Your Ultimate Guide to Sourcing Backpack Sprayer Battery

Guide to Backpack Sprayer Battery Powered

- Introduction: Navigating the Global Market for backpack sprayer battery powered

- Understanding backpack sprayer battery powered Types and Variations

- Key Industrial Applications of backpack sprayer battery powered

- Strategic Material Selection Guide for backpack sprayer battery powered

- In-depth Look: Manufacturing Processes and Quality Assurance for backpack sprayer battery powered

- Comprehensive Cost and Pricing Analysis for backpack sprayer battery powered Sourcing

- Spotlight on Potential backpack sprayer battery powered Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for backpack sprayer battery powered

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the backpack sprayer battery powered Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of backpack sprayer battery powered

- Strategic Sourcing Conclusion and Outlook for backpack sprayer battery powered

Introduction: Navigating the Global Market for backpack sprayer battery powered

As the demand for efficient agricultural practices and effective pest control rises globally, battery-powered backpack sprayers have emerged as an indispensable tool for businesses across various sectors. These sprayers offer unmatched portability, ease of use, and versatility, making them ideal for landscapers, agricultural professionals, and pest control operators alike. Unlike traditional sprayers, battery-powered models eliminate the need for manual pumping or cumbersome cords, allowing users to operate with greater efficiency and comfort.

This guide serves as a comprehensive resource for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. It covers a wide array of critical topics, including:

- Types of Backpack Sprayers: Explore various models tailored to different applications.

- Materials and Manufacturing Quality Control: Understand the factors that influence durability and performance.

- Supplier Insights: Identify reliable manufacturers and distributors in the global market.

- Cost Considerations: Gain clarity on pricing structures and value propositions.

- Market Trends: Stay informed about the latest innovations and shifts in consumer preferences.

- FAQs: Address common queries to facilitate smarter purchasing decisions.

By delving into this guide, B2B buyers will be empowered to make informed sourcing decisions that align with their operational needs and business objectives. Equip your business with the knowledge necessary to navigate the global market for battery-powered backpack sprayers effectively, ensuring you remain competitive in an evolving landscape.

Understanding backpack sprayer battery powered Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Battery-Powered Sprayer | Portable, lightweight, and easy to operate | Gardening, landscaping, pest control | Pros: Affordable, user-friendly; Cons: Limited pressure and capacity compared to advanced models. |

| High-Pressure Battery Sprayer | Higher psi ratings, suitable for tough applications | Agriculture, large-scale pest control | Pros: Powerful spray capabilities; Cons: Heavier and may require more maintenance. |

| Multi-Function Sprayer | Interchangeable nozzles for various spraying patterns | Diverse agricultural tasks | Pros: Versatile for different applications; Cons: Complexity may deter less experienced users. |

| Commercial Battery Sprayer | Designed for heavy-duty use, larger tank capacities | Professional landscaping, agriculture | Pros: Long-lasting battery life; Cons: Higher initial investment, potential weight issues. |

| Compact Battery Sprayer | Smaller, more maneuverable design for tight spaces | Urban gardening, small-scale pest control | Pros: Easy to transport and store; Cons: Limited tank size and less spray volume. |

Standard Battery-Powered Sprayer

Standard battery-powered sprayers are designed for general use in gardening and landscaping. They typically feature a lightweight construction and an easy-to-use interface, making them ideal for small to medium-sized applications. B2B buyers should consider factors such as tank capacity and battery life, as these can significantly impact operational efficiency, especially in larger gardens or commercial setups.

High-Pressure Battery Sprayer

These sprayers are engineered to deliver higher psi ratings, making them suitable for more challenging tasks, such as agricultural applications and large-scale pest control. They often come with robust battery capacities to support extended use. When purchasing, B2B buyers should weigh the benefits of increased power against the potential for higher weight and maintenance needs, which can affect user comfort and operational costs.

Multi-Function Sprayer

Multi-function battery sprayers are equipped with interchangeable nozzles that allow users to switch between different spraying patterns, enhancing versatility. This feature is particularly beneficial for diverse agricultural tasks, where specific application techniques are necessary. Buyers should evaluate the complexity of these models, as their multifunctionality may require a steeper learning curve for operators unfamiliar with advanced sprayer systems.

Commercial Battery Sprayer

Designed for heavy-duty applications, commercial battery sprayers typically boast larger tank capacities and longer battery life. They are ideal for professional landscaping and agricultural needs, where efficiency and durability are paramount. B2B buyers should consider the initial investment required for these sprayers, as well as their weight, which may pose challenges for manual handling during extended use.

Compact Battery Sprayer

Compact battery sprayers are designed for maneuverability and ease of use in tight spaces, making them perfect for urban gardening and small-scale pest control. Their smaller size allows for easy transportation and storage, but buyers should be mindful of their limited tank size and spray volume. When selecting a compact sprayer, B2B buyers should ensure that it meets their specific application needs without sacrificing performance.

Key Industrial Applications of backpack sprayer battery powered

| Industry/Sector | Specific Application of backpack sprayer battery powered | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Crop protection and pest control | Efficient application of pesticides, reducing labor costs | Battery life, nozzle variety, and tank capacity |

| Horticulture | Fertilization and nutrient application | Enhanced plant health and growth, improved yield | Compatibility with fertilizers, pressure settings, and ergonomics |

| Landscaping | Weed and invasive plant management | Time-saving and effective treatment of large areas | Weight, battery efficiency, and ease of mobility |

| Public Health | Mosquito control and disease prevention | Mitigating health risks and protecting communities | Chemical compatibility, safety features, and maintenance needs |

| Facilities Management | Disinfecting surfaces in public spaces | Ensuring cleanliness and safety in high-traffic areas | Tank size, pressure capacity, and ease of cleaning |

Agriculture

In the agricultural sector, battery-powered backpack sprayers are essential for effective crop protection and pest control. These sprayers allow farmers to apply pesticides and herbicides efficiently, minimizing labor costs and ensuring uniform coverage. For international buyers, especially in regions like Africa and South America, the focus should be on sprayers with long battery life and high tank capacity to accommodate larger fields. Additionally, compatibility with various pesticides is crucial for maximizing effectiveness and minimizing waste.

Horticulture

In horticulture, these sprayers are used for fertilization and nutrient application, promoting healthy plant growth. The ability to adjust spray patterns and pressure settings enables precise application, which is vital for maximizing yield. Buyers from the Middle East and Europe should consider models that can handle a range of fertilizers and nutrients while ensuring ergonomic designs for user comfort during extended use. This adaptability can significantly enhance the productivity of horticultural operations.

Landscaping

Landscapers utilize battery-powered backpack sprayers for weed and invasive plant management. The portability and ease of use of these sprayers allow for quick treatment of expansive areas, reducing the time spent on manual weeding. B2B buyers in this sector should prioritize sprayers that are lightweight and have efficient battery life, as these factors directly impact operational efficiency. The ability to switch nozzles for different applications is also a significant advantage.

Public Health

In public health, battery-powered backpack sprayers play a critical role in mosquito control and disease prevention. They allow for the targeted application of insecticides in urban areas, helping to mitigate health risks associated with vector-borne diseases. Buyers should look for sprayers that are compatible with a variety of insecticides and have safety features to protect operators. The ability to cover large areas quickly is also essential for effective public health interventions.

Facilities Management

These sprayers are increasingly used in facilities management for disinfecting surfaces in public spaces, particularly in response to health crises. The effectiveness of these sprayers in delivering disinfectants ensures cleanliness and safety in high-traffic areas. International buyers must consider factors such as tank size for large area coverage, pressure capacity for effective application, and ease of cleaning the equipment to maintain hygiene standards.

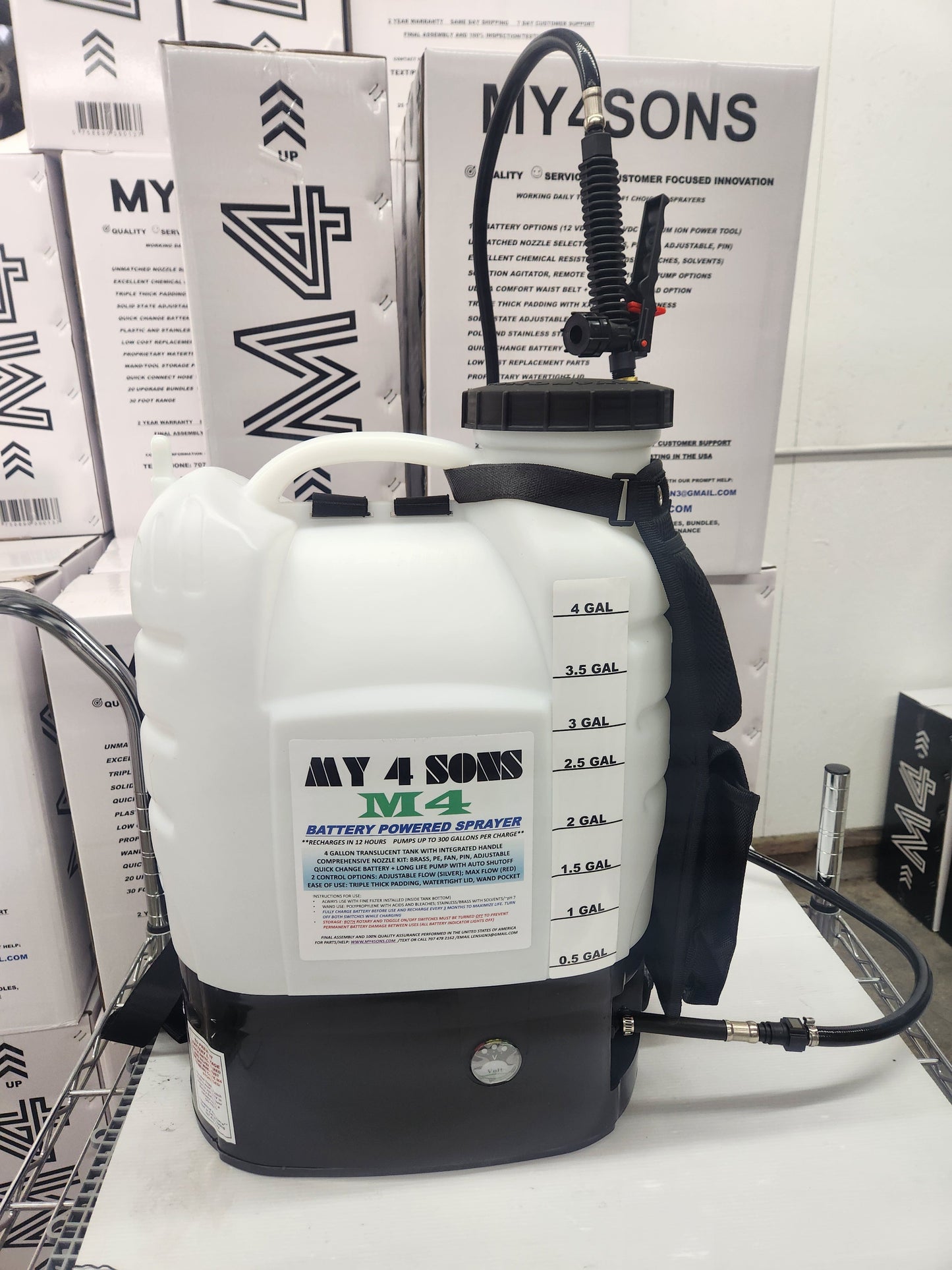

Related Video: #1 Rated MY4SONS M4 Battery Powered Backpack Sprayer Quick Start Video September 2019

Strategic Material Selection Guide for backpack sprayer battery powered

When selecting materials for battery-powered backpack sprayers, international B2B buyers must consider various factors that influence performance, durability, and cost-effectiveness. The following analysis covers four common materials used in the construction of these sprayers, focusing on their properties, advantages, disadvantages, and specific considerations for buyers in diverse markets like Africa, South America, the Middle East, and Europe.

Polyethylene (PE)

Key Properties:

Polyethylene is lightweight, resistant to impact, and has a good chemical resistance profile. It can typically handle temperatures up to 80°C (176°F) and pressures around 10 bar (145 psi), making it suitable for various liquids used in agricultural applications.

Pros & Cons:

The main advantages of polyethylene are its low cost, ease of fabrication, and resistance to corrosion and UV light. However, it may not be as durable as other materials under extreme conditions, and its mechanical strength can diminish at higher temperatures.

Impact on Application:

Polyethylene is compatible with a wide range of chemicals, including fertilizers and pesticides, making it ideal for agricultural use. However, it may not be suitable for highly corrosive substances.

Considerations for International Buyers:

Buyers should ensure compliance with local regulations regarding chemical storage and transportation. Standards such as ASTM D3350 for polyethylene pipe materials may be relevant.

Aluminum

Key Properties:

Aluminum is lightweight yet strong, with excellent corrosion resistance. It typically withstands temperatures up to 150°C (302°F) and pressures exceeding 20 bar (290 psi), making it suitable for high-performance applications.

Pros & Cons:

Aluminum’s advantages include its high strength-to-weight ratio and resistance to corrosion, which can extend the lifespan of the sprayer. However, it is more expensive than polyethylene and may require special manufacturing processes like welding or anodizing.

Impact on Application:

Aluminum is compatible with a variety of media, including corrosive chemicals, which makes it versatile for different agricultural applications. However, it may not be suitable for very acidic or alkaline substances without proper coatings.

Considerations for International Buyers:

Buyers should be aware of international standards such as ISO 9001 for quality management systems and ensure that suppliers adhere to these standards for consistent product quality.

Stainless Steel

Key Properties:

Stainless steel offers excellent corrosion resistance and can handle high temperatures (up to 300°C or 572°F) and pressures (up to 30 bar or 435 psi).

Pros & Cons:

The primary advantage of stainless steel is its durability and long lifespan, making it suitable for heavy-duty applications. However, it is significantly more expensive than both polyethylene and aluminum, and its weight can be a drawback for portability.

Impact on Application:

Stainless steel is ideal for harsh environments and is compatible with a wide range of chemicals, including those that may corrode other materials. This makes it a preferred choice for professionals in pest control and agriculture.

Considerations for International Buyers:

Buyers should ensure compliance with food safety standards (if applicable) and environmental regulations. Standards such as ASTM A240 for stainless steel sheet and plate may also be relevant.

PVC (Polyvinyl Chloride)

Key Properties:

PVC is a versatile plastic that offers good chemical resistance and can handle temperatures up to 60°C (140°F) and pressures around 10 bar (145 psi).

Pros & Cons:

PVC is cost-effective and easy to mold into various shapes, making it suitable for complex designs. However, it has lower temperature and pressure ratings compared to other materials and can become brittle over time.

Impact on Application:

PVC is compatible with many chemicals, making it suitable for agricultural applications. However, it may not be ideal for high-temperature or high-pressure applications.

Considerations for International Buyers:

Buyers should verify compliance with local regulations regarding plastic materials and chemical compatibility. Standards such as ASTM D1784 for PVC materials may be important.

| Material | Typical Use Case for backpack sprayer battery powered | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene (PE) | Tanks and components for chemical storage | Low cost, good chemical resistance | Less durable under extreme conditions | Low |

| Aluminum | Structural components and frames | Lightweight, high strength | Higher cost, requires special fabrication | Medium |

| Stainless Steel | Heavy-duty applications, corrosive environments | Excellent durability, corrosion resistant | High cost, heavier weight | High |

| PVC | Hoses and fittings for various chemicals | Cost-effective, easy to mold | Lower temperature/pressure ratings | Low |

This strategic material selection guide provides B2B buyers with a comprehensive overview of the materials used in battery-powered backpack sprayers, enabling informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for backpack sprayer battery powered

Manufacturing Processes for Battery-Powered Backpack Sprayers

The manufacturing of battery-powered backpack sprayers involves several key stages that ensure both functionality and quality. Understanding these stages can help B2B buyers from Africa, South America, the Middle East, and Europe make informed purchasing decisions.

1. Material Preparation

The first step in manufacturing backpack sprayers is material preparation. Manufacturers typically use high-density polyethylene (HDPE) for the tank due to its durability and resistance to chemicals. Other materials include:

- Metal Components: Often used for the spray wand and internal pump mechanisms.

- Rubber Seals: Ensure leak-proof connections between components.

- Battery Units: Lithium-ion batteries are favored for their lightweight and high energy density.

Quality control begins at this stage, where materials are inspected for compliance with specifications and international standards.

2. Forming

The forming stage involves shaping the prepared materials into the various components of the sprayer. Key techniques include:

- Injection Molding: Commonly used for creating the tank and other plastic components. This method allows for complex shapes and a high level of detail.

- Metal Fabrication: The spray wand and pump parts are typically produced through processes like stamping or machining, ensuring precision in dimensions and fit.

During this stage, manufacturers must adhere to strict guidelines to minimize defects, ensuring the integrity of the products.

3. Assembly

The assembly stage is crucial for the functionality of the backpack sprayer. This process includes:

- Component Integration: All parts, including the tank, pump, spray wand, and battery, are assembled.

- Wiring and Connections: Electric components are connected, ensuring that the battery and pump work harmoniously.

Quality checks at this stage, known as In-Process Quality Control (IPQC), help ensure that each assembled unit meets quality standards before moving to the next phase.

4. Finishing

The finishing stage typically involves:

- Surface Treatment: Components may receive coatings to enhance durability and resistance to corrosion.

- Final Assembly: This includes adding labels, final inspections, and packaging.

This phase is critical as it often involves the last chance to address any aesthetic or functional issues before the product reaches the market.

Quality Assurance Practices

Quality assurance (QA) is integral to the manufacturing of battery-powered backpack sprayers. It ensures that products meet established standards and customer expectations.

International Standards

B2B buyers should be aware of relevant international standards that manufacturers often comply with, such as:

- ISO 9001: This standard focuses on quality management systems and is widely recognized globally. Compliance indicates that the manufacturer follows consistent processes and meets customer requirements.

- CE Marking: For products sold in the European market, CE marking indicates conformity with health, safety, and environmental protection standards.

Industry-Specific Standards

Specific industry standards also apply, particularly for agricultural equipment:

- API Standards: The American Petroleum Institute (API) provides standards for equipment used in agriculture, ensuring safety and reliability.

Quality Control Checkpoints

Quality control checkpoints throughout the manufacturing process include:

- Incoming Quality Control (IQC): Inspects raw materials and components upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Conducted during the manufacturing process to catch defects early.

- Final Quality Control (FQC): A thorough inspection of the final product before packaging and shipping.

Common Testing Methods

Manufacturers utilize various testing methods to ensure the functionality and safety of backpack sprayers:

- Pressure Testing: Ensures that the tank and connections can withstand the maximum operating pressure.

- Battery Performance Tests: Assess the efficiency and longevity of the battery under typical usage conditions.

- Leak Testing: Identifies any potential leaks in the assembly, which is critical for safety and performance.

Verifying Supplier Quality Control

B2B buyers should take proactive steps to verify the quality control processes of their suppliers:

- Conduct Audits: Regular audits of suppliers can help ensure compliance with quality standards and identify areas for improvement.

- Request Quality Reports: Suppliers should provide documentation of their quality control processes, including test results and compliance certifications.

- Third-Party Inspections: Engage third-party agencies to conduct independent inspections of manufacturing facilities and processes.

Navigating QC Nuances for International Buyers

For international buyers, particularly from diverse markets such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential:

- Cultural Differences: Be aware of potential cultural differences in business practices and quality expectations. Clear communication is vital.

- Regulatory Compliance: Different regions may have specific regulations regarding agricultural equipment. Ensure your supplier is knowledgeable about the compliance requirements in your market.

- Logistics Challenges: Consider the logistics of importing products, including potential delays and additional inspections that may be required upon arrival.

By understanding the manufacturing processes and quality assurance practices associated with battery-powered backpack sprayers, B2B buyers can make more informed decisions, ensuring they select high-quality products that meet their operational needs.

Comprehensive Cost and Pricing Analysis for backpack sprayer battery powered Sourcing

When sourcing battery-powered backpack sprayers, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers. This analysis will guide buyers from regions such as Africa, South America, the Middle East, and Europe in making informed purchasing decisions.

Cost Components

-

Materials: The primary materials include high-density polyethylene (HDPE) for tanks, aluminum or plastic for frames, and lithium-ion batteries. The choice of materials significantly affects durability, weight, and overall performance. Premium materials may lead to higher upfront costs but can result in lower maintenance and replacement costs.

-

Labor: Labor costs vary significantly by region. In countries with lower labor costs, such as those in South America and parts of Africa, the manufacturing cost may be lower. However, quality assurance and skilled labor are necessary for assembly and testing, which can increase costs.

-

Manufacturing Overhead: This includes utilities, facility costs, and equipment depreciation. Manufacturers with advanced production technologies may achieve higher efficiency, which can lower the overall cost per unit.

-

Tooling: The initial investment in tooling for production molds can be substantial but is often amortized over large production runs. Buyers should inquire about the tooling costs if they are considering customized designs.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but adds to the cost. Certifications (like ISO) can also influence pricing, as they require compliance with specific standards.

-

Logistics: Shipping costs can vary based on the distance from the manufacturing facility to the buyer’s location, chosen shipping method, and Incoterms. Buyers should factor in potential customs duties and taxes, which can significantly affect total costs.

-

Margin: Manufacturers typically mark up costs to establish a profit margin. This margin can vary widely based on the supplier’s market positioning, brand strength, and production scale.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Ordering in bulk typically leads to discounts. Buyers should assess their needs and consider pooling orders with other buyers to meet MOQ requirements.

-

Specifications/Customization: Custom features such as larger tank capacities, different nozzle types, or enhanced battery life can increase costs. Buyers should clearly define their requirements to avoid unnecessary expenses.

-

Materials: The choice of materials directly impacts cost. Buyers should evaluate the balance between cost and durability to ensure long-term value.

-

Quality/Certifications: Higher-quality products with certifications may have a higher initial price but can result in lower total cost of ownership (TCO) due to reduced maintenance and longer lifespan.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their products due to perceived quality and service.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) dictate who bears shipping costs and risks, affecting the overall cost structure. Buyers should negotiate favorable terms to minimize expenses.

Buyer Tips

-

Negotiation: Engage in negotiations with suppliers to secure better pricing, especially when committing to larger orders. Leverage competition among suppliers to achieve favorable terms.

-

Cost Efficiency: Focus on the total cost of ownership rather than just the purchase price. Consider factors like maintenance, warranty, and expected lifespan when evaluating offers.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and international shipping costs, which can impact pricing. It’s advisable to request price quotes in your local currency to avoid unexpected costs.

-

Research and Due Diligence: Conduct thorough research on potential suppliers, including reviews and certifications. This can prevent costly mistakes and ensure that you partner with reputable manufacturers.

Disclaimer: Prices for battery-powered backpack sprayers can vary widely based on specifications, order size, and supplier factors. Always request a detailed quotation and consider all cost components for accurate budgeting.

Spotlight on Potential backpack sprayer battery powered Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘backpack sprayer battery powered’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for backpack sprayer battery powered

Key Technical Properties of Battery-Powered Backpack Sprayers

When selecting a battery-powered backpack sprayer, understanding the essential technical properties is crucial for making informed purchasing decisions. Here are several critical specifications that B2B buyers should consider:

-

Tank Capacity

The tank capacity typically ranges from 4 to 6.5 gallons. This specification determines how much liquid can be carried, impacting the efficiency of spraying tasks. A larger capacity allows for extended use without frequent refills, which is essential for large agricultural fields or extensive landscaping projects. -

Maximum Pressure (PSI)

Measured in pounds per square inch (psi), the maximum pressure indicates the force with which the liquid is sprayed. Higher psi values (e.g., 85-150 psi) allow for more effective penetration of foliage and better coverage. For buyers in regions with dense vegetation, higher pressure models are preferred to ensure thorough application of pesticides or fertilizers. -

Battery Capacity (Ah)

Battery capacity, measured in amp-hours (Ah), reflects how long the sprayer can operate on a single charge. For instance, a sprayer with an 8 Ah battery can run longer between charges, which is particularly advantageous in remote areas or for large jobs. B2B buyers should assess their operational needs and select a model that balances weight and battery life. -

Weight

The weight of the backpack sprayer is crucial for user comfort and mobility. Lightweight models (around 10-12 lbs) reduce user fatigue, especially during prolonged use. For businesses that require frequent application, selecting a lighter sprayer can enhance productivity and reduce the risk of injury. -

Spray Nozzles

Many battery-powered backpack sprayers come with interchangeable nozzles for different spraying applications. The availability of multiple nozzle types allows users to customize their spraying technique based on the task—be it broad coverage or targeted application. This versatility can significantly enhance operational efficiency. -

Charging Time

Understanding the charging time of the battery is essential for planning use. A sprayer that charges fully within a few hours is more practical for businesses with tight schedules. Fast charging capabilities can minimize downtime and maximize productivity.

Common Trade Terms in the Backpack Sprayer Industry

Familiarity with industry terminology is key for B2B buyers. Here are some common terms that may arise in procurement discussions:

- OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand name. When sourcing backpack sprayers, understanding which models are OEM can help buyers assess quality and reliability.

Illustrative Image (Source: Google Search)

-

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is critical for budget planning, especially for smaller businesses or new entrants that may not need large quantities of sprayers. -

RFQ (Request for Quotation)

An RFQ is a formal document that solicits price quotes from suppliers. B2B buyers should prepare detailed RFQs to ensure they receive competitive pricing and accurate specifications tailored to their needs. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, risks, and responsibilities, ensuring smoother logistics for imported sprayers. -

Lead Time

Lead time refers to the time taken from placing an order until the product is delivered. Understanding lead times is vital for planning and inventory management, especially for agricultural buyers who may have seasonal needs. -

Warranty

A warranty is a promise from the manufacturer regarding the quality and longevity of the product. Knowing the warranty terms helps buyers gauge the level of risk involved in their investment and ensures they are covered for potential defects.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions, optimizing their procurement processes and enhancing operational efficiency in their respective industries.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the backpack sprayer battery powered Sector

Market Overview & Key Trends

The global market for battery-powered backpack sprayers is witnessing robust growth, primarily driven by the increasing demand for efficient and portable spraying solutions across various sectors, including agriculture, landscaping, and pest control. This trend is particularly pronounced in regions such as Africa, South America, the Middle East, and Europe, where agricultural efficiency is paramount due to varying climatic conditions and resource availability.

International B2B buyers should note the emerging technologies enhancing battery efficiency, such as lithium-ion batteries, which offer longer run times and quicker charging. Additionally, sprayers are increasingly equipped with smart technology, enabling remote monitoring and precision application, which significantly reduces waste and enhances productivity. As environmental regulations tighten globally, buyers are also leaning towards models that comply with sustainability standards, thus influencing sourcing decisions.

Furthermore, the rise of e-commerce platforms has simplified sourcing for international buyers, enabling them to access a broader range of suppliers and models. This democratization of access allows buyers from emerging markets to evaluate options based on performance metrics such as tank capacity, pressure output, and battery life, ensuring they find the best fit for their operational needs.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a central focus in the battery-powered backpack sprayer sector. Environmental impacts associated with traditional sprayers, such as chemical runoff and excessive energy consumption, have prompted a shift towards more sustainable practices. Buyers are encouraged to seek products that utilize eco-friendly materials and manufacturing processes, which can significantly reduce the carbon footprint of their operations.

Ethical supply chains are equally important. Ensuring that suppliers adhere to fair labor practices and sustainable sourcing of materials is vital for maintaining brand integrity and compliance with international regulations. Certifications such as ISO 14001 (Environmental Management) and Energy Star can serve as indicators of a supplier’s commitment to sustainability.

Illustrative Image (Source: Google Search)

Additionally, many manufacturers are now exploring the use of biodegradable and recyclable components in their products. This not only appeals to environmentally conscious buyers but also aligns with the growing consumer demand for sustainable solutions in various industries. Thus, selecting suppliers who prioritize sustainability can enhance a company’s reputation and marketability.

Brief Evolution/History

The evolution of backpack sprayers has transformed significantly over the decades. Initially designed for manual operation, these sprayers have transitioned into electric and battery-powered models, reflecting advancements in technology and changing user preferences. The introduction of battery-powered options has facilitated greater mobility and ease of use, particularly in regions where labor costs are rising, and operational efficiency is crucial.

The integration of features such as ergonomic designs, adjustable straps, and variable pressure settings has made these sprayers not only more user-friendly but also more effective in application. As the market continues to evolve, the focus on innovation, sustainability, and efficiency will likely drive further advancements in design and functionality, catering to the specific needs of international B2B buyers.

Related Video: Solo’s 441 Battery-Powered Backpack Sprayer

Frequently Asked Questions (FAQs) for B2B Buyers of backpack sprayer battery powered

-

What factors should I consider when vetting suppliers for battery-powered backpack sprayers?

When vetting suppliers, prioritize their experience in manufacturing battery-powered backpack sprayers, focusing on their production capacity, quality control processes, and adherence to international standards. Check for certifications like ISO 9001 or CE marking, which indicate quality assurance. Also, evaluate their customer service responsiveness, delivery reliability, and references from previous international clients. Conducting factory audits or requesting product samples can further assure you of their manufacturing capabilities. -

Can I customize the backpack sprayers to fit my specific needs?

Many manufacturers offer customization options for battery-powered backpack sprayers, including tank capacity, nozzle types, and branding. Discuss your specific requirements with potential suppliers to see what modifications they can accommodate. Customizations may also extend to color schemes and packaging. Ensure that any customization does not compromise quality and that the supplier can meet regulatory requirements in your target market. -

What is the typical minimum order quantity (MOQ) and lead time for these products?

The MOQ for battery-powered backpack sprayers can vary widely based on the supplier and the level of customization required, generally ranging from 100 to 500 units. Lead times also depend on the supplier’s production schedule, typically taking 4 to 12 weeks for standard orders. For urgent needs, discuss the possibility of expedited production or partial shipments. Clear communication regarding your timeline will help align expectations with the supplier. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms can vary, but common practices include a 30% deposit upon order confirmation and the remaining 70% before shipment. Some suppliers may offer more favorable terms based on your relationship or order size. Consider using secure payment methods such as letters of credit or escrow services to mitigate risks. Always clarify payment terms in the contract to avoid misunderstandings later. -

How can I ensure quality assurance and certification compliance?

To ensure quality, request documentation proving compliance with relevant international standards, such as ISO certifications or safety standards like CE or RoHS. Conducting third-party inspections or audits before shipment can help verify that the products meet your quality expectations. Establishing a clear quality assurance process with your supplier, including detailed specifications and testing protocols, will facilitate smoother transactions and reduce the risk of defects. -

What logistics considerations should I keep in mind when importing these sprayers?

When importing battery-powered backpack sprayers, consider shipping methods (air vs. sea), costs, and estimated delivery times. Be aware of customs regulations and tariffs in your country, which can affect total landed costs. Engaging a reliable freight forwarder can streamline the logistics process, ensuring compliance with shipping regulations and timely delivery. Additionally, consider warehousing options if you anticipate high demand or need to manage inventory effectively. -

What should I do if there is a dispute with my supplier?

In the event of a dispute, first, attempt to resolve the issue amicably through direct communication with the supplier. Refer to your contract, which should outline dispute resolution procedures. If necessary, consider mediation or arbitration, as these methods can be less costly and quicker than litigation. Document all communications and agreements to support your case. Having a clear understanding of local laws and international trade agreements will also be beneficial. -

Are there specific certifications required for exporting battery-powered backpack sprayers to different regions?

Yes, certification requirements can vary significantly by region. For instance, products sold in Europe may need CE certification, while those in the Middle East might require GCC compliance. In Africa and South America, regulations can differ by country, often focusing on safety and environmental impact. Research the specific requirements for your target markets and communicate with your supplier to ensure that products meet all necessary certifications before shipment.

Strategic Sourcing Conclusion and Outlook for backpack sprayer battery powered

In conclusion, strategic sourcing of battery-powered backpack sprayers is pivotal for international B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. The insights gathered from current models emphasize the importance of balancing price, performance, and usability. Key features such as tank capacity, battery life, and spraying pressure are critical when selecting a sprayer that meets specific operational needs.

Illustrative Image (Source: Google Search)

Investing in high-quality backpack sprayers can significantly enhance productivity in agricultural, landscaping, and pest control sectors. As the demand for efficient and eco-friendly solutions rises, buyers should prioritize sourcing from suppliers that offer durable, reliable, and innovative products.

Looking ahead, the market for battery-powered sprayers is expected to grow, driven by technological advancements and increasing environmental awareness. Buyers are encouraged to engage with manufacturers that can provide not only competitive pricing but also after-sales support and comprehensive warranty options. By adopting a proactive sourcing strategy, businesses can position themselves favorably in an evolving landscape, ensuring they meet the diverse needs of their customers effectively.