Master Sourcing Transparent Small Backpacks: Key Insights

Guide to Transparent Small Backpack

- Introduction: Navigating the Global Market for transparent small backpack

- Understanding transparent small backpack Types and Variations

- Key Industrial Applications of transparent small backpack

- Strategic Material Selection Guide for transparent small backpack

- In-depth Look: Manufacturing Processes and Quality Assurance for transparent small backpack

- Comprehensive Cost and Pricing Analysis for transparent small backpack Sourcing

- Spotlight on Potential transparent small backpack Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for transparent small backpack

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the transparent small backpack Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of transparent small backpack

- Strategic Sourcing Conclusion and Outlook for transparent small backpack

Introduction: Navigating the Global Market for transparent small backpack

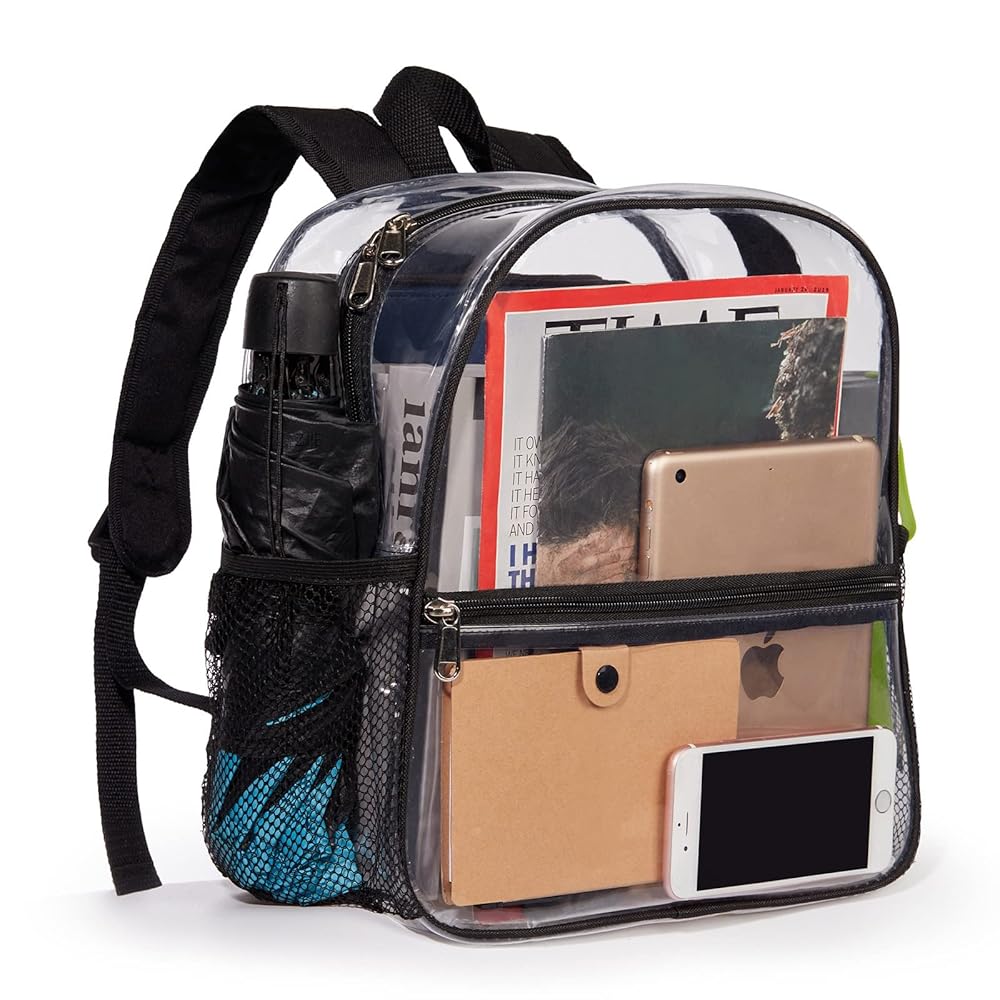

Navigating the global market for transparent small backpacks presents a unique opportunity for international B2B buyers looking to tap into a growing trend. These versatile bags are not only functional but also align with the increasing demand for visibility in consumer goods, allowing brands to showcase their products while enhancing security. As sustainability and transparency become paramount in consumer purchasing decisions, transparent small backpacks are rising in popularity across various sectors, including retail, education, and corporate gifting.

This comprehensive guide aims to equip B2B buyers—especially from Africa, South America, the Middle East, and Europe—with the essential knowledge to make informed sourcing decisions. We will explore various types of transparent small backpacks, examine materials that enhance durability and aesthetic appeal, and discuss manufacturing processes and quality control measures crucial for maintaining product integrity.

Additionally, the guide will highlight key suppliers and regions known for producing high-quality transparent backpacks, alongside an analysis of cost factors and market trends. A dedicated FAQ section will address common queries, ensuring that buyers are well-prepared to navigate the complexities of international sourcing. By leveraging this information, businesses can enhance their procurement strategies, optimize costs, and ultimately, drive success in a competitive marketplace.

Understanding transparent small backpack Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Clear PVC Backpack | Made from durable, transparent PVC material | Events, schools, security purposes | Pros: Lightweight, easy to clean; Cons: Limited durability in extreme conditions. |

| Mesh Transparent Backpack | Features mesh panels for ventilation and visibility | Outdoor events, sports, travel | Pros: Breathable, lightweight; Cons: Less water-resistant than solid materials. |

| Eco-Friendly Transparent Bag | Constructed from recycled materials, often biodegradable | Sustainable brands, eco-conscious consumers | Pros: Appeals to environmentally aware markets; Cons: May cost more than conventional options. |

| Fashion-Forward Transparent Bag | Stylish designs with transparent elements combined with fabric | Fashion retailers, promotional use | Pros: Trendy appeal, versatile; Cons: Higher price point due to design complexity. |

| Clear Stadium Compliant Bag | Designed to meet stadium regulations for security checks | Sports events, concerts | Pros: Ensures compliance with regulations; Cons: Limited design options due to regulations. |

Clear PVC Backpack

The clear PVC backpack is a popular choice for its durability and lightweight properties. Made from high-quality, transparent PVC, these backpacks are often used in settings where visibility is essential, such as schools and events. B2B buyers should consider the balance between cost and quality, as cheaper versions may not withstand heavy use. Additionally, they are easy to clean, making them suitable for various environments.

Mesh Transparent Backpack

Mesh transparent backpacks incorporate breathable mesh panels, enhancing ventilation while maintaining visibility. These backpacks are particularly suitable for outdoor events and sports, where airflow can be a significant factor. For B2B buyers, the key consideration is the trade-off between breathability and water resistance, as these bags may not perform well in wet conditions. They are often lightweight and easy to carry, appealing to active consumers.

Eco-Friendly Transparent Bag

Eco-friendly transparent bags are increasingly popular among brands focusing on sustainability. Constructed from recycled or biodegradable materials, these bags cater to environmentally conscious consumers. B2B buyers should assess the sourcing of materials and the certifications of suppliers to ensure genuine eco-friendliness. While they may carry a higher price point, their appeal to niche markets can justify the investment.

Fashion-Forward Transparent Bag

Fashion-forward transparent bags combine style with functionality, featuring trendy designs that incorporate transparent elements. These bags are often seen in retail and promotional settings, appealing to fashion-conscious consumers. B2B buyers should weigh the design complexity and associated costs against potential market demand. While they offer a unique selling proposition, the higher price point may limit their appeal in more budget-sensitive markets.

Clear Stadium Compliant Bag

Designed specifically to meet security regulations at stadiums and large events, clear stadium compliant bags are a must for any sports or concert venue. These bags typically feature a simple design that ensures compliance while providing ample space for essentials. B2B buyers should consider the limited design options and focus on functionality when sourcing these bags. Although they may lack in aesthetics, their practicality is a significant selling point in high-traffic environments.

Related Video: Large Language Models (LLMs) – Everything You NEED To Know

Key Industrial Applications of transparent small backpack

| Industry/Sector | Specific Application of Transparent Small Backpack | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Education | Student backpacks for schools and universities | Promotes transparency for safety and compliance | Durability, material quality, customization options |

| Events and Promotions | Promotional giveaways at trade shows and festivals | Enhances brand visibility while ensuring security | Cost-effectiveness, lead times, branding capabilities |

| Retail and Merchandising | Retail display for merchandise | Attracts customers with visibility of products | Quality of materials, design flexibility, MOQ considerations |

| Travel and Tourism | Luggage for airport travel and tourism | Compliance with security regulations, convenience | Weight, size specifications, regulatory compliance |

| Sports and Recreation | Gear bags for sports teams and outdoor activities | Lightweight and practical for active use | Material durability, waterproof options, color variations |

Education

Transparent small backpacks are increasingly being adopted in educational institutions, particularly in regions where safety and compliance are paramount. These backpacks allow security personnel to quickly inspect contents without the need for physical searches, thus enhancing safety protocols. For international B2B buyers, sourcing backpacks that meet local educational regulations and standards is critical. Durability and material quality are essential factors, as these products must withstand daily wear and tear while remaining visually appealing to students.

Events and Promotions

In the events sector, transparent small backpacks serve as effective promotional giveaways at trade shows and festivals. They provide businesses with a unique opportunity to enhance brand visibility while ensuring that attendees can easily access their belongings. Buyers in this sector should prioritize cost-effectiveness and lead times, as promotional items are often needed on short notice. Additionally, branding capabilities such as custom logos and colors can make these backpacks a standout option for marketing initiatives.

Retail and Merchandising

Retailers can utilize transparent small backpacks as a display solution for merchandise, allowing customers to see the products inside without opening the bag. This application not only attracts customers but also promotes a sense of transparency and trust. When sourcing these backpacks, businesses should focus on the quality of materials and design flexibility to ensure that the product aligns with their brand image. Consideration of minimum order quantities (MOQs) is also crucial, especially for smaller retailers.

Travel and Tourism

In the travel and tourism industry, transparent small backpacks can be used as luggage that complies with airport security regulations. These backpacks allow for quick inspections, making travel more convenient for customers. International buyers should consider weight and size specifications when sourcing these products, as they must fit within airline regulations. Compliance with security standards is essential, and sourcing from reputable manufacturers can help ensure that these requirements are met.

Sports and Recreation

For sports teams and outdoor activities, transparent small backpacks offer a lightweight and practical solution for carrying gear. They are particularly useful for events where gear checks are required, as the transparent design allows for easy inspection. Buyers should focus on material durability, especially for outdoor applications, and may also want to explore waterproof options to protect contents from the elements. Color variations can also appeal to different teams or organizations, enhancing brand identity.

Related Video: What is Industrial Automation?

Strategic Material Selection Guide for transparent small backpack

When selecting materials for transparent small backpacks, international B2B buyers must consider various factors, including performance properties, manufacturing complexities, and regional compliance standards. The following analysis covers four common materials used in the production of transparent small backpacks, providing insights into their properties, advantages, disadvantages, and considerations for sourcing.

Polyvinyl Chloride (PVC)

Key Properties:

PVC is a durable thermoplastic known for its excellent resistance to abrasion, chemicals, and UV light. It can withstand a temperature range of -10°C to 60°C, making it suitable for various climates.

Pros & Cons:

PVC is relatively inexpensive and easy to manufacture, allowing for high-volume production. However, it is less environmentally friendly, and its rigidity can limit comfort and flexibility in backpack design.

Impact on Application:

PVC is compatible with a variety of printing techniques, making it suitable for branding and customization. However, its chemical composition can lead to off-gassing, which may be a concern for sensitive users.

Considerations for International Buyers:

Buyers must ensure compliance with environmental regulations, such as REACH in Europe or similar standards in other regions. Certification for non-toxicity (e.g., ASTM D4236) may also be necessary.

Thermoplastic Polyurethane (TPU)

Key Properties:

TPU is a flexible, transparent material that offers excellent abrasion resistance, elasticity, and temperature tolerance, typically between -40°C and 80°C. It also has good chemical resistance.

Pros & Cons:

TPU provides a softer feel and greater flexibility compared to PVC, enhancing user comfort. However, it is generally more expensive to produce, which can impact the overall cost of the backpack.

Impact on Application:

The material’s flexibility makes it ideal for applications requiring movement, such as sports or outdoor activities. Its compatibility with various printing methods allows for branding without compromising transparency.

Considerations for International Buyers:

Buyers should verify compliance with international standards like ISO 9001 for quality management and ensure that suppliers can provide certifications for material safety and performance.

Polyethylene Terephthalate (PET)

Key Properties:

PET is a lightweight, strong, and transparent thermoplastic with excellent resistance to moisture and chemicals. It can withstand temperatures up to 70°C and is often recycled, making it an eco-friendlier option.

Pros & Cons:

PET is cost-effective and widely available, making it suitable for mass production. However, it can be less durable than PVC or TPU, leading to potential wear and tear over time.

Impact on Application:

PET’s moisture resistance makes it suitable for backpacks intended for outdoor use. However, its lower elasticity may limit its application in designs requiring stretch or flexibility.

Considerations for International Buyers:

Buyers should look for suppliers that adhere to recycling standards and sustainability practices, especially in regions with stringent environmental regulations, such as the EU’s Circular Economy Package.

Nylon

Key Properties:

Nylon is a synthetic polymer known for its high tensile strength, durability, and resistance to abrasion and mildew. It typically performs well in a temperature range of -40°C to 120°C.

Pros & Cons:

Nylon is highly durable and offers excellent resistance to wear and tear, making it suitable for rugged use. However, it is more expensive than other materials and may require special treatments to enhance its water resistance.

Impact on Application:

Nylon’s strength makes it ideal for backpacks designed for heavy loads or outdoor activities. Its compatibility with various coatings allows for customization in terms of water resistance and aesthetics.

Considerations for International Buyers:

Buyers should ensure compliance with international quality standards, such as ISO 14001 for environmental management, and verify that suppliers use ethically sourced nylon to meet growing consumer demand for sustainable practices.

| Material | Typical Use Case for transparent small backpack | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyvinyl Chloride (PVC) | Basic promotional or fashion backpacks | Cost-effective, durable | Less environmentally friendly, rigid | Low |

| Thermoplastic Polyurethane (TPU) | Sports or outdoor activity backpacks | Flexible, comfortable | Higher production cost | High |

| Polyethylene Terephthalate (PET) | Eco-friendly backpacks for casual use | Lightweight, recyclable | Less durable than PVC or TPU | Medium |

| Nylon | Heavy-duty outdoor backpacks | High strength and durability | More expensive, requires treatments | High |

In summary, selecting the right material for transparent small backpacks involves balancing performance properties, cost, and compliance with regional standards. Buyers should consider their target market’s preferences and the intended use of the backpacks to make informed sourcing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for transparent small backpack

The manufacturing process for transparent small backpacks involves several key stages, each critical to ensuring the final product meets quality and performance standards. International B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, need to understand these processes to make informed sourcing decisions.

Manufacturing Process Overview

1. Material Preparation

The journey begins with selecting appropriate materials. Transparent small backpacks typically use materials such as PVC, TPU, or other synthetic polymers known for their durability and transparency. Key considerations during this stage include:

- Material Sourcing: Ensure that suppliers can provide high-quality materials that comply with international safety standards, such as REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) in Europe.

- Pre-Production Testing: Conduct tests on the raw materials for transparency, flexibility, and resistance to environmental conditions. This step helps avoid issues during later production stages.

2. Forming

Forming is where the raw materials are shaped into the desired components of the backpack. Common techniques include:

- Thermoforming: This involves heating the plastic material until pliable and then shaping it using molds. This method is widely used for creating the transparent body of the backpack.

- Die Cutting: For precision, die cutting is used to create various components, such as straps and pockets, from sheets of material.

Quality control during this stage is crucial to ensure that the dimensions and shapes meet specifications.

3. Assembly

Once the components are formed, they are assembled into the final product. This stage often involves:

- Sewing and Welding: Transparent backpacks may require specialized welding techniques to ensure waterproof seams. For areas that need stitching, high-strength threads and UV-resistant materials are used to enhance durability.

- Attachment of Accessories: This includes adding zippers, buckles, and straps. Suppliers should ensure that these components are sourced from reputable manufacturers to maintain quality.

4. Finishing

The final stage includes several finishing processes that enhance the appearance and functionality of the backpack:

- Quality Checks: Each backpack undergoes visual inspections for defects such as scratches or misaligned components.

- Packaging: Proper packaging is essential to protect the product during shipping and handling. This includes using materials that prevent scratching and deformation.

Quality Assurance Protocols

Quality assurance (QA) is essential throughout the manufacturing process to ensure that the final products meet international standards and customer expectations. For transparent small backpacks, international B2B buyers should be familiar with the following QA practices:

Relevant International Standards

- ISO 9001: This standard focuses on quality management systems and is applicable to any organization, ensuring consistent quality in products and services.

- CE Marking: In the European market, CE marking indicates that the product complies with EU safety, health, and environmental protection standards.

Industry-Specific Standards

- API (American Petroleum Institute): For backpacks that may come into contact with chemicals, compliance with API standards ensures material safety and performance.

Quality Control Checkpoints

To maintain high-quality standards, manufacturers implement various checkpoints throughout the production process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet quality specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process allows for the early detection of defects.

- Final Quality Control (FQC): Before packaging, the final product is thoroughly inspected for defects, ensuring that it meets all specifications.

Common Testing Methods

B2B buyers should be aware of the following testing methods commonly used in the industry:

- Tensile Testing: Assesses the strength and elasticity of materials.

- Transparency Testing: Measures the clarity of the material to ensure it meets customer requirements.

- Water Resistance Testing: Ensures that the backpack can withstand exposure to moisture, crucial for outdoor use.

Verifying Supplier Quality Control

To ensure that suppliers adhere to quality standards, international B2B buyers can take several actionable steps:

- Audits: Conduct regular audits of suppliers’ facilities to assess compliance with international standards and internal quality protocols.

- Quality Reports: Request detailed quality control reports, including results from IQC, IPQC, and FQC stages.

- Third-Party Inspections: Hire independent inspection agencies to conduct pre-shipment inspections. This adds a layer of assurance that the products meet the required specifications before they leave the factory.

QC and Certification Nuances for International Buyers

Understanding the nuances of quality control and certification is vital for international buyers:

- Cultural Differences: Be aware that quality expectations may vary by region. For example, manufacturers in Europe may have stricter quality controls compared to those in emerging markets.

- Documentation: Ensure that all certifications and quality reports are documented and available for review. This is crucial for compliance with import regulations in various countries.

- Communication: Establish clear lines of communication with suppliers regarding quality expectations. This includes setting up regular updates and feedback loops to address any potential issues promptly.

By understanding the manufacturing processes and quality assurance practices for transparent small backpacks, international B2B buyers can make informed decisions that enhance their sourcing strategies and ensure the delivery of high-quality products to their markets. This comprehensive approach not only mitigates risks but also strengthens supplier relationships and brand reputation in a competitive global marketplace.

Related Video: How a Backpack is Made : Every Step on the Production Line

Comprehensive Cost and Pricing Analysis for transparent small backpack Sourcing

In the competitive landscape of transparent small backpack sourcing, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis breaks down the key cost components and influencers that shape pricing, offering actionable insights tailored for buyers from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The choice of materials significantly impacts costs. Transparent backpacks often utilize PVC or TPU for visibility and durability. Prices for these materials can vary based on quality, sourcing locations, and market fluctuations. Eco-friendly materials, while often more expensive, can enhance brand reputation and appeal to environmentally conscious consumers.

-

Labor: Labor costs depend on the manufacturing country. Regions like Vietnam and Indonesia offer competitive labor rates, while maintaining quality. Countries with advanced manufacturing capabilities may command higher wages but can also deliver superior craftsmanship, which can justify the expense.

-

Manufacturing Overhead: This includes expenses related to factory operations, equipment maintenance, and utilities. Overhead can vary based on the production scale and efficiency of the factory. A well-established factory may offer better pricing due to economies of scale.

-

Tooling: Custom designs may require specific tooling, which incurs additional costs. Tooling expenses are often amortized over larger order quantities, so higher MOQs can mitigate this cost per unit.

-

Quality Control (QC): Investing in quality control is essential to avoid returns and maintain brand integrity. The cost of QC can vary based on the complexity of the product and the certification standards required by the buyer’s market.

Illustrative Image (Source: Google Search)

- Logistics: Shipping costs can vary widely based on the mode of transport (air vs. sea), distance, and shipping terms (Incoterms). For international buyers, understanding these costs is essential for accurate budgeting.

Illustrative Image (Source: Google Search)

- Margin: Suppliers typically mark up prices to cover their risks and ensure profitability. Margins can be influenced by the supplier’s reputation, market demand, and the complexity of the order.

Price Influencers

-

Volume/MOQ: Higher order quantities generally lead to lower per-unit costs. Suppliers are more inclined to offer discounts at higher volumes due to reduced handling and production costs.

-

Specifications/Customization: Customized designs or specifications can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials: The choice of material significantly affects pricing. High-quality, sustainable materials can increase the price but may provide a competitive edge.

-

Quality and Certifications: Compliance with international standards (e.g., ISO, REACH) may incur additional costs but is essential for accessing certain markets.

-

Supplier Factors: The supplier’s reliability, experience, and production capacity can influence pricing. Established suppliers may offer better quality but at a premium price.

-

Incoterms: Understanding Incoterms is vital for determining responsibility for costs and risks during shipping. Different terms can impact the overall landed cost of the product.

Buyer Tips

-

Negotiation: Always negotiate pricing, especially for larger orders. Suppliers often have room to adjust their margins, particularly if they value a long-term partnership.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes all expenses from sourcing to delivery. This holistic view can help identify the best overall value rather than just the lowest price.

-

Pricing Nuances: Be aware of fluctuations in raw material costs and labor rates in different countries. Regularly review market trends to make informed sourcing decisions.

-

Supplier Diversification: Adopt a “China Plus One” strategy by sourcing from multiple countries. This mitigates risks associated with single-source dependency and can optimize costs.

-

Request Samples: Always request samples before finalizing orders. This helps verify quality and avoids costly mistakes during mass production.

Disclaimer

Prices and cost structures provided are indicative and may vary based on numerous factors, including market conditions, supplier negotiations, and specific order requirements. Always conduct thorough research and due diligence when sourcing to ensure the best outcomes for your business.

Spotlight on Potential transparent small backpack Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘transparent small backpack’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for transparent small backpack

When sourcing transparent small backpacks, understanding the essential technical properties and trade terminology is crucial for making informed decisions. Here’s a breakdown of the key specifications and terms that will enhance your purchasing strategy.

Critical Specifications for Transparent Small Backpacks

-

Material Grade

– Definition: Refers to the quality and type of materials used in the production of the backpack, such as PVC, TPU, or other transparent plastics.

– B2B Importance: Higher-grade materials offer better durability and transparency, which are essential for aesthetic appeal and product longevity. Buyers must assess material certifications to ensure compliance with safety standards. -

Tolerance

– Definition: The allowable variation in dimensions and characteristics of the backpack, such as size, thickness, and weight.

– B2B Importance: Tolerance levels affect the fit and functionality of the backpack. Understanding these specifications helps in avoiding production errors and ensuring product consistency, which is critical for brand reputation. -

Weight Capacity

– Definition: The maximum weight that the backpack can safely carry without compromising its integrity.

– B2B Importance: Knowing the weight capacity is vital for targeting specific market segments, such as students or travelers, who may have different needs. It also aids in compliance with safety regulations. -

Water Resistance

– Definition: The ability of the backpack to withstand water exposure, often indicated by a specific rating (e.g., IPX5).

– B2B Importance: In regions with high humidity or frequent rainfall, water resistance can be a significant selling point. Buyers should prioritize suppliers that can provide clear testing results for water resistance. -

Zipper Quality

– Definition: The type and durability of zippers used in the backpack, often measured by material (e.g., nylon vs. metal) and strength.

– B2B Importance: Zipper failure is a common issue in backpacks. High-quality zippers enhance product reliability and customer satisfaction, reducing the risk of returns. -

Eco-Friendliness

– Definition: The environmental impact of materials used, including whether they are recyclable or produced using sustainable practices.

– B2B Importance: Increasingly, consumers are seeking eco-friendly products. Manufacturers that emphasize sustainability can gain a competitive edge, especially in markets where environmental standards are stringent.

Common Trade Terms in the Backpack Industry

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships is essential for buyers looking for customized products. It indicates the ability to adapt designs based on specific buyer needs. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: MOQs can affect pricing and inventory management. Buyers should negotiate MOQs to align with their sales forecasts and financial capabilities. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to solicit price quotes from suppliers.

– Importance: An RFQ is critical for comparing costs and ensuring transparency in pricing. It helps buyers obtain detailed information about product specifications and terms. -

Incoterms (International Commercial Terms)

– Definition: A set of pre-defined commercial terms published by the International Chamber of Commerce, used in international transactions.

– Importance: Familiarity with Incoterms helps buyers understand the logistics and responsibilities associated with shipping, including who is liable for shipping costs, insurance, and risk during transit. -

Lead Time

– Definition: The amount of time that elapses from the placement of an order until the product is delivered.

– Importance: Lead times are crucial for inventory planning and meeting customer demand. Buyers should clarify lead times with suppliers to avoid stockouts. -

Quality Control (QC)

– Definition: The processes and procedures employed to ensure that products meet specified requirements and standards.

– Importance: Effective QC measures are vital for maintaining product consistency and quality. Buyers should inquire about a supplier’s QC practices to mitigate risks associated with defective products.

By understanding these technical properties and trade terminologies, B2B buyers can make more informed decisions, ultimately enhancing their supply chain efficiency and product offerings in the competitive market for transparent small backpacks.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the transparent small backpack Sector

The global market for transparent small backpacks is experiencing significant growth, driven by a combination of fashion trends, consumer preferences, and functionality. As urban lifestyles evolve, the demand for versatile and stylish yet practical bags has surged. The transparent backpack trend aligns with the growing consumer interest in minimalist designs and the need for security in crowded spaces, such as schools, concerts, and sporting events. This trend is particularly relevant for international B2B buyers looking to tap into youth markets in regions like Africa, South America, the Middle East, and Europe.

Emerging technologies are reshaping sourcing strategies in this sector. Innovations such as 3D printing and advanced manufacturing techniques enable brands to offer customized products with shorter lead times. Additionally, B2B platforms are evolving, providing buyers with access to a wider range of suppliers across diverse regions, including Southeast Asia and Latin America. Sourcing strategies are increasingly adopting the “China Plus One” approach, where companies maintain Chinese manufacturing relationships while exploring alternatives in countries like Vietnam and India. This diversification helps mitigate risks associated with geopolitical tensions and supply chain disruptions.

Sustainability & Ethical Sourcing in B2B

The environmental impact of the fashion industry has prompted B2B buyers to prioritize sustainability in their sourcing decisions. For transparent small backpacks, this means selecting materials that are not only durable but also eco-friendly. Brands are increasingly using recycled materials, such as RPET (recycled polyethylene terephthalate), which reduces plastic waste and offers a sustainable alternative to traditional materials.

Ethical sourcing is crucial for maintaining a positive brand image and meeting consumer expectations. B2B buyers should seek suppliers who adhere to fair labor practices and have certifications that validate their commitment to sustainability. Certifications such as Global Recycle Standard (GRS) and OEKO-TEX® can provide assurance that the materials used in the production of transparent small backpacks meet environmental and social standards. By focusing on ethical supply chains, businesses can enhance their brand reputation and appeal to environmentally conscious consumers.

Brief Evolution/History

The transparent backpack has evolved from a niche product to a mainstream accessory, particularly in urban settings. Initially popularized by festival-goers and students needing to comply with security regulations, the design has transcended its functional roots to become a fashion statement. Over the years, advancements in material technology have allowed manufacturers to create more stylish and durable options, catering to a broader audience. This evolution presents a unique opportunity for B2B buyers to capitalize on the growing trend while aligning with consumer values around transparency and sustainability.

As the market continues to expand, international B2B buyers must remain vigilant about sourcing trends and sustainability practices to effectively compete in this dynamic sector.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of transparent small backpack

-

What key factors should I consider when vetting suppliers for transparent small backpacks?

When vetting suppliers, prioritize quality assurance certifications (ISO, BSCI, etc.), previous client references, and production capacity. Check for compliance with international standards and environmental regulations, as these are crucial for maintaining your brand’s reputation. Utilize platforms like Alibaba to review supplier ratings and feedback. Additionally, consider conducting factory visits or hiring third-party inspection services to evaluate manufacturing practices firsthand. -

Can I customize the design of transparent small backpacks, and what is the process?

Yes, most manufacturers offer customization options. Begin by providing your specifications, including materials, dimensions, colors, and branding elements. Request samples to confirm that the design meets your expectations before proceeding with bulk production. Ensure that you clarify minimum order quantities (MOQs) and any additional costs associated with customization. Establish a timeline for design approval to avoid delays. -

What are the typical MOQs and lead times for sourcing transparent small backpacks?

MOQs for transparent small backpacks can range from 500 to 5,000 units, depending on the supplier and customization complexity. Lead times typically vary from 4 to 8 weeks, influenced by factors such as order size, supplier location, and production schedules. Always confirm these details upfront and consider potential delays due to shipping or sourcing materials, especially during peak seasons.

Illustrative Image (Source: Google Search)

-

What payment methods are commonly used in international transactions for bulk orders?

International B2B transactions often utilize methods like wire transfers, PayPal, or letters of credit. Wire transfers are the most common due to their security and speed, but they require trust in the supplier. For larger orders, consider using letters of credit, which provide additional security by ensuring that payment only occurs once the goods are shipped and documentation is verified. Always discuss payment terms upfront to avoid misunderstandings. -

How can I ensure quality assurance and compliance with certifications?

To ensure quality, establish a clear quality control (QC) process with your supplier, detailing inspection points throughout production. Request certifications relevant to your market, such as safety standards or material compliance (e.g., REACH, RoHS). Consider hiring third-party inspection services to conduct pre-shipment inspections, which can identify defects and ensure that products meet specified standards before they reach your market. -

What logistics considerations should I be aware of when importing backpacks?

When importing transparent small backpacks, consider shipping methods (air vs. sea), costs, and transit times. Air freight is faster but more expensive, while sea freight is cost-effective for large orders. Be aware of customs duties and tariffs specific to your country, and ensure that all documentation is complete to avoid delays. Partnering with a reliable freight forwarder can streamline logistics and provide expertise in navigating customs regulations.

-

How should I handle disputes with suppliers?

To effectively manage disputes, maintain open lines of communication with your supplier. Clearly outline terms in your contract, including quality expectations and delivery timelines. If issues arise, try to resolve them amicably through negotiation first. If necessary, involve a third-party mediator or arbitration service, especially if the supplier is in a different country. Having a clear dispute resolution process outlined in your contract can significantly ease tensions. -

What are the best practices for managing the supply chain for transparent small backpacks?

Implementing a robust supply chain management strategy involves diversifying suppliers to mitigate risks and ensure consistent quality. Utilize technology for real-time tracking of orders and inventory levels. Regularly communicate with your suppliers to stay informed about production schedules and potential disruptions. Additionally, building strong relationships with suppliers can enhance collaboration and lead to better pricing and terms in the long run.

Strategic Sourcing Conclusion and Outlook for transparent small backpack

The strategic sourcing of transparent small backpacks presents significant opportunities for international B2B buyers. As the demand for unique and functional products rises globally, understanding the diverse manufacturing landscapes of regions like China, Vietnam, India, and Bangladesh can provide a competitive edge.

Key Takeaways:

– Diversification is Essential: Embrace a “China Plus One” strategy by sourcing from multiple countries to enhance supply chain resilience and optimize costs.

– Quality and Compliance: Prioritize suppliers who maintain high-quality standards and adhere to environmental and social compliance, as this is increasingly crucial for market access in developed regions.

– Cost Analysis: Look beyond unit prices to the total cost of ownership, factoring in logistics and quality control expenses.

As you navigate the sourcing landscape, consider leveraging local expertise and trusted partners to mitigate risks and streamline operations. The future of the transparent small backpack market is promising, and proactive engagement with suppliers will position your business for success. By investing in strategic sourcing now, you can ensure your offerings remain relevant and appealing in an evolving marketplace.