Master Sourcing Strategies for the Mount Everest Backpack

Guide to Mount Everest Backpack

- Introduction: Navigating the Global Market for mount everest backpack

- Understanding mount everest backpack Types and Variations

- Key Industrial Applications of mount everest backpack

- Strategic Material Selection Guide for mount everest backpack

- In-depth Look: Manufacturing Processes and Quality Assurance for mount everest backpack

- Comprehensive Cost and Pricing Analysis for mount everest backpack Sourcing

- Spotlight on Potential mount everest backpack Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for mount everest backpack

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the mount everest backpack Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of mount everest backpack

- Strategic Sourcing Conclusion and Outlook for mount everest backpack

Introduction: Navigating the Global Market for mount everest backpack

Navigating the global market for the Mount Everest backpack requires a keen understanding of both the product and the ever-evolving landscape of consumer demand. As a critical item for outdoor enthusiasts and adventure seekers, the Mount Everest backpack combines durability, functionality, and style, making it essential for businesses catering to this niche market. With an increasing number of international buyers from regions like Africa, South America, the Middle East, and Europe—particularly in countries such as Kenya and Poland—there is a growing need for reliable sourcing and manufacturing insights.

This guide provides a comprehensive overview of the Mount Everest backpack, covering essential aspects such as various types, material options, manufacturing processes, quality control measures, and supplier evaluations. By delving into these topics, buyers can make informed decisions that align with their business strategies and consumer preferences.

Understanding the nuances of the Mount Everest backpack market empowers B2B buyers to identify suitable suppliers and negotiate competitive pricing while ensuring product quality. Whether you are sourcing for retail, wholesale, or direct-to-consumer channels, this guide equips you with actionable insights to navigate the complexities of the global backpack market effectively. By leveraging this information, your business can thrive in an increasingly competitive landscape, appealing to customers who demand both performance and reliability in their outdoor gear.

Understanding mount everest backpack Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Technical Climbing Pack | Lightweight, streamlined design with gear loops | Professional mountaineering teams | Excellent weight distribution but limited storage for casual use |

| Expedition Backpack | High capacity, durable materials, weather-resistant | Adventure tourism, expeditions | Great for long trips, but can be bulky and expensive |

| Hydration Pack | Integrated water reservoir with hose system | Hiking tours, desert expeditions | Convenient hydration, but limited storage for other gear |

| Daypack | Compact design for short excursions | Day hikes, urban exploration | Lightweight and versatile, but not suitable for heavy gear |

| Travel Backpack | Multiple compartments and travel-friendly features | Outdoor retailers, travel agencies | Versatile for various activities, but may lack specialized features |

Technical Climbing Pack

Technical climbing packs are designed specifically for high-altitude mountaineering. They feature a lightweight and streamlined design that allows climbers to carry essential gear without excess weight. These packs often include gear loops for ice tools and hydration sleeves. For B2B buyers, the primary consideration is the balance between weight and capacity, as well as the pack’s durability against harsh weather conditions. While they excel in performance, their limited storage capacity may not meet the needs of casual users.

Expedition Backpack

Expedition backpacks are built for extended trips into the wilderness, featuring high-capacity storage, durable materials, and weather-resistant designs. These packs are ideal for adventure tourism and professional expeditions, accommodating a significant amount of gear while ensuring comfort during long treks. For B2B buyers, key considerations include the pack’s weight, ease of access to gear, and the quality of materials used. While they provide ample space and durability, their bulkiness and higher price point can be drawbacks for some buyers.

Hydration Pack

Hydration packs integrate a water reservoir and hose system, allowing users to drink on the go. These packs are particularly useful for hiking tours and desert expeditions, where staying hydrated is crucial. B2B buyers should focus on the capacity of the hydration system, overall pack weight, and additional storage options for gear. Although they offer convenience, their limited storage capacity for other equipment may not suit all outdoor activities.

Daypack

Daypacks are compact backpacks designed for short excursions, making them ideal for day hikes or urban exploration. They typically feature a lightweight design and multiple compartments for organization. For B2B buyers, the versatility and portability of daypacks are significant advantages, as they can cater to a wide range of activities. However, their smaller size may not accommodate larger gear, making them less suitable for heavy-duty outdoor adventures.

Travel Backpack

Travel backpacks are designed with multiple compartments and travel-friendly features, such as padded laptop sleeves and adjustable straps. They are versatile enough for various activities, from outdoor adventures to urban travel. B2B buyers should consider the pack’s organization, comfort, and durability when evaluating options. While they provide excellent versatility, they may lack the specialized features required for specific outdoor activities, which could be a limitation for some users.

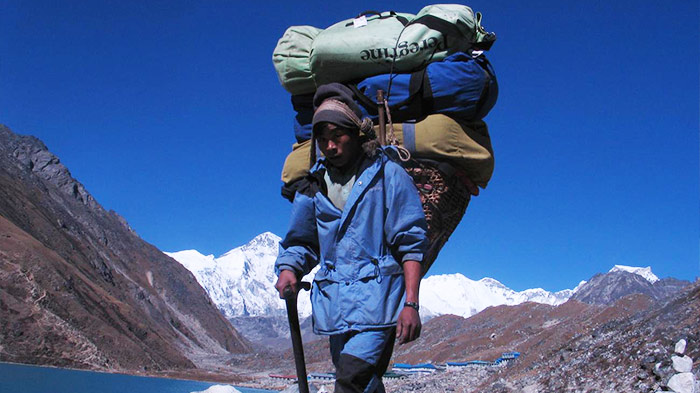

Related Video: Everything A Sherpa Guide Carries To The Summit Of Everest | Inside Everest | Business Insider

Key Industrial Applications of mount everest backpack

| Industry/Sector | Specific Application of mount everest backpack | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Outdoor Recreation | Hiking and Adventure Tours | High durability and capacity for gear storage | Material quality, weather resistance, and design features |

| Education | School and University Use | Versatile design for carrying books and laptops | Ergonomic support, weight distribution, and size options |

| Travel and Tourism | Backpacking and Travel Packages | Lightweight and functional for travelers | Customization options, branding, and material choice |

| Emergency Services | First Response and Rescue Operations | Robust construction for carrying emergency supplies | Compliance with safety standards and quick access features |

| Corporate Gifting | Promotional Giveaways for Businesses | Brand visibility and customer loyalty | Custom branding options and bulk pricing considerations |

Outdoor Recreation

The mount everest backpack is ideal for the outdoor recreation industry, particularly in hiking and adventure tours. Its robust construction and ample storage capacity allow adventurers to carry essential gear such as food, water, and safety equipment. For international buyers, especially from regions like Africa and South America, sourcing a backpack that can withstand diverse climates and terrains is crucial. Buyers should prioritize materials that offer durability and water resistance to ensure longevity during treks.

Education

In the education sector, the mount everest backpack serves as an essential tool for students in schools and universities. Its versatile design accommodates books, laptops, and other study materials, making it a popular choice among students. For B2B buyers in Europe, such as in Poland, the focus should be on ergonomic support to prevent back strain, especially for students carrying heavy loads. Customization options for branding can also enhance school spirit and visibility.

Travel and Tourism

The mount everest backpack is a favored choice in the travel and tourism industry, particularly for backpacking adventures. Its lightweight design and functional compartments make it convenient for travelers who need to pack efficiently. International buyers from the Middle East and Europe should consider sourcing options that allow for personalization to cater to various travel needs. Additionally, ensuring that the backpack is designed for ease of access can significantly enhance the travel experience.

Emergency Services

In emergency services, the mount everest backpack is utilized for first response and rescue operations. Its robust construction allows for the safe transport of critical emergency supplies, such as medical kits and communication devices. Buyers from Africa and other regions should ensure that the backpacks comply with safety standards and feature quick access compartments for rapid deployment during emergencies. This focus on functionality can greatly enhance response times and operational efficiency.

Corporate Gifting

The mount everest backpack is increasingly used for corporate gifting, providing businesses with a unique promotional item. This application not only offers brand visibility but also fosters customer loyalty through practical gifts. When sourcing for this purpose, companies from South America and Europe should look for customization options that allow for branding and bulk pricing. Selecting high-quality materials will ensure that the backpacks are well-received and used frequently, reinforcing brand recognition.

Related Video: Introduction to Uses and Gratifications Theory

Strategic Material Selection Guide for mount everest backpack

When selecting materials for a Mount Everest backpack, international B2B buyers must consider various factors, including durability, weight, water resistance, and cost. The following analysis examines four common materials used in the production of high-performance backpacks, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from diverse regions such as Africa, South America, the Middle East, and Europe.

1. Nylon

Key Properties:

Nylon is known for its exceptional strength-to-weight ratio, making it ideal for high-altitude backpacks. It is also water-resistant and has good abrasion resistance, which is crucial in harsh environments.

Pros & Cons:

The advantages of nylon include its lightweight nature and durability, which can withstand significant wear and tear. However, nylon can be more expensive than other materials, and its manufacturing process can be complex, particularly when incorporating specialized coatings for enhanced water resistance.

Impact on Application:

Nylon backpacks are suitable for various outdoor activities, including mountaineering and trekking, due to their lightweight and durable characteristics.

Considerations for International Buyers:

Buyers should ensure that nylon used complies with international standards such as ASTM D751 for fabric strength. Additionally, sourcing from manufacturers who can provide certifications for water resistance is advisable.

2. Polyester

Key Properties:

Polyester is a synthetic material that offers good durability and resistance to UV light and mildew. It is slightly heavier than nylon but is often more cost-effective.

Pros & Cons:

The main advantage of polyester is its affordability and ease of dyeing, allowing for vibrant colors and designs. However, it may not be as strong as nylon, and its water resistance can vary based on the specific type used.

Impact on Application:

Polyester is suitable for less extreme conditions, making it a good choice for casual backpacks or those used in milder climates.

Considerations for International Buyers:

Buyers should check for compliance with standards such as ISO 105 for colorfastness and UV resistance, particularly for markets in Africa and the Middle East where sun exposure is significant.

3. Ripstop Fabric

Key Properties:

Ripstop is a type of nylon or polyester fabric that incorporates a reinforcing technique to prevent tears from spreading. It is lightweight yet exceptionally durable.

Pros & Cons:

The primary advantage of ripstop is its tear resistance, which is crucial for high-stress areas of a backpack. However, it can be more expensive due to the specialized weaving process, and it may not provide the same level of water resistance as coated fabrics.

Impact on Application:

Ripstop is ideal for high-altitude expeditions and extreme outdoor activities where durability is paramount.

Considerations for International Buyers:

Buyers should confirm that the ripstop fabric meets relevant strength standards, such as ASTM D5034 for tearing strength. Additionally, they should consider the environmental impact of sourcing materials, particularly in regions with strict sustainability regulations.

4. Ballistic Nylon

Key Properties:

Ballistic nylon is a heavy-duty fabric originally developed for military applications. It is extremely durable and resistant to abrasion and tearing.

Pros & Cons:

The key advantage of ballistic nylon is its unparalleled strength and durability, making it suitable for the most demanding conditions. However, it is heavier and more expensive than standard nylon or polyester, which may not be suitable for all backpack designs.

Impact on Application:

This material is particularly well-suited for backpacks designed for extreme conditions, such as mountaineering and military use.

Considerations for International Buyers:

Buyers should ensure that ballistic nylon meets international standards for performance and safety, such as MIL-STD-662 for ballistic resistance. Additionally, they should evaluate the cost-effectiveness of using such high-end materials in their target markets.

Summary Table

| Material | Typical Use Case for mount everest backpack | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | High-altitude trekking and mountaineering | Lightweight and durable | Higher cost, complex manufacturing | High |

| Polyester | Casual backpacks and milder climates | Cost-effective and vibrant designs | Less durable than nylon | Medium |

| Ripstop Fabric | Extreme outdoor activities | Tear-resistant | More expensive, variable water resistance | High |

| Ballistic Nylon | Military and extreme condition backpacks | Unmatched strength and durability | Heavier and more costly | High |

This material selection guide provides essential insights for international B2B buyers, enabling informed decisions when sourcing materials for high-performance Mount Everest backpacks. By understanding the properties, advantages, and considerations of each material, buyers can better align their product offerings with market demands and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for mount everest backpack

The manufacturing of a Mount Everest backpack involves several critical stages, each designed to ensure that the final product meets the high standards expected by outdoor enthusiasts and travelers. Understanding these processes and the associated quality assurance measures is essential for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

Manufacturing Process Overview

-

Material Preparation

– Selection of Fabrics: The choice of materials is crucial. For a Mount Everest backpack, materials such as high-denier nylon, polyester, or specialized fabrics like ripstop and ballistic nylon are commonly used. These materials provide durability, water resistance, and abrasion resistance, essential for extreme conditions.

– Sourcing: B2B buyers should ensure that their suppliers source materials from reputable manufacturers who comply with international standards for environmental sustainability and ethical labor practices. Certificates like OEKO-TEX Standard 100 can be a good indicator of material safety. -

Forming

– Cutting: The cutting process involves precision machinery to ensure that fabric pieces are cut according to design specifications. This stage is critical for maintaining consistency and reducing waste.

– Seam Construction: Innovative techniques like heat sealing are often employed to create waterproof seams, particularly in high-stress areas. This helps to enhance the backpack’s durability and functionality.

Illustrative Image (Source: Google Search)

-

Assembly

– Sewing: The assembly stage involves sewing together various components, including the main body, straps, pockets, and zippers. Heavy-duty sewing machines are used, and reinforced stitching is applied in high-stress areas.

– Attachment of Accessories: This includes adding zippers, buckles, and adjustable straps. The choice of accessories must align with the backpack’s intended use—heavy-duty options for mountaineering backpacks and lighter options for casual use. -

Finishing

– Quality Check and Cleaning: After assembly, backpacks are typically cleaned and inspected for any defects. This step is vital to ensure the product is free from manufacturing residues and ready for the market.

– Branding: Finally, branding elements such as logos or labels are applied, which can be done through methods like embroidery or heat transfer, ensuring they are durable and visually appealing.

Quality Assurance Procedures

Quality control (QC) is integral to the manufacturing process and is often guided by international standards such as ISO 9001. Here’s a breakdown of the key components:

-

International and Industry Standards

– ISO 9001: This standard outlines the criteria for a quality management system, emphasizing customer satisfaction and process improvement.

– CE Marking: For products sold in Europe, ensuring compliance with CE standards is vital, indicating that the backpack meets EU safety, health, and environmental protection requirements.

– API Standards: For specialized backpacks (like those used in technical climbing), adherence to API standards may be necessary, ensuring that materials and construction methods meet rigorous safety benchmarks. -

QC Checkpoints

– Incoming Quality Control (IQC): This stage involves inspecting raw materials and components upon arrival at the manufacturing facility. Buyers should request IQC reports to verify that materials meet their specifications.

– In-Process Quality Control (IPQC): Conducted during the manufacturing process, this involves random inspections at various stages to catch defects early. B2B buyers should inquire about the frequency and methods of IPQC.

– Final Quality Control (FQC): Before shipping, a sample of finished backpacks is inspected for defects in stitching, material integrity, and overall appearance. It’s advisable for buyers to receive FQC reports, including details of any issues found and how they were resolved. -

Common Testing Methods

– Durability Testing: This may include abrasion tests, tensile strength tests, and waterproof tests to ensure that the backpack can withstand harsh conditions.

– Field Testing: Some manufacturers conduct field tests with outdoor enthusiasts to evaluate performance in real-world conditions. B2B buyers can benefit from feedback from these tests when selecting suppliers. -

Supplier Verification

– Audits and Reports: Buyers should conduct regular audits of their suppliers to verify compliance with quality standards. Requesting detailed QC reports, including test results and corrective actions taken, is essential.

– Third-Party Inspections: Engaging third-party inspection services can provide unbiased quality assessments. This is particularly useful for international buyers who may not be able to conduct on-site inspections.

– Certifications and References: Verify suppliers’ certifications and seek references from other B2B clients to ensure reliability and quality consistency.

Nuances for International Buyers

B2B buyers from regions like Africa, South America, the Middle East, and Europe should be aware of several nuances when dealing with international suppliers:

- Cultural Sensitivity: Understand local manufacturing practices and cultural norms which may affect communication and quality expectations.

- Regulatory Compliance: Familiarize yourself with import regulations, including tariffs and compliance standards in your home country.

- Language Barriers: Ensure that contracts and quality specifications are clear and understood by both parties, possibly involving legal advisors familiar with international trade.

In summary, understanding the manufacturing processes and quality assurance measures for Mount Everest backpacks is crucial for B2B buyers. By focusing on material selection, robust manufacturing techniques, and stringent quality control, buyers can ensure they source high-quality products that meet their market’s demands.

Related Video: How a Backpack is Made : Every Step on the Production Line

Comprehensive Cost and Pricing Analysis for mount everest backpack Sourcing

Understanding the Cost Structure of Mount Everest Backpack Sourcing

When sourcing Mount Everest backpacks, international B2B buyers must navigate a complex cost structure. Here’s a breakdown of the primary cost components involved:

-

Materials: The choice of materials significantly impacts the cost. High-quality fabrics like nylon or polyester can range from $1 to $5 per yard, depending on the specifications. Specialized materials like ballistic nylon or ripstop may incur additional costs due to their durability and water resistance.

-

Labor: Labor costs vary by region and manufacturing practices. In countries like China or Vietnam, labor costs may be lower, averaging between $0.50 to $2.00 per hour. However, in Europe or South America, labor rates can be significantly higher, impacting the overall manufacturing cost.

-

Manufacturing Overhead: This includes utilities, rent, and equipment depreciation. Typically, this can add 15-25% to the total production cost. Efficient factories with modern equipment may reduce overhead costs, which can be a negotiating point for buyers.

-

Tooling: Custom tooling for specific designs can range from $500 to $5,000, depending on complexity. Buyers should consider whether the design will be a one-time project or if it will lead to larger production runs, which can justify the investment.

-

Quality Control (QC): Implementing a robust QC process is essential to ensure product quality. This can add 5-10% to the production costs but is crucial for maintaining brand reputation. Random sampling and inspections during production help mitigate defects.

-

Logistics: Shipping costs can vary widely depending on the Incoterms chosen (e.g., FOB, CIF) and the shipping method (air vs. sea). Buyers should account for customs duties and taxes as well, which can add an additional 10-30% to the total landed cost.

-

Margin: Suppliers typically mark up their costs by 20-50% to cover profit margins. Understanding the market and supplier reputation can help negotiate more favorable terms.

Factors Influencing Pricing

Several factors affect the pricing of Mount Everest backpacks:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes generally lead to lower per-unit costs. Buyers should assess their capacity to purchase in bulk to take advantage of economies of scale.

-

Specifications/Customization: Custom designs or unique features can increase costs. Buyers should weigh the benefits of customization against the added expenses.

-

Material Quality/Certifications: High-quality materials and certifications (e.g., ISO, environmental standards) often come at a premium. Buyers should determine the necessary quality level to avoid overspending.

-

Supplier Factors: Supplier reliability, reputation, and experience can influence costs. Established suppliers may charge more but offer better quality assurance and delivery reliability.

-

Incoterms: The choice of Incoterms affects shipping costs and responsibilities. Understanding these terms can help buyers manage total costs effectively.

Tips for International B2B Buyers

-

Negotiation: Always negotiate prices, especially for larger orders. Leverage multiple supplier quotes to create competition.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO) rather than just the upfront price. Consider long-term factors such as durability and maintenance.

-

Pricing Nuances: Be aware of regional pricing differences. For example, sourcing from Asia may be cheaper, but consider logistics and lead times when sourcing from Europe or South America.

-

Supplier Relationships: Build strong relationships with suppliers for better pricing and terms. Long-term partnerships can lead to better service and lower costs.

-

Local Regulations: Understand import duties and local regulations in your region to avoid unexpected costs.

Disclaimer

Prices provided are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Spotlight on Potential mount everest backpack Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘mount everest backpack’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for mount everest backpack

When sourcing or manufacturing a Mount Everest backpack, understanding the essential technical properties and trade terminology is vital for international B2B buyers. This knowledge can greatly impact product quality, pricing, and supplier reliability.

Critical Technical Properties

-

Material Grade

– Definition: The quality and type of materials used in the backpack’s construction, such as nylon, polyester, or canvas.

– B2B Importance: High-grade materials ensure durability, weather resistance, and longevity, which are crucial for outdoor gear intended for extreme conditions. Buyers should consider the specific use cases and select materials that meet those requirements. -

Water Resistance Rating (WRR)

– Definition: A measure of how effectively a fabric can repel water, usually indicated in millimeters (e.g., 1000mm WRR).

– B2B Importance: For backpacks designed for mountainous terrains, a higher WRR is essential to protect contents from moisture. Understanding WRR helps buyers make informed decisions about product suitability for various climates. -

Load Capacity

– Definition: The maximum weight a backpack can safely carry, often specified in liters (L) for volume or kilograms (kg) for weight.

– B2B Importance: Knowing the load capacity is crucial for ensuring the backpack can accommodate the intended gear and supplies without compromising safety or comfort. This is particularly important for buyers targeting adventure and expedition markets. -

Stitching Quality and Reinforcement

– Definition: The type and strength of stitching used, including reinforced areas where stress is likely to occur.

– B2B Importance: Quality stitching affects the backpack’s durability and performance. Buyers should verify the stitching technique to minimize returns due to defects and ensure customer satisfaction.

Illustrative Image (Source: Google Search)

-

Breathability

– Definition: The ability of the backpack material to allow moisture to escape, often measured in grams of water vapor per square meter per day (g/m²/day).

– B2B Importance: Breathable materials enhance comfort, particularly in humid or active conditions. This property is vital for outdoor enthusiasts and can be a key selling point in marketing. -

Weight

– Definition: The overall weight of the backpack itself, which impacts usability and comfort.

– B2B Importance: A lighter backpack allows for easier transport, especially during long treks. Buyers should balance weight with durability to meet their target market’s needs.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Significance: Understanding OEM relationships helps buyers identify manufacturers that can provide customized products under their brand, ensuring quality control and brand consistency. -

MOQ (Minimum Order Quantity)

– Definition: The smallest number of units a supplier is willing to sell.

– Significance: Knowing the MOQ is crucial for budget management and inventory planning. Buyers must ensure they can meet these requirements to avoid excess costs. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to solicit price quotes from suppliers.

– Significance: An RFQ allows buyers to compare pricing and terms from multiple manufacturers, facilitating informed decision-making and negotiation. -

Incoterms (International Commercial Terms)

– Definition: A series of pre-defined commercial terms published by the International Chamber of Commerce relating to international commercial law.

– Significance: Familiarity with Incoterms helps buyers understand their responsibilities and risks in shipping, including costs, insurance, and ownership transfer. -

AQL (Acceptable Quality Level)

– Definition: The maximum number of defective items considered acceptable during random sampling quality inspections.

– Significance: AQL is essential for quality assurance in manufacturing. Buyers should specify AQL standards to ensure products meet their quality expectations. -

Lead Time

– Definition: The time taken from placing an order to delivery.

– Significance: Understanding lead times is essential for inventory management and customer satisfaction. Buyers must account for production schedules and shipping delays to ensure timely product availability.

By mastering these technical properties and trade terms, B2B buyers can make more informed decisions when selecting Mount Everest backpacks that meet their market demands and customer expectations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the mount everest backpack Sector

Market Overview & Key Trends

The global backpack market, particularly for specialized models like the Mount Everest backpack, is experiencing robust growth driven by increasing outdoor activities, travel, and urban commuting. Key trends influencing this market include the rise of e-commerce, which has made sourcing more accessible for B2B buyers across regions such as Africa, South America, the Middle East, and Europe. For instance, platforms like Alibaba facilitate international trade, but buyers must navigate pricing variability and supplier reliability.

Emerging technologies, such as 3D printing and advanced fabric technologies, are reshaping product design and manufacturing processes. These innovations allow for greater customization, enhancing the appeal of backpacks tailored for specific activities like trekking or climbing. Moreover, the demand for multifunctional backpacks that combine durability with style is on the rise, particularly among younger consumers.

B2B buyers should also be aware of shifting consumer preferences toward sustainable products. As more brands prioritize eco-friendly materials and ethical production processes, international buyers need to align their sourcing strategies with these trends to remain competitive. Understanding local market dynamics, including cultural preferences and economic conditions, is essential for successful market entry and product positioning.

Sustainability & Ethical Sourcing in B2B

In today’s market, sustainability is no longer a choice but a necessity. The environmental impact of backpack production can be significant, particularly concerning resource consumption and waste generation. B2B buyers must prioritize suppliers who adopt sustainable practices, such as using recycled materials and reducing carbon footprints.

Ethical sourcing is equally important, as consumers increasingly demand transparency regarding labor practices in the supply chain. Brands that can demonstrate their commitment to ethical standards often enjoy a competitive edge. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® are indicators of sustainable practices and can enhance brand credibility.

For the Mount Everest backpack specifically, materials like recycled polyester and organic cotton are gaining traction. These materials not only reduce environmental impact but also appeal to eco-conscious consumers. B2B buyers should seek suppliers who offer these green certifications and can provide detailed information about their sourcing practices, ensuring that the products align with their corporate sustainability goals.

Illustrative Image (Source: Google Search)

Brief Evolution/History

The Mount Everest backpack has evolved significantly since its inception, paralleling advancements in outdoor gear technology. Initially designed for climbers, these backpacks have expanded in function and design, catering to a broader audience of adventurers and travelers. The evolution reflects a growing emphasis on durability, comfort, and versatility, with innovations in lightweight materials and ergonomic designs enhancing user experience.

As outdoor activities gained popularity in the late 20th century, the demand for high-quality, specialized backpacks surged. This trend has led manufacturers to focus on creating products that not only meet the rigorous demands of high-altitude climbing but also appeal to a diverse consumer base, from casual hikers to urban commuters. For B2B buyers, understanding this historical context aids in recognizing the value and potential of investing in specialized products tailored to evolving market needs.

Related Video: Exim Trade Conclave 2025 LIVE | Finance Minister Nirmala Sitharaman Delivers Keynote Address | N18L

Frequently Asked Questions (FAQs) for B2B Buyers of mount everest backpack

-

How can I effectively vet suppliers for Mount Everest backpacks?

To vet suppliers, start by researching their background, production capacity, and customer reviews. Request samples to assess product quality firsthand. Use platforms like Alibaba or industry-specific directories to find verified manufacturers. Consider visiting the factory if possible, as this can provide insights into their operations and quality control processes. Additionally, check if they have necessary certifications, such as ISO or environmental standards, which indicate a commitment to quality and sustainable practices. -

Can I customize the design of the Mount Everest backpack?

Yes, many manufacturers offer customization options. This can include altering the backpack’s size, color, materials, or adding features like extra pockets or unique branding. When considering customization, provide clear specifications and design prototypes to the manufacturer. Be mindful that more extensive customization may affect lead times and costs. Discuss these factors upfront to ensure that your expectations align with the manufacturer’s capabilities. -

What is the typical minimum order quantity (MOQ) for Mount Everest backpacks?

MOQs vary significantly by manufacturer, typically ranging from 100 to 1,000 units. Smaller manufacturers might accommodate lower MOQs, while larger factories often require higher quantities to justify production costs. Discuss your specific needs with potential suppliers to negotiate terms that work for both parties. Keep in mind that larger orders may result in lower per-unit costs, which can be beneficial for your overall budget. -

What are the average lead times for production and delivery?

Lead times depend on several factors, including the complexity of your order, the manufacturer’s production capacity, and your location. Generally, production can take anywhere from 4 to 12 weeks. Once produced, shipping can add an additional 2 to 6 weeks, depending on the shipping method and distance. It’s crucial to communicate your timeline requirements with suppliers early in the process to ensure they can meet your delivery needs. -

What quality assurance measures should I look for?

Quality assurance (QA) is vital in ensuring that the Mount Everest backpacks meet your standards. Look for suppliers that conduct regular quality checks throughout the production process. Ask about their QA protocols, including material inspections, in-process checks, and final product evaluations. Request documentation of their quality certifications and any test reports that validate the durability and functionality of the backpacks, especially if they are intended for rigorous outdoor use. -

Are there specific certifications I should verify with suppliers?

Yes, certain certifications can indicate a manufacturer’s commitment to quality and safety. Look for certifications such as ISO 9001 for quality management systems, ISO 14001 for environmental management, and Oeko-Tex Standard 100 for textile safety. If the backpacks are intended for specific markets, such as Europe, ensure compliance with relevant regulations and standards. These certifications not only enhance product credibility but also ensure that your purchases adhere to international safety and environmental standards. -

What logistics considerations should I keep in mind when importing?

When importing Mount Everest backpacks, consider shipping methods (air vs. sea), customs regulations, and import duties applicable to your country. Engage a reliable freight forwarder to navigate logistics, including documentation and customs clearance. Familiarize yourself with local import laws to avoid delays. Additionally, consider the total landed cost, which includes production, shipping, and tariffs, to better manage your budget and pricing strategy. -

How should I handle disputes with suppliers?

To minimize disputes, establish clear contracts that outline terms of sale, delivery schedules, and quality expectations. Maintain open communication with suppliers to address any issues promptly. In case of a dispute, refer to your contract for resolution procedures. Consider using third-party mediation or arbitration services if direct negotiation fails. Building a strong relationship with your supplier can also foster goodwill and facilitate smoother conflict resolution in the future.

Strategic Sourcing Conclusion and Outlook for mount everest backpack

In conclusion, the strategic sourcing of Mount Everest backpacks is crucial for B2B buyers looking to capitalize on the growing demand in outdoor and adventure markets. By prioritizing quality materials such as nylon, polyester, and specialized fabrics, buyers can ensure the durability and functionality of their products. Furthermore, understanding the manufacturing process—from design to quality control—empowers buyers to select reliable suppliers who meet their standards.

Key takeaways include:

- Invest time in design and conceptualization to create backpacks that stand out in a competitive market.

- Focus on material selection that aligns with the intended use, ensuring both performance and cost-effectiveness.

- Implement thorough quality control measures to maintain product integrity and customer satisfaction.

As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek to expand their offerings, embracing strategic sourcing can lead to significant market advantages. The future of the Mount Everest backpack market is promising, with opportunities for innovation and growth. Now is the time to act—engage with reputable suppliers, explore diverse materials, and elevate your product line to meet the evolving needs of consumers.