Master Backpack Pattern Sourcing: Your Essential B2B Guide

Guide to Backpack Pattern

- Introduction: Navigating the Global Market for backpack pattern

- Understanding backpack pattern Types and Variations

- Key Industrial Applications of backpack pattern

- Strategic Material Selection Guide for backpack pattern

- In-depth Look: Manufacturing Processes and Quality Assurance for backpack pattern

- Comprehensive Cost and Pricing Analysis for backpack pattern Sourcing

- Spotlight on Potential backpack pattern Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for backpack pattern

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the backpack pattern Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of backpack pattern

- Strategic Sourcing Conclusion and Outlook for backpack pattern

Introduction: Navigating the Global Market for backpack pattern

Backpacks have become essential items across various sectors, catering to students, professionals, and adventurers alike. For international B2B buyers from Africa, South America, the Middle East, and Europe, understanding the nuances of backpack patterns is crucial for capitalizing on market opportunities. With the growing demand for unique, functional, and sustainable designs, sourcing high-quality backpack patterns can significantly reduce product development costs and enhance competitive advantage.

This guide offers a comprehensive exploration of the global backpack pattern market, detailing the different types of designs and their applications. Buyers will find insights into material selection, manufacturing processes, and quality control measures essential for producing high-caliber products. Furthermore, the guide features an analysis of leading suppliers, cost structures, and market trends, equipping businesses with the knowledge to make informed procurement decisions.

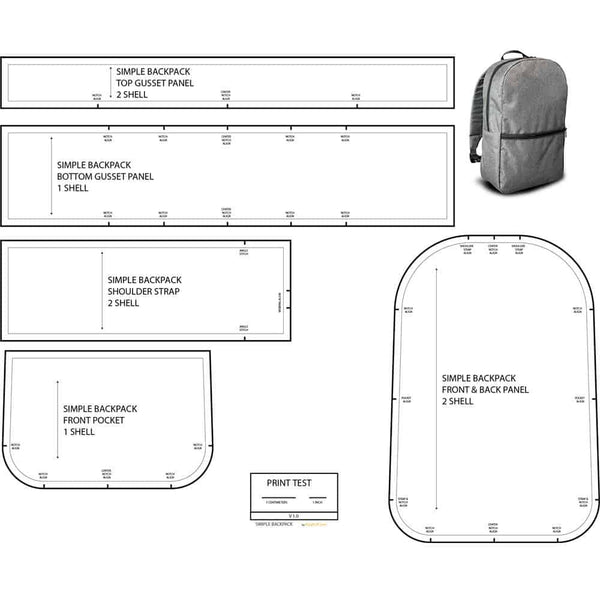

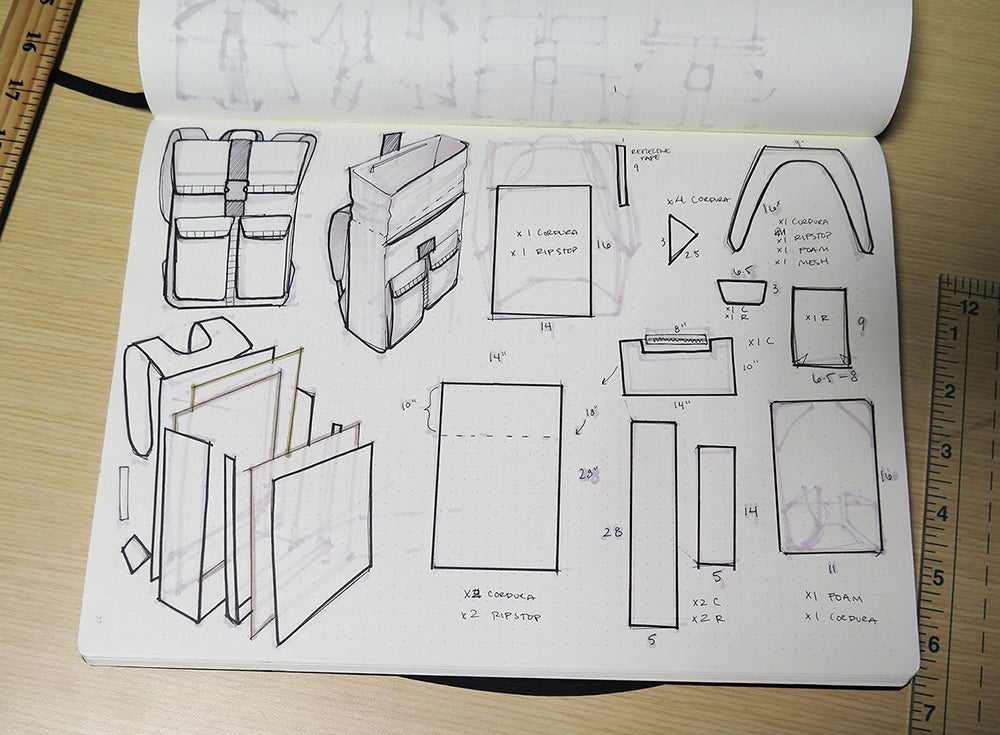

Illustrative Image (Source: Google Search)

By leveraging this guide, B2B decision-makers can navigate the complexities of sourcing backpack patterns effectively. Whether you are aiming to adapt to shifting consumer preferences or seeking to establish robust supply chains, the actionable insights provided will empower you to optimize your sourcing strategies. This resource not only addresses common pain points but also highlights opportunities for collaboration and innovation in the ever-evolving backpack market.

Understanding backpack pattern Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Daypack | Large main compartment, front zipper pocket, adjustable straps | Educational institutions, retail, promotional goods | Pros: High demand, adaptable branding. Cons: Basic design limits customization. |

| Mini Backpack Zipper Pouch | Compact size, full zipper access, key ring or strap loop | Souvenir shops, corporate gifting, boutique accessories | Pros: Low material cost, scalable production. Cons: Limited use for heavy loads. |

| 2-in-1 Convertible Bag | Doubles as backpack and tote; flexible strap system | Bookstores, educational suppliers, lifestyle brands | Pros: Versatile for multiple uses. Cons: Slightly increased production complexity. |

| Drawstring Backpack | Unstructured sack with pulling cord closure, lightweight | Events, mass giveaways, sports clubs | Pros: Fast to sew, inexpensive. Cons: Offers little protection or support. |

| Structured Laptop Backpack | Reinforced panels, interior pockets, padded laptop sleeve | Corporate gifts, tech retail, executive markets | Pros: High value-added, functional for professionals. Cons: Requires higher sewing skill and material quality. |

Classic Daypack

The classic daypack is characterized by its straightforward design, featuring a large main compartment and a front zipper pocket. This type is ideal for educational institutions and retail environments due to its broad appeal and affordability. B2B buyers should note that while the classic daypack allows for ample branding opportunities, its basic design may limit customization options. It is particularly suited for high-volume orders where predictability in specifications is crucial.

Mini Backpack Zipper Pouch

Mini backpack zipper pouches are compact and feature full zipper access, making them perfect for souvenirs or corporate gifts. Their smaller size translates to lower material costs and quicker manufacturing cycles, appealing to businesses seeking cost-effective options. However, B2B buyers should consider that these pouches are not suitable for heavy loads, which limits their utility compared to full-sized backpacks. They are best used in markets where novelty and lightweight products are in demand.

2-in-1 Convertible Bag

The 2-in-1 convertible bag offers the flexibility of being used as both a backpack and a tote, catering to diverse consumer needs. This design is particularly appealing to bookstores and lifestyle brands looking to differentiate their offerings. While the versatility adds value, it also introduces slight complexity in production. B2B buyers should evaluate their target market’s preferences for multifunctional products, as this can influence sales and inventory strategies.

Drawstring Backpack

The drawstring backpack is a lightweight, unstructured option that is easy to produce and cost-effective. It is especially popular for events, mass giveaways, and sports clubs, making it an attractive option for buyers in markets with budget constraints. However, the lack of structure means it offers minimal protection for contents, which may limit its appeal for higher-value items. B2B buyers should consider the intended use when choosing this type, focusing on short-term applications.

Structured Laptop Backpack

Structured laptop backpacks are designed with reinforced panels and padded compartments, making them ideal for corporate gifts and tech retail. They offer significant value due to their functionality and appeal to professional markets. However, these backpacks require a higher level of craftsmanship and quality materials, which can increase production costs. B2B buyers must weigh the benefits of durability and brand image against the potential for higher investment in manufacturing.

Related Video: Large Language Models (LLMs) – Everything You NEED To Know

Key Industrial Applications of backpack pattern

| Industry/Sector | Specific Application of Backpack Pattern | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Education | School Backpacks | High demand, brand visibility, and customization options | Quality of materials, durability, and compliance with safety standards |

| Travel & Tourism | Travel Backpacks | Enhanced customer experience and brand loyalty | Weight, comfort features, and eco-friendly materials |

| Corporate Gifts | Branded Laptop Backpacks | Professional image and client appreciation | Customization options, lead times, and bulk pricing |

| Sports & Recreation | Sports Backpacks | Functionality and appeal to active consumers | Material performance, style variations, and cost efficiency |

| Retail | Fashionable Mini Backpacks | Trend responsiveness and impulse buying | Design flexibility, seasonal trends, and production speed |

Education

Backpack patterns are extensively used in the education sector, particularly for school backpacks. These designs cater to students’ needs for durability and functionality while providing ample space for books and supplies. B2B buyers in this sector must prioritize quality materials that withstand daily wear and tear, alongside compliance with safety standards. Customization options allow educational institutions to showcase their branding, enhancing visibility and loyalty among students and parents. This is especially relevant in regions like Africa and South America, where local manufacturers can produce affordable yet high-quality options.

Travel & Tourism

In the travel and tourism industry, backpack patterns are tailored to create travel backpacks that enhance the user experience. These backpacks often feature ergonomic designs, multiple compartments, and lightweight materials to accommodate travelers’ needs. International B2B buyers should focus on sourcing backpacks that provide comfort and durability, as well as eco-friendly materials to appeal to environmentally conscious consumers. This approach not only meets the demands of modern travelers but also aligns with global sustainability trends, making it a smart investment for businesses looking to build brand loyalty.

Corporate Gifts

Branded laptop backpacks are increasingly popular as corporate gifts, serving as practical and stylish items for professionals. These backpacks often include padded compartments for laptops and additional pockets for organization, making them ideal for business use. B2B buyers should consider customization options that allow for company logos and branding, enhancing the perceived value of the gift. Sourcing high-quality materials and ensuring timely delivery are critical factors, particularly for companies in Europe and the Middle East that aim to impress clients and partners with thoughtful, functional gifts.

Sports & Recreation

Backpack patterns designed for sports and recreation focus on functionality and style, appealing to active consumers. These backpacks often feature specialized compartments for gear, hydration systems, and breathable materials for comfort during physical activities. B2B buyers in this sector must prioritize sourcing materials that offer durability and performance under various conditions. Additionally, understanding regional preferences for styles and colors can help businesses cater to local markets, particularly in Africa and South America, where outdoor activities are popular.

Retail

In the retail sector, fashionable mini backpacks are a growing trend, appealing to consumers seeking stylish accessories. These compact designs are ideal for boutiques and souvenir shops, offering a unique product that can drive impulse purchases. B2B buyers should focus on sourcing patterns that allow for quick production and flexibility in design to keep up with seasonal trends. Collaborating with local manufacturers can help reduce costs and improve turnaround times, making it easier for retailers to respond to changing consumer demands effectively.

Related Video: Uses of Metals and Non Metals

Strategic Material Selection Guide for backpack pattern

When selecting materials for backpack patterns, international B2B buyers must consider various factors, including durability, cost, manufacturing complexity, and specific application needs. Here, we analyze four common materials used in backpack manufacturing, highlighting their properties, advantages, disadvantages, and considerations for buyers from diverse regions such as Africa, South America, the Middle East, and Europe.

1. Polyester

Key Properties: Polyester is known for its excellent durability and resistance to stretching and shrinking. It can withstand a temperature range of -40°F to 140°F, making it suitable for various climates. Polyester is also resistant to mold and mildew, which is advantageous in humid environments.

Pros & Cons: The material is lightweight and cost-effective, making it a popular choice for budget-conscious brands. However, it can be less breathable than other fabrics, which may affect comfort in hot conditions. Manufacturing polyester backpacks is relatively straightforward, but the reliance on synthetic fibers raises sustainability concerns.

Impact on Application: Polyester is compatible with various printing techniques, allowing for vibrant designs. It is ideal for everyday backpacks and promotional items.

Considerations for International Buyers: Buyers should ensure compliance with environmental regulations regarding synthetic materials. Understanding local preferences for sustainable options is crucial, especially in European markets.

2. Nylon

Key Properties: Nylon is renowned for its strength and elasticity. It has a high resistance to abrasion and can handle significant wear and tear. Nylon’s temperature tolerance ranges from -40°F to 180°F, providing versatility across different climates.

Pros & Cons: While nylon offers superior durability and is lightweight, it can be more expensive than polyester. The manufacturing process can be complex due to the need for specialized sewing techniques to prevent fraying.

Impact on Application: Nylon is particularly suitable for outdoor and adventure backpacks, where durability is paramount. Its water-resistant properties make it ideal for hiking and travel gear.

Considerations for International Buyers: Buyers should be aware of potential compliance issues with chemical treatments used in nylon production, particularly in regions with stringent environmental standards.

3. Canvas

Key Properties: Canvas is a heavy-duty fabric made from cotton or a blend of cotton and synthetic fibers. It is known for its strength and durability, with a temperature tolerance of -20°F to 120°F. Canvas is breathable and offers a natural feel.

Pros & Cons: The main advantage of canvas is its sturdiness and aesthetic appeal, making it popular for fashion-oriented backpacks. However, it is heavier than synthetic materials and can absorb moisture, which may lead to mold if not treated properly. The manufacturing process can be labor-intensive.

Impact on Application: Canvas is well-suited for casual and fashion backpacks. It is compatible with various dyeing techniques, allowing for unique designs.

Considerations for International Buyers: Buyers should consider the sourcing of cotton and its environmental impact. Compliance with organic standards may also be relevant in certain markets, particularly in Europe.

4. Recycled Materials (e.g., Recycled PET)

Key Properties: Recycled PET (rPET) is derived from post-consumer plastic bottles, providing a sustainable alternative to virgin polyester. It retains similar properties to polyester, including durability and resistance to moisture.

Pros & Cons: The primary advantage of rPET is its reduced environmental footprint, appealing to eco-conscious consumers. However, it can be more expensive than traditional polyester due to the recycling process. Manufacturing complexity may also increase, requiring specialized equipment.

Impact on Application: rPET is suitable for brands targeting eco-friendly markets, making it ideal for promotional items and sustainable product lines.

Considerations for International Buyers: Buyers should verify the sourcing and certification of recycled materials to ensure compliance with sustainability claims. Understanding regional consumer preferences for eco-friendly products is critical, particularly in Europe and North America.

Summary Table

| Material | Typical Use Case for backpack pattern | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Everyday backpacks, promotional items | Lightweight, cost-effective | Less breathable, sustainability concerns | Low |

| Nylon | Outdoor and travel backpacks | Superior durability, abrasion resistance | Higher cost, complex manufacturing | Med |

| Canvas | Casual and fashion backpacks | Sturdy, aesthetically appealing | Heavier, moisture-absorbing | Med |

| Recycled Materials (rPET) | Eco-friendly product lines | Reduced environmental footprint | Higher cost, manufacturing complexity | High |

This strategic material selection guide provides B2B buyers with actionable insights into the properties and applications of various materials used in backpack manufacturing. By understanding these factors, businesses can make informed decisions that align with their market strategies and consumer preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for backpack pattern

The backpack manufacturing process is a multi-stage operation that involves various techniques and quality control (QC) measures to ensure that the final product meets market expectations. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding these processes is crucial to sourcing high-quality backpacks that align with their business needs.

Manufacturing Process

The manufacturing of backpacks can be broken down into four main stages: Material Preparation, Forming, Assembly, and Finishing.

Material Preparation

The first stage involves selecting and preparing the materials that will be used in the backpack. Common materials include:

- Fabric: Options such as nylon, polyester, and eco-friendly alternatives like recycled polyester.

- Zippers and Hardware: High-quality zippers are essential for durability; manufacturers often choose YKK or equivalent brands.

- Padding and Linings: Depending on the backpack type, additional materials may be required for comfort and protection.

During this stage, manufacturers will also conduct tests on materials to assess their durability, weight, and resistance to wear and tear. This step is vital for ensuring that the selected materials will stand up to the intended use of the backpack.

Forming

Once materials are prepared, the next step is forming the backpack components. This typically involves:

- Cutting: Using automated cutting machines for precision. This ensures that all fabric pieces are uniform in size and shape.

- Sewing: The cut pieces are then sewn together using specialized industrial sewing machines. Advanced techniques, such as double stitching and bar tacking, are employed in high-stress areas to enhance durability.

Automation plays a significant role in this stage, increasing efficiency and consistency while reducing labor costs. This is particularly beneficial for B2B buyers looking for competitive pricing without sacrificing quality.

Assembly

The assembly stage combines all the components into the final product. Key activities include:

- Attaching Straps and Handles: Depending on the backpack design, various strap configurations may be used.

- Incorporating Pockets and Compartments: This stage may involve adding internal pockets, laptop sleeves, and other organizational features.

Quality at this stage is critical. Manufacturers often implement in-process quality checks (IPQC) to ensure that each backpack meets design specifications before moving on to the next stage.

Finishing

The final stage involves finishing touches that enhance the backpack’s appearance and functionality. This includes:

- Quality Control Checks: A final inspection is performed to check for any defects, such as loose threads or uneven stitching.

- Packaging: Backpacks are carefully folded and packaged for shipping, often with attention to branding and presentation.

Quality Assurance

Quality assurance in the backpack manufacturing process is essential for maintaining product standards and ensuring customer satisfaction. International standards and industry-specific certifications guide these practices.

Relevant International Standards

-

ISO 9001: This standard provides a framework for quality management systems and is widely recognized across industries. Manufacturers certified under ISO 9001 demonstrate their commitment to consistent quality and continual improvement.

-

CE Marking: Particularly relevant for products sold in Europe, CE marking indicates that the backpack complies with EU safety, health, and environmental protection standards.

-

API Standards: While primarily used in the oil and gas sector, some manufacturing processes in the backpack industry also adopt API standards for specific materials or components.

QC Checkpoints

Quality control involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected for quality before production begins. This prevents defects from carrying over into the finished product.

-

In-Process Quality Control (IPQC): Conducted during manufacturing, this involves regular checks to ensure that the production process adheres to set standards.

-

Final Quality Control (FQC): After assembly, a comprehensive inspection is conducted to catch any defects before the product is shipped.

Common Testing Methods

B2B buyers should be aware of various testing methods that manufacturers may use, including:

- Tensile Strength Tests: Evaluates the strength of seams and straps.

- Water Resistance Tests: Ensures that materials can withstand moisture.

- Abrasion Resistance Tests: Assesses how well materials hold up against wear.

Verifying Supplier Quality Control

For B2B buyers, particularly in regions like Africa and South America, verifying a supplier’s quality control processes is crucial. Here are actionable strategies:

-

Supplier Audits: Conduct regular audits of potential suppliers to evaluate their facilities, processes, and adherence to international standards.

-

Quality Reports: Request detailed quality reports that outline testing methods, results, and any corrective actions taken for defects.

-

Third-Party Inspections: Engage third-party inspection services to conduct random checks on production runs. This adds an extra layer of assurance regarding quality.

-

Certifications: Verify that suppliers possess relevant certifications (e.g., ISO, CE) and ensure they are up to date.

Conclusion

Understanding the manufacturing processes and quality assurance measures in backpack production enables B2B buyers to make informed sourcing decisions. By focusing on manufacturers that prioritize quality through rigorous QC checkpoints and adhere to international standards, businesses can secure reliable partnerships that meet their product needs and consumer expectations. With the right insights and strategies, international buyers can confidently navigate the competitive landscape of backpack manufacturing.

Related Video: How a Backpack is Made : Every Step on the Production Line

Comprehensive Cost and Pricing Analysis for backpack pattern Sourcing

Analyzing the cost structure and pricing for backpack pattern sourcing is essential for international B2B buyers to make informed decisions. This analysis focuses on the various components of costs involved in backpack production, the factors influencing pricing, and strategic tips for negotiation and procurement.

Cost Components

-

Materials: The choice of materials significantly affects cost. Eco-friendly options, such as recycled polyester or organic cotton, often come at a premium compared to conventional materials. Expect to allocate approximately 30-50% of total costs on materials, depending on the quality and sustainability standards.

-

Labor: Labor costs vary by region, with countries like Vietnam offering competitive rates compared to China. Labor typically accounts for 20-30% of production costs. Understanding local wage standards and labor practices can help buyers gauge overall expenses.

Illustrative Image (Source: Google Search)

-

Manufacturing Overhead: This includes utilities, facility maintenance, and administrative expenses. Overhead can constitute around 10-20% of total costs. Buyers should inquire about the manufacturer’s operational efficiency to estimate this component accurately.

-

Tooling: Initial costs for tooling, such as molds and cutting dies, can be substantial but are often amortized over large production runs. Buyers can expect tooling costs to represent 5-10% of the total cost, particularly for custom patterns.

-

Quality Control (QC): Rigorous QC measures are essential to ensure product durability and compliance with specifications. Allocating around 5-10% of costs for quality assurance processes is advisable, especially for products targeting premium markets.

-

Logistics: Shipping and handling costs can vary significantly based on the chosen Incoterms and shipping methods. Logistics might account for 10-15% of total costs, with air freight being more expensive than sea freight. Regional regulations and tariffs can further influence these costs.

-

Margin: Manufacturers typically add a profit margin of 10-30% on the total cost, depending on market competition and product uniqueness.

Price Influencers

Several factors can affect the pricing of backpack patterns:

-

Volume/MOQ: Minimum order quantities (MOQs) can greatly impact the unit cost. Higher volumes usually lead to lower per-unit costs, making it beneficial for buyers to consolidate orders.

-

Specifications/Customization: Custom designs and specifications can increase production complexity and costs. Standard patterns are often more cost-effective, while bespoke designs may require additional investment in tooling and labor.

-

Materials Quality/Certifications: Premium materials and certifications (e.g., OEKO-TEX, GOTS) can lead to higher costs but may enhance brand value and marketability.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established manufacturers may charge higher rates for their proven quality and service.

-

Incoterms: Understanding the implications of different Incoterms (e.g., FOB, CIF) is crucial for managing logistics costs and responsibilities.

Buyer Tips

-

Negotiation: Leverage your purchasing power by negotiating for better terms based on volume commitments or long-term partnerships. Be prepared to discuss the specifics of your requirements to foster collaborative relationships.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO) rather than just the upfront costs. This includes potential savings from quality improvements, reduced returns, and enhanced brand reputation.

-

Pricing Nuances: For international buyers, factors such as currency fluctuations, import duties, and local market conditions can affect pricing. Always account for these variables in your budgeting.

-

Research and Benchmarking: Conduct thorough market research to understand pricing norms across regions, especially in Africa, South America, the Middle East, and Europe. Benchmarking against competitors can provide leverage during negotiations.

Disclaimer

Prices for backpack patterns can vary widely based on the factors discussed. The estimates provided are indicative and should be validated with specific suppliers to obtain accurate quotations tailored to your requirements.

Spotlight on Potential backpack pattern Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘backpack pattern’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for backpack pattern

Understanding the technical properties and trade terminology associated with backpack patterns is essential for international B2B buyers. This knowledge aids in making informed decisions, ensuring product quality, and optimizing procurement strategies. Below are the critical specifications and common jargon relevant to the backpack manufacturing industry.

Key Technical Properties

-

Material Grade

– Definition: This refers to the quality and type of fabric used in backpack production, such as nylon, polyester, or organic cotton.

– B2B Importance: Selecting the appropriate material grade affects durability, weight, cost, and environmental impact. For buyers in markets with diverse climates, understanding material properties ensures suitability for end-user needs. -

Tolerance

– Definition: Tolerance indicates the allowable deviation from specified dimensions during production, affecting fit and functionality.

– B2B Importance: High tolerance levels are crucial for ensuring that components like zippers, straps, and pockets fit together correctly, leading to a more reliable final product. Buyers should seek manufacturers that maintain tight tolerances for consistent quality. -

Water Resistance Rating (WRR)

– Definition: This rating measures the ability of the fabric to resist water penetration, typically expressed in millimeters (e.g., 1000mm WRR).

– B2B Importance: For buyers targeting outdoor or travel markets, understanding WRR helps in selecting backpacks that meet consumer expectations for durability and protection against the elements. -

Load Capacity

– Definition: This specification indicates the maximum weight a backpack can safely carry, often measured in kilograms or pounds.

– B2B Importance: Knowing the load capacity is vital for targeting specific consumer segments, such as students or hikers. Buyers should ensure that their product offerings align with the expected use cases of their target markets. -

Sustainability Index

– Definition: This index evaluates the environmental impact of materials and manufacturing processes, often considering factors like recyclability and carbon footprint.

– B2B Importance: With increasing consumer demand for sustainable products, a high sustainability index can enhance brand reputation and appeal to eco-conscious buyers, particularly in regions like Europe and North America. -

Design Specifications

– Definition: These encompass the detailed features of the backpack, including dimensions, pocket layouts, and strap configurations.

– B2B Importance: Clear design specifications facilitate accurate production and customization, helping brands to differentiate their products in competitive markets.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships is crucial for buyers looking to collaborate with manufacturers who can provide tailored products under their brand name. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers manage inventory levels and production costs, particularly important for startups or businesses testing new markets. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to invite them to submit price proposals for specific goods or services.

– Importance: RFQs are essential for comparing pricing and terms from multiple manufacturers, enabling buyers to make informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of standardized trade terms that define the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms helps buyers understand shipping costs, risks, and obligations, which is vital for successful international trade operations. -

Lead Time

– Definition: The time taken from placing an order to the delivery of the product.

– Importance: Understanding lead times is crucial for inventory management and meeting market demands, especially in fast-paced industries. -

Quality Control (QC)

– Definition: The processes and procedures in place to ensure that products meet specified quality standards.

– Importance: A robust QC system is critical for maintaining product consistency and reducing returns, making it an essential consideration for B2B buyers focused on brand reputation.

By equipping themselves with knowledge of these technical properties and trade terms, B2B buyers can enhance their procurement strategies, ensure product quality, and ultimately meet the diverse needs of their customers across various regions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the backpack pattern Sector

Market Overview & Key Trends

The global backpack pattern market is experiencing significant transformation, driven by shifts in consumer behavior, technological advancements, and a growing emphasis on sustainability. Customization has emerged as a critical trend, allowing brands to differentiate their offerings in a saturated market. Businesses are increasingly leveraging digital design tools that enable rapid prototyping and tailored backpack patterns, catering to specific regional preferences and consumer needs in Africa, South America, the Middle East, and Europe.

In addition, the adoption of smart manufacturing technologies is reshaping production processes. Automation and AI-driven analytics are enhancing efficiency, reducing lead times, and improving quality control. International buyers should pay attention to sourcing strategies that prioritize flexibility and responsiveness, particularly in regions where market conditions can shift quickly. For example, buyers in Nigeria and Brazil can benefit from localized manufacturing partnerships that minimize shipping costs and lead times.

Moreover, the sustainability movement is reshaping sourcing decisions. Eco-conscious consumers demand products made from sustainable materials, prompting manufacturers to explore options like recycled fabrics and biodegradable components. As a result, B2B buyers should align their sourcing strategies with these trends to meet market expectations and appeal to environmentally aware customers.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer just a buzzword; it is a crucial factor influencing purchasing decisions in the backpack pattern sector. The environmental impact of manufacturing processes—ranging from carbon emissions to waste generation—has prompted a push towards ethical sourcing practices. This includes selecting suppliers that prioritize sustainability and maintain transparent supply chains.

B2B buyers should look for manufacturers that offer green certifications such as Global Organic Textile Standard (GOTS) or OEKO-TEX, which ensure that materials and processes meet high environmental and social standards. Using sustainable materials like recycled polyester, organic cotton, and water-based dyes not only reduces the environmental footprint but also enhances the brand image and appeal among eco-conscious consumers.

Moreover, ethical sourcing contributes to social responsibility, ensuring fair labor practices and safe working conditions in manufacturing facilities. By prioritizing suppliers who uphold these values, businesses can mitigate risks associated with reputational damage and foster loyalty among consumers who prioritize ethical considerations in their purchasing decisions.

Brief Evolution/History

The evolution of backpack patterns can be traced back to the 20th century when backpacks began to gain popularity among students and outdoor enthusiasts. Initially designed for functionality, the focus shifted towards style and personalization as consumer preferences evolved. The late 1990s and early 2000s saw the rise of branded backpacks, driven by the growth of lifestyle and outdoor brands.

In recent years, the introduction of advanced materials and production techniques has further transformed the market. The advent of digital design tools and eco-friendly materials has enabled brands to create innovative, sustainable products that resonate with modern consumers. This historical context is essential for B2B buyers as it underscores the importance of innovation and sustainability in current sourcing strategies. Understanding this evolution helps brands to anticipate market trends and align their product offerings accordingly.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of backpack pattern

-

How can I effectively vet suppliers for backpack patterns?

When vetting suppliers, begin by researching their industry reputation and experience. Look for certifications that demonstrate quality standards, such as ISO or OEKO-TEX. Request samples to assess material quality and manufacturing capabilities. Additionally, verify their production capacity and delivery times to ensure they can meet your demands. Engaging with past clients can provide insights into their reliability and service levels. Utilize platforms like Alibaba or Global Sources to access verified suppliers and read reviews. -

What customization options should I consider when sourcing backpack patterns?

Customization can range from design elements like color, fabric, and size to functional features such as pockets or closures. Discuss your specific needs with potential suppliers early in the negotiation process. Ensure they can accommodate your design specifications, including any branding requirements like logos or labels. It’s also beneficial to inquire about their ability to create prototypes, allowing you to test designs before committing to larger orders. This flexibility can significantly enhance your product’s market appeal. -

What are the typical minimum order quantities (MOQs) and lead times for backpack patterns?

Minimum order quantities can vary widely based on the supplier’s capabilities and your customization needs. Generally, MOQs range from 50 to 500 units for custom designs, while standard patterns may have lower MOQs. Lead times typically range from 4 to 12 weeks, depending on the complexity of the design and the supplier’s location. It’s crucial to discuss these aspects upfront and factor in potential delays in shipping or customs, especially when sourcing internationally. -

How should I manage payment terms and conditions with suppliers?

Establishing clear payment terms is essential for a smooth transaction. Common practices include a deposit (usually 30-50%) upfront, with the balance paid upon completion of production or prior to shipping. Consider using secure payment methods like PayPal or escrow services to mitigate risks. Additionally, negotiate payment schedules that align with your cash flow. Document all terms in a formal contract to prevent disputes and ensure both parties are aligned on expectations. -

What quality assurance measures should I implement when sourcing backpack patterns?

Quality assurance is critical to ensure product consistency and customer satisfaction. Request detailed quality control processes from your suppliers, including inspections at various production stages. Consider implementing third-party inspections before shipment to verify compliance with your standards. Certifications such as ISO 9001 can also provide assurance of quality management practices. Moreover, establishing a clear return policy for defective items can protect your investment. -

What certifications should I look for in backpack manufacturing?

Certifications are indicators of a supplier’s commitment to quality and sustainability. Look for ISO certifications related to quality management and environmental practices. Additionally, certifications like OEKO-TEX ensure that materials used are free from harmful substances. If your target market values sustainability, consider suppliers with certifications like GOTS (Global Organic Textile Standard) for organic materials. These certifications can enhance your brand’s credibility and appeal to eco-conscious consumers. -

How can I navigate logistics and shipping when sourcing internationally?

Logistics can be complex, especially when dealing with international suppliers. Start by understanding your shipping options, including air freight for speed or sea freight for cost-effectiveness. Work with suppliers who have experience in international shipping to streamline the process. It’s also advisable to use a reliable freight forwarder who can handle customs clearance and documentation. Ensure you have a clear understanding of shipping costs, potential tariffs, and delivery timelines to avoid unexpected expenses.

Illustrative Image (Source: Google Search)

- What steps should I take in case of a dispute with a supplier?

In the event of a dispute, maintain clear and professional communication with your supplier. Document all interactions and agreements to have a record of what was discussed. Start by attempting to resolve the issue amicably, possibly through mediation. If the dispute escalates, refer to the terms outlined in your contract regarding conflict resolution. Consider engaging legal counsel if necessary, especially for significant financial disputes, and ensure you understand the laws governing international trade in your jurisdiction.

Strategic Sourcing Conclusion and Outlook for backpack pattern

The backpack manufacturing landscape presents numerous opportunities for international B2B buyers, especially those based in Africa, South America, the Middle East, and Europe. By leveraging strategic sourcing, businesses can access diverse patterns that cater to unique regional demands and consumer preferences. The rise of customization and sustainable production methods allows brands to differentiate themselves and meet the growing expectations of eco-conscious consumers.

Understanding the various backpack patterns—from classic daypacks to structured laptop bags—enables buyers to make informed decisions that align with their market strategies. The availability of free sewing patterns can significantly lower development costs and foster innovation, allowing businesses to respond swiftly to market changes.

As you navigate this dynamic industry, consider forging partnerships with manufacturers that prioritize quality, sustainability, and flexibility. The future of backpack manufacturing lies in adapting to consumer trends while maintaining operational efficiency.

Now is the time to take action: evaluate your sourcing strategies, explore new patterns, and partner with reliable manufacturers to ensure your backpack offerings stand out in a competitive marketplace. Embrace the potential of the global backpack market and position your brand for sustained growth and success.