-defined contract that includes terms for dispute resolution can also help mitigate risks and clarify the process should issues occur.

Strategic Sourcing Conclusion and Outlook for rucksack backpack pattern

In conclusion, strategic sourcing for rucksack backpack patterns represents a vital opportunity for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. By focusing on quality materials and innovative designs, businesses can effectively meet the diverse demands of their markets. The integration of sustainable practices and adaptability in sourcing can significantly enhance product appeal and competitiveness.

Key Takeaways:

- Quality Over Quantity: Prioritize sourcing high-quality fabrics and components that enhance durability and functionality, ensuring customer satisfaction and brand loyalty.

- Sustainability Matters: Engage suppliers who prioritize eco-friendly materials and production processes, aligning with the growing consumer preference for sustainable products.

- Customization Opportunities: Leverage the demand for personalized rucksack designs to differentiate your offerings in the marketplace.

As the global market continues to evolve, buyers should remain proactive in exploring emerging trends and technologies. Embrace partnerships that foster innovation and efficiency in production. By doing so, you can position your business for success in a competitive landscape. Take action today—evaluate your sourcing strategies and make informed decisions that will drive growth in your rucksack backpack offerings.