Unlock Profitable Sourcing Strategies for Square Backpacks

Guide to Square Backpack

- Introduction: Navigating the Global Market for square backpack

- Understanding square backpack Types and Variations

- Key Industrial Applications of square backpack

- Strategic Material Selection Guide for square backpack

- In-depth Look: Manufacturing Processes and Quality Assurance for square backpack

- Comprehensive Cost and Pricing Analysis for square backpack Sourcing

- Spotlight on Potential square backpack Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for square backpack

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the square backpack Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of square backpack

- Strategic Sourcing Conclusion and Outlook for square backpack

Introduction: Navigating the Global Market for square backpack

In today’s dynamic global market, the square backpack has emerged as a vital product for businesses across various sectors, from education to outdoor recreation. As a versatile and functional accessory, it caters to the growing demand for stylish yet practical solutions, making it an attractive option for international B2B buyers. Understanding the nuances of sourcing square backpacks can significantly impact your supply chain efficiency and product offerings.

This comprehensive guide delves into the essential aspects of square backpacks, covering everything from types and materials to manufacturing processes and quality control standards. It provides insights into leading suppliers from key manufacturing regions, highlighting their unique advantages and capabilities. By examining factors such as cost structures, market trends, and compliance with social and environmental standards, this guide equips buyers with the knowledge necessary to make informed sourcing decisions.

For international buyers from Africa, South America, the Middle East, and Europe, understanding the intricacies of the square backpack market is crucial for optimizing procurement strategies. With the right information, businesses can navigate the complexities of global sourcing, leverage competitive advantages, and ultimately enhance their product offerings. This guide serves as a valuable resource, empowering you to confidently engage with suppliers and capitalize on the growing demand for square backpacks in diverse markets.

Understanding square backpack Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Square Backpack | Simple, boxy design with a large main compartment | School supplies, corporate gifts | Pros: Cost-effective, versatile. Cons: Basic design may lack premium appeal. |

| Technical Square Backpack | Enhanced features like hydration reservoirs and gear loops | Outdoor gear, adventure sports | Pros: Durable, functional. Cons: Typically higher cost, may be over-engineered for casual use. |

| Fashion Square Backpack | Trendy materials and designs, often with branding | Fashion retail, promotional giveaways | Pros: Attractive to younger demographics. Cons: Higher price point, may sacrifice utility for style. |

| Eco-Friendly Square Backpack | Made from sustainable materials, often with a focus on reducing environmental impact | Corporate sustainability initiatives, eco-conscious brands | Pros: Strong brand alignment with sustainability. Cons: May have limited color/design options. |

| Modular Square Backpack | Interchangeable components, customizable compartments | Corporate events, tech storage solutions | Pros: Highly customizable, adaptable. Cons: Potentially complex design, may require user education. |

Classic Square Backpack

The classic square backpack is characterized by its straightforward, boxy shape and large main compartment. This type is widely used for school supplies and corporate gifts, making it a staple in the B2B market. Buyers appreciate its cost-effectiveness and versatility, although its basic design might not appeal to brands looking to convey a premium image. When sourcing, consider factors like material durability and branding options to enhance marketability.

Technical Square Backpack

Designed for outdoor enthusiasts, the technical square backpack features enhanced functionalities such as hydration reservoirs, gear loops, and reinforced stitching. This type is ideal for B2B applications in the outdoor gear and adventure sports sectors. While these backpacks are known for their durability and functionality, they often come at a higher price point. Buyers should weigh the benefits of advanced features against their target market’s needs and budget constraints.

Fashion Square Backpack

Fashion square backpacks are distinguished by their trendy materials and designs, often featuring prominent branding. These backpacks cater primarily to fashion retail and promotional giveaways aimed at younger demographics. While they can command a higher price point due to their stylish appeal, buyers should be cautious as these products may sacrifice utility for aesthetics. When selecting suppliers, look for those who can balance style with practicality to meet customer expectations.

Eco-Friendly Square Backpack

The eco-friendly square backpack is crafted from sustainable materials, emphasizing environmental responsibility. This type is particularly relevant for businesses focused on corporate sustainability initiatives and eco-conscious branding. Buyers will find that these backpacks align well with modern consumer values, but they may have limited options in terms of color and design. Sourcing from manufacturers that prioritize sustainability can enhance brand reputation and appeal to a growing market segment.

Modular Square Backpack

Modular square backpacks feature interchangeable components and customizable compartments, making them highly adaptable for various uses. They are particularly suited for corporate events and tech storage solutions, where flexibility is essential. While the customization options can be a significant advantage, the complexity of the design may require additional education for users. Buyers should assess the market demand for modularity against the potential learning curve for their customers.

Related Video: Large Language Models (LLMs) – Everything You NEED To Know

Key Industrial Applications of square backpack

| Industry/Sector | Specific Application of Square Backpack | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Education | Student backpacks for schools and universities | Enhances student mobility and organization | Durability, design for comfort, eco-friendly materials |

| Outdoor Recreation | Hiking and travel backpacks | Provides convenience and storage for outdoor gear | Weather-resistant fabrics, ergonomic design, scalability |

| Corporate Gifts | Branded promotional backpacks | Strengthens brand visibility and customer loyalty | Customization options, quality assurance, lead times |

| Logistics and Transport | Cargo backpacks for delivery personnel | Increases efficiency in carrying goods | Load capacity, material strength, compliance with safety standards |

| Retail | Fashionable square backpacks for retail outlets | Appeals to trend-conscious consumers | Style variety, pricing strategies, seasonal availability |

Education

In the education sector, square backpacks are extensively used by students in schools and universities. These backpacks are designed to provide ample space for books, laptops, and other educational materials, enhancing mobility and organization. For international buyers, particularly in regions like Africa and South America, sourcing durable and stylish backpacks that can withstand daily wear and tear is crucial. Eco-friendly materials are increasingly sought after due to growing environmental awareness among consumers.

Outdoor Recreation

Square backpacks are essential for outdoor enthusiasts, particularly in hiking and travel applications. These backpacks offer a practical solution for carrying gear, snacks, and personal items during excursions. Buyers should prioritize sourcing weather-resistant fabrics and ergonomic designs to ensure comfort during long hikes. Additionally, scalability is vital for businesses looking to cater to varying customer demands in different regions, especially in Europe where outdoor activities are popular.

Corporate Gifts

In the realm of corporate gifting, branded square backpacks serve as effective promotional items. They not only enhance brand visibility but also foster customer loyalty by providing a practical product that recipients can use daily. Key considerations for international B2B buyers include customization options that align with brand identity, quality assurance to maintain a positive brand image, and lead times that align with marketing campaigns.

Logistics and Transport

In logistics, square backpacks are utilized by delivery personnel for transporting goods efficiently. These backpacks are designed to handle varying loads while ensuring comfort for the wearer. When sourcing for this application, businesses must consider load capacity, material strength, and compliance with safety standards to protect both the goods being transported and the individuals carrying them.

Retail

The retail sector sees a demand for fashionable square backpacks that appeal to trend-conscious consumers. Retailers can leverage these backpacks to enhance their product offerings, especially during seasonal promotions. Key sourcing considerations include a variety of styles to cater to diverse consumer preferences, competitive pricing strategies to maximize margins, and ensuring availability to meet seasonal demand spikes.

Related Video: 10 Nifty Uses for Oscillating Multitool Saws

Strategic Material Selection Guide for square backpack

When selecting materials for square backpacks, international B2B buyers must consider a variety of factors that impact product performance, durability, and cost. Here, we analyze four common materials: polyester, nylon, canvas, and leather, highlighting their properties, advantages, disadvantages, and specific considerations for buyers from diverse regions.

Polyester

Key Properties: Polyester is known for its excellent resistance to stretching and shrinking, quick drying capabilities, and UV resistance. It typically performs well in various temperature ranges, making it suitable for outdoor applications.

Pros & Cons: The durability of polyester is notable, as it withstands wear and tear effectively. It is also lightweight, which is advantageous for backpack design. However, polyester can be less breathable than other materials, potentially leading to discomfort in warmer climates. Additionally, while it is relatively inexpensive, the quality can vary significantly based on the manufacturing process.

Impact on Application: Polyester is compatible with various media, including water-resistant coatings, enhancing its suitability for outdoor and travel backpacks.

Considerations for Buyers: Buyers should ensure compliance with international standards such as ASTM and REACH for chemical safety. Sourcing from reputable suppliers who adhere to quality control measures is crucial, particularly for markets in Europe and North America.

Nylon

Key Properties: Nylon boasts high tensile strength, abrasion resistance, and elasticity. It performs well under pressure and is often used in high-performance applications.

Pros & Cons: The primary advantage of nylon is its durability and resistance to wear, making it ideal for rugged use. However, it can be more expensive than polyester and may absorb moisture, which can lead to mold if not treated properly. Additionally, nylon’s production can have a higher environmental impact unless sourced from recycled materials.

Impact on Application: Nylon is particularly suited for applications requiring high strength and resilience, such as hiking or tactical backpacks.

Considerations for Buyers: Buyers should seek suppliers that offer recycled nylon options to align with sustainability goals. Compliance with environmental standards is becoming increasingly important, especially in European markets.

Canvas

Key Properties: Canvas is a heavy-duty fabric, typically made from cotton or a cotton-polyester blend. It is known for its durability and ability to withstand wear and tear.

Pros & Cons: The primary advantage of canvas is its robustness and aesthetic appeal. It can be treated for water resistance, enhancing its functionality. However, canvas is heavier than synthetic materials, which may not be suitable for all backpack designs. Additionally, it can be more expensive due to the quality of the raw materials.

Impact on Application: Canvas works well for casual, everyday backpacks and is compatible with various printing techniques for branding.

Considerations for Buyers: Buyers should be aware of the sourcing of cotton and its environmental impact. Compliance with organic standards may be necessary for certain markets, particularly in Europe.

Leather

Key Properties: Leather is a natural material known for its strength, durability, and aesthetic appeal. It offers good resistance to wear and tear and can be treated for water resistance.

Pros & Cons: Leather provides a premium look and feel, making it suitable for high-end backpack designs. However, it is typically more expensive and requires more maintenance than synthetic materials. Leather can also be less suitable for extreme weather conditions unless treated properly.

Impact on Application: Leather is ideal for luxury or fashion-oriented backpacks, appealing to consumers looking for style and durability.

Considerations for Buyers: Buyers must consider ethical sourcing and compliance with regulations regarding animal products. Additionally, understanding the tanning process and its environmental implications is crucial, especially in regions with strict environmental laws.

Summary Table

| Material | Typical Use Case for square backpack | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Everyday use, travel backpacks | Lightweight, quick-drying | Less breathable, quality varies | Low |

| Nylon | High-performance, tactical backpacks | High durability, abrasion-resistant | More expensive, moisture absorption | Medium |

| Canvas | Casual, branding-focused backpacks | Robust, aesthetic appeal | Heavier, potentially higher cost | Medium |

| Leather | Luxury, fashion-oriented backpacks | Premium look and durability | Expensive, requires maintenance | High |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and considerations of various materials for square backpacks, enabling informed sourcing decisions tailored to their market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for square backpack

The manufacturing process for square backpacks involves several key stages, each with specific techniques and quality assurance measures that are vital for B2B buyers to understand. This section provides an in-depth look at these processes, ensuring that international buyers, particularly from Africa, South America, the Middle East, and Europe, are well-informed about what to expect when sourcing these products.

Manufacturing Process Stages

Material Preparation

The first stage of manufacturing square backpacks involves the selection and preparation of raw materials. Common materials include high-denier nylon, polyester, and leather, which are chosen based on durability, weight, and cost.

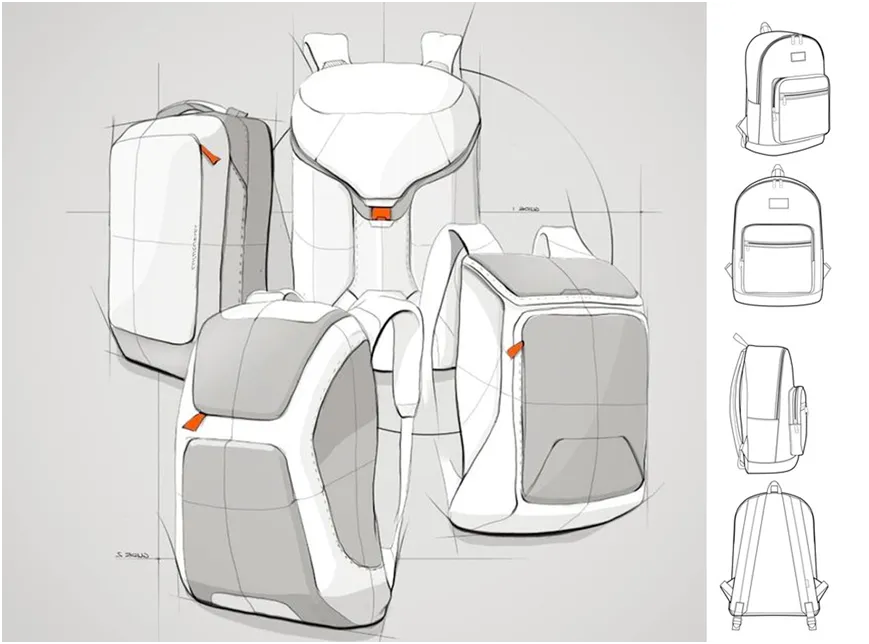

Illustrative Image (Source: Google Search)

- Key Techniques:

- Material Sourcing: Establish relationships with reliable suppliers who provide high-quality materials. For B2B buyers, ensure that suppliers can provide certifications for the materials used, such as recycled content for sustainability.

- Cutting: Materials are cut into specific shapes according to the design specifications using automated cutting machines or manual cutting tools. Precision in this stage is critical to minimize waste and ensure uniformity.

Forming

In this stage, the cut materials are shaped into components of the backpack. This includes creating the main body, pockets, straps, and any additional features.

- Key Techniques:

- Stitching: Industrial sewing machines are utilized to stitch together the various components. The quality of stitching affects the backpack’s durability and functionality. Double stitching is often employed in high-stress areas.

- Molding: For backpacks with molded components (like frames or stiffened bases), thermoplastic materials may be heated and shaped to provide structure.

Assembly

The assembly stage involves combining all components into a finished backpack. This includes attaching straps, zippers, and any hardware.

- Key Techniques:

- Quality Assembly Practices: Skilled labor is essential at this stage to ensure that all components are securely attached and aligned correctly. Quality control measures should be in place to check for defects during assembly.

- Integration of Features: Any additional features, such as pockets, ventilation systems, or ergonomic designs, should be integrated seamlessly.

Finishing

The final stage of the manufacturing process focuses on the aesthetics and functionality of the backpack.

- Key Techniques:

- Trimming and Detailing: Excess threads are trimmed, and additional features like branding labels or decorative elements are added.

- Final Inspection: A thorough inspection is conducted to ensure that the backpack meets design specifications and quality standards before packaging.

Quality Assurance Standards

Quality assurance is critical in the manufacturing of square backpacks, as it ensures that the final product meets international standards and customer expectations.

Relevant International Standards

- ISO 9001: This standard focuses on quality management systems and is applicable to any organization looking to enhance customer satisfaction through effective quality management.

- CE Marking: For products sold in the European market, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: If backpacks are intended for specific industries (e.g., military or outdoor), compliance with industry-specific standards may be necessary.

Quality Control Checkpoints

Implementing a robust quality control system involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Quality checks are conducted during the manufacturing process to catch any defects early.

- Final Quality Control (FQC): The finished backpacks are subjected to a final inspection to ensure they meet quality criteria before shipping.

Common Testing Methods

B2B buyers should be aware of various testing methods used in quality assurance, including:

– Tensile Testing: Assesses the strength of materials and seams.

– Water Resistance Testing: Determines how well the backpack can withstand water exposure.

– Durability Testing: Simulates wear and tear to evaluate the longevity of the backpack.

Verifying Supplier Quality Control

For international B2B buyers, verifying the quality control processes of potential suppliers is crucial to mitigate risks and ensure product quality.

- Audits: Conduct regular audits of suppliers to assess their quality management systems and production processes. This can include reviewing their compliance with ISO standards and other certifications.

- Quality Reports: Request detailed quality reports that outline the results of inspections and testing conducted throughout the manufacturing process.

- Third-Party Inspections: Engage third-party inspection services to conduct independent assessments of the manufacturing facilities and products. This provides an unbiased evaluation of quality standards.

Considerations for International Buyers

When sourcing square backpacks from international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, buyers should consider the following nuances:

- Cultural Differences: Understand the cultural context and business practices of the supplier’s country, as this can affect communication and negotiation.

- Regulatory Compliance: Ensure that suppliers comply with local regulations regarding labor practices, environmental standards, and import/export laws.

- Supply Chain Resilience: Diversifying suppliers across different regions can enhance supply chain resilience, helping to mitigate risks associated with political instability or natural disasters.

In summary, a comprehensive understanding of the manufacturing processes and quality assurance measures for square backpacks is essential for B2B buyers. By focusing on material quality, effective manufacturing techniques, and stringent quality control, buyers can ensure that they source high-quality products that meet their market needs.

Related Video: How a Backpack is Made : Every Step on the Production Line

Comprehensive Cost and Pricing Analysis for square backpack Sourcing

The cost structure for sourcing square backpacks involves several key components that international B2B buyers must consider. Understanding these components and how they interact can help in making informed purchasing decisions.

Cost Components

-

Materials: The choice of materials significantly impacts the overall cost. Common materials for square backpacks include polyester, nylon, and canvas. Higher-quality materials, such as genuine leather or eco-friendly fabrics, tend to increase costs but may justify a higher retail price due to perceived value.

-

Labor: Labor costs vary by region. Countries like China and Vietnam offer competitive labor rates, while India may provide lower costs for artisan craftsmanship. Buyers should assess the balance between labor quality and cost, especially if the backpack features complex designs.

-

Manufacturing Overhead: This includes costs associated with factory operations, including utilities, rent, and administrative expenses. These overheads can differ widely based on the country of production and the factory’s operational efficiency.

-

Tooling: If customization is required, tooling costs can be substantial. This includes the expenses for molds or specialized machinery needed to produce unique designs or features.

-

Quality Control (QC): Investing in quality control processes is essential to ensure product consistency and meet international standards. Buyers must factor in these costs, especially if they require third-party inspections.

-

Logistics: Shipping and handling costs can vary based on the supplier’s location, shipping methods, and chosen Incoterms. Buyers should consider both freight costs and the potential impact of tariffs or customs duties.

-

Margin: Suppliers will typically add a margin to their costs, which can vary based on the supplier’s market position and the perceived value of the product. Negotiating this margin can lead to significant savings.

Price Influencers

Several factors can influence the final price of square backpacks:

-

Volume/MOQ: Minimum order quantities (MOQs) can impact pricing. Larger orders generally lead to lower per-unit costs. However, buyers should ensure they can sell through the inventory to avoid excess stock.

-

Specifications/Customization: Custom designs or additional features (like waterproofing or added compartments) will increase costs. Buyers should weigh the benefits of customization against the price increases.

-

Materials: As mentioned, the choice of materials plays a crucial role in pricing. Eco-friendly or premium materials can attract a higher price.

-

Quality and Certifications: Products that meet specific quality standards or certifications (like ISO or environmental certifications) may have higher costs associated with compliance but can enhance marketability.

-

Supplier Factors: The reliability and reputation of the supplier can influence pricing. Established suppliers with a track record of quality may charge more but offer greater assurance.

-

Incoterms: Understanding Incoterms is crucial for calculating total costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect shipping responsibilities and costs.

Buyer Tips

-

Negotiation: Leverage your purchasing power by negotiating with suppliers. Consider discussing long-term partnerships for better rates.

-

Cost-Efficiency: Evaluate total costs, including shipping and duties, rather than focusing solely on unit price. A lower upfront cost may lead to higher long-term expenses.

-

Total Cost of Ownership (TCO): Factor in the TCO, which includes all costs related to the product over its lifecycle, such as maintenance and disposal.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, sourcing from a local supplier in South America may reduce shipping costs but could have higher material costs compared to Asian suppliers.

Disclaimer

Prices and costs can fluctuate based on market conditions, geopolitical factors, and changes in supply chain dynamics. Therefore, it is essential for buyers to conduct thorough market research and engage in continuous dialogue with suppliers to stay informed about pricing trends.

Spotlight on Potential square backpack Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘square backpack’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for square backpack

When sourcing square backpacks for B2B purposes, understanding the essential technical properties and trade terminology is crucial for making informed decisions. Below are critical specifications and industry terms that will aid international buyers, especially from regions like Africa, South America, the Middle East, and Europe.

Key Technical Properties

-

Material Grade

– Definition: Refers to the type and quality of fabric or material used in the construction of the backpack. Common materials include polyester, nylon, and canvas.

– B2B Importance: High-grade materials ensure durability and resistance to wear and tear, which is essential for customer satisfaction and brand reputation. Choosing the right material can also impact cost and pricing strategies. -

Tensile Strength

– Definition: The maximum amount of tensile (pulling) stress that a material can withstand before failure.

– B2B Importance: This property is vital for ensuring that the backpack can hold its contents without tearing. Buyers should prioritize suppliers who can provide tensile strength data to avoid product returns and maintain brand integrity. -

Water Resistance

– Definition: The ability of the backpack’s material to resist water penetration.

– B2B Importance: In regions with varied weather conditions, water-resistant backpacks are crucial for outdoor and travel markets. This feature can enhance the product’s appeal and broaden market reach. -

Capacity (Volume)

– Definition: Measured in liters, this refers to the internal space available for storage.

– B2B Importance: Understanding the capacity allows buyers to target specific consumer needs, whether for school, travel, or outdoor activities. It also aids in effective inventory management and market segmentation. -

Dimensions

– Definition: The physical size of the backpack, including height, width, and depth.

– B2B Importance: Accurate dimensions are essential for logistics, storage, and ensuring compatibility with customer preferences. It also affects shipping costs and handling. -

Weight

– Definition: The total weight of the backpack when empty.

– B2B Importance: Lightweight backpacks are more appealing to consumers, especially in markets focused on travel and outdoor activities. This can influence purchasing decisions and impact shipping costs.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships can help buyers negotiate better prices and ensure quality, as they often have established manufacturing standards and practices. -

MOQ (Minimum Order Quantity)

– Definition: The smallest amount of product that a supplier is willing to sell.

– Importance: Knowing the MOQ is critical for inventory planning and cash flow management. Smaller brands should seek suppliers with lower MOQs to avoid excess inventory. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to solicit price quotes from suppliers for specific products.

– Importance: Issuing an RFQ allows buyers to compare prices and terms from multiple suppliers, leading to better negotiating power and cost savings. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms published by the International Chamber of Commerce (ICC).

– Importance: Familiarity with Incoterms helps buyers understand shipping responsibilities, costs, and risks. This knowledge is essential for smooth logistics and compliance in international trade.

Illustrative Image (Source: Google Search)

-

Lead Time

– Definition: The amount of time it takes from placing an order to receiving the goods.

– Importance: Understanding lead times is essential for supply chain management and meeting customer demands. Buyers should negotiate lead times that align with their market needs. -

Customs Compliance

– Definition: Adhering to the regulations and laws governing the import and export of goods.

– Importance: Ensuring customs compliance is crucial to avoid delays, fines, and confiscation of goods. Buyers should work with suppliers who are knowledgeable about customs regulations in their target markets.

By grasping these technical properties and trade terms, international B2B buyers can make more informed sourcing decisions, ultimately leading to better product quality and market success.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the square backpack Sector

Global drivers influencing the square backpack market include a growing emphasis on functionality, urban lifestyles, and increased environmental awareness among consumers. The global bags and luggage market is projected to expand significantly, reaching approximately $85 billion by 2030. Notably, the rise of e-commerce has transformed how international B2B buyers engage with suppliers, facilitating quicker sourcing processes and enabling access to a broader range of manufacturers.

Emerging sourcing trends include the “China Plus One” strategy, where businesses diversify their supply chains to mitigate risks associated with relying solely on Chinese manufacturers. Countries such as Vietnam, India, and Bangladesh are becoming prominent alternatives, offering competitive pricing and quality. Vietnam, for example, has become a manufacturing powerhouse, particularly for technical backpacks, thanks to its strategic location and favorable trade agreements with the US and EU.

For international buyers from regions like Africa, South America, the Middle East, and Europe, understanding the dynamics of lead times, minimum order quantities (MOQs), and scalability is crucial. Factors such as supplier reliability, material accessibility, and compliance with international standards can significantly impact sourcing strategies. Leveraging digital procurement tools can also enhance supplier collaboration and provide greater transparency in cost structures, thus enabling buyers to optimize their sourcing processes.

Sustainability & Ethical Sourcing in B2B

The environmental impact of the square backpack industry is significant, particularly concerning raw material extraction, manufacturing processes, and end-of-life disposal. As consumers increasingly demand sustainable products, B2B buyers must prioritize ethical sourcing and supply chain transparency. This shift is not merely a trend but a necessity for maintaining a competitive edge in the global market.

Sustainable materials such as recycled plastics, organic cotton, and eco-friendly leather alternatives are gaining traction. Certifications like Global Organic Textile Standard (GOTS) and the Forest Stewardship Council (FSC) serve as benchmarks for sustainability, enabling buyers to make informed decisions regarding their suppliers. Establishing relationships with manufacturers who prioritize ethical labor practices and environmentally friendly production methods is essential for aligning with the growing consumer demand for responsible products.

Moreover, integrating sustainability into sourcing strategies can lead to long-term cost savings and brand loyalty. As regulations surrounding environmental standards tighten globally, proactive adherence to sustainability practices will not only mitigate risks but also enhance brand reputation among discerning consumers.

Brief Evolution/History

The square backpack, a design that marries functionality with aesthetic appeal, has evolved significantly over the past few decades. Initially popularized by outdoor enthusiasts, the square backpack’s versatility has led to its adoption in urban settings, making it a staple for students and professionals alike.

Historically, the design has transitioned from simple, utilitarian forms to more complex structures that incorporate various materials and technology, such as padded compartments for electronics and waterproof fabrics. This evolution reflects broader trends in consumer preferences towards multifunctional and stylish products, driving innovation within the sector. For B2B buyers, understanding this historical context can inform product development and marketing strategies, ensuring alignment with current consumer expectations.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of square backpack

-

What criteria should I use to vet suppliers for square backpacks?

When vetting suppliers, prioritize factors such as quality assurance, reliability, and compliance with international standards. Assess their production capabilities, previous client references, and certifications such as ISO or compliance with environmental regulations. A factory visit, if feasible, can provide insights into their operational practices. Additionally, consider their experience in exporting to your region, as this can significantly impact logistics and communication. -

Can I customize square backpacks to fit my brand’s needs?

Yes, many manufacturers offer customization options for square backpacks, including materials, colors, and branding elements such as logos and tags. It’s important to discuss your specific requirements upfront, including the design and functionality you envision. Be aware that customization may affect minimum order quantities (MOQs) and lead times, so clarify these aspects during your negotiations to ensure they align with your business needs. -

What are typical MOQs and lead times for square backpacks?

Minimum order quantities (MOQs) for square backpacks typically range from 500 to 5,000 pieces, depending on the manufacturer and the level of customization. Standard lead times can vary from 4 to 8 weeks, influenced by factors such as the complexity of the design and the supplier’s production schedule. Always confirm these details before placing an order to avoid unexpected delays that could impact your supply chain.

-

What payment terms are commonly used in international B2B transactions?

Payment terms can vary widely, but common practices include 30% upfront deposit and 70% upon shipment. Some suppliers may offer flexible terms such as letter of credit or escrow services for larger orders to mitigate risk. It’s crucial to negotiate terms that protect your interests while maintaining a good relationship with the supplier. Ensure that any agreed-upon terms are documented clearly in your contract. -

How can I ensure quality assurance for square backpacks?

To ensure quality, request samples before finalizing your order. Establish a quality control process that includes in-line inspections and final product checks. Consider hiring a third-party inspection service to verify compliance with your specifications and industry standards. Additionally, reviewing the supplier’s quality certifications and past performance can provide confidence in their ability to deliver products that meet your standards. -

What certifications should I look for in a supplier?

Key certifications to look for include ISO 9001 for quality management systems, ISO 14001 for environmental management, and compliance with REACH or OEKO-TEX for safety in textiles. These certifications indicate a commitment to quality and safety standards that are essential for market access, especially in Europe and North America. Ensure that suppliers can provide up-to-date documentation to support their claims. -

What logistics considerations should I keep in mind when sourcing square backpacks?

Logistics is critical in international sourcing. Assess factors like shipping methods (air vs. sea), customs clearance, and import duties specific to your country. Work closely with your supplier and logistics provider to determine the most efficient shipping routes and timelines. It’s also advisable to build in some buffer time for unexpected delays, especially during peak seasons or due to geopolitical issues. -

How should I handle disputes with suppliers?

To effectively manage disputes, establish clear communication channels and a process for addressing issues as they arise. Include a dispute resolution clause in your contracts, specifying whether mediation or arbitration will be used. Document all communications and agreements thoroughly. If disputes escalate, consider engaging a third-party mediator to facilitate negotiations and avoid potential legal challenges that can be costly and damaging to business relationships.

Strategic Sourcing Conclusion and Outlook for square backpack

In conclusion, the strategic sourcing of square backpacks presents a significant opportunity for international B2B buyers. By diversifying suppliers across regions such as China, Vietnam, India, and Bangladesh, companies can leverage unique advantages in quality, pricing, and craftsmanship. It is essential to focus on total cost of ownership, including shipping, duties, and quality control, rather than just unit prices.

Illustrative Image (Source: Google Search)

Buyers should prioritize supplier reliability, lead times, and compliance with social and environmental standards to maintain a strong brand reputation. The emerging trends towards sustainability and ethical production are also becoming increasingly important in decision-making processes.

As the global bags and luggage market continues to expand, the demand for innovative and durable products like square backpacks will grow. B2B buyers from Africa, South America, the Middle East, and Europe should take proactive steps to engage with suppliers that align with their strategic goals and values.

By adopting a forward-thinking approach to sourcing, businesses can not only enhance their product offerings but also position themselves favorably in a competitive marketplace. Embrace the opportunity to build resilient and diverse supply chains that can adapt to the changing dynamics of global trade.